Table of Contents

Advertisement

Quick Links

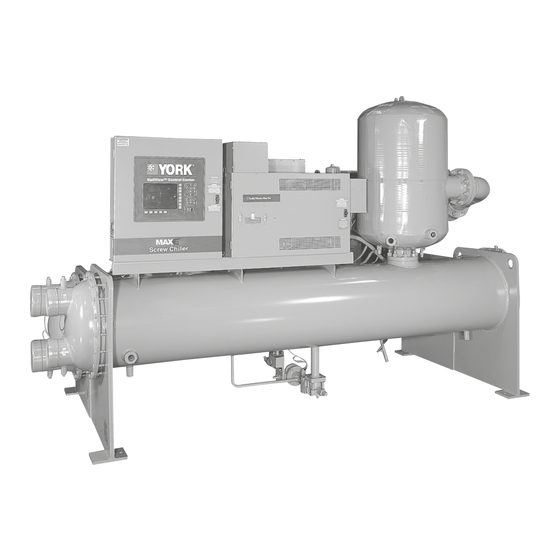

ROTARY SCREW LIQUID CHILLERS

INSTALLATION, OPERATION, MAINTENANCE Supersedes: 160.81-NOM1 (212) Form 160.81-NOM1 (1020)

MODELS

YR TB TB T0 THROUGH YR VD VD T1

YR TB TB T0 THROUGH YR XD XD T3

INCLUDING

FIELD RE-ASSEMBLY FOR FORM 2, 3, 7 AND 8 SHIPMENT

(STYLE A AND B)

00562VIP

R-134a

Issue Date:

October 3, 2020

Advertisement

Table of Contents

Summary of Contents for York YR TB TB T0

- Page 1 ROTARY SCREW LIQUID CHILLERS INSTALLATION, OPERATION, MAINTENANCE Supersedes: 160.81-NOM1 (212) Form 160.81-NOM1 (1020) MODELS YR TB TB T0 THROUGH YR VD VD T1 YR TB TB T0 THROUGH YR XD XD T3 INCLUDING FIELD RE-ASSEMBLY FOR FORM 2, 3, 7 AND 8 SHIPMENT...

- Page 2 FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 IMPORTANT! READ BEFORE PROCEEDING! GENERAL SAFETY GUIDELINES This equipment is a relatively complicated apparatus. which it is situated, as well as severe personal injury or During installation, operation maintenance or service, death to themselves and people at the site. individuals may be exposed to certain components or This document is intended for use by owner-authorized conditions including, but not limited to: refrigerants,...

- Page 3 Planned Service Agreement that leverages real time and generalized conditions. In lieu of the traditional and historical data, delivering performance reporting, maintenance program, a Johnson Controls YORK corrective actions required and data enabled guidance Conditioned Based Maintenance (CBM) program can for optimal operation and lifecycle assurance.

- Page 4 FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 NOMENCLATURE The model number denotes the following characteristics of the unit: YR TB – STYLE MOTOR VOLTAGE Volts/Phase/HZ 17 = 200 / 208-3-60 28 = 230 / 240-3-60 40 = 380-3-60 46 = 440 / 460 / 480-3-60 58 = 575 / 600-3-60 50 = 380 / 400-3-50 55 = 415-3-50...

-

Page 5: Table Of Contents

FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 TABLE OF CONTENTS SECTION 1 – INSTALLATION ..........................9 General ................................9 Construction Drawings ............................. 9 Installation Restrictions ............................ 9 Inspection – Damage – Shortage ........................10 Data Plate ............................... 10 Location ................................10 Foundation ..............................10 Clearance for Service Requirements ...................... - Page 6 FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 TABLE OF CONTENTS (CONT'D) Capacity Control ............................51 Need for Maintenance or Service ........................52 Normal Safety Shutdown and Repairs ......................52 Safety Shutdowns ............................52 Cycling Shutdowns ............................52 Stopping the System ............................53 Prolonged Shutdown ............................

- Page 7 TABLE 11 - Refrigerant Relief Characteristics ...................... 36 TABLE 12 - Variable Orifice Pressure Differential Setpoints ................. 51 TABLE 13 - Operation / Inspection / Maintenance Requirements for York YR Chillers ......... 57 TABLE 14 - Maintenance Schedule ........................57 TABLE 15 - Compressor Oil Limits ........................

- Page 8 FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 9: Section 1 - Installation

FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 SECTION 1 – INSTALLATION GENERAL INSTALLATION RESTRICTIONS This instruction describes the installation of a Model No valves or connections should be opened under any YR Rotary Screw Liquid Chiller. The standard unit is circumstances because such action will result in loss of shipped as a single factory assembled, piped, wired and the factory refrigerant or nitrogen charge. -

Page 10: Inspection - Damage - Shortage

3 on page 12. cal passageway, such as an elevator shaft, contact YORK Factory for special rigging Equipment room should be ventilated to allow ad- instructions. equate heat removal. Check ANSI, state, local or other codes. -

Page 11: Figure 1 - Unit Rigging

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 If optional shipping skids are used, remove them be- Units shipped dismantled should be as- fore lowering the unit to its mounting position. Rig the sembled under the supervision of a John- unit to its final location on the floor or mounting pad by son Controls representative. -

Page 12: Table 3 - Unit Weights

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 TABLE 3 - UNIT WEIGHTS SHIPPING OPERATING REFRIGERANT LOADING PER COMP. SHELLS WEIGHT WEIGHT CHARGE ISOLATOR (LBS) (KG) (LBS) (KG) (LBS) (KG) (LBS) (KG) TATA 12864 5835 13468 6108 3367 1527 TATB 12946 5872... - Page 13 FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 TABLE 3 - UNIT WEIGHTS (CONT'D) SHIPPING OPERATING REFRIGERANT LOADING PER WEIGHT WEIGHT CHARGE ISOLATOR COMP. SHELLS (LBS) (KG) (LBS) (KG) (LBS) (KG) (LBS) (KG) VBVB* 12530 5683 14170 6427 3542 1606 VBVC* 12600...

-

Page 14: Figure 2 - Compressors - Evaporator, Condenser And Waterboxes Dimensions

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 MOTOR/COMPRESSOR RELIEF VALVE (SEE TABLE) MOTOR/COMPRESSOR RELIEF VALVE (SEE TABLE) TOP VIEW 8-1/2" (216 mm) ISOLATION VALVE RELIEF VALVES NOTE: OPTIONAL (SEE TABLE) RELIEF VALVES* TOP VIEW 8-1/2" WITH ISOLATION WITHOUT ISOLATION LOCATION (216 mm) VALVES... -

Page 15: Table 4 - Overall Dimensions

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 OVERALL DIMENSIONS TABLE 4 - OVERALL DIMENSIONS EVAPORATOR – CONDENSER SHELL CODES DIM. T0 AND T1 COMPRESSORS T1 COMPRESSORS T2 AND T3 COMPRESSORS T - T V - V T - T V - V W - W W - W... -

Page 16: Locating And Installing Isolator Pads

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 LOCATING AND INSTALLING ISOLATOR PADS The isolator pads should be located in accordance with The unit should be level within 1/4 inch (6 mm) from the floor layout of the dimensional product drawing, one end to the other end and from front to the rear. -

Page 17: Figure 4 - Standard Neoprene Vibration Isolator Pad Mounts (Metric)

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 FLOOR LAYOUT EVAPORATOR SHELLS END SHEET END SHEET DIMENSION "C" From Figure 2 (pages 12 and 13) CONDENSER 22 mm DIA. HOLE 76.2 SUPPORT FOOT 152.4 76.2 DIMENSION "A" From Figure 2 (pages 12 and 13) DIMENSIONS ARE TYPICAL ALL 4 CORNERS 203.2... -

Page 18: Installing Optional Spring Isolators

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 INSTALLING OPTIONAL SPRING ISOLATORS When ordered, 4 spring type isolator assemblies will Unit). If the leveling bolts are not long enough to level be furnished with the unit. The 4 assemblies are identi- unit due to an uneven or sloping floor or foundation, cal and can be placed at any of the 4 corners of the unit. -

Page 19: Figure 6 - Spring Isolators (Optional) (Metric)

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 DIM "C" SEE FIGURE 2 (Pages 12 and 13) DIM "A" SEE FIGURE 2 (Pages 12 and 13) ALL DIMENSIONS ARE IN MILLIMETERS LD07379 FIGURE 6 - SPRING ISOLATORS (OPTIONAL) (METRIC) JOHNSON CONTROLS... -

Page 20: Shipping Form 2, 3, 7, And 8

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 SHIPPING FORM 2, 3, 7, AND 8 This instruction explains the procedure to be used for All wiring integral with the compressor is shipped on reassembling the Model YR Rotary Screw Chiller the compressor, and all conduit is shipped on the heat shipped disassembled. -

Page 21: Inspection - Damage - Shortage

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 When more than one unit is involved, the DATA PLATE major parts of each unit will be marked A unit data plate is mounted on the control center as- to prevent mixing of assemblies. (Piping sembly of each unit, giving unit model number, design and Wiring Drawings to be furnished by working pressure, water passes, refrigerant charge, se-... -

Page 22: Table 5 - Form 3 Field Assembly Parts

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 Evaporator-Condenser Shells – Remove all refriger- TABLE 5 - FORM 3 FIELD ASSEMBLY PARTS ant connection covers. ITEM NO. DESCRIPTION Shells are shipped with a 5 psig (34 kPa) COMPRESSOR WITH MOTOR nitrogen charge. -

Page 23: Figure 9 - Form 3 Field Assembly - Exploded View

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 LD09971 FIGURE 9 - FORM 3 FIELD ASSEMBLY – EXPLODED VIEW JOHNSON CONTROLS... -

Page 24: Figure 10 - Form 7 Shipment

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 Form 7 Shipment 1. Locate evaporator and condenser shells in their 6. Lift compressor-motor assembly and remove final position. packing materials and shipping skids. Keep the compressor unit supported by the hoist until all 2. -

Page 25: Table 6 - Form 7 Field Assembly Parts

MAINTENANCE of this manual. 19. Evacuate and charge with refrigerant. 20. Charge the oil separator with the proper type and quantity of YORK oil. 21. All Units – Complete installation and finally level the unit. Refer to SECTION 1 – INSTALLATION of this manual. -

Page 26: Figure 11 - Form 7 Field Assembly - Exploded View

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 LD09972 FIGURE 11 - FORM 7 FIELD ASSEMBLY – EXPLODED VIEW JOHNSON CONTROLS... -

Page 27: Table 7 - Form 8 Field Assembly Parts

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 Form 8 Shipment TABLE 7 - FORM 8 FIELD ASSEMBLY PARTS ITEM NO. DESCRIPTION 1. Assemble vibration isolators to the unit. (Refer to Locating and Installing Isolator Pads on page COMPRESSOR WITH MOTOR 16.) GASKET 6-3/4"... -

Page 28: Figure 12 - Form 8 Field Assembly - Exploded View

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 LD09973 FIGURE 12 - FORM 8 FIELD ASSEMBLY – EXPLODED VIEW JOHNSON CONTROLS... -

Page 29: Vacuum Dehydration

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 VACUUM DEHYDRATION When this point is reached, practically all of the air To obtain a sufficiently dry system, the following in- has been evacuated from the system, but there is still structions have been assembled to provide an effective a small amount of moisture left. -

Page 30: Table 9 - System Pressures

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 TABLE 9 - SYSTEM PRESSURES *GAUGE ABSOLUTE BOILING INCHES OF MERCURY MILLIMETERS TEMPERATURES (HG) BELOW ONE PSIA OF MERCURY MICRONS OF WATER °F (°C) STANDARD (HG) ATMOSPHERE 14.696 760,000 212 (100) 10.24* 9.629 500,000... -

Page 31: Piping Connections

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 PIPING CONNECTIONS EVAPORATOR AND CONDENSER WATER PIPING After the unit is leveled (and wedged in place for op- tional spring isolators) the piping connections may be YR chillers have evaporator and condenser liquid fabricated;... -

Page 32: Table 10 - Water Flow Rate Limits - Gpm (L/S)

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 drive coolant temperature, fail-closed, and set for a tem- System Turnover Rate (STR) = perature above dewpoint. It can be requested as factory- Volume of chilled water system (gallons) supplied on a chiller order by special quotation. Design chilled water flow rate (gpm) Chilled Water Circuit As noted previously, if the STR is above 15 minutes,... -

Page 33: Figure 14 - Schematic Of A Typical Piping Arrangement

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 LD07069 FIGURE 14 - SCHEMATIC OF A TYPICAL PIPING ARRANGEMENT Condenser Water Circuit For proper operation of the unit, condenser refrigerant This is a guideline for estimating ECW minimum. Ac- pressure must be maintained above evaporator pres- tual ECW minimum will vary. -

Page 34: Figure 15 - Cooling Tower Piping With 3 Port By-Pass Valve

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 Cooling Tower Roof Sump w/ Strainer 3-Way Diverting Valve Alternate Bypass Condenser Gauges Controller LD10024 FIGURE 15 - COOLING TOWER PIPING WITH 3 PORT BY-PASS VALVE Stop Valves Checking Piping Circuits and Venting Air Stop valves may be provided (by others) in the evapo- After the water piping is completed, but before any wa- rator and condenser water piping, adjacent to the unit... -

Page 35: Refrigerant Relief Piping

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 REFRIGERANT RELIEF PIPING Piping should be properly supported to Each unit is equipped with relief device(s) on the prevent any strain on relief valve mount- evaporator, condenser and oil separator for the purpose ing. -

Page 36: Unit Piping

1-1/4 - 11-1/2 (FEM) CONDENSER DUAL RELIEF VALVE Where: SHELL OUTLET Cr = Rated capacity of YORK supplied relief valve at CODE LBS. AIR PER 235 PSIG. MIN. (kPa) Relief valve set pressure - 235 PSIG (1,621 kPa). 42.1 (290.3) 55.9 (385.4) 1-11-1/2 (FEM) 53.8 (370.9) 55.9 (385.4) -

Page 37: Insulation

FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 To ensure proper motor rotation, the INSULATION starter power input and starter to motor Insulation of the type specified for the job, or minimum connections must be checked with a phase thickness to prevent sweating of 30°F (-1°... - Page 38 The work (as checked below) is in process and will be completed by: _____________ / ____________ / Month Year The following work must be completed in accordance with installation instructions: A. YORK CHILLER D. ELECTRICAL WIRING 1. Unit assembled (if shipped dismantled) and 1. ELECTRO-MECHANICAL STARTER refrigerant piping installed under Johnson a.

- Page 39 Phone Number: evacuated, dehydrated and charged ....__________________________________________ F. CONDITIONS 1. YORK oil for compressor on job ....... 2. Cooling load available for testing and operating unit ............ 3. Personnel available for final wiring connections .. 4. Personnel available for start-up and testing ..

- Page 40 FORM 160.81-NOM1 SECTION 1 – INSTALLATION ISSUE DATE: 10/3/2020 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 41: Section 2 - Chiller Commissioning

FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 SECTION 2 – CHILLER COMMISSIONING OPTIVIEW CONTROL CENTER MOTOR Refer to Operator's Manual (Form 160.81‑O1) and Motor Service Manual (Form 160.81‑M1) for more informa- tion concerning the OptiView Control Center. Check the voltage supply to make certain it is the …... -

Page 42: Start-Up

FORM 160.81-NOM1 SECTION 2 – CHILLER COMMISSIONING ISSUE DATE: 10/3/2020 START-UP OPERATING LOG SHEET 1. If the chilled water pump is manually operated, A permanent daily record of system operating condi- start the pump – the OptiView Control Center will tions (temperatures and pressures) recorded at regular not allow the chiller to start unless chilled liquid intervals throughout each 24 hour operating period... -

Page 43: Customer (Operating Personnel) Instruction

FORM 160.81-NOM1 SECTION 2 – CHILLER COMMISSIONING ISSUE DATE: 10/3/2020 Leak Check (Visual) Maintenance Thoroughly check all fittings and connections for Review the maintenance schedule with the cus- … … … … oil and refrigerant leaks. tomer. Review the preventative maintenance schedule …... - Page 44 FORM 160.81-NOM1 SECTION 2 – CHILLER COMMISSIONING ISSUE DATE: 10/3/2020 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 45: Section 3 - Operation

BASIC DESCRIPTION Oil Separator The oil separator removes the oil that was injected into The YORK YR Chiller package uses a refrigerant- the compressor. The oil separator is a two stage design. flooded evaporator and a liquid-cooled condenser. The Most of the oil separates by a centrifugal force in the compressor is a heavy-duty, industrial-rated rotary first stage. -

Page 46: Figure 18 - Yr Screw Chiller Component Layout Drawing - Design Level "A

FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 FIGURE 18 - YR SCREW CHILLER COMPONENT LAYOUT DRAWING – DESIGN LEVEL “A” JOHNSON CONTROLS... -

Page 47: Figure 19 - Yr Screw Chiller System Schematic - Design Level "A

FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 LD07962 FIGURE 19 - YR SCREW CHILLER SYSTEM SCHEMATIC – DESIGN LEVEL “A” JOHNSON CONTROLS... - Page 48 FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 LD07963 FIGURE 17 - YR SCREW CHILLER SYSTEM SCHEMATIC – DESIGN LEVEL “A” (CONT’D) JOHNSON CONTROLS...

-

Page 49: Oil System

FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 tor timing variances and assure the valve is positioned Variable Orifice at the 75% closed position, the duration of the “Start Since liquid refrigerant is transferred from the Con- Sequence Initiated” period is programmable. denser to the Evaporator via the Condenser-Evaporator pressure differential, a large differential can create an OIL SYSTEM... -

Page 50: Oil Eductor Circuit

Refer to Figure 20 on vice. page 49. Do not add oil. YORK YR Chiller packages are pre-charged with the correct amount The eductors operate using the “jet pump” principle. of YORK oil during functional testing Discharge pressure gas and oil flows through a filter after manufacture. -

Page 51: Liquid Refrigerant Circuit

FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 Oil-rich refrigerant flows into the eductor block through the filter drier from the evaporator. The oil rich refrigerant mixes with the discharge pressure gas and flows into the compressor suction line. The filter driers should be changed annually or when excessive amount of oil is indicated in the refrigerant charge. -

Page 52: Need For Maintenance Or Service

FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 NEED FOR MAINTENANCE OR SERVICE Mod “B” Solid State Starter • LCSSS Shutdown – Requesting Fault Data If the system is malfunctioning in any manner, or the unit is stopped by one of the safety controls, please call •... -

Page 53: Stopping The System

FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 STOPPING THE SYSTEM 2. If freezing temperatures are encountered while The OptiView™ Control Center can be programmed to the system is idle, carefully drain the cooling wa- start and stop automatically (maximum, once each day) ter from the cooling tower, condenser, condenser whenever desired. - Page 54 FORM 160.81-NOM1 SECTION 3 – OPERATION ISSUE DATE: 10/3/2020 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 55: Section 4 - Operating Inspections

FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 SECTION 4 – OPERATING INSPECTIONS GENERAL Weekly Check the Refrigerant charge. By following a regular inspection using the display readings of the OptiView Control Center, and mainte- Quarterly nance procedure, the operator will avoid serious oper- ating difficulty. - Page 56 FORM 160.81-NOM1 SECTION 4 – OPERATING INSPECTIONS ISSUE DATE: 10/3/2020 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 57: Section 5 - Maintenance

The procedure is given in the left- hand at the bottom of the form to maintain warranty valida- column and the frequency required is marked with an tion. TABLE 13 - OPERATION / INSPECTION / MAINTENANCE REQUIREMENTS FOR YORK YR CHILLERS PROCEDURE DAILY WEEKLY MONTHLY YEARLY... -

Page 58: Compressor Oil

Yearly oil analysis is recommended to verify the con- The Oil Charge tinued use of the compressor oil. YORK oil types approved for YR Chillers and the It is very important to take the oil sample quantity of oil required is listed in Table 16 on page after the oil filter. -

Page 59: Figure 23 - Charging Oil

FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 water loop. This can cause refrigerant in the oil this manual) condition for an extended period of separator to condense, creating a liquid level (oil time refrigerant can again condense in the oil sep- and refrigerant mixture) that exceeds the top of arator. -

Page 60: Oil Temperature Control

The oil should be charged into the oil separator using power supply to the starter to energize the oil the YORK Oil Charging Pump – YORK Part No. 070- heater. This will keep the concentration of refrig- 10654. To charge oil, proceed as follows: erant in the oil to a minimum. -

Page 61: Oil Filter Replacement

FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 The YORK control panel will automatically display the message “DIRTY OIL FILTER” when the differ- ential pressure reaches 15 PSID across the oil filter. A safety shutdown will be initiated if the oil pressure dif- ferential pressure reaches 25 PSID. -

Page 62: Determining Correct Refrigerant Charge Level

Should it become necessary to add refrigerant charge All filter driers and angle shut off valves use Primore to a YORK YR Chiller; add charge until the evaporator Rotalock fittings. These fittings use a Teflon fiber approach and refrigerant gas discharge superheat are at ®... -

Page 63: Condensers And Evaporators

TUBES Condenser Tubes – The standard condenser tubes used Chemical Cleaning Procedure in YORK YR Chillers are internally enhanced copper Chemical cleaning is an effective method to remove tubes. scale from internally enhanced copper tubes. However, If the equipment is located in an unheated... -

Page 64: Evaporator Tubes

When chemical cleaning of the condenser tubes is re- EVAPORATOR TUBES quired, it may be necessary to calculate the internal The standard evaporator tubes used in YORK YR volume of the waterside condenser tubes. This infor- Chillers are internally enhanced copper tubes. -

Page 65: Megohm The Motor

FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 LD00475 FIGURE 26 - DIAGRAM, MEGOHM MOTOR WINDINGS MEGOHM THE MOTOR Make certain that the motor disconnect switch (circuit If any leaks are indicated, they must be repaired im- breaker) is in the open position. Megohm the motor as mediately. -

Page 66: Evacuation And Dehydration Of Unit

FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 and tube sheets may be considered tight. If refrig- 5. Close the system charging valve and the stop erant is detected at the vents, the heads must be valve between the vacuum indicator and the vac- removed, the leak located (by means of soap test uum pump (See Figure 19 on page 47). -

Page 67: Handling Refrigerant For Dismantling And Repairs

FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 The refrigerant charge level must be checked after the Improved results can be obtained by admitting water pressure and temperature have equalized between the into the tube during the cleaning process. This can be condenser and evaporator. -

Page 68: Compressor

FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 tubes to be further investigated. If the probable COMPRESSOR location of the leaky tubes has been determined, Maintenance for the compressor assembly consists of treat that section in the following manner (if the checking the operation of the oil return system and location is not definite, all the tubes will require changing the dehydrator, checking and changing the... - Page 69 FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 In any operating system it is most important to pro- 1. The condenser tubes should be cleaned annually vide a planned maintenance and inspection of its func- or earlier if conditions warrant. If the temperature tioning parts to keep it operating at its peak efficiency.

-

Page 70: Figure 27 - Evacuation Of The Chiller

FORM 160.81-NOM1 SECTION 5 – MAINTENANCE ISSUE DATE: 10/3/2020 Charging Valve Vacuum Pump Thermistor Vacuum Gauge LD009186 FIGURE 27 - EVACUATION OF THE CHILLER JOHNSON CONTROLS... -

Page 71: Section 6 - Troubleshooting

FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 SECTION 6 – TROUBLESHOOTING TROUBLESHOOTING GUIDE When an operating problem develops, compare all op- Successful problem solving requires an organized ap- erating information on the OPERATING DISPLAY proach to define the problem, identify the cause, and with normal operating conditions. - Page 72 FORM 160.81-NOM1 SECTION 6 – TROUBLESHOOTING ISSUE DATE: 10/3/2020 TABLE 18 – OPERATING ANALYSIS CHART (CONT'D) RESULTS POSSIBLE CAUSE REMEDY 2. SYMPTOM: ABNORMALLY LOW SUCTION PRESSURE Temperature difference between leaving Insufficient charge of refrigerant. Check for leaks and charge refrigerant into chilled water and refrigerant in evapora- system.

-

Page 73: Pressure/Temperature Conversion Tables

FORM 160.81-NOM1 SECTION 6 – TROUBLESHOOTING ISSUE DATE: 10/3/2020 PRESSURE/TEMPERATURE CONVERSION TABLES The numbers in bold-face type in the center column perature will be found in the left column. If converting refer to the temperature, either in Centigrade or Fahr- Centigrade to Fahrenheit, the equivalent temperature enheit, which is to be converted to the other scale. -

Page 74: Temperature Conversion Tables

FORM 160.81-NOM1 SECTION 6 – TROUBLESHOOTING ISSUE DATE: 10/3/2020 TEMPERATURE CONVERSION TABLES The numbers in bold-face type in the center column perature will be found in the left column. If converting refer to the temperature, either in Centigrade or Fahr- Centigrade to Fahrenheit, the equivalent temperature enheit, which is to be converted to the other scale. -

Page 75: Temperature

FORM 160.81-NOM1 ISSUE DATE: 10/3/2020 The following factors can be used to convert from English to the most common SI Metric values. TABLE 19 - SI METRIC CONVERSION MEASUREMENT MULTIPLY ENGLISH UNIT BY FACTOR TO OBTAIN METRIC UNIT Capacity Tons Refrigerant Effect (ton) 3.516 Kilowatts (kW) Power... - Page 76 5000 Renaissance Drive, New Freedom, Pennsylvania USA 17349 1-800-524-1330 Subject to change without notice. Printed in USA Copyright © by Johnson Controls 2020 www.johnsoncontrols.com ALL RIGHTS RESERVED Form 160.81-NOM1 (1020) Issue Date: October 3, 2020 Supersedes: 160.81-NOM1 (212)

Need help?

Do you have a question about the YR TB TB T0 and is the answer not in the manual?

Questions and answers