Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for RAYLASE SUPERSCAN II

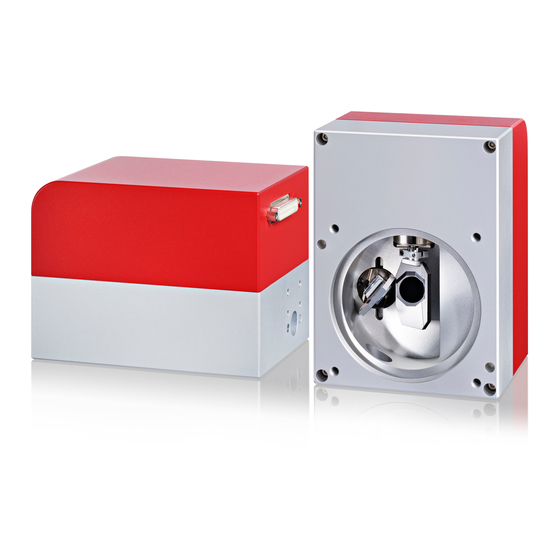

- Page 1 2-Axis Laser Beam Deflection Units SUPERSCAN II...

- Page 2 This manual has been compiled by RAYLASE for its customers and employees. RAYLASE reserves the right to change the product described in this manual and the infor- mation contained therein without prior notice. The software included in the product and this manual itself are protected by copyright. All rights are reserved.

-

Page 3: Table Of Contents

Contents CONTENTS BASIC SAFETY INSTRUCTIONS .................. 4 Laser safety ........................4 Laser shutter ........................4 Signs ..........................4 Classification of laser devices ..................5 Laser area ........................6 Special hazards caused by mirrors made of beryllium ........... 7 Special hazards caused by lenses made of zinc selenide ..........7 BASIC INFORMATION .................... -

Page 4: Basic Safety Instructions

( page 5, Classifica- tion of laser devices). The mirrors of the SUPERSCAN II high-speed versions are made of beryllium. The rating plate indicates if this applies to the present deflection unit ( page 13, Detailed Description). -

Page 5: Classification Of Laser Devices

Basic safety instructions Chapter 1 Lenses for CO2 laser deflection units with linear translator modules are made of zinc selenide. The rating plate indicates if this applies to the present deflection unit ( page 13, Detailed Description). In addition, these deflection units are provided with the adjacent sign. -

Page 6: Laser Area

However, the applicable local and national standards, rules and regulations are binding. cover RAYLASE deflection unit laser shutter deflected laser beam reflected laser beam laser area working surface RAYLASE 2-Axis Deflection Unit SS-II MN065_v1.0.1... -

Page 7: Special Hazards Caused By Mirrors Made Of Beryllium

Basic safety instructions Chapter 1 Special hazards caused by mirrors made of beryllium Beryllium mirrors can be destroyed by improper loading. This can lead to a release of berylli- um dusts. These dusts can cause cancer, are toxic if swallowed and very toxic by inhalation. Please observe the specified maximum applicable laser power in the data sheet. -

Page 8: Basic Information

You should therefore familiarize yourself with the content of this manual before using the deflection unit for the first time. In case of any queries, please contact RAYLASE. The operating manual must be accessible to anyone who will be involved in developing, in- stalling or using a laser device featuring the RAYLASE deflection unit. -

Page 9: Module Overview

Basic information Chapter 2 Module overview The illustration below shows three typical laser devices that are realized using RAYLASE and customer-specific modules (indicated by dotted lines). Fig. 1 Laser system Module overview RAYLASE SP-ICE control card RAYLASE RLC-PCI control card... -

Page 10: Warranty

E-mail: info@raylase.de Customer support The RAYLASE support services are available for your problems either in respect to the deflec- tion unit or this manual. Before calling for support, please make sure you refer to any appropriate sections in the manuals on the supplied CD that may answer your questions. -

Page 11: Status Leds

Basic information Chapter 2 Status LEDs The status LEDs allow you to check important functions and statuses of the deflection unit. They are located on the front or on the top of the deflection unit (depends on type). LED arrangement Name Color Meaning CLK error... -

Page 12: Technical Data

│ │ │ │ Additional information or customer shortcut └─ └─── └─ └────────── └─ └ GG-TTTT-AA [WWWWWWWWWWW] VV/D Note: All mirrors have, in addition to the above coatings, a deflector for the wavelength 633nm. RAYLASE 2-Axis Deflection Unit SS-II MN065_v1.0.1... -

Page 13: Detailed Description

The deflection unit conforms to the requirements of the following directives: EU Directive 2004/108/EC (EMC) WEEE Directive 2012/19/EC RoHS II 2011/65/EU Directive 2006/42/EC on machinery For details of conformity with other directives, contact RAYLASE. MN065_v1.0.1 2-Axis Laser Beam Deflection Unit SS-II... -

Page 14: Functional Description

F-Theta lens or protection glass ( page 15, F-Theta lens). Fig. 2 Functional principle Only for deflection units with water cooling Digital interface Input coolant Power supply Output coolant Beam input Beam output Marking field Status LEDs Galvanometer scanners with mirrors RAYLASE 2-Axis Deflection Unit SS-II MN065_v1.0.1... -

Page 15: F-Theta Lens

Functional description Chapter 4 Only for deflection units fitted with an F-Theta lens F-Theta lens The F-Theta lens is designed especially for use with 2-axis deflection units. It focuses the laser beam at optimum quality to any position on the marking field. At the same time, it pro- vides partial optical compensation for the barrel-shaped distortion that is unavoidable when using a two-axis deflection unit. -

Page 16: Digital Interface

Functional description Digital interface The deflection unit is connected to a RAYLASE control card using the 25-pin D-SUB connect- or. All signals are compatible with RAYLASE's extended function XY2-100 standard. If the deflection unit is equipped with an 9-pin D-SUB connector, the power supply for the unit is performed on this connector. -

Page 17: Power Supply

Functional description Chapter 4 Power supply The 9-pin D-SUB connector provides the deflection unit with power. The power supply must be provided by the OEM customer. Refer to the following connection and parameter table: Designation Voltage Current Residual Noise ripple ≤100mV ≤0.5% DC at 1, 2, 6... -

Page 18: Installation

Note: The deflection unit may only be installed using the pins and screws specified by RAYLASE. Follow the installation drawing supplied. o For details about the connection, the deflection unit to a RAYLASE control card, refer to the corresponding manual. -

Page 19: Maintenance And Cleaning

MAINTENANCE AND CLEANING The subsystem doesn‘t contain any components that require regular maintenance. Repairs may only be carried out by RAYLASE or RAYLASE certified service centers because special know-how and comprehensive testing methods are required. RAYLASE offers worldwide certified service and repair centers. -

Page 20: Instructions For Cleaning Lenses And Protective Glasses

The mirror surfaces are extremely sensitive and may only be cleaned by experienced person- nel. We strongly recommend sending the deflection unit in to RAYLASE for the mirror clean- ing, as opening of the deflection unit by unauthorized personnel voids the warranty. -

Page 21: Special Notes For Mirrors Made Of Beryllium And Lenses Made Of Zinc Selenide

Label the defective deflection unit with a clear warning and send the unit airtight and well packaged to RAYLASE. The persons commissioned with the dismantling of the deflection unit must wear suitable protective clothing and respirators. -

Page 22: Troubleshooting

X and Y axis Incorrect cabling reversed If the fault cannot be resolved, contact RAYLASE Customer Service for further assistance. RAYLASE 2-Axis Deflection Unit SS-II MN065_v1.0.1... -

Page 23: Disposal

Disposal Chapter 8 DISPOSAL For the disposal of the deflection unit, note local policies, regulations and laws. If the mirrors are made of beryllium, the local Hazardous Substance Regulations must be considered. The rating plate shows which deflection units are concerned ( page 13, Detailed Description) MN065_v1.0.1 2-Axis Laser Beam Deflection Unit SS-II... - Page 24 Technical data ..........12 Troubleshooting ..........22 Installation ............. 18 Warranty ............10 Laser beam deflection unit ......14 Laser safety ............. 4 XY2-100 Standard ......... 17 Manufacturer ..........10 Zinkselenid ..........7, 21 RAYLASE 2-Axis Deflection Unit SS-II MN065_v1.0.1...

- Page 25 SUPERSCAN-IIE General Specifications Typical Deflection (optical) ±0.393 rad Voltage ±15 to ±18 V Resolution optically 12 µrad Power Current 3 A, RMS, max. 10 A Repeatability (RMS) 2 µrad Supply Max. Gaindrift < 15 ppm/K Ripple / Max. 200 mVpp, @ 20 MHz Noise bandwidth Max.

- Page 26 Auto calibration option [K] available for all SUPERSCAN II models with reference sensors for automatic drift compensation which ensures process stability. BE and SC mirrors allow for higher speed performance due to the lightweight mirror substrates and optimized mirror mounts.

Need help?

Do you have a question about the SUPERSCAN II and is the answer not in the manual?

Questions and answers