Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for LELY HIBISCUS 485 P

- Page 1 O P E R A T O R ’ S M A N U A L HIBISCUS 485 P B-HV.022. 0306 www.lely.com...

- Page 3 ® HIBISCUS is a registered trademark. The right of exclusive use belongs to the companies of the LELY Group. ©2006. All rights reserved. Nothing of this publication may be reproduced and/or published by printing, photocopying, microfilm or any other way without the prior written permission of LELY INDUSTRIES N.V.

-

Page 5: Table Of Contents

CONTENTS ........................page PREFACE ........................5 WARRANTY CONDITIONS....................5 TYPE- AND SERIAL NUMBER OF YOUR MACHINE ...........5 SAFETY INSTRUCTIONS ....................6 EXPLANATION OF SAFETY DECALS ON THE MACHINE ..........7 1 INTRODUCTION ......................8 2 LINKAGE TO THE TRACTOR..................8 3 TRANSPORT........................9 4 MACHINE ADJUSTMENTS...................10 Swath width ......................10 Working height.....................10 Cam track adjustment..................11 5 OPERATING THE HIBISCUS®... -

Page 7: Preface

PREFACE This Operator’s Manual is meant for personnel that are operating the machine and are responsible for its daily maintenance. Kindly read this manual fully prior to starting work. Such instructions as are related to your safety and/or that of others are marked in the margin by a warning triangle with exclamation mark. -

Page 8: Safety Instructions

- Use flashing lights or other safety signs, when required. - Don’t stand on the machine. - Use genuine LELY parts only. - Remove the pressure from hydraulic systems before starting work on them and/or before coupling/ uncoupling hydraulic hoses. -

Page 9: Explanation Of Safety Decals On The Machine

EXPLANATION OF SAFETY DECALS ON THE MACHINE - Carefully read operator’s manual before handling the machine. Observe instructions and safety rules when operating. - Danger of parts dropping down. Keep away from the parts movement areas. - Danger of getting jammed by moving parts. Keep out of reach of all parts as long as they have not yet been blocked, or are otherwise prevented from moving. -

Page 10: Introduction

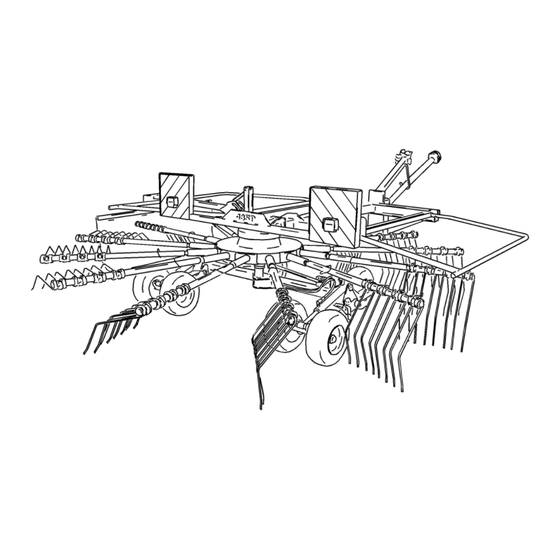

1 INTRODUCTION The LELY HIBISCUS 485 P (fig. 1) is a pull type, single cam rake for side delivery. The machine has 1 rotor with 13 tine arms, each equipped with 4 double tines. The tines give a clean sweep and move the grass to left hand side in an airy windrow. -

Page 11: Transport

3 TRANSPORT After the machine has been adjusted to the transport position, it can be transported by the tractor. Transport width amounts to 2.35 m. Put the machine into the transport position as follows: - Slide the swath curtain inwards and lock it by means of the locking pin. -

Page 12: Machine Adjustments

4 MACHINE ADJUSTMENTS Put the machine into the working position as follows: - Unblock the effect of the rams by opening the ram valves. - Slide the tine arms onto the rotor (fig. 6). - Pull out the locking bar and fold down the protection guard. Then slide the bar back into the locked position and check that it is properly secured. -

Page 13: Cam Track Adjustment

Cam track adjustment Rising and descending of the tines that are fitted on the tine arms is ensured by the cam track. By adjusting this system, rise and descent moments can be changed. Correct adjustment depends upon crop/terrain conditions and forward speed. - Page 14 By using only part of the full working width, smaller night swaths can be made (fig. 12). If fuller windrows are required, double swaths (fig. 13) or multiple swaths (fig. 14) can be made. E-12...

-

Page 15: Forward Speed And Pto Speed

If some crop is left in the middle behind the machine (fig. 15), the draw bar ramshould be shortened until the crop material is taken up effectively. In case the crop is not effectively taken up on the sides (fig. 16), the draw bar ram has to be extended whilst -if need be- the height adjustment or cam track should be corrected. -

Page 16: Dismounting From The Tractor

6 DISMOUNTING FROM THE TRACTOR The machine can be dismounted from the tractor both in the working and in the transport position. Always place the machine on hard, even ground. - Switch off the tractor engine. - Block the effect of the rams by closing the ram valves (fig. 17). - Fit the parking jack to the draw bar. -

Page 17: Maintenance

7 MAINTENANCE • Correct machine servicing is necessary with a view to reliable and safe working. Maintenance after operations - Clean the machine thoroughly. - Check the tines and tine arms for tightness and damages, if any. - Grease the machine with a rust preventive. Pay special attention to the tines. -

Page 18: Intermittent Maintenance

- Pivot points (A, fig. 21) of the tandem wheels to be greased every 40 working hours. - Grease the pivoting points of the rams of the wheel assembly every 40 working hours (B, fig. 21). - Grease the cam track inside the rotor with a high grade grease (Molykote BR2 Plus) every 1,000 hectares or once every year. -

Page 19: Ahydraulic Scheme

Supplement A - Convince yourself of the presence and undamaged condition of all safety decals on the machine (fig. 23). D C A (P/N 9.1170.0408.0) (P/N 9.1170.0420.5) -2x- (P/N 9.1170.0689.1) -2x- (P/N 9.1170.0125.4) (P/N 16.61.175) HYDRAULIC SCHEME Legend: Single acting ram 4 Double acting ram Breather 5 Throttle... -

Page 20: Boptional Extras

Tyres A choice of 2 tyre specs can be made for the HIBISCUS 485 P cam rake: 16/6.5-8 or 18.5/8.5-8. This choice makes it possible to adjust your machine tyre size to the prevailing ground conditions. -

Page 21: Ctechnical Details

Supplement C TECHNICAL DETAILS ® 485 P HIBISCUS Working width 3.85 - 4.75 m Transport width 2.35 m Transport height 2.65 m Transport length 4.60 / 5.55 m Diameter of rotor 3.80 m (incl. tine arms) Number of tine arms Number of tines / tine arm 4 double tines Swath width... - Page 22 www.lely.com...

Need help?

Do you have a question about the HIBISCUS 485 P and is the answer not in the manual?

Questions and answers