Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Ouring 3DTALK T-real MINI

-

Page 2: Table Of Contents

Jiangsu Ouring 3D Technology Co., Ltd. Contents 1. PRODUCT DESCRIPTION ..................... 3 1.1 Product introduction ......................3 1.2 Precautions ..........................4 2. PRODUCT OVERVIEW ......................5 2.1 Product appearance ......................5 2.2 Product specification ......................8 3. OPERATING INSTRUCTIONS....................9 4. -

Page 3: Product Description

Jiangsu Ouring 3D Technology Co., Ltd. 1. Product Description 1.1 Product introduction This document is a user guide for 3DTALK brand, T-real series MINI 3D printers. Please read the document carefully before unpacking and using 3D printers of 3DTALK T-real MINI. -

Page 4: Precautions

Jiangsu Ouring 3D Technology Co., Ltd. 1.2 Precautions (Please read the following content carefully.) Note: Please do use the designated power adapter included in the machine. thus preventing material Caution: Wear goggles during removal of auxiliary support materials, chippings from hurting your eyes Note: In the printing process, slight odor may be generated due to high temperature, but it will not make person feel uncomfortable. -

Page 5: Product Overview

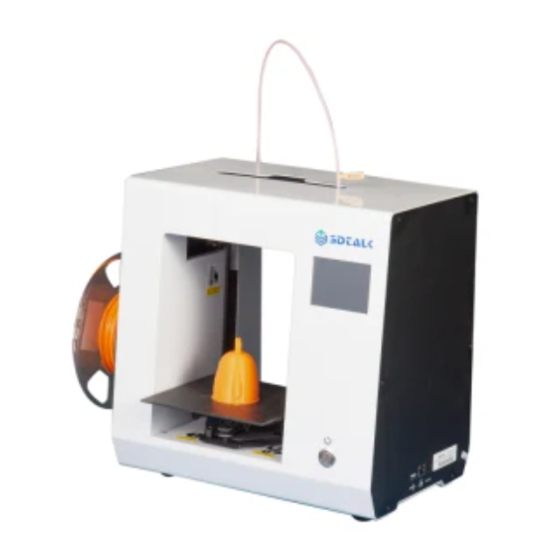

Jiangsu Ouring 3D Technology Co., Ltd. 2. Product Overview 2.1 Product appearance I. Front view of printer (10) (1) Framework (2) Power button (3) Platform height adjusting knob (4) Printing platform (5) Touch screen (6) extruder (7) Filament guide tube... - Page 6 Jiangsu Ouring 3D Technology Co., Ltd. II. Side view of printer (1) USB interface (2) Network port (3) Power interface (4) Filament feeder III. Coordinate axes Y-axis Z-axis axis X-axis Note: X-axis: Left and right Y-axis: Front and back Z-axis: Up and down...

- Page 7 Jiangsu Ouring 3D Technology Co., Ltd. PC matte paper (With 2 sheets) Note: All screws in the list of accessories are spares and can be replaced according to the actual situations. Regarding the accessory pictures in the list of accessories, the actual accessory appearances shall prevail.

-

Page 8: Product Specification

Jiangsu Ouring 3D Technology Co., Ltd. 2.2 Product specification Specifications and characteristics MINI Specifications and Characteristics Technology Printing Technology FDM (Fused Deposition Modeling) Function Building volume 160x160x155mm 0.075mm (corresponding to 0.2mm nozzle) 0.1mm (corresponding to 0.4mm nozzle) Precision of layer height 0.2mm (corresponding to 0.4mm nozzle) - Page 9 Jiangsu Ouring 3D Technology Co., Ltd. Operating system Windows / ios Control software Control system based on browser + touch screen control Power supply AC input 220V/50HZ Requirement for power supply Voltage: 220V, maximum power: 200W Print Filament Support Environmental requirements Room temperature: 15°C-30°C...

-

Page 10: Operating Instructions

Jiangsu Ouring 3D Technology Co., Ltd. 3. Operating Instructions Installing printing build plate Step 1:Remove the print board from the protective foam and place it on the three knob magnets of printer. The printing board is equipped with a strong magnet to automatically adhere to the printing build plate. - Page 11 Jiangsu Ouring 3D Technology Co., Ltd. Step 4: Turn on the power supply and press down the power switch on the front panel. Step 5: Filament Extrude and Takeback Filament Extrude 1. Hang the PLA filament to the tray support already mounted 2.Manually press down the handle of the filament feeder to separate the two gears and at the...

- Page 12 Jiangsu Ouring 3D Technology Co., Ltd. 3.Click this button on the main screen 4. Click select the appropriate wire change temperature, and then click (factory original PLA material temperature is suggested as 190 ° C, display temperature is the current setting temperature), when the interface [current temperature] reaches the set temperature, the wire feeder will feed the filament to the printhead and then flow out.

- Page 13 Jiangsu Ouring 3D Technology Co., Ltd. Filament Takeback Click this button on the main screen, and then click on the next page 2. When the [current temperature] of the interface reaches the set temperature, the feeder will take the filament out of the nozzle within 5 seconds, then press the feeder handle to pull the filament out.

- Page 14 Jiangsu Ouring 3D Technology Co., Ltd. Leveling of printing build plate The correct leveling of the printing build plate is a guarantee of print quality. The MINI printer adopts a semi-automatic leveling operation that integrates build plate leveling and print gap adjustment into one. It just needs a few steps to adjust the gap between the nozzle and the build plate.

- Page 15 Jiangsu Ouring 3D Technology Co., Ltd. 2.Click the [Next] button, after the nozzle and the build plate stop moving, place an A4 paper between the build plate and the nozzle, and adjust the distance between the them by adjusting the knob on the lower side of the nozzle.. This level is leveled out when the distance reaches a slight friction as twitching the A4 paper.

- Page 16 Jiangsu Ouring 3D Technology Co., Ltd. 1. Ensure that there is printed material in the nozzle. 2. Ensure that the vertical distance of each point on the printing build plate is equal to the nozzle. 3. Ensure that the distance between the printing build plate and the nozzle is moderate.

-

Page 17: Printer Operation Interface

Jiangsu Ouring 3D Technology Co., Ltd. 4.Printing Operation Interface... -

Page 18: Removing Model

Jiangsu Ouring 3D Technology Co., Ltd. 5.Removing model Here are the following steps to remove the models from the print build plate. Shovel the model down with a spatula -For small size models Grasp the front of the printing build plate with your hand, lift up and remove the build... -

Page 19: Routine Maintenance

Jiangsu Ouring 3D Technology Co., Ltd. 6. Routine Maintenance 1.Printer shall be stored in a dry and ventilated working environment. In case of out of use for a long time, the filament can be withdrawn from the nozzle and sealed with packaging membranes, thus preventing dampness and deterioration. -

Page 20: Warranty

Warranty principles: 1.The 3DTALK T-real MINI printers purchased from proper channels authorized by our company can enjoy the replacement service by virtue of the proof of purchase within 7 days from the... - Page 21 Jiangsu Ouring 3D Technology Co., Ltd.

Need help?

Do you have a question about the 3DTALK T-real MINI and is the answer not in the manual?

Questions and answers