Table of Contents

Advertisement

Quick Links

April 2019

OMATION

®

Series 410 Envelopener

®

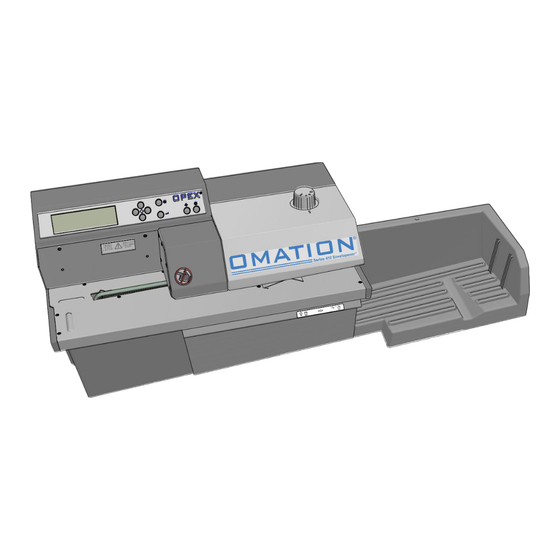

OMATION® Series 410 Envelopener™ Operator Manual

9286910OM-EN

Revision 19-01

Original Instructions

®

™

OMATION

Series 410 Envelopener

WARNING

Read this manual thoroughly before attempting to operate or service this

equipment. Keep a current copy for your reference.

®

© 2019 OPEX

Corporation

All rights reserved. This document is provided by OPEX for use by their customers, partners and dealers. No portion

of these materials may be reproduced, published, or stored in a database or retrieval system, other than for its

intended use without the express, written consent of OPEX Corporation.

Advertisement

Chapters

Table of Contents

Summary of Contents for Opex OMATION Envelopener 410 Series

- Page 1 © 2019 OPEX Corporation All rights reserved. This document is provided by OPEX for use by their customers, partners and dealers. No portion of these materials may be reproduced, published, or stored in a database or retrieval system, other than for its...

-

Page 2: Contacting Opex

Fax: +1 856.727.1955 https://www.opex.com/ If you find errors, inaccuracies, or any other issues or concerns with this document, please contact the OPEX Technical Writers via email at: GroupTechwriters@opex.com For help with opexservice website-related issues, please contact the OPEX Web Developers via email at: GroupWebDev@opex.com... -

Page 3: Eu Declaration Of Conformity

Technical documentation is compiled in accordance with Part B of Annex VII of the machinery directive. This documentation is available on a reasoned request by appropriate national authority to our authorized representative: NAME OPEX Business Machines Pty Ltd ADDRESS Level 12, 225 George Street... -

Page 4: Eu Declaration Of Conformity France: Fr

EU Declaration of Conformity OM410 This declaration of conformity is issued under the sole responsibility of the manufacturer. NAME OPEX Corporation Manufacturer ADDRESS 835 Lancer Drive, Moorestown, NJ 08057, USA Technical documentation is compiled in accordance with Part B of Annex VII of the machinery directive. This documentation is available on a... -

Page 5: Eu Declaration Of Conformity Germany: Gr

EU Declaration of Conformity OM410 This declaration of conformity is issued under the sole responsibility of the manufacturer. NAME OPEX Corporation Manufacturer ADDRESS 835 Lancer Drive, Moorestown, NJ 08057, USA Technical documentation is compiled in accordance with Part B of Annex VII of the machinery directive. This documentation is available on a... -

Page 6: Eu Declaration Of Conformity Republic Of Ireland: Ir

Technical documentation is compiled in accordance with Part B of Annex VII of the machinery directive. This documentation is available on a Technical File reasoned request by appropriate national authority to our authorized representative: NAME OPEX Business Machines GmbH ADDRESS 104 Lower Baggot Street Dublin 2... -

Page 7: Eu Declaration Of Conformity Switzerland: Sw

Technical documentation is compiled in accordance with Part B of Annex VII of the machinery directive. This documentation is available on a Technical File reasoned request by appropriate national authority to our authorized representative: NAME OPEX Business Machines GmbH ADDRESS Pilatustrasse 41 6003 Luzern... -

Page 8: Eu Declaration Of Conformity United Kingdom: Uk

Technical documentation is compiled in accordance with Part B of Annex VII of the machinery directive. This documentation is available on a Technical File reasoned request by appropriate national authority to our authorized representative: NAME OPEX Business Machines GmbH ADDRESS 29/32 Queensbrook Bolton Technology Exchange... -

Page 9: Document History

0.3. Document History Date Changes (click blue text to go to that page) 19-01 Apr 30, 2019 Initial release CE compliant OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... -

Page 10: Table Of Contents

Table of Contents 0.1. Contacting OPEX ..................2 0.2. EU Declaration of Conformity ..............3 0.2.1. EU Declaration of Conformity Australia: AU ........3 0.2.2. EU Declaration of Conformity France: FR ........4 0.2.3. EU Declaration of Conformity Germany: GR ........5 0.2.4. - Page 11 ............. . . 63 G.1. List of Terms ..................64 Table of Contents OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 12 Table of Contents OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 13: Introduction

1. Introduction 1.1. About This Manual ........14 1.1.1. -

Page 14: About This Manual

1.1. About This Manual ® This manual contains information about the OPEX OMATION Series 410 ™ Envelopener and its operational procedures and safety-related components, including: • safety information, safety hazards and precautions • main component identification and function • system specifications •... -

Page 15: Safety

2. Safety 2.1. Introduction ......... . . 16 2.1.1. -

Page 16: Introduction

2.1. Introduction The information provided in this chapter is intended to educate you on various safety issues regarding the operation and maintenance of the OPEX equipment described in this manual. This chapter provides an explanation of the safety conventions used throughout this manual, as well as safety guidelines to be observed when working with this equipment. -

Page 17: Safety Message Conventions

CAUTION Indicates a hazardous situation that, if not avoided, could result in minor or moderate injury. NOTICE Indicates information considered important, but not hazard related (e.g. messages relating to property damage). Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... -

Page 18: Safety Guidelines

- Do not modify the design or configuration of the equipment Machine design without consulting OPEX or your authorized representative. - Machine maintenance, particular operations, and all Machine Maintenance adjustments, whether mechanical or electrical, shall be carried out by persons authorized to do so in accordance with a safe system of work. -

Page 19: Consignes De Sécurité - Traduction Française

- Ne modifiez pas la conception ou la configuration Conception de la machine de l'équipement sans consulter OPEX ou votre représentant autorisé. - La maintenance de la machine, les opérations L'entretien des machines particulières et tous les réglages, qu'ils soient mécaniques ou électriques,... -

Page 20: Safety Labels

Though they appear different, the locations of these labels are identical. -The feeder warning label is found on the front of the machine, Feeder Warning above where envelopes are fed (Figure 2-1). Figure 2-1: Feeder Warning label Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 21 - The “keep fingers away from gaps near moving parts” Pinch point warnings label (1637200) is found at the beginning and end of the feed belt path (Figure 2-2). Figure 2-2: Pinch Point label Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 22 Figure 2-3: Disconnect Power Before Opening label - The following label (P24838-01) is found on Dielectric and ground test label the rear of the machine (Figure 2-4). Figure 2-4: Dielectric and Ground Test label Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 23 Figure 2-5: FCC Compliance Label - The machine’s model, serial number, and related info is Model and Serial provided on this label (8176900) on the back (Figure 2-6). Figure 2-6: Model / Serial Label Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 24 North American machines only (Figure 2-7). Figure 2-7: ICES-003 Label - The following label (9280100) is located on the handle of the Chip Bin Label Chip Bin (Figure 2-8). Figure 2-8: Chip Bin Label Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 25: Interlock System

1. The interlock system will stop all the motors in the machine whenever the nip arm cover (Figure 2-9) or chip bin tray (Figure 2-10) is removed. Figure 2-9: Top cover removal interlock triggering Figure 2-10: Bin tray removal interlock triggering Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... -

Page 26: Ergonomics

Personal protective equipment (PPE) refers to wearable safety items such as gloves, safety glasses, hard hats, and high-visibility vests. Before starting, find out what PPE is required per local law and the specific job site. Safety OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... -

Page 27: Overview

3. Overview 3.1. System Overview ........28 3.2. -

Page 28: System Overview

Nip arm cover Cut depth knob Envelope feed hopper Feed Chip Bin Output tray On/Off switch belt Feed Retard assembly (left side) thumper (under cover) Figure 3-1: Main Components Front View Overview OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 29 Please take time to familiarize yourself with the various parts of the machine, which are referred to throughout this manual in Figure 3-1 on page WARNING Read and follow all information in before attempting to Chapter 2: “Safety” operate this equipment. Overview OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 30: Equipment Model/Serial Number Locations

3.2. Equipment Model/Serial Number Locations Before contacting OPEX Technical Support, locate the Model/Serial label on your machine so that you can provide the assisting technician with your Reference Serial Number (Figure 3-3). See “Contacting OPEX” on page 2 contact information. - Page 31 4. Operation 4.1. Operation ..........32 4.1.1.

-

Page 32: Operation

Cancel button - used to cancel actions (such as to stop a job run), or back out of a screen. Arrow buttons - used to navigate through the data on the LCD screen. Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 33 Pressing the right arrow while the last item on the last page is highlighted will cause the screen to wrap to the first item in the list. Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 34: The Run Screen

4.1.2.1. RUN This selection will turn the motor on to process mail using the currently selected job. 4.1.2.2. CHANGE JOB This selection will allow the operator to change the currently selected job. Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 35 “record,” and open up a new one. 4.1.2.5. STATISTICS This will show the DISPLAY STATISTICS screen, which will allow the user to display and optionally print their statistics (Figure 4-3). Figure 4-3: Display Statistics screen Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 36 Through the Select Job menu (Figure 4-4), the Series 410 can be set to print the date, the time a piece was processed, its sequence number, or any combination of the three. Figure 4-4: Printing via Jobs Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 37: Operating Instructions

42). 3. Press the “1” position on the AC power switch on the left side of the machine to supply power to the machine (Figure 4-5). Figure 4-5: AC power switch Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 38 5. Use the arrow buttons to highlight ZERO COUNT, then press the Enter button to reset the count (Figure 4-7). Use the arrows to navigate to ZERO COUNT..then press Enter to reset. Figure 4-7: Resetting the counter Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 39 7. Select a job by highlighting it with the arrow buttons, and then pressing Enter (Figure 4-8). Use the arrow buttons to navigate to the desired job..then press Enter to select it. Figure 4-9: Selecting the Date + Time job Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 40 9. Once ready to begin, use the arrow buttons to highlight Run, and then press Enter to start the machine (Figure 4-11). The screen will display “RUN MODE ACTIVE” and elapsed run time. Select RUN, then press Enter Figure 4-11: Starting the machine Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 41 16. Once the Envelope Feed Hopper is empty, empty the output tray. 17. To continue processing, load more mail onto the Envelope Feed Hopper. Note: The feed hopper can be loaded with the machine running. Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 42: Output Tray Position

Simply lift the output tray up, move it to the desired position, and press it down onto the stepped tray hitch (see Figure 4-12). Against the machine 1” away 2” away Fully detached for large mail Figure 4-12: Output tray positions Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... -

Page 43: Clearing Jams

You may have to remove the nip arm cover. This is described in “Routine Maintenance” on page Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... -

Page 44: Routine Maintenance

2. Press the catch release button on the right side of the cover until a “click” is heard and lift the right side (Figure 4-13). 1 Push until a click is heard... 2 ...and lift up on this side Figure 4-13: Cover catch release button Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 45 3. Continue lifting the cover off on the left side to remove it (Figure 4-14). Figure 4-14: Lifting the Nip arm cover 4. Lift the Nip arm wheels to clean under them (Figure 4-15). Figure 4-15: Lifting the nip wheels Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 46 - Use denatured alcohol on areas with stains, if necessary. - Any non-flammable commercially available cleaning solution may be ® used to clean the machine. When cleaning the Opex OMATION Series ™ 410 Envelopener , DO NOT USE aerosol cleaners or compressed air because of the flammable nature of many of these products.

-

Page 47: Replacing The Print Cartridge

1. Either unplug the AC power cord, or turn off the AC power switch on the left side of the machine. 2. Remove the Nip Arm Cover (as shown on 44) to expose the printer page cartridge (Figure 4-16). Print Cartridge Figure 4-16: Printer Cartridge Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 48 4. Replace the printer cartridge and push into place (Figure 4-18). Figure 4-18: Replacing the printer cartridge 5. Replace the Nip Arm Cover and run a printing job to test the printer. Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 49: Cutter Adjustment

Deepest Cut No Cut Deeper Cut Standard Cut Figure 4-19: Standard Cut position 2. Remove the nip assembly cover (see “Cleaning the Series 410 Envelopener™” on page 44). Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 50 4. Replace the cover and run an envelope through to verify if it has been cut now. 5. If envelopes are not being cut, repeat steps 1 through 4 as needed. Increments smaller than 1/4 turn can be used to fine tune the cutter. Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 51: Resetting The Circuit Breaker

2. Unplug the power cord and push the circuit breaker toward the machine to close it (Figure 4-22). Circuit Breaker Open Circuit Breaker Closed Push Figure 4-22: Closing the circuit breaker Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 52 3. Plug the power cord back into the machine. 4. Verify the machine has a power display and operates normally. If the circuit breaker pops back out, call OPEX Tech Support to have the machine serviced (See “Contacting OPEX” on page Operation OMATION®...

-

Page 53: User Replaceable Parts

The parts on the following pages can be replaced by the user. If you're viewing the electronic version of the manual on a tablet, click or tap the circle pointing to the part to skip to its page (Figure 4-23). Figure 4-23: User Replaceable Parts Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 54 9131300 Complete Output Tray with all parts Click to return 7221810 Rubber Foot 4X 7662300 Screw 4X 7584100 Sound Dampening Pad 7603700 Spreader Bar 7549180 Tray only Figure 4-24: Output Tray Assembly Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 55 7023100 Magnet 7618700 Sticker 7549166 Tray only 9131400 Complete Tray Assembly with all parts Click to return Figure 4-25: Chip Bin Tray Assembly Figure 4-26: 3387500 Printer Cartridge (under transport cover) Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 56 Click to return Figure 4-27: 8067050 Cutter Depth Knob Click to return Figure 4-28: 8096750 Transport Cover Click to return Figure 4-29: 8069225 Transport Cover Latch (under transport cover) Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

- Page 57 OPEX Part #109003 (North America) OPEX Part #2282101 (UK) OPEX Part #2282102 (France, Germany) Click to return Figure 4-30: AC Power Cords Table 4-1: Additional Power Cords Country Part Number Australia # 109008 Denmark # 109015 India, South Africa # 109016...

- Page 58 This page intentionally left blank Operation OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 59: Specifications

5. Specifications 5.1. Physical Specifications ....... . . 60 5.2. Features ..........60 5.3. -

Page 60: Physical Specifications

Cut depth 2 = 0.014” (0.356mm) Cut depth 3 = 0.060” (1.524mm) The cut adjustment screw changes the cut depth 0.0044” for every ¼ turn of the screw. Printer Prints, Date, Time, and Sequence number Specifications OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... -

Page 61: Electrical Requirements

JAPAN: 1024 BTU/h (max @ 100v/3A) Operating and Storage 40°F – 100°F(4.4°C – 37.8°C), Humidity 10 – 90% Temperature range Non-condensed. Decibel Rating Does not exceed safety standard of 80 dB. Specifications OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 62 This page intentionally left blank. Specifications OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

-

Page 63: Glossary

G. Glossary OMATION® Series 410 Envelopener™ Operator Manual... -

Page 64: List Of Terms

- This separates the mail to one piece at a time as the Retard Assembly stack of mail is pulled up to the entrance of the retard assembly. - Separate or choose one at a time. Singulate OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation... - Page 65 Utilizing a vast global workforce of direct employees, OPEX serves a variety of industries including financial services, insurance, healthcare, government, retail, non-profits, utilities, telecommunication, service bureaus, educational institutions and fulfillment operations.

- Page 66 OMATION ® Series 410 Envelopener ® OMATION® Series 410 Envelopener™ Operator Manual OPEX Corporation...

Need help?

Do you have a question about the OMATION Envelopener 410 Series and is the answer not in the manual?

Questions and answers