Hubner U-ONE-Compact UOC40 Configuration Manual

Profibus-dp - module, profibus-dp interface

Hide thumbs

Also See for U-ONE-Compact UOC40:

- Configuration instructions (29 pages) ,

- Configuration manual (28 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Hubner U-ONE-Compact UOC40

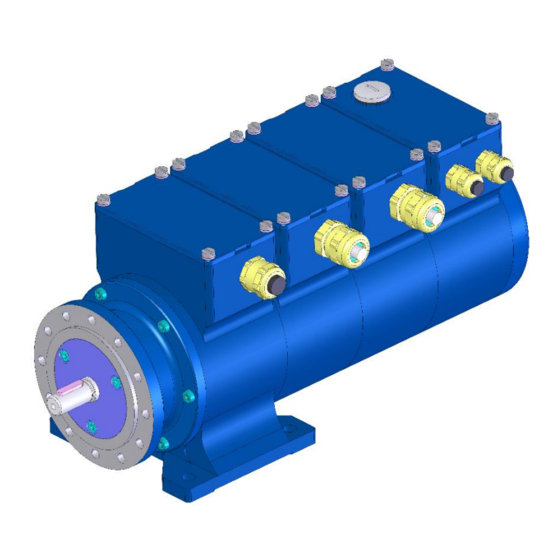

- Page 1 English Configuration manual for Profibus-module PROFIBUS-DP interface Read the configuration manual prior to assembly, starting installation and handling! Keep for future reference Translation of the original configuration manual EPF Published Nov. 2018 ID 74547...

- Page 2 Johannes Hubner Fabrik elektrischer Maschinen GmbH. Subject to errors and changes due to technical improvements. Copyright © Johannes Hubner Fabrik elektrischer Maschinen GmbH. All rights reserved. Trademarks PROFIBUS™, PROFINET™ and PROFIsafe™, as well as the relevant logos, are registered trademarks of PROFIBUS Nutzerorganisation e.V.

- Page 3 ® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module Change reservation The manual has been drawn up with the utmost care and attention. Nevertheless, we cannot exclude the possibility of errors in form and content. All rights, subject to errors and changes due to technical improvements reserved. Font styles Italic or bold font styles are used for the title of a document or are used for highlighting.

-

Page 4: Table Of Contents

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module Content 1 General Information ......................6 1.1 Applicability ........................6 2 Basic safety instructions ....................7 2.1 Explanation of symbols and notes ................... 7 2.2 Warranty and liability ....................... 8 2.3 Organizational measures ....................8 2.4 Personnel selection and qualification;... - Page 5 ® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 4.2.3.1 Start scaling .....................25 4.2.3.2 Stop scaling ......................25 5 Diagnostic messages ......................26 6 Faults ..........................28 6.1 Fault table ........................28 6.2 LED display for error and status messages ..............29 UOC40_EPF-Config-manual-en_R1...

-

Page 6: General Information

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 1 General Information These configuration-manual contain the following topics: ● Basic safety instructions with declaration of the intended use ● Characteristics ● Parameterization ● Error causes and remedies This configuration-manual is supplementary to other documentation, such as operating and assembly instructions, product data sheets, dimension drawings, connection diagrams, brochures etc. -

Page 7: Basic Safety Instructions

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 2 Basic safety instructions 2.1 Explanation of symbols and notes Warnings are indicated by symbols in these configuration manual. The warnings are introduced by signal words that express the scope of the hazard. The warnings must be strictly heeded;... -

Page 8: Warranty And Liability

Configuration-manual PROFIBUS-DP - module 2.2 Warranty and liability In principle the "General Terms and Conditions" of Johannes Hubner - Fabrik elektrischer Maschinen GmbH apply. These are available to the operator with the Order Confirmation or when the contract is concluded at the latest. Warranty and liability claims in the case of... -

Page 9: Installation And Commissioning

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 3 Installation and commissioning 3.1 User manual The module can be used as a multiturn or singleturn absolute encoder. It can be configured to the profiles CLASS 1 (Huebner 1.0), with parameterization of the count direction, or CLASS 2 (Huebner 2.0), with the additional setting of the resolution in units/turn and the total measuring range. -

Page 10: Profibus For The Absolute Encoder

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 3.2 Profibus for the absolute encoder ® The module behaves like a multiturn encoder that has been designed to operate with Profibus It can be configured and parameterized to the following profiles, as a multiturn or singleturn encoder: Absolute encoder profile Parameterization options... -

Page 11: Joining The Encoder To The Profibus

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 3.3 Joining the encoder to the Profibus After the encoder has been installed and the electrical connections have been made, it is joined to the Profibus system. The following is an example, using the COM PROFIBUS V 5.0 installation software with an IM308C Profibus-DP master. -

Page 12: Configuring The Encoder

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 3.4 Configuring the encoder Now select the profile for the encoder operation. The input and output address are then assigned, and the parameterization can be carried out. This function can be called up by the PARAMETERS button in the CONFIGURE window, and provides a clear and simple way of setting the parameters. -

Page 13: Parameterization In Hex Code

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module NOTE! Total measuring range = units per revolution x number of revolutions The number of revolutions must have a value 2 , where n can be from 0 to 12 If this is not taken into account, the encoder will detect a parameter error. This is indicated on the cover of the terminal box. -

Page 14: Operating The Encoder In The Huebner 2.1 And Huebner 2.2 Profiles

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 3.7 Operating the encoder in the Huebner 2.1 and Huebner 2.2 profiles Compared with the standard profiles, these two profiles offer several additional functions which can be parameterized through COM Profibus®, as is explained below. The SCALING FUNCTION must be activated as a precondition for using these additional functions. -

Page 15: Desired Measuring Units Per

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 3.8 Desired measuring units per … Compared with the HUEBNER 2.0 (CLASS 2) profile, three different scaling options are availa- ble. Required resolution: units per: revolution max. total measuring range physical pulse 3.8.1 Desired measuring units per revolution Here you can define the number of units that the encoder produces per revolution. -

Page 16: Desired Measuring Units Per Physical Pulse

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 3.8.3 Desired measuring units per physical pulse This setting is always referred to the division of the code disk into 4096 pulse intervals. The number that is entered in the entry fields for MEASURING UNITS is the number of parts into which the value entered for PHYSICAL PULSES is to be divided. -

Page 17: Data Transfer Modes For Profibus

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 4 Data transfer modes for Profibus Three data transfer modes are needed for operating the encoder on a Profibus®: When the system is started up, the data that are required for configuration and parameterization are transferred in the DDLM_SET_PRM mode from the master to the encoder (attached as a slave). -

Page 18: Class 2 Functionality (Octet 9.1)

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 4.1.1.1 Class 2 functionality (Octet 9.1) This bit can be set to 0, to switch over to Class1 operation. 4.1.1.2 Scaling function control (octet 9.3) If this bit is cleared, the encoder has a resolution of 4096 units per revolution, and a total meas- uring range of 4096 x 4096 units (corresponding to 4096 revolutions). - Page 19 ® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module Bits and bytes for parameterization of HÜBNER 2.1 and HÜBNER 2.2 Bit – Nr. Octet Parameter Count direction (code se- right = 0, left = 1 quence) Class 2 functionality off = 0, on = 1 Commissioning diagnostics Scaling function control off = 0, on = 1...

- Page 20 ® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module Singleturn/Multiturn single-turn = 0, multi-turn = 1 Reserved Reserved Velocity/speed dimension 5 + 4 00H units/second unit 01H units/100 msec 01H units/10 msec 11H rpm Reserved Reserved UOC40_EPF-Config-manual-en_R1...

-

Page 21: Huebner 2.1 And 2.2 (Octet 9.6)

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 4.1.2.1 HUEBNER 2.1 and 2.2 (octet 9.6) This bit is used to enable the other encoder functions which are available in this profile (in octet 26). 4.1.2.2 Measuring units per xxx (octet 10 – 13) + required measuring units (octet 26.0 and 26.1) The bits for the desired measuring units (octet 26.0 and 26.1) can be used to store a value in octet 10 –... -

Page 22: Octet 27 - 39 Active (Octet 26.7)

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 4.1.2.5 Octet 27 – 39 active (octet 26.7) When this bit is set, access is enabled to octets 27 to 39. This enables the functions: upper and lower limit switches, scaling through physical pulses, Singleturn/Multiturn, and the dimension for the velocity/speed (only for HUEBNER 2.2). -

Page 23: Accept Preset Value

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module The status bits are interpreted as follows: Bit 25 0 = encoder not ready 1 = encoder ready Bit 26 0 = commissioning mode 1 = normal mode 0 = software limit switch 1 = software limit switch Bit 27 min. -

Page 24: Set Count Direction (Code Sequence)

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 4.2.2 Set count direction (code sequence) In commissioning mode, the count direction can be reversed online, by using bit 28. After changing over, the encoder sends back the present direction to the master. A 0 means that the count direction is clockwise (looking at the shaft end), a 1 means it is counter-clockwise (anti- clockwise). -

Page 25: Scaling The Encoder With The Teach-In Method

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 4.2.3 Scaling the encoder with the teach-in method This method provides an automatic scaling of the encoder. After starting the procedure, the sys- tem moves over a defined path. Then the system is stopped, and the number of units into which the path is to be divided is entered. -

Page 26: Diagnostic Messages

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module Since the preset value is cancelled when scaling is started, it must be set again in a subsequent operation. The scaling is stored in non-volatile memory in the encoder. In order to be able to carry on us- ing the scaling values if the encoder is replaced, it is a good idea to transfer the total measuring range to the Profibus master. - Page 27 ® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module Operating time 23-0 is incremented every 6 minutes, while the 28–31 supply voltage is applied Zero point shift 23-0 preset value 32–35 Parameterized 23-0 only if the value resolution per Resolution per revo- 40–43 revolution lution was entered...

-

Page 28: Faults

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 6 Faults 6.1 Fault table absolute part Faults Possible cause Remedy Soiled gasket or seal sur- Clean gasket of terminal box faces of terminal box cover cover and seal surfaces Damaged gasket of terminal Replace gasket of terminal box cover box cover... -

Page 29: Led Display For Error And Status Messages

® U-ONE -Compact UOC40 Configuration-manual PROFIBUS-DP - module 6.2 LED display for error and status messages Two LEDs (one red, one green) are built into the cover of the terminal box, and are visible through a window. They are used to indicate errors and the momentary status of the encoder. Each one of the LEDs can have the state;...

Need help?

Do you have a question about the U-ONE-Compact UOC40 and is the answer not in the manual?

Questions and answers