Advertisement

Advertisement

Table of Contents

Summary of Contents for Hawke Power Ex

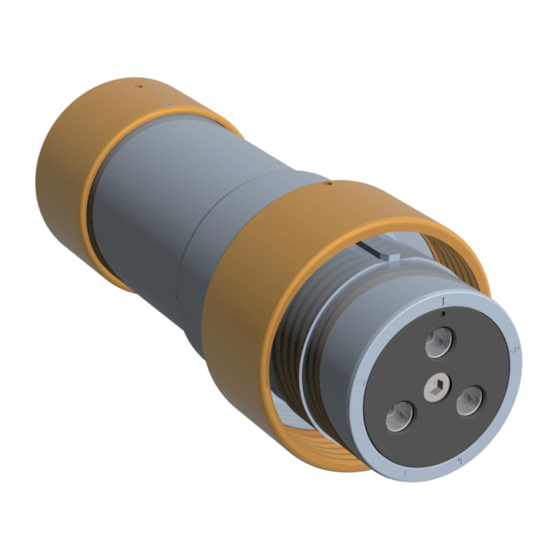

- Page 1 Power POWER CONNECTOR TERMINATION / HOOK UP PROCEDURE (AI365 Rev 5 – 01Mar16) Hawke International UK Office, Oxford Street West, Sales: +44 (0) 161 830 6698 Ashton-under-Lyne, Technical: +44 (0) 161 830 6697 Lancashire. Fax: +44 (0) 161 830 6648 OL7 0NA.

-

Page 2: Important Note

(typically to BS 6346 standards) is used in portable / semi-portable applications. In addition, Hawke recommends that barrier type glands are fitted to flexible power and loose filled control cabling entering the connectors to maintain the Exd protection concept and to reduce the potential for core movements within the cable being transferred to the connector’s internal components. - Page 3 7) Crimp the lugs or contacts onto the conductors with the lug going over the bare earth wire. (excluding internal earth wire if being used) using suitable crimp tool. (Hawke recommend Elpress crimp tools). Contact sizes of 185mm² and larger should be adjacently double crimped as shown.

- Page 4 Power Termination Procedure (AI365 Rev 5 – 01Mar16) 12) Tighten the 2 grub screws on the internal earth lug into b) CONTACT SIZES 300 – 630mm². the earth conductor as tight as possible so that the earth Push the rear retainer over the contact. Place the wire is sufficiently clamped.

-

Page 5: Hook Up Procedure

Power Termination Procedure (AI365 Rev 5 – 01Mar16) 17) Tighten down the 2 grub screws on the rear engaging 20) The connector is now ready for installation. Please refer nut. to the hook up procedure. HOOK UP PROCEDURE GRUB SCREWS Before commencing hook up, a visual inspection should be carried out on the cable / gland / connector assembly. -

Page 6: Technical Specification

5) Fully tighten the engaging nut with strap wrench if TECHNICAL SPECIFICATION necessary and then tighten the grub screw on the engaging nut. All Hawke Power connectors have a maximum working voltage of 750VAC. GRUB SCREW Other voltage ratings available on special request.

Need help?

Do you have a question about the Power Ex and is the answer not in the manual?

Questions and answers