Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ATI Technologies 9150‑PCFC‑12

- Page 1 ATI Passive Compliant Force Control (Models 9150‑PCFC‑12) Product Manual Document #: 9610-50-1036 Engineered Products for Robotic Productivity Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com...

- Page 2 Manual, Passive Compliant Force Control Document #9610-50-1036-04 Foreword CAUTION: This manual describes the function, application, and safety considerations of this product. This manual must be read and understood before any attempt is made to install or operate the product, otherwise damage to the product or unsafe conditions may occur. Information contained in this document is the property of ATI Industrial Automation, Inc (ATI) and shall not be reproduced in whole or in part without prior written approval of ATI.

-

Page 3: Table Of Contents

Manual, Passive Compliant Force Control Document #9610-50-1036-04 Table of Contents Glossary ............................5 Safety ............................6 Explanation of Notifications ......................6 General Safety Guidelines ......................6 Safety Precautions ........................6 PCFC Safe Working Environment ....................6 Product Overview ........................7 Features and Benefits of the PCFC ..................... - Page 4 Manual, Passive Compliant Force Control Document #9610-50-1036-04 RS485 Serial Console ......................... 22 Set/Cal Commands ........................24 Filter Parameters ......................... 25 Maintenance ..........................26 Routine Operational Maintenance ..................... 26 Utilities ............................26 Troubleshooting ........................27 Parts and Accessories ......................27 Accessories and Tools ....................... 27 Specifications .........................

-

Page 5: Glossary

Manual, Passive Compliant Force Control Document #9610-50-1036-04 Glossary Definition Term Device for removing contamination from air supply lines. Typically refers to removal of Air Filter particulates. Coalescing Filter Device that removes liquid aerosols from the supply air lines. The ability of the device to passively move in response to protrusions on or deviations of Compliance the work piece. -

Page 6: Safety

Manual, Passive Compliant Force Control Document #9610-50-1036-04 1. Safety The safety section describes general safety guidelines to be followed with this product, explanations of the notifications found in this manual, and safety precautions that apply to the product. Product specific notifications are imbedded within the sections of this manual (where they apply). -

Page 7: Product Overview

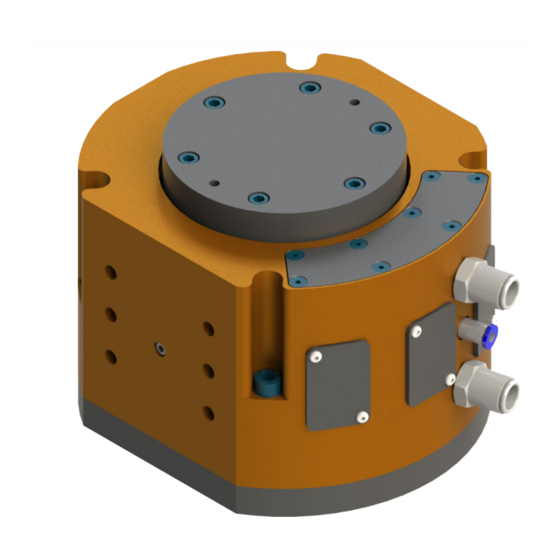

Manual, Passive Compliant Force Control Document #9610-50-1036-04 2. Product Overview ATI's PCFC device is a robust, stand‑alone, passive compliance device to be used with an end‑effector. Figure 2.1—Product Overview Compliance Slide Note: Tool shown with blank cover plates. Customer will machine bolt pattern Retract Compliance Fitting for tooling and mounting. -

Page 8: Technical Description

Manual, Passive Compliant Force Control Document #9610-50-1036-04 2.2 Technical Description A technical overview of the product is provided in the following tables and graphs. For additional technical specifications, refer to Section 8—Specifications. 2.2.1 Environmental Limitations 2.2.1.1 Operation Table 2.1—Operation Mounted to machining center by means various, Installation position customer‑supplied end‑effector. -

Page 9: Compliance Unit Performance

Manual, Passive Compliant Force Control Document #9610-50-1036-04 2.3 Compliance Unit Performance The force created by the compliance mechanism varies linearly with air pressure as shown in Figure 2.2. This does not account for friction or the weight of the carriage and attached tooling. Measurements may vary from one product to another and should only be treated as nominal. -

Page 10: Part Numbering Guide

Manual, Passive Compliant Force Control Document #9610-50-1036-04 2.4 Part Numbering Guide Figure 2.3—Part Numbering Guide PCFC-12 Part Number Guide 9150- PCFC - 12 - (Blank) = ATI Version, Orange = Euro Version, Black Sensing Option = Default Hall Effect Position Sensing (Blank) = No Sensing (Note 3) -

Page 11: Installation

Manual, Passive Compliant Force Control Document #9610-50-1036-04 3. Installation The compliance housing incorporates a rear mounting pattern to which an interface plate can be installed (Refer to Section 3.5—Axial Mount Installation.) An interface plate for side mounting to fixed surface is available (Refer to Section 3.6—Side Mount Installation.) The device must be rigidly mounted prior to use. -

Page 12: Axial Mount Installation

Manual, Passive Compliant Force Control Document #9610-50-1036-04 3.5 Axial Mount Installation A blank rear cover plate is provided to allow axial mounting off the rear of the PCFC housing. This plate must be modified by the system integrator or by the owner/user of the PCFC. Machining must allow for fasteners to be counter‑sunk flush or below flush of rear cover plate surface that mounts to PCFC body. -

Page 13: Side Mount Installation

Manual, Passive Compliant Force Control Document #9610-50-1036-04 3.6 Side Mount Installation The side mount pattern of the PCFC consists of (2) dowel pin holes and (4) threaded holes as shown Figure 3.2. If the PCFC is mounted to a fixed surface, the robot carries the part to the end‑effector attached to the PCFC. -

Page 14: Customer Tooling Installation

Manual, Passive Compliant Force Control Document #9610-50-1036-04 3.7 Customer Tooling Installation The inner slide cover plate must be machined to interface with customer tooling. This plate must be modified by the system integrator or by the owner/user of the PCFC. Figure 3.3—Customer Tooling Mounting (6) M4 Socket Head Cap Screw... - Page 15 Manual, Passive Compliant Force Control Document #9610-50-1036-04 ATI recommends the use of our regulator kit (ATI Part # 9005‑50‑6133) which was designed for this purpose. If the customer is supplying their own regulators, they must meet the following criteria: 1. The regulators must be controlled by an analog signal (either 0…5VDC, 0…10VDC, or 4…20 mA). By default, the PCFC is set to the 0…5VDC output setting.

-

Page 16: Electrical Connections

Manual, Passive Compliant Force Control Document #9610-50-1036-04 3.9 Electrical Connections Refer to the following for electrical connection pinouts. Cable shielding is required. A cable is available for purchase separately from the PCFC part number. Refer to Section 3.10—Mating Cable. Figure 3.4—M12 8-Pin Connector Wiring (Face View Shown) Table 3.2—M12 8-Pin Connector Wiring Signal name Description... -

Page 17: Operation

Manual, Passive Compliant Force Control Document #9610-50-1036-04 4. Operation These operating instructions are intended to help system integrators program, start up, and complete a robotic cell containing the device. The system integrator should be familiar with the task in general and should have extensive knowledge relating to robots and automation incorporating robots. -

Page 18: Minimum Requirements For Operation

Manual, Passive Compliant Force Control Document #9610-50-1036-04 4.2 Minimum Requirements for Operation The following sections describes the minimum requirements for operating the PCFC. 4.2.1 Air Quality The air supply should be clean, dry, filtered, and non‑lubricated. A coalescing filter that has elements rated for 5 micron or better is required. -

Page 19: Normal Operation Led Behavior

Manual, Passive Compliant Force Control Document #9610-50-1036-04 4.3 Normal Operation LED Behavior Figure 4.2—LEDs Full Extend Start of Safe Travel End of Travel Robot Crash (> 95% Travel Zone (Extension (< 5% Extension) (Extension (Extension >= 5% and Extension) > 70% and >= 30% and <... -

Page 20: Gravity Compensation

Manual, Passive Compliant Force Control Document #9610-50-1036-04 4.3.1 Gravity Compensation The PCFC sensor kit supports gravity compensation. This feature allows the tool to automatically adjust the compliance force as the tool’s orientation changes with respect to gravity. A sensor built into the tool tracks the tool’s movements and notes when the tool rotates about X or Y. -

Page 21: Gravity Compensation Procedure

Manual, Passive Compliant Force Control Document #9610-50-1036-04 4.3.1.1 Gravity Compensation Procedure 1. Position the PCFC oriented tool side straight down with all tooling attached and connections made. Do not move the PCFC until the entire procedure is finished. NOTICE: The regulator that the PCFC is controlling should be connected to the retract pressure. -

Page 22: Rs485 Serial Console

Manual, Passive Compliant Force Control Document #9610-50-1036-04 4.4 RS485 Serial Console Table 4.2—PCFC Default Values Parameter Name Default Value paramWrites filTcAccl filTc minPos maxPos 3300 Location Insert your location here serNum Serial number hwProdCode HW Product Code hwRev Baud 115200 productName ATI Compliance Regulator posOutputRange... - Page 23 Manual, Passive Compliant Force Control Document #9610-50-1036-04 The following serial console commands are available to use with a program like PuTTY (available online) with a default baud rate of 115200. Table 4.3—Serial Console Commands Command Operand(s) Description Print help text Help Print firmware version SysVer...

-

Page 24: Set/Cal Commands

Manual, Passive Compliant Force Control Document #9610-50-1036-04 4.5 Set/Cal Commands The following fields can be called after entering Set or Cal to read the current value of a field or write a new value to writable fields. Table 4.4—Set/Cal Commands Example Read/ Field... -

Page 25: Filter Parameters

Manual, Passive Compliant Force Control Document #9610-50-1036-04 Table 4.4—Set/Cal Commands Example Read/ Field Long Name Type Description Contents Write Gravity compensation Calibration Read/ CalWeight gain calculated from weight Write calibration process (%) Calibration Time to delay between Read/ DelayRamp ramp Uint16 1000 steps in Write... -

Page 26: Maintenance

Manual, Passive Compliant Force Control Document #9610-50-1036-04 5. Maintenance Periodically visually inspect the purge air opening for damage, and use a clean cloth to clean the opening. 5.1 Routine Operational Maintenance When subjected to normal use, this robust unit will provide hours of operation before service or repair is necessary. -

Page 27: Troubleshooting

Manual, Passive Compliant Force Control Document #9610-50-1036-04 6. Troubleshooting The following section provides troubleshooting information to help diagnose conditions with the product and service procedures to help resolve these conditions. Table 6.1—Troubleshooting Symptom Cause Resolution Unequal compliance Defective regulator Replace defective regulator Clean the compliance slide with compressed Compliance slide contaminated air and alcohol. -

Page 28: Drawings

Manual, Passive Compliant Force Control Document #9610-50-1036-04 9. Drawings To access the PCFC Drawings, use the following links: • https://www.ati‑ia.com/app_content/Documents/9630‑50‑PCFC‑12.auto.pdf • https://www.ati‑ia.com/app_content/Documents/9630‑50‑PCFC‑PNEUMATIC.auto.pdf 10. Terms and Conditions of Sale ATI warrants the compliant tool product will be free from defects in design, materials and workmanship for a period of one (1) year from the date of shipment and only when used in compliance with manufacturer’s specified normal operating conditions.

Need help?

Do you have a question about the 9150‑PCFC‑12 and is the answer not in the manual?

Questions and answers