EVAPCO ESW4 Rigging And Assembly Instructions

Closed circuit coolers

Hide thumbs

Also See for ESW4:

- Maintenance instruction (21 pages) ,

- Operation and maintenance instruction (58 pages)

Advertisement

Quick Links

Assembly Instructions

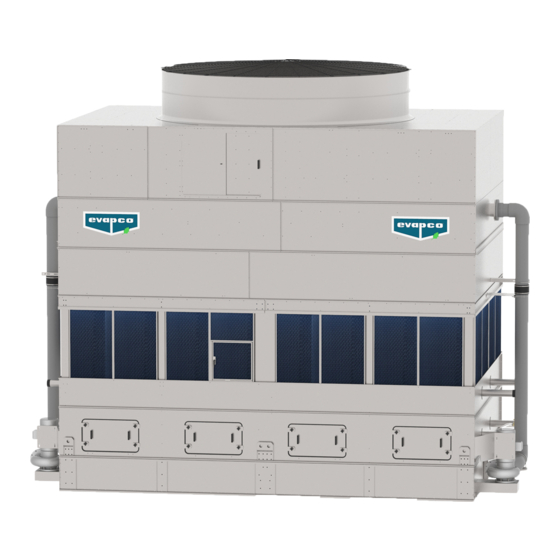

ESW4 CLOSED CIRCUIT COOLERS

EVAPCO, Inc. — World Headquarters & Research/Development Center

North America

EVAPCO, Inc.

World Headquarters

P.O. Box 1300

Westminster, MD 21158 USA

410-756-2600 p | 410-756-6450 f

marketing@evapco.com

EVAPCO East

5151 Allendale Lane

Taneytown, MD 21787 USA

410-756-2600 p | 410-756-6450 f

marketing@evapco.com

EVAPCO East

Key Building

Taneytown, MD USA

410-756-2600 p

marketing@evapco.com

EVAPCO Midwest

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO West

Madera, CA USA

559-673-2207 p

contact@evapcowest.com

EVAPCO Iowa

Lake View, IA USA

712-657-3223 p

EVAPCO Iowa

Sales & Engineering

Medford, MN USA

507-446-8005 p

evapcomn@evapcomn.com

EVAPCO Newton

Newton, IL USA

618-783-3433 p

evapcomw@evapcomw.com

EVAPCOLD

Greenup, IL USA

217-923-3431 p

evapcomw@evapcomw.com

EVAPCO S

Rigging and

EVAPCO Products are Manufactured Wordwide

P.O. Box 1300 • Westminster, MD 21158 USA

410-756-2600 p • marketing@evapco.com • evapco.com

EVAPCO-BLCT Dry Cooling, Inc.

Bridgewater, NJ 08807 USA

908-379-2665 p

info@evapco-blct.com

EVAPCO-BLCT Dry Cooling, Inc.

Littleton, CO 80127 USA

908-379-2665 p

info@evapco-blct.com

EVAPCO Power México S. de R.L. de C.V.

Calle Iglesia No. 2, Torre E

Tizapan San Ángel, Del. Álvaro Obregón

Ciudad de México, D.F. México 01090

+52 (55) 8421-9260 p

info@evapco-blct.com

Refrigeration Vessels & Systems Corporation

A wholly owned subsidiary of EVAPCO, Inc.

Bryan, TX USA

979-778-0095 p

rvs@rvscorp.com

EvapTech, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

Edwardsville, KS USA

913-322-5165 p

marketing@evaptech.com

Tower Components, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

Ramseur, NC USA

336-824-2102 p

mail@towercomponentsinc.com

EVAPCO Alcoil, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

York, PA USA

717-347-7500 p

info@alcoil.net

Visit EVAPCO's Website at:

PECIALISTS IN

Europe

EVAPCO Europe BVBA

European Headquarters

Heersterveldweg 19

Industrieterrein Oost

3700 Tongeren, Belgium

(32) 12-395029 p | (32) 12-238527 f

evapco.europe@evapco.be

EVAPCO Europe, S.r.l.

Milan, Italy

(39) 02-939-9041 p

evapcoeurope@evapco.it

EVAPCO Europe, S.r.l.

Sondrio, Italy

EVAPCO Europe GmbH

Meerbusch, Germany

(49) 2159 6956 18 p

info@evapco.de

EVAPCO Air Solutions

A wholly owned subsidiary of EVAPCO, Inc.

Aabybro, Denmark

(45) 9824 4999 p

info@evapco.dk

EVAPCO Air Solutions GmbH

Garbsen, Germany

(49) 5137 93875-0 p

info@evapcoas.de

Evap Egypt Engineering Industries Co.

A licensed manufacturer of EVAPCO, Inc.

Nasr City, Cairo, Egypt

2 02 24022866/2 02 24044997 p

primacool@link.net / shady@primacool.net

EVAPCO Middle East DMCC

Dubai, United Arab Emirates

+971 4 448 7242 p

info@evapco.ae

EVAPCO S.A. (Pty.) Ltd.

A licensed manufacturer of EVAPCO, Inc.

Isando 1600, Republic of South Africa

(27) 11-392-6630 p

evapco@evapco.co.za

evapco.com

H

T

P

EAT

RANSFER

RODUCTS AND

Bulletin ESW419RIG

Asia/Pacific

EVAPCO Asia/Pacific Headquarters

1159 Luoning Road

Baoshan Industrial Zone

Shanghai 200949, P.R. China

(86) 21-6687-7786 p | (86) 21-6687-7008 f

marketing@evapcochina.com

EVAPCO (Shanghai) Refrigeration Equipment Co., Ltd.

Baoshan Industrial Zone Shanghai, P.R. China

(86) 21-6687-7786 p

marketing@evapcochina.com

Beijing EVAPCO Refrigeration Equipment Co., Ltd.

Huairou District Beijing, P.R. China

010-6166-7238 p

evapcobj@evapcochina.com

EVAPCO Air Cooling Systems (Jiaxing) Company, Ltd.

Building 10, 1133 Taoyuan Road,

Jiaxing, Zhejiang, China

(86) 573 83119379 p

info@evapcoacs.cn

EVAPCO Australia (Pty.) Ltd.

Riverstone NSW 2765, Australia

(61) 2 9627-3322 p

sales@evapco.com.au

EvapTech Asia Pacific Sdn. Bhd

A wholly owned subsidiary of EvapTech, Inc.

Puchong, Selangor, Malaysia

(60-3) 8070-7255 p

marketing-ap@evaptech.com

South America

EVAPCO Brasil

Equipamentos Industriais Ltda.

Al. Vênus, 151 – CEP: 13347-659

Indaiatuba –São Paulo – Brasil

(55+11) 5681-2000 p

vendas@evapco.com.br

Fan Technology Resources

Cruz das Almas – Indaiatuba

São Paulo, Brasil 13308-200

55 (11) 4025-1670 p

fantr@fantr.com

S

ERVICES

Advertisement

Summary of Contents for EVAPCO ESW4

- Page 1 Bulletin ESW419RIG Rigging and Assembly Instructions ESW4 CLOSED CIRCUIT COOLERS EVAPCO Products are Manufactured Wordwide EVAPCO, Inc. — World Headquarters & Research/Development Center P.O. Box 1300 • Westminster, MD 21158 USA 410-756-2600 p • marketing@evapco.com • evapco.com North America Europe Asia/Pacific EVAPCO, Inc.

- Page 2 This includes piping, ductwork, conduit, and electrical connections. These items must be flexibly attached to the Evapco unit so as not to transmit additional loads to the equipment as a result of seismic or wind forces.

- Page 3 12' (3.6m) 22' (6.7m) 21' (6.4m) Table 2 – Minimum “H” Dimension for Basin Sections Figure 2 – ESW4 Bottom Section Figure 3 – ESW4 Bottom Section 4 point rig 18’ (5.5m) and 22’ (6.7m) 6 point rig Important: The lifting devices should be used only for lifting where no danger exists and for final positioning of the...

- Page 4 ESW4 Closed Circuit Coolers Rigging the Bottom Section: Extended Lifts The preferred method for extended lifts is to use slings under the unit as shown in Figures 4 and 5. Spreader bars should always be used between the cables at the top of the section to prevent damage to the upper portion of the basin. Safety slings and skids should be removed before final positioning of the unit.

- Page 5 18' (5.5m) Table 3 – Minimum “H” Dimension for Top Sections Figure 7 – ESW4 Top Section Important: The “U” Bolts should be used only for lifting where no danger exists and for final positioning of the section. For extended lifts, safety slings should be provided under the section as described on page 6.

- Page 6 ESW4 Closed Circuit Coolers Rigging the Top Section: Extended Lifts The preferred method for extended lifts is to use slings under the unit as shown in Figure 8. Spreader bars should always be used between the cables at the top of the section to prevent damage to the upper flanges or fan cylinder.

- Page 7 ESW4 Closed Circuit Coolers 3-Section Shipments In some cases, a unit is shipped in 3 sections (Fan, Casing and Basin) in lieu of the standard 2 sections (Fan + Casing, and Basin). This is often done to reduce the shipping height of each individual...

- Page 8 On units which are longer than 12’ (3.6m) (“L” > 12’ (3.6m)), a drift pin should be used at an intermediate pair of bolt holes in the rigging seam to allow for proper alignment. Notes: Bolts can be driven upward through the mating flanges if access is restricted. All rigging hardware is provided by EVAPCO. Drift pins are by others.

- Page 9 ESW4 Closed Circuit Coolers Mounting Fan Screens 12’ (3.6m) and 14’ (4.2m) wide units will be shipped with the fan screens in the basin. Under these circumstances use the following procedures to mount the fan screen on the discharge cylinder.

- Page 10 ESW4 Closed Circuit Coolers (applicable to 8.5’ (2.6m) wide models only) External Motor Installation 8.5’ (2.6m) Wide Models 1. Study Figure 15 before installing the motor base on the unit. 2. Insert the lifting device into “U” bolt A on motor base B.

- Page 11 ESW4 Closed Circuit Coolers Optional Motor Davit This accessory is available to aid in the removal of fan motors and gear boxes. The assembly consists of a davit and a mounting base/channel that is attached to the side of the unit next to the access door (Figure 18). Both of these items will ship loose in the unit’s basin.

- Page 12 ESW4 Closed Circuit Coolers Optional Sloped Ladders When sloped ladders are supplied with a unit, they are shipped NOTE: Upper Section of Unit Must Be Properly Oriented in the basin section, if there is room. One sloped ladder will be with Respect to Lower Section.

- Page 13 ESW4 Closed Circuit Coolers Optional Working Platform and Ladder The working platform and ladder will either be shipped in the basin or shipped separately due to basin accessories that interfere with storage. The platform is partially assembled prior to shipment for minimal field assembly.

- Page 14 ESW4 Closed Circuit Coolers General Information - Start-up & Maintenance Start-up Details Shipping Chocks and Debris Remove any chocks that have been placed inside the unit for shipping purposes. Be sure to remove the chocks from between the fan and fan guard if applicable. Clean all debris from the basin prior to start-up. Clean and secure all access doors.

- Page 15 ESW4 Closed Circuit Coolers Starting Sequence Before starting the unit, check that all access openings, safety screens and covers are in place. Start the unit as outlined below: 1. Fill the pan to the overflow level. 2. Bump start and check the spray water pump(s) for proper rotation. Directional arrows are found on the pump impeller housing.

- Page 16 Mounted in Fan Section Water Level Indicator Strapped Inside Unit Basin Table 7 – Unit Accessory Shipping Location EVAPCO, Inc. • P.O. Box 1300 • Westminster, MD 21158 USA : 410-756-2600 • F : 410-756-6450 • E- : marketing@evapco.com Printed on recycled paper...

Need help?

Do you have a question about the ESW4 and is the answer not in the manual?

Questions and answers