Bentone B40 MF Installation And Maintenance Instruction

Hide thumbs

Also See for B40 MF:

- Installation and maintenance instruction (48 pages) ,

- Installation and maintenance instruction (48 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Bentone B40 MF

- Page 1 178 056 56-6 2019-01-10 Providing sustainable energy solutions worldwide Installation and Maintenance instruction B40 MF, B45-2 MF...

- Page 2 Bentone B40 MF/B45-2 MF...

-

Page 3: Table Of Contents

Air setting B45-2 MF Damper motor _________________ BURNER SERVICING ________________________________________ Servicing the combustion assembly _________________ Servicing air dampers ____________________________________ Replacement of damper motor B45-2 MF __________ Replacement of oil pump B40 MF / B45-2 MF ____ Replacement of preheaters _____________________________ Bentone B40 MF/B45-2 MF... - Page 4 • Burner pipes, fan wheels and air dampers may contain sharp edges. • The surface temperature of the burner’s components can exceed 60 °C. • Caution: The burner has moving parts, and there is risk of crushing injuries. 165 105 60 Bentone B40 MF/B45-2 MF Bentone...

- Page 5 - fi tting and installation work has been completed and approved - electrical installation has been correctly performed - fl ue gas ducts and combustion air ducts are not blocked - all actuators and control and safety devices are in working order and correctly set Bentone B40 MF/B45-2 MF...

- Page 6 • Make sure everything is delivered and the goods have not been damaged during transit. • If something is wrong with a delivery, report it to the supplier. • Transport damage must be reported to the shipping company. Bentone B40 MF/B45-2 MF...

- Page 7 General Bentone B40 MF/B45-2 MF...

-

Page 8: Technical Data

Burner tube, Burner tube, burner tube Dimension B Dimension C Dimension D Standard 1 1.1.1 Burner output 29.5 kg/h mbar mbar Used lower calorifi c value of 10.00 kWh/kg for rapeseed oil in accordance with DIN 51605:2010-10 Bentone B40 MF/B45-2 MF... -

Page 9: Dimensions B45-2

Burner tube, Burner tube, burner tube Dimension B Dimension C Dimension D Standard 1 mbar 1.2.1 Burner output 55.0 kg/h Used lower calorifi c value of 10.00 kWh/kg for rapeseed oil in accordance with DIN 51605:2010-10 Bentone B40 MF/B45-2 MF... -

Page 10: Dimensions, Flange

45° Solid/semi-solid The burner pump is factory set at 24 bar and 60° Solid/semi-solid test operated using Roadway 80. 80° Solid/semi-solid Pump pressure 28 bar (24-28 bar) 24 bar (20-28 bar) high viscosity oils low viscosity oils Bentone B40 MF/B45-2 MF... -

Page 11: Oil Grades

This procedure ensures a good start after standstill. Altered structure of the oil can give rise to altered viscosity, pumpabilty and ignita- bility. This can cause the pump, valves and nozzles to get blocked Bentone B40 MF/B45-2 MF... -

Page 12: Nozzle For Bio Oils, 20-28 Bar

61,1 11,00 54,1 56,7 59,3 61,7 64,0 11,50 56,5 59,3 61,9 64,5 66,9 12,00 59,0 61,9 64,6 67,3 69,8 Rapeseed oil compliant with DIN 51605:2010-10 Viscosity: 36.0 mm / s, at 40 °C preheater 160 °C Bentone B40 MF/B45-2 MF... -

Page 13: Nozzle For Fossil Oils, 22-28 Bar

11,00 63,04 747,63 65,84 780,87 68,53 812,76 71,12 843,44 12,00 70,75 839,1 73,9 876,41 76,91 912,2 79,82 946,63 The table applies to oil with a viscosity of 4.4 mm /s at a density of 830 kg/m Bentone B40 MF/B45-2 MF... -

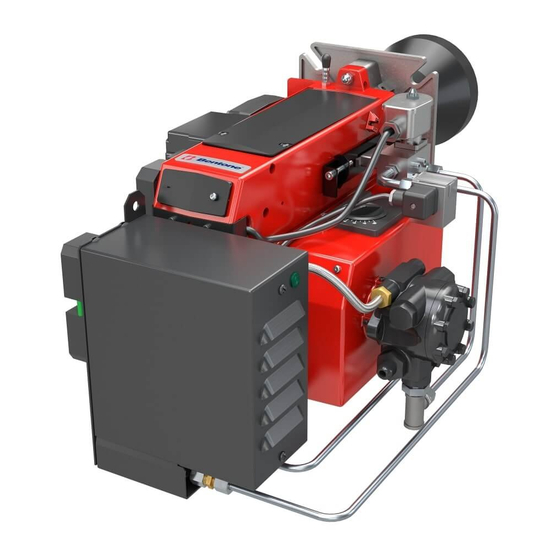

Page 14: Description B40 Mf

Fan housing Pressure control pump Nozzle assembly control Inlet pump Scale, nozzle assembly control Nozzle assembly Solenoid valve NO Brake plate Valve block Nozzle Burner tube Cavity immersion heater nozzle holder Cavity immersion heater valve block Preheater Bentone B40 MF/B45-2 MF... - Page 15 5-pole Euro plug (feed preheater) Damper motor 4-pole Euro plug (control signal preheater) Connecting pipe, preheater valve block Capacitor Connecting pipe, pump preheater Motor Ignition electrodes Air intake Spring pressure piston Ignition transformer Preheater Air damper Valve seat Bentone B40 MF/B45-2 MF...

-

Page 16: Description B45-2 Mf

Measuring nipple, fan pressure Pressure piston max. load Valve block Valve seat Burner tube Front nozzle holder Burner fl ange Pressure piston min. load Pressure outlet pump Air intake Pump Brake plate Return pump Nozzle Pressure control pump Preheater Bentone B40 MF/B45-2 MF... - Page 17 7-pole Euro plug (min. load feed) Ignition transformer Air damper Fan wheel Air intake Connecting pipe, valve block return Capacitor Connecting pipe, preheater valve block Motor Connecting pipe, pump preheater Fan housing Damper motor Switch 0-I Indicator, min. load Switch I-II Bentone B40 MF/B45-2 MF...

-

Page 18: Installation

The vacuum should not fall below 0 bar in the suction line during start-up. 2.3.1 Proposed pipe routing for oil distribution systems without transport pump This type of connection should be used only when the oil has a viscosity less than 30 mm²/s Self-cleaning fi lter Bentone B40 MF/B45-2 MF... -

Page 19: Electrical Connection

Make sure the burner operations switch (S1) is off. Turn on the main switch. If any electrical connection is used other than that recommended by Bentone, there may be a danger of damage to property and personal injury. Bentone B40 MF/B45-2 MF... -

Page 20: Nozzle Selection

Burner installation 2.7.1 Hole pattern Make sure the hole pattern on the boiler is designed for burner flange. Combustion device B40 MF ø 115-175 M10-M12 ø 195-245 B45-2 MF ø 135-(175) 200 M10-M12 ø (195) 224-260 Bentone B40 MF/B45-2 MF... -

Page 21: Burner Installation

Insulate between the burner and boiler door to reduce radiated heat. • Fit the burner body on the fl ange, B40 MF • Slide the burner body on the guides, B45-2 MF Lock the burner body using with the nut/nuts. -

Page 22: Function Description

For installers 3. FUNCTION DESCRIPTION B40 MF 1-stage burner When the installation calls for heat, the burner's preheater starts to heat the oil. Once the oil reaches the set temperature, the burner receives the signal to start. Hot oil is flushed throughout the burner's oil system. -

Page 23: B45-2 Mf 2-Stage Burner

This process extinguishes the burner fl ame. In the same process, oil heating is also interrupted. Oil pump Preheater Nozzle assembly Leak pipe Nozzle 1 Nozzle 2 Solenoid valve 1 NO Solenoid valve 2 NC Cut valve 1 Cut valve 2 Bentone B40 MF/B45-2 MF... -

Page 24: Basic Settings

The setting value for 200 kW in accordance with basic setting tables. For the correct procedure when implementing settings, see 4.7 Nozzle assembly control, brake plate B40 MF and 4.8 Air setting B40 MF (See technical data ) Effects and nozzle selection from example... -

Page 25: Examples Of Basic Setting B45-2 Mf

Once the burner has started and established a flame, it will be necessary to adjust the settings so that they are adapted to the installation in question and the fuel used at the time. Bentone B40 MF/B45-2 MF... -

Page 26: Setting Values For Nozzle Assembly B40 Mf

For installers Setting values for nozzle assembly B40 MF Setting values for air damper B40 MF Setting values for nozzle assembly B45-2 MF Setting values for air damper B45-2 MF Bentone B40 MF/B45-2 MF... -

Page 27: Nozzle Assembly Control, Brake Plate

The nozzle assembly control is used to achieve the most favourable pressure drop across the brake plate as possible in the various power stages. 1 nozzle (B40 MF) The nozzle assembly control is manually adjusted (B) in order to achieve optimal pressure loss for good combustion. -

Page 28: Air Setting B45-2 Mf Damper Motor

Once the red or orange cam has been moved, check whether the black cam must be changed. The black cam must be between the orange and red cam. Return the operations switch to Stage 1 and check combustion. Bentone B40 MF/B45-2 MF... - Page 29 Slide the white release button inwards and release. Changing the position of the motor until the gears engage with each other. Solenoid valve Stage 2 (black) Stage 2 (red) Stage 1 (orange) Closed damper (blue) Releasing buttonN.B. The upperposition is thestandard position Bentone B40 MF/B45-2 MF...

-

Page 30: Burner Servicing

Fit the Euro plugs and turn on the main current. Check combustion *. NB: When soiled, always replace nozzles with new nozzles. Do not clean. Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. Bentone B40 MF/B45-2 MF... -

Page 31: Servicing Air Dampers

For installers Servicing air dampers Removal and installation, B40 MF Break the main current and disconnect the Euro plugs from the burner. Loosen the nut (G) and remove the burner from the burner fl ange. Note the position of the air damper and loosen the air damper locking screw. -

Page 32: Replacement Of Damper Motor B45-2 Mf

Set the damper motor notches as on the motor that has been replaced. Fit the Euro plugs and turn on the main current. Check combustion. * Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. Bentone B40 MF/B45-2 MF... -

Page 33: Replacement Of Oil Pump B40 Mf / B45-2 Mf

For installers Replacement of oil pump B40 MF / B45-2 MF Removal and installation Break the main current and disconnect the Euro plugs from the burner. Undo the oil hoses from the pump. Remove the immersion heater from the pump. -

Page 34: Replacement Of Preheaters

Use caution when operating the burner, surfaces may be hot. When servicing oil bearing components, check the oil density when the burner is commissioned after servicing. Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. Bentone B40 MF/B45-2 MF... -

Page 35: Replacement Of Electrical Components

Fit the preheater hood using the screws (S). Fit the Euro plugs and turn on the main current. Start the burner. Check combustion. * Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. Bentone B40 MF/B45-2 MF... -

Page 36: Check Oil Line Seals

Start the burner. Check combustion. * Pressure piston (V) and O-ring (Z) should be replaced at least every 10 year. Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. Bentone B40 MF/B45-2 MF... -

Page 37: Replacement Of Pressure Piston And Seat

• Fit the burner and the burner fl ange together and secure with the nut (G). Fit the Euro plugs and turn on the main current, B40 MF. • Press the burner together and lock using the nuts (H). Fit the Euro plugs and turn on the main current, B45-2 MF. -

Page 38: Immersion Heaters For Extra Preheating

B45-2 MF Route the cable in the same track as the immersion heater to the pump Plug the immersion heater electrically, see wiring diagram see B40 MF or B45-2 MF Fit the Euro plugs and turn on the main current. - Page 39 Install the immersion heater in its intended hole (B) on the nozzle holder. Lock the immersion heater in the hole using the supplied nipple Plug the immersion heater electrically, see wiring diagram see B40 MF and B45-2 MF Route the cable through the new hole specifi cally intended for the purpose and on into the connection point.

-

Page 40: Replacement Of Pump Filter

Cleaning is done by turning a knob on the fi lter that scrapes the surface of the fi lter. Where a self-cleaning fi lter is installed, the reliability of the burner may be increased without having to perform a complete service of the fi lter. Bentone B40 MF/B45-2 MF... -

Page 41: Preheater

If the burner stops during operation because the temperature in the preheater is too low, preheater function should be checked. Check, for example, safety thermostats, power to the immersion heater(s), function immersion heater(s), etc. Bentone B40 MF/B45-2 MF... -

Page 42: Adjustment Of Preheater Operating Thermostat

When using a new oil grade, check combustion and adjust the burner settings in order to achieve good combustion. Bentone B40 MF/B45-2 MF... -

Page 43: Pump Instruction Pump E4Nc-1069 7P

Change the oil pump oil fi lter in accordance with the following. Close the oil valves Unscrew the cover on the pump. Replace the oil fi lter. Replace head gasket. Mount the cover on the pump. Open the oil valves. Bentone B40 MF/B45-2 MF... -

Page 44: Function

Oil under pressure 1. Gear set By passed oil returned to tank, or to suction 2. By-pass hole 6. Pressure adj u stment 7. To nozzle 3. Pressure gauge port 4. By-pass plug installed 8. Return Bentone B40 MF/B45-2 MF... -

Page 45: Return Oil Pressure Switch

The pressure switch may be set to max. 3.5 bar, which is the highest pressure for which the oil pump is designed at the return side. Setting a higher pressure will damage the gaskets in the pump. Reset button Press switch setting Bentone B40 MF/B45-2 MF... -

Page 46: Electrical Equipment

For installers 8. ELECTRICAL EQUIPMENT B40 MF wiring diagram LMO24.255 ... Bentone B40 MF/B45-2 MF... -

Page 47: B45-2 Mf Wiring Diagram Lmo24.255

For installers B45-2 MF wiring diagram LMO24.255... Bentone B40 MF/B45-2 MF... -

Page 48: Component List Lmo24.255

If burner operation is interrupted by the main switch or thermostat, a new start will take place once conditions as specified in paragraph 1 are met. The machine blocks Red light in the machine is on. The burner is restarted by pressing the reset button. Bentone B40 MF/B45-2 MF... -

Page 49: Technical Data Lmo24.255

Max. output at dark, start: 5.5 μ A Enclosure type IP 40 Safety time 5 sec Check of photo current Photo current is measured using a DC ampmeter (torsion coil instrument) connected in series with the photocell. Bentone B40 MF/B45-2 MF... -

Page 50: Colour Codes

If the reset button is instead kept pressed a second time for at least 3 seconds, you can, via an interface, obtain the corresponding information on a computer or flue gas analyser. To return to normal operation: Press the reset button for 1 second Bentone B40 MF/B45-2 MF... -

Page 51: Fault Location

Check preheater function New oil type Adjust the preheater's set operating tem- perature Ensure that the new oil's physical parame- ters are within the limits for which the burner is designed. If not, change the oil. Bentone B40 MF/B45-2 MF... -

Page 52: Delayed Ignition

Pump worn Replace the pump Pump run using impure oil that has worn the Replace pump and install self-cleaning pump out prematurely filter in the oil system Blocked pump filter Check, clean pump filter Bentone B40 MF/B45-2 MF... -

Page 53: Declaration Of Confirmity

10. DECLARATION OF CONFIRMITY... - Page 54 OIL BURNERS MAINTENANCE INSTRUCTIONS General information If the burner starts but does not ignite Keep the boiler room clean. Ensure that the boiler Make an attempt to start the burner. room has permanent fresh air intake. Switch off before Never make close repeated start attempts. dismantling the oil burner.

- Page 56 Enertech AB. P.O Box 309, SE-341 26 Ljungby. www.bentone.se, www.bentone.com...

Need help?

Do you have a question about the B40 MF and is the answer not in the manual?

Questions and answers