Table of Contents

Advertisement

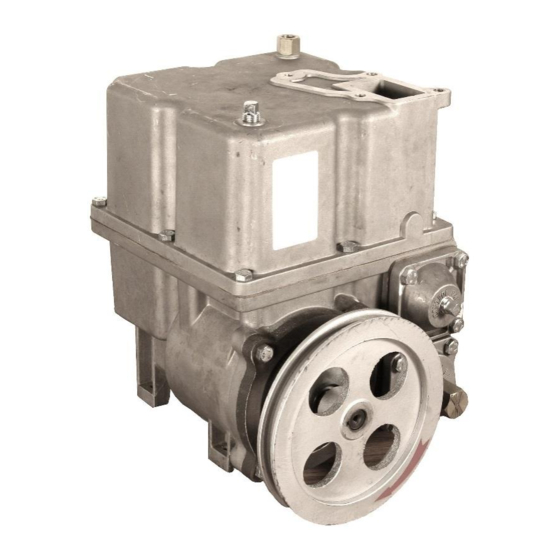

BENNETT T140 HYDRAULIC HIGH FLOW

PUMPING UNIT

T-140 Hydraulic Pumping Units

Operation, Service, & Parts Manual

112272 Rev H 10/26/18

Introduction / Operation / Troubleshooting / Parts

Only Trained Personnel May Work on This Equipment

READ THIS MANUAL

This manual has important information for safe installation and operation of this equipment. Read and understand this manual

before applying power. Keep this manual and tell all service personnel to read this manual. If you do not follow the instructions,

you can cause bodily injury, death, or damage to the equipment.

Bennett 1218 E. Pontaluna Road, Spring Lake, MI 49456

USA 800-235-7618 ~ Outside USA 231-798-1310

sales@bennettpump.com ~ www.bennettpump.com

Advertisement

Table of Contents

Summary of Contents for Bennett T140

- Page 1 Keep this manual and tell all service personnel to read this manual. If you do not follow the instructions, you can cause bodily injury, death, or damage to the equipment. Bennett 1218 E. Pontaluna Road, Spring Lake, MI 49456 USA 800-235-7618 ~ Outside USA 231-798-1310...

- Page 2 The material included in this technical manual is accurate at the date of publication. The intent of this manual is to assist. If further assistance is required, please contact the Bennett Technical Service Department at 1-800-423-6638. Bennett Marketing Services can be contacted by mail, facsimile, telephone or e-mail at the locations specified below: Bennett Pump Company...

-

Page 3: Table Of Contents

Bennett T140 Operation, Service, & Parts Manual Table of Contents TABLE OF CONTENTS TABLE OF CONTENTS SAFETY INFORMATION General Information........................................1 Hazardous locations ........................................1 Codes and Standards ........................................1 Unauthorized Alteration of Bennett Products ..............................1 Abbreviations and Acronyms ..................................... 1 PRODUCT INTRODUCTION Features ............................................... - Page 4 Bennett T140 Operation, Service, & Parts Manual Table of Contents Page Intentionally Left Blank...

-

Page 5: Safety Information

FUEL ETHANOL IS POISONOUS AND SHOULD NOT BE INGESTED. Note: Bennett Pump highly recommends all technicians observe HSSE policies defined by the supplier. Bennett Pump does not impose any DISCONNECT ALL POWER, RELIEVE PRESSURE TO THIS EQUIPMENT, restrictions or additional requirements contained in Environmental AND ASSOCIATED COMPRESSOR DURING INSTALLATION, SERVICE, OR Standards®... -

Page 6: General Information

Petroleum Institute Recommended Practice RP 2003, Protection Against Ignitions Arising out of Static, Lightening, and Stray Currents. Service of the Bennett products and all accessories (e.g. Nozzles, Hoses, and Breakaways) must be performed by a technician who is trained in accordance to all codes, requirements, standards, and regulations. -

Page 7: Product Introduction

The Type 140 is a high flow pumping unit intended for use with Petroleum Products (gasoline, gasoline/alcohol blends up to 15% ethanol, diesel fuel, fuel oil, lubricating oil and vapors of these fluids). The T140 is a rotary vane type, flammable-liquid pumps that is provided with an integral strainer, pressure relief valve, air eliminator, and adjustable bypass valve which is set to return liquid, under pressures exceeding 50 psi, to the suction side of the pump. -

Page 8: Features

100% hydro-static tested prior to shipment COMPATIBLE HIGH FLOW METERS The T140 pumping unit is fully compatible with the High Flow FPP Meter. Refer to the list below for part numbers. High Flow Meter with Integral Pulse Output .............................. Part # 107850 1-1/2”... -

Page 9: Pump Curves - U.s. Market

Bennett T140 Operation, Service, & Parts Manual Product Introduction PUMP CURVES – U.S. MARKET 100 mm Stator T140 Max. By Pass Setting 765 RPM #2 Diesel Fuel 10.3 16.0 21.8 29.0 35.8 39.3 41.6 44.2 46.0 46.8 47.4 50.8 PSIG FIGURE 2 PUMP CURVE –... -

Page 10: Exterior Dimensions

Bennett T140 Operation, Service, & Parts Manual Product Introduction EXTERIOR DIMENSIONS 11.57” [294.0 mm] 2.84” [68 mm] 9.01” [229 mm] FLANGED OUTLET- BACK VIEW FLANGED - FRONT VIEW 12.7” [323.1 mm] FLANGED OUTLET- SIDE VIEW 1.63” [40mm] FLANGED OUTLET- TOP VIEW... - Page 11 Bennett T140 Operation, Service, & Parts Manual Product Introduction 11.49” [291.9 mm] 2.84” [68 mm] 9.01” [229 mm] TUBE OUTLET- BACK VIEW TUBE - FRONT VIEW 12.7” [323.1 mm] TUBE OUTLET- SIDE VIEW 1.63” [40mm] TUBE OUTLET- TOP VIEW TUBE OUTLET - BOTTOM VIEW...

-

Page 12: Inlet & Mounting Dimensions

Bennett T140 Operation, Service, & Parts Manual Product Introduction INLET & MOUNTING DIMENSIONS When installing units that contain a high alcohol product (e.g. E100). Confirm that the plumbing is designed to handle the selected petroleum product. For multi-hose units, piping must align with the footprint. - Page 13 Bennett T140 Operation, Service, & Parts Manual Product Introduction FLANGED AND TUBULAR SIDE INLET SIDE INLET CENTER FIGURE 7...

- Page 14 Bennett T140 Operation, Service, & Parts Manual Product Introduction Page Intentionally Left Blank...

-

Page 15: Operation

OPERATION The following section describes each of the main components of the T140 pumping unit and the interface characteristics at each component. Refer to the diagram on the next page for item locations. For any questions, please contact Bennett Technical Support at 1-800-423-6638. -

Page 16: Float And Air Separator

Bennett T140 Operation, Service, & Parts Manual Operation FLOAT AND AIR SEPARATOR Before gasoline can be accurately measured by the meter, air and vapors must be eliminated. The Type 140 pumping unit eliminates air and vapor through the air separator, and float assembly. The float assembly employed is shown in Figure 9. -

Page 17: Troubleshooting

TROUBLESHOOTING This section provides basic troubleshooting. It is not a substitute for technical training. Improper handling of equipment and/or improperly performing the included procedures could damage your DISPENSER! For any additional questions, please contact Bennett Technical Support at 1- 800-423-6638. - Page 18 Bennett T140 Operation, Service, & Parts Manual Troubleshooting TO TEST THE VACUUM O F THE PUMP, FOLLOW T HIS PROCEDURE: Remove the pipe plug in the center of the strainer or filter cover. The cover is marked for easy identification.

- Page 19 Bennett T140 Operation, Service, & Parts Manual Troubleshooting Figure 15...

- Page 20 Bennett T140 Operation, Service, & Parts Manual Troubleshooting Figure 16...

-

Page 21: How To Correct Problems On Pumping Units

Bennett T140 Operation, Service, & Parts Manual Troubleshooting Figure 17 HOW TO CORRECT PROBL EMS ON PUMPING UNITS Use the table in each section to determine the cause and solution. PROBLEM 1: THE MOTOR STARTS BUT THE PUMP DOES NOT DELIVER FUEL. - Page 22 Bennett T140 Operation, Service, & Parts Manual Troubleshooting PROBLEM 2: THE PUMP RUNS BUT DELIVERY IS SLOW. Refer to the table below for a description of various causes of the problem and the solution. Cause Solution The fuel supply level is low.

-

Page 23: Vapor Lock

Bennett T140 Operation, Service, & Parts Manual Troubleshooting VAPOR LOCK Vapor lock is a problem that results from ambient temperatures, vapor pressure of the product, and the installation. It is not a characteristic of a pump. REASONS FOR VAPOR LO CK ... - Page 24 Bennett T140 Operation, Service, & Parts Manual Troubleshooting To Measure A Pump’s Suction, the Working Pressure must be Atmospheric Pressure (14.7 PSI) = 30” of Mercury converted to Inches Of Vacuum. To figure, multiply the Working Pressure by 2. The result is the number of inches of vacuum that a pump can create before the product change to a vapor (i.e.

- Page 25 Bennett T140 Operation, Service, & Parts Manual Troubleshooting It takes 1 inch of vacuum by the pump to overcome the restriction of 1” of vacuum to overcome the restriction of angle an angle check or foot valve. (Not part of the pump, but a necessary check valve or foot valve part of the installation.) See Figure 24.

- Page 26 Bennett T140 Operation, Service, & Parts Manual Troubleshooting Using the same formulas as before, the Working Pressure equal Atmospheric Pressure less the Vapor Pressure. See Figure 27. 14.7 PSI - (Atmospheric Pressure) 95°F - 12.0 PSI - (Vapor Pressure of the product) 2.7 PSI - (Working Pressure)

-

Page 27: Parts

Parts SECTION 5: PARTS PARTS Use the illustrations to determine the part required identified by an item number. Please contact Bennett Customer Service Department at 231- 719-6050 for any additional information. TO PLACE AN ORDER FO R PARTS To place an order for parts please contact us by mail, email, phone, fax, or web using the information provided below. Note: Verbal orders cannot be accepted. -

Page 28: T140 Part Numbers

Bennett T140 Operation, Service, & Parts Manual Parts T140 PART NUMBERS All T140 Bennett Pumping Units include part number 111103. Refer to the pumping unit assembly on the following pages for exploded diagram and parts list. Part # Description 111103... -

Page 29: T140 Pumping Unit Assembly

Bennett T140 Operation, Service, & Parts Manual Parts T140 PUMPING UNIT ASSEMBLY Refer to the Type 140 Parts Lists on the following pages for part numbers, description, and comments. Note: Item numbers are not listed in numerical order. -

Page 30: Type 140 Pumping Unit Parts List

Refer to the Type 140 assembly on the previous page for reference number locations. Note: Not all parts are shown. If the part is not included in this list then it is not available for purchase through Bennett Pump Company. -

Page 31: T140 Kits

Gasket – Atmospheric Cover 114991 Stator Lip Seal 114992 Rotor Cover Lip Seal 113658 Plug (For Service) T140 – USE WITH 111018 (P/N 111018 REPLACED BY 114992) OVER FLOW CHECK VALV E – P/N 112166 Part No. Description Qty. 112165... - Page 32 Qty. 112161 Instructions Kit T140 Sump Float 109892 Float Atmospheric Assembly N888301 Float Assembly (Non-Reversing) 111007 O-Ring Atmospheric Float T140 PU (Added per BOM) 111059 Gasket Atmospheric (Added per BOM) 8 BLADE – P/N 112168 Part No. Description Qty. 112167...

- Page 33 Bennett T140 Operation, Service, & Parts Manual Parts ROTOR & BEARING REBUILD 100MM – P/N 115731 Part No. Description Qty. 115734 Instructions Kit Rotor & Bearing Rebuild T140 (100mm) 115735 Rotor Assembly and Shaft Assembly (100mm) 115715 Needle Bearing (100mm) 115714 Ball Bearing (100mm)

- Page 34 Bennett T140 Operation, Service, & Parts Manual Parts Page Intentionally Left Blank...

- Page 35 Bennett T140 Operation, Service, & Parts Manual Page Intentionally Left Blank...

- Page 36 Bennett 1218 E. Pontaluna Road, Spring Lake, MI 49456 USA 800-235-7618 ~ Outside USA 231-798-1310 sales@bennettpump.com ~ www.bennettpump.com...

Need help?

Do you have a question about the T140 and is the answer not in the manual?

Questions and answers