Table of Contents

Advertisement

OPERATOR'S MANUAL

HWH JOYSTICK-CONTROLLED

210 SERIES LEVELING SYSTEM

Ph: 800/321-3494 (or) 563/724-3396 | Fax: 563/724-3408

AP23364 - U.S.

AP23724 - Europe

H H

W

CORPORATION

R

FEATURING:

Joystick BI-AXIS Control

Hydraulic Leveling

Kick-Down Jacks

Integrated Control Console

HWH

HYDRAULIC LEVELING

ON

NOT IN

PARK/

EXTEND

BRAKE

FRONT

EXTEND

EXTEND

LEFT

RIGHT

EXTEND

REAR

ON

OFF

CAUTION!

UNDERSTAND OPERATOR'S MANUAL BEFORE USING.

BLOCK FRAME AND TIRES SECURELY BEFORE

REMOVING TIRES OR CRAWLING UNDER VEHICLE.

HWH CORPORATION

(On I-80, Exit 267 South)

2096 Moscow Road | Moscow, Iowa 52760

www.hwh.com

R

R

OPERATE

STORE

FRONT

FUSE

5 AMP

STORE

REAR

OPERATE

ML23419/MP05.2007

26FEB04

Advertisement

Table of Contents

Summary of Contents for HWH 210 Series

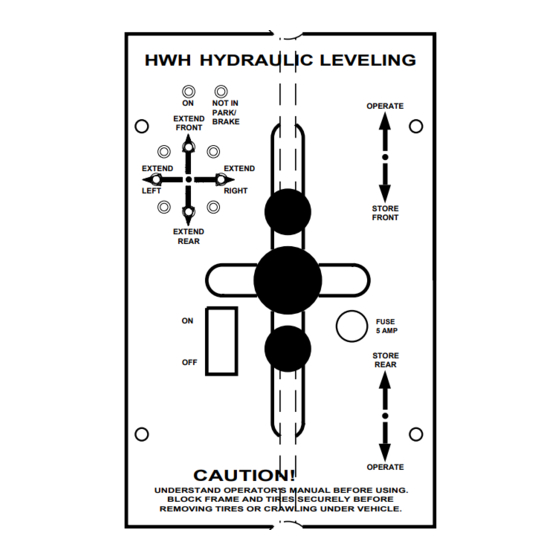

- Page 1 CORPORATION OPERATOR’S MANUAL HWH JOYSTICK-CONTROLLED 210 SERIES LEVELING SYSTEM FEATURING: Joystick BI-AXIS Control Hydraulic Leveling Kick-Down Jacks Integrated Control Console HYDRAULIC LEVELING NOT IN OPERATE PARK/ EXTEND BRAKE FRONT EXTEND EXTEND LEFT RIGHT STORE FRONT EXTEND REAR FUSE 5 AMP...

-

Page 2: How To Obtain Warranty Service

HWH CORPORATION personnel will contact you to the problem quickly. If the dealer has difficulty solving determine whether or not your claim is valid. If it is, HWH the problem, he should immediately contact the Customer CORPORATION will authorize repair or replacement of the Service Department, at HWH CORPORATION. -

Page 3: Control Identification

CONTROL IDENTIFICATION "NOT IN FRONT STORE LEVER PARK/BRAKE" LIGHT (Operate Position) HYDRAULIC LEVELING "ON" LIGHT NOT IN OPERATE PARK/ EXTEND FRONT STORE LEVER BRAKE FRONT (Store/Travel Position) WARNING LIGHTS (4 - Red) EXTEND EXTEND LEFT RIGHT STORE FRONT JACK CONTROL LEVER EXTEND REAR LEVELING LIGHTS... -

Page 4: Operating Procedures

OPERATING PROCEDURES SITE SELECTION Maintain adequate clearance in all directions for vehicle, Care must be taken not to raise the rear of the vehicle too room extensions, awnings, doors, steps, ect. Vehicle may high or the vehicle may roll forward or backward off the jacks. move in any direction due to jacks extending or retracting, If parking on soft ground or asphalt paving, wood blocks or settling of jacks or vehicle, equipment malfunction, ect. - Page 5 OPERATING PROCEDURES RETRACT PROCEDURES STORE/TRAVEL POSITION EXTEND POSITION STORE/TRAVEL POSITION FRONT HYDRAULIC LEVELING STORE NOT IN OPERATE PARK/ EXTEND BRAKE FRONT LEVER EXTEND EXTEND LEFT RIGHT JACK STORE FRONT EXTEND REAR CONTROL FUSE REAR LEVER 5 AMP STORE REAR STORE LEVER OPERATE CAUTION!

-

Page 6: Fluid Levels

All major components of the system can be replaced To eliminate this problem, periodically check the leveling jacks with rebuilt parts or can be sent to HWH CORPORATION to and break loose any ice which may be causing improper operation. -

Page 7: System Adjustment

MAINTENANCE SYSTEM ADJUSTMENT SET SCREW, LOWER UPPER HORIZONTAL ADJUSTING ADJUSTING SET SCREW ADJUSTMENT ADJUSTING ADJUSTING LOCK NUTS, HEAVY DUTY STOP STANDARD & VERTICAL LEVELING LOW PROFILE ADJUSTMENT UNITS UNITS 6,000 lb. JACKS 9,000 lb. JACKS 16,000 lb. JACKS JACK ADJUSTMENT There are two basic adjustments which are made at the time 2. - Page 8 210 JOYSTICK CONTROLLED - INTEGRATED CONTROL CONSOLE SENSING UNIT ADJUSTMENT SENSING UNIT ADJUSTMENT MUST ADJUST SIDE TO SIDE BEFORE FRONT TO REAR. CLOCKWISE = CLOCKWISE = LOWER FRONT LOWER LEFT RAISE REAR RAISE RIGHT COUNTER COUNTER CLOCKWISE = CLOCKWISE = LOWER REAR LOWER RIGHT RAISE FRONT...

-

Page 9: Troubleshooting

TROUBLE SHOOTING 210/225 SERIES BI-AXIS VALVE The following is a list of problems, and possible solutions, which might occur to the leveling system. NOTE: Only qualified technicians should install or repair leveling systems on vehicles. A knowledge of hydraulics, welding, the vehicle’s suspension and electrical system, as well as an understanding of the leveling system’s hydraulics and electronics is required. - Page 10 HYDRAULIC LINE CONNECTION DIAGRAM 210/225 BI-AXIS VALVE CLASS-C CONSOLE PRESSURE HYDRAULIC HOSE ASSY. - 228" (EXISTING HOSE MAY BE 222") RETURN (PUSH LOCK HOSE) 3/8 RETURN LINE PRESSURE RIGHT FRONT JACK RETURN LEFT FRONT JACK HYDRAULIC HYDRAULIC HOSE HOSE ASSY 102" ASSY 150"...

- Page 11 ELECTRICAL CONNECTION DIAGRAM 210 SERIES - INTEGRATED CONTROL CONSOLE HYDRAULIC LEVELING NOTE:ALL WIRING CONNECTIONS SEE PANEL NOT IN OPERATE PARK/ EXTEND BRAKE FRONT TO THE 210 VALVE ARE MADE IN CONNECTION EXTEND EXTEND LEFT RIGHT STORE FRONT THE CONSOLE. EXTEND...

-

Page 12: Electrical Connection Diagram

ELECTRICAL CONNECTION DIAGRAM 200/210/225 SERIES BI - AXIS VALVE PUMP RELAY PUMP RELAY CONNECTION DIAGRAM PUMP MUST BE MOUNTED SOLIDLY TO FRAME. SOME PUMPS HAVE A GROUND CABLE THAT IS TO BE ATTACHED TO THE GROUND STUD. NOTE: THE FOUR DIGIT WIRE NUMBER SUPERSEDES ANY AND ALL WIRE COLORS. - Page 13 ELECTRICAL CONNECTION DIAGRAM 210 SERIES PANEL CONNECTIONS SENSING UNIT CONNECTIONS FROM VALVE TO SENSING UNIT SEE DETAIL A WHITE - GROUND NO CONNECTION RED (0200) - REAR GREEN (0300) - RIGHT SIDE YELLOW (0100) - LEFT SIDE BLACK (0400) - FRONT...

- Page 14 (RED) 6120 12V ACC. TO PARK BRAKE LIGHT ON DASH NEGATIVE (BLUE) 9000 PARK BRAKE POSITIVE PARK BRAKE +12V (BLUE) 6820 (BLACK) 8600 PUMP CR1-2 WHITE RELAY VALVE SW. (BROWN) 7699 (PURPLE) 6121 LR - (GREEN) 4000 MASTER WARN LF - (ORANGE) 1000 LIGHT WARNING RF - (GRAY) 2000...

- Page 15 NOTE: DO NOT USE (PURPLE) WIRE - 6121 REMOVE (PURPLE) WIRE - 6121 6111 FROM HARNESS. NOTE: SPLICE (BROWN) WIRE - 7699 FROM HWH LIGHT PLATE TO (BROWN) - 7699 PIGTAIL WITH BUTT CONNECTOR. PIGTAIL JACKS DOWN LIGHT PROVIDED - (BROWN) 7699 INCLUDED IN HARDWARE KIT.

Need help?

Do you have a question about the 210 Series and is the answer not in the manual?

Questions and answers

were can i buy replacement parts