Summary of Contents for KEB COMBILINE Z1I05-1001 Series

- Page 1 COMBILINE Z1 INSTRUCTIONS FOR USE | INSTALLATION SINUS EMC FILTER Translation of the original manual Document 20146892 EN 02...

-

Page 3: Preface

PREFACE Preface The described hard- and software are developments of the KEB Automation KG. The enclosed documents correspond to conditions valid at printing. Misprint, mistakes and technical changes reserved. Signal words and symbols Certain operations can cause hazards during the installation, operation or thereafter. -

Page 4: Laws And Guidelines

If applicable, the license terms of this software are contained in the instructions for use. The instructions for use are already available to you, can be downloaded free of charge from the KEB website or can be requested from the respec- tive KEB contact person. -

Page 5: Table Of Contents

TAbLE OF CONTENTS Table of Contents Preface ..............................3 Signal words and symbols ......................3 More symbols ..........................3 Laws and guidelines ........................4 Warranty and liability ........................4 Support ............................4 Copyright ............................4 Table of Contents ........................... 5 List of Figures ............................7 List of Tables ............................ - Page 6 TAbLE OF CONTENTS 4.1.1 Motor operation ........................19 4.1.2 AIC operation ........................20 4.1.2.1 Using the sine-wave filter in conjunction with AIC (Active Infeed Controller) ....21 4.2 Connection temperature measurement and fan ................. 21 4.2.1 Rated data of the integrated fans ..................22 4.2.2 Overtemperature shutdown ....................22 4.3 Connection power terminals ......................23 4.3.1 Filter type 0D ........................

-

Page 7: List Of Figures

LIST OF FIGURES List of Figures Figure 1: Electrical equivalent circuit diagram of the sine EMC filters ..........17 Figure 2: Schematic diagram ......................18 Figure 3: Motor operation ........................19 Figure 4: Complete circuitry with additional elements ..............20 Figure 5: Connection principle filter type 0D ................... 21 Figure 6: Connection principle filter types 0H...0Y ................21 Figure 7: Filter type 0D........................23 Figure 8: Filter type 0H and 0L ...................... -

Page 8: List Of Tables

LIST OF TAbLES List of Tables Table 1: IP protection classes ......................15 Table 2: Climatic conditions ......................15 Table 3: Mechanical ambient conditions ..................16 Table 4: Chemical/mechanical active substances ................. 16 Table 5: Equipment classification ....................16 Table 6: Electrical data ........................17 Table 7: Installation of a complete AIC filter................... -

Page 9: Standards For Emc Components

STANDARDS FOR EMC COMPONENTS Standards for EMC components Product standards: EN 61558-1 Safety of transformers, reactors, power supply units and combinations thereof - Part 1: General requirements and tests (IEC 96/449/CD:2015) EN 61558-2-20 Safety of transformers, reactors, power supply units and combinations thereof - Part 2-20: Particular requirements and tests for small reactors (IEC 61558-2- 20:2010);... -

Page 10: Basic Safety Instructions

► Read the instructions for use ! ► Observe the safety and warning instructions ! ► If anything is unclear, please contact KEB Automation KG ! 1.1 Target group This instruction manual is determined exclusively for electrical personnel. Electrical per- sonnel for the purpose of this instruction manual must have the following qualifications: •... -

Page 11: Installation

bASIC SAFETy INSTRUCTIONS 1.3 Installation DANGER Do not operate in an explosive environment! ► The COMBIVERT is not intended for the use in potentially explosive environment. CAUTION Maximum design edges and high weight! Contusions and bruises! ► Never stand under suspended loads. ►... -

Page 12: Electrical Connection

bASIC SAFETy INSTRUCTIONS 1.4 Electrical connection DANGER Voltage at the terminals and in the device! Danger to life due to electric shock! ► For any work on the unit switch off the supply voltage and secure it against switching on. ► The supplied drive converters and filters form a technical unit and must therefore not be disconnected from the mains independently of one another. -

Page 13: Repair

1.7 Disposal Electronic devices of the KEB Automation KG are exclusively professional devices for further industrial processing (so-called B2B devices). Manufacturers of B2B devices are obliged to take back and recycle devices manufac- tured after 14.08.2018. -

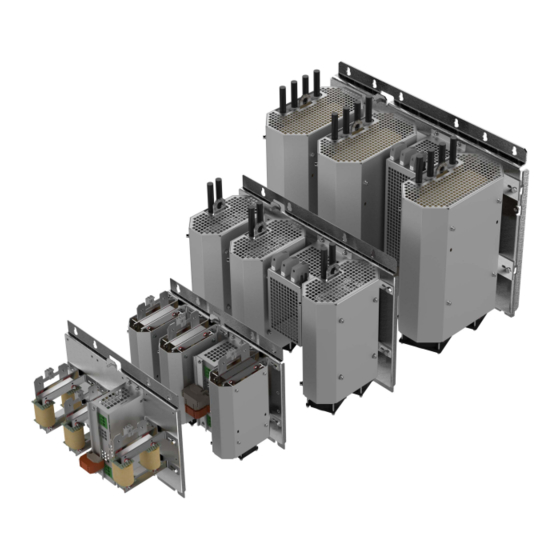

Page 14: Product Description

PRODUCT DESCRIPTION 2 Product Description This instructions for use describes the sine-wave EMC filters of the series 0xZ1I05- 1001. The x at the second position of the material number is representative of the corresponding letter of the filter type D, H, L, P, S, X or Y. Sine-wave EMC filters as combination of sine-wave filters with EMC level reduce sym- metrical and asymmetrical interferences and support the compliance with legal limit values. The sine-wave EMC filter is an electrical low-pass filter which filters out the switching frequency from the PWM (Pulse Width Modulation) output signal of the drive converter. A sinusoidal voltage with low ripple is generated at the filter output, which causes a sinusoidal motor current. -

Page 15: Technical Data

OPERATING CONDITIONS 3 Technical Data 3.1 Operating conditions 3.1.1 IP protection classes Filter type Protection classes IP 00 IP 20 IP 20 IP 20 IP 20 IP 20 IP 20 Table 1: IP protection classes 3.1.2 Climatic conditions Storage Standard Class Notes Surrounding temperature... -

Page 16: Mechanical Ambient Conditions

OPERATING CONDITIONS 3.1.3 Mechanical ambient conditions Storage Standard Class Notes Vibration amplitude 1.5 mm (2…9 Hz) Vibration limits EN 60721-3-1 Acceleration amplitude 5 m/s² (9…200 Hz) Shock limit values EN 60721-3-1 40 m/s²; 22 ms Transport Standard Class Notes Vibration amplitude 3.5 mm (2…9 Hz) Vibration limits Acceleration amplitude 10 m/s²... -

Page 17: Electrical Data

ELECTRICAL DATA 3.2 Electrical data Sine EMC filter xxZ1I05-1001 The two x at the 1st and 2nd digit of the material number are representative for the corresponding size of the filter type. Filter type Connection cross-section supply A / mm² 2 x 70 Connection cross-section ++/-- A / mm²... -

Page 18: Installation And Connection

INSTALLATION AND CONNECTION 4 Installation and Connection 4.1 Schematic diagram ① TZ/L TZ/L TZ/L ② C1-C2 C3-C4 C5-C6 ③ ④ Legend ① Temperature monitoring T1, T2 Temperature switch (NC contact) TZ / L Temperature switch ② Main connections U1, V1, W1 Connection drive converter U2,V2, W2 Connection motor / mains Choke ③... -

Page 19: Motor Operation

INSTALLATION AND CONNECTION 4.1.1 Motor operation ① ② ③ T1 T2 T1 T2 ④ 24 V Legend ① Drive converter U, V, W Output terminals of the drive converter T1,T2 Connection terminals temperature monitoring ++, - - Output terminals DC link ②... -

Page 20: Aic Operation

INSTALLATION AND CONNECTION 4.1.2 AIC operation ④ ① ② ③ T1 T2 T1 T2 L1.1 L1.2 L2.1 L2.2 L3.1 L3.2 ⑤ 24 V Legend ① EMC filter L1, L2, L3 Supply from the supply system L1`, L2`, L3` Output EMC filter ② Mains choke L1.1, L2.1, L3.1 Input mains choke L1.2, L2.2, L3.2 Output mains choke ③... -

Page 21: Using The Sine-Wave Filter In Conjunction With Aic (Active Infeed Controller)

INSTALLATION AND CONNECTION 4.1.2.1 Using the sine-wave filter in conjunction with AIC (Active Infeed Controller) When using the sine-wave filter in conjunction with AIC (Active Infeed Controller), the following items are required to build a complete AIC filter: Sine-wave EMC filter Mains choke EMC filter 0DZ1I05-1001 12Z1B04-1000 12E6T60-3000 0HZ1I05-1001 14Z1B04-1000 14E6T60-3000 0LZ1I05-1001 18Z1B04-1000 18E6T60-3000 0PZ1I05-1001 22Z1B04-1000 22E6T60-3000 0SZ1I05-1001 24Z1B04-1000 24E6T60-3000 0XZ1I05-1001 27Z1B04-1000 26U5A0U-3000 0YZ1I05-1001 29Z1B04-1001 30U5A0W-3000 Table 7: Installation of a complete AIC filter 4.2 Connection temperature measurement and fan Figure 5: Connection principle filter type 0D... -

Page 22: Rated Data Of The Integrated Fans

INSTALLATION AND CONNECTION 4.2.1 Rated data of the integrated fans Description Data Connection terminals +, - Rated DC voltage 24 V Permissible DC voltage range 18 V...27.6 V 0H, 0L: 3 x 0.13 A = 0.4 A Rated current 0P, 0S: 6 x 0.5 A = 3 A 0X, 0Y: 6 x 1.2 A = 7.2 A Flat fuse ATC 32 V Company Bussmann 0H, 0L: ATC1 (1.0 A) -

Page 23: Connection Power Terminals

INSTALLATION AND CONNECTION 4.3 Connection power terminals 4.3.1 Filter type 0D V1/V2 U1/U2 W1/W2 U1/U2 V1/V2 W1/W2 Figure 7: Filter type 0D... -

Page 24: Filter Type 0H And 0L

INSTALLATION AND CONNECTION 4.3.2 Filter type 0H and 0L U1/U2 V1/V2 W1/W2 V1/V2 U1/U2 W1/W2 Figure 8: Filter type 0H and 0L... -

Page 25: Filter Type 0P And 0S

INSTALLATION AND CONNECTION 4.3.3 Filter type 0P and 0S ++ - - Filter type Used wire-end ferrules A25 - 16 A50 - 20 Figure 9: Filter type 0P and 0S If necessary, the user is free to exchange the wire-end ferrules against ring crimp connectors. -

Page 26: Filter Type 0X And 0Y

INSTALLATION AND CONNECTION 4.3.4 Filter type 0X and 0y V1 V1 W1 W2 ++ - - Filter type Used wire-end ferrules A95 - 25 2 x A70 - 25 Figure 10: Filter type 0X and 0Y If necessary, the user is free to exchange the wire-end ferrules against ring crimp connectors. -

Page 27: Alternative Connection Option

INSTALLATION AND CONNECTION 4.3.4.1 Alternative connection option The user is free to exchange the wire-end ferrules against ring crimp connectors. In this case, the end of the ferrule corresponds to the centre of the opening in the ring crimp connector. Figure 11: Alternative connection option... -

Page 28: Transport

INSTALLATION AND CONNECTION 4.4 Transport The filter types 0P, 0S, 0X and 0Y are delivered with lifting eyes. These serve to accom- modate corresponding lifting devices for the transport. WARNING Wrong chain angle damages the lifting eyes! ► Maintain a chain angle of max. 60°. ► Always attach to two lifting eyes simultaneously. ► Do not place the filter on the fans. ► Do not stand under the floating filter during transport. 60°... -

Page 29: Mechanical Construction

INSTALLATION AND CONNECTION 4.5 Mechanical construction NOTICE Observe the cable length! The maximum permissible cable length between filter and drive con- verter is 1.5 m. For filters that are already delivered with cable, the cable may be shortened as required, but not extended. 4.5.1 Dimensions filter type 0D 153,5 160,8 Figure 13: Dimensions filter type 0D Standard Connection cable Length in m Connection ++/-- Wire end ferrule... -

Page 30: Dimensions Filter Type 0H And 0L

INSTALLATION AND CONNECTION 4.5.2 Dimensions filter type 0H and 0L 173,5 Figure 14: Dimensions filter type 0H and 0L Standard Connection cable Length in m Connection ++/-- Wire end ferrule Table 11: Length of the connection cables filter type 0H and 0L... -

Page 31: Dimensions Filter Type 0P And 0S

INSTALLATION AND CONNECTION 4.5.3 Dimensions filter type 0P and 0S 233,5 Figure 15: Dimensions filter type 0P and 0S Standard Connection cable Length in m Connection Wire end ferrule ++/-- Table 12: Length of the connection cables filter type 0P and 0S... -

Page 32: Dimensions Filter Type 0X And 0Y

INSTALLATION AND CONNECTION 4.5.4 Dimensions filter type 0X and 0Y Figure 16: Dimensions filter type 0X and 0Y Standard Connection cable Length in m Connection Wire end ferrule ++/-- Table 13: Length of the connection cables filter type 0X and 0Y... -

Page 33: Control Cabinet Installation

NOTICE Observe installation position! The sine-wave filters must always be mounted hanging with the venti- lation grilles downwards and the cable versions upwards in the control cabinet. In case of another installation method, please contact KEB. 4.6.1 Installation distances of the sine-wave EMC filters Dimen- Installation distances Distance in mm... -

Page 34: Emc Conform Installation In The Control Cabinet

INSTALLATION AND CONNECTION 4.6.2 EMC conform installation in the control cabinet EMC conform installation in a Rittal TS8 control cabinet through the example of filter type 0Y. L1 L2 L3 5 4 3 2 1 5 4 3 2 1 13 12 11 10 13 12 11 10 9 8 7 6 15 16 17 18 19 20 21 22 23 24 25 15 16 17 18 19 20 21 22 23 24 25 9 8 7 6 ①... -

Page 35: Fan Replacement

INSTALLATION AND CONNECTION 4.7 Fan replacement If the fan is defective, it can be replaced. The following figure shows how to change the fan. The following must be observed: ① The arrows on the fan for the correct direction of the air flow. ② The correct wiring of the 24 V DC voltage supply at the terminals +/-. ① ② Figure 19: Fan replacement Filter type Part number fan Required quantity No fan —... -

Page 36: Mode Of Action

MODE OF ACTION 5 Mode of Action 5.1 Sine EMC filter in motor operation 5.1.1 Mode of action sine EMC filter Voltage Ph-Ph at Current Ph-Ph at drive converter output drive converter output Figure 20: Voltage / current at the drive converter output Voltage Ph-Ph with sine-wave EMC Current Ph-Ph with sine-wave EMC filter... -

Page 37: Figure 22: Voltage U Against Pe And Phase Current At The Drive Converter

MODE OF ACTION Voltage against PE Phase current Figure 22: Voltage U against PE and phase current at the drive converter Voltage against PE with sine-wave EMC filter Figure 23: Voltage U against PE with sine-wave EMC filter At the output phases against earth, no purely sinusoidal voltage is generated. The third harmonic of the output frequency for voltage rise is contained in the output signal of the drive converter. -

Page 38: Measurement Of The Emitted Interference With Unshielded Motor Lines

MODE OF ACTION 5.1.2 Measurement of the emitted interference with unshielded motor lines ..Peak Average Quasi Peak Quasi Peak upper limit Figure 24: Measurement of the emitted interference with unshielded motor lines NOTICE Pay attention to distances when laying the cables! An unshielded motor cable can be used, when using a sine-wave EMC filter. A distance of 20 cm between the motor line to mains, bus and control lines must be maintained. -

Page 39: Active Infeed Controller Operation

MODE OF ACTION 5.2 Active Infeed Controller operation 5.2.1 Comparison of mains harmonics Comparison of mains harmonics from a drive converter with B6 rectification and 4 % U choke to an Active Infeed Controller (AIC) with sine-wave EMC filter. Order AIC + sine-wave EMC filter B6 with 4% U choke Figure 25: Comparison of mains harmonics in % with the same motor power Voltage Ph-Ph against earth Voltage Ph-Ph against earth Phase current Phase current Figure 26:... -

Page 40: Mode Of Action Sine-Wave Emc Filter In Aic

MODE OF ACTION 5.2.2 Mode of action sine-wave EMC filter in AIC The mains current of the choke solution (=> Figure 28) hardly differs from the sine-wave EMC filter solution (=> Figure 29), while the voltage quality "DC link + and - against earth" is much better with the sine-wave EMC solution. By reducing the switching-frequency voltage components (=>... -

Page 41: Certifications

CERTIFICATIONS 6 Certifications 6.1 CE-Marking CE marked sine filter - EMC were developed and manufactured to comply with the regulations of the Low-Voltage Directive. The harmonized standards EN 61558-1 as well as are applied as base. EN 61558-2-20 EN 61800-5-1... -

Page 42: Revision History

REVISION HISTORy 7 Revision History Version Date Description 2017-06 Completion pre-series 2017-11 Change of title picture, insert operating conditions, extension technical data 2020-01 Insertion of new figures, adaptation of drawings, editorial revisions... - Page 43 CEP 13569-430 Portal do Sol, São Carlos Brazil Gangnam Gu 135- 757 Seoul Republic of Korea Tel: +55 16 31161294 E-Mail: roberto.arias@keb.de Tel: +82 2 6253 6771 Fax: +82 2 6253 6770 E-Mail: vb.korea@keb.de Czech Republic KEB Automation GmbH Russian Federation KEB RUS Ltd.

- Page 44 Automation with Drive www.keb.de KEB Automation KG Suedstrasse 38 32683 Barntrup Tel. +49 5263 401-0 E-Mail: info@keb.de...

Need help?

Do you have a question about the COMBILINE Z1I05-1001 Series and is the answer not in the manual?

Questions and answers