Summary of Contents for Doosan DE08TS

- Page 1 SB4097E02 Sep. 2011 DE 08 TS Diesel Engine Specification System Operation Testing & Adjusting D100, D120, D150 D110S-5, D130S-5, D160S-5...

- Page 3 If a tool, procedure, work method or operating technique not specifically recommended by DOOSAN is used, you must satisfy yourself that it is safe for you and others. You should also ensure that the product will not be damaged or made unsafe by the operation, lubrication, maintenance or repair procedures you choose.

-

Page 5: Table Of Contents

Engine Specifications ..........6 Oil pan ............32 Specifications............6 Vibration damper..........33 Remove & Install Forks ........7 Timing gear case cover ........33 Performance curve(DE08TS-140PS) ....8 Oil pump ............33 Performance curve(DE08TS-160PS) ....9 Piston and connecting rod ......33 Cylinder liner...........34 Engine Assembly............10 Camshaft gear and idle gear ......34 Engine sectionnal view(longitudinal)....10... - Page 6 Fuel feed pump..........80 Injection nozzle ..........84 Diagnostics and troubleshooting.....86 Turbocharger ............88 Main data and Specifications......88 General descriptions........89 Functions ............90 Precaution for operation .........91 Walk-around check and servicing....92 Periodical checking and servicing ....93 Diagnostics and troubleshooting.....95 Special Tool List DE08TS Diesel Engines Index...

-

Page 7: General Information

Due to the application of OMEGA combustion system nuts torques. and optimal utilization of intake and exhaust port configuration within the cylinder head, the DE08TS 12. When service operation is completed, make a diesel engines discharge very low level of hazardous... -

Page 8: Engine Specifications

16 / 13 Oil cooler type Water cooled Water pump Centrifugal type driven by belt Cooling Method Fresh water forced circulation Cooling water capacity (engine only) (lit) Thermostat type Wax pallet type (71 ~ 85°C) DE08TS Diesel Engines General Information... -

Page 9: Remove & Install Forks

(kg.m / rpm) (rpm) (rpm) (BTDC°) ECDFA 140 / 2,200 55 / 1,400 2,370 TIER-II DE08TS & STAGE-II ECDFB 160/2,200 63/1,400 2,370 * Note : All data are based on operation without cooling fan at KS-R1004. DE08TS Diesel Engines General Information... -

Page 10: Performance Curve(De08Ts-140Ps)

Performance curve (DE08TS - 140PS) 1000 1400 1800 2200 REVOLUTION (rpm) Standard KS-R1004 Rated Power 140 ps / 2,200 rpm Max Torque 55 kg.m / 1,400 rpm Fuel consumption 180 g / PS.h DE08TS Diesel Engines General Information... -

Page 11: Performance Curve(De08Ts-160Ps)

Performance curve (DE08TS - 160PS) 1000 1400 1800 2200 REVOLUTION (rpm) Standard KS-R1004 Rated Power 160 ps / 2,200 rpm Max Torque 63 kg.m / 1,400 rpm Fuel consumption 180 g / PS.h DE08TS Diesel Engines General Information... -

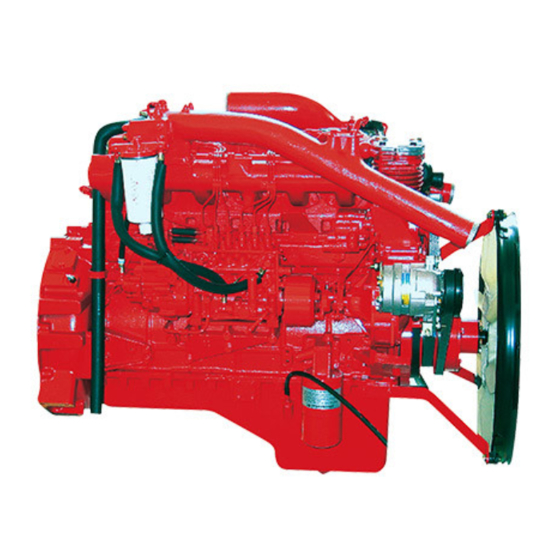

Page 12: Engine Assembly

6. Breather 15. Tappet 24. Oil suction pipe 7. Cylinder head cover 16. Cam shaft 25. Oil pan 8. Exhaust valve spring 17. Fly wheel 26. Crank shaft 9. Cylinder head 18. Oil seal (Rear) DE08TS Diesel Engines General Information... -

Page 13: Engine Sectionnal View(Cross)

3. Fuel injection nozzle 11. Timing gear case 4. Intake manifold 13. Connecting rod 5. Air heater 14. Oil spray nozzle 6. Rocker arm 15. Oil filter 7. Rocker arm bracket 16. Oil cooler 8. Exhaust manifold DE08TS Diesel Engines General Information... -

Page 14: Engine Assembly View

19. Crank shaft pulley (Air cleaner to intake manifold) 12. Oil filter 20. Vibration damper 5. Fuel filter 13. Fuel injection pump 21. Oil cooler 7. Air compressor (if equipped) 14. Air compressor pulley 22. Starter 15. Thermostat DE08TS Diesel Engines General Information... -

Page 15: Major Maintenance

4. Since DE08TS (diesel engine of D1146 series) cylinder liner is dry type, particularly the cooling 7. Amount of Anti-freeze in winter water control should be applied thoroughly.by the... -

Page 16: Fan Belt

First oil change : 50 hr operating b. Every oil chang : 250hr operating 4. The following oils are also recommended. Recommend oil Engine model SAE No. API No. SAE15W40 ACEA-E2 or ACEA-E3 DE08TS SAE10W40 (API CH-4) DE08TS Diesel Engines Major Maintenance... -

Page 17: Oil Filter

3. As for the valve clearance, adjust it when in cold, as follows. Model Intake Valve Exhaust Valve DE08TS 0.3 mm 0.3 mm DE08TS Diesel Engines Major Maintenance... -

Page 18: Cylinder Compression Pressure

“ “ of lower figure. e. After reinsuring the valve clearances, retighten if necessary. Cylinder compression pressure 1. Stop the engine after warming up, and take out noz- zle holder assembly. EFM1005I EFM1004I DE08TS Diesel Engines Major Maintenance... -

Page 19: Injection Nozzle

Fuel supply pump Every time of engine oil replacement, the fuel strain- er installed at the fuel supply pump should be removed and cleaned. DE08TS Diesel Engines Major Maintenance... -

Page 20: Diagnosis And Remedy

Air mixture in fuel Normal Inspect supply pump valve strainer Injection pump Retighten connection Clean Normal dasassembly parts. Replace gasket Replace Inspect fuel filter Air removal Element polluted Continuous air mixing Overflow valve poor Supply pump Replace disassembly DE08TS Diesel Engines Major Maintenance... - Page 21 Retighten Normal Normal Abnormal disassembly Replace Check thermostat Replace Adjust Repair repair Normal Replace injection pump Repair Inspect radiator Damage Replace Check cooling Repair Normal water pump Replace Clean cooling Normal water passage Engine disassembly DE08TS Diesel Engines Major Maintenance...

- Page 22 Inspect injection nozzle injection pressure, Replace Normal atomizing state Normal Adjust Replace Engine disassembly (valve assembly) Check injection timing Normal Adjustment Disassemble engine or Check turbocharger injection pump Repair Normal Replace Disassemble injection pump or engine DE08TS Diesel Engines Major Maintenance...

- Page 23 Too high Normal Refer to engine overheat Inspect oil quality Normal Check oil relief Water & fuel mixed Improper valve in oil Replace with Disassemble engine Retighten recommended oil Normal or injection pump Replace Disassemble engine DE08TS Diesel Engines Major Maintenance...

- Page 24 Check injection timing Adjust Normal Repair Replace Check valve Inspect compressed cylinder liner, clearance pressure piston ring, piston Normal Disassemble Adjust injection pump Normal Inspect head gasket Replace Normal Disassemble engine (valve assembly, piston, cylinder liner etc.) DE08TS Diesel Engines Major Maintenance...

- Page 25 Confirm Unconfirmed Inspect compressed Disassemble pressure engine Too low Normal Check valve clearance and Inspect injection cylinder head gasket for damage pump Normal Adjust Replace Normal Adjust Check fuel quality Disassemble engine Use specified fuel DE08TS Diesel Engines Major Maintenance...

- Page 26 Repair Replace Normal Battery self Battery over Battery room Electrolytic charging discharge damage liquid's standard Inspect generator Charging Replace Voltage regulator Replenish Abnormal Normal Adjust Check charged stated Replace Discharging Disassemble generator Voltage regulator DE08TS Diesel Engines Major Maintenance...

- Page 27 Fan belt loosened, worn, damaged Adjust or replace • Cooling water pump’s function Repair or replace lowered • Water temp. regulator’s operation Replace poor • Valve clearance incorrect Adjust • Exhaust system’s resistance Clean or replace increased DE08TS Diesel Engines Major Maintenance...

- Page 28 Wear of valve stem seal Replace seal • Cylinder head gasket’s leak Replace gasket • (3) Oil leak Looseness of connection parts Replace gasket, repair • Various parts’ packing poor Replace packing • Oil seal poor Replace oil seal DE08TS Diesel Engines Major Maintenance...

-

Page 29: Maintenance

1. Remove the oil drain plug of oil pan and pour the engine oil into the prepared vessel. 1. Loosen the rubber hose connected to the cooling water pipe and remove the thermostat. 2. Remove the rubber hose of the by-pass line. DE08TS Diesel Engines Maintenance... -

Page 30: Starter

(If the fuel filter is of cartridge type, disassemble the cartridge element only.) 1. Loosen the cooling water pump and the rubber hose clamps of connected pipes, and disassemble 2. Remove the oil cooler fixing bolts and take off the oil cooler. DE08TS Diesel Engines Maintenance... -

Page 31: Oil Filter

1. Remove the oil pipe between cylinder block and cooler. air compressor. 2. Unscrew the water pump fixing bolts from the 2. Unscrew the air compressor fixing bolts and take cylinder block and take off the water pump. off the air compressor. DE08TS Diesel Engines Maintenance... -

Page 32: Cylinder Head Cover

2. Then disassemble the exhaust manifold and gas- WARNING ket. 3. Scrap the used gasket. Take care not to damage the nozzle at disassem- bly. 3. Take out the seal ring from the nozzle hole of the cylinder head and discard it. DE08TS Diesel Engines Maintenance... -

Page 33: Intake Manifold

When reassembling the bush, cool the bush in dry ice and press the bush while aligning the WARNING bush with the oil hole of the rocker arm. Be sure that piece of the gasket do not come into the cooling water passage. DE08TS Diesel Engines Maintenance... -

Page 34: Cylinder Head

Oil pan WARNING Try not to make any damage on the contact sur- faces. EAMD034I 1. Unscrew the oil pan fixing bolts and remove the oil pan. 2. Remove the oil pan gasket and discard it. DE08TS Diesel Engines Maintenance... -

Page 35: Vibration Damper

4. The disassembled piston assembly should be han- dled to prevent bumping each other, and stored as the cylinder’s order. 5. In order for connecting rod cap not to be swapped, temporarily assemble to the corresponding con- necting rod. DE08TS Diesel Engines Maintenance... -

Page 36: Cylinder Liner

1. Unscrew the camshaft gear fixing bolts and remove the camshaft gear. 3. Remove the piston ring with a plier. 2. Unscrew the camshaft gear fixing bolts and remove the camshaft gear. DE08TS Diesel Engines Maintenance... -

Page 37: Fuel Injection Pump

Injection pump drive gear Water chamber cover 1. Unscrew the fixing bolts and remove the water chamber cover. 2. Remove the remnant gasket thoroughly. EA9M3021 1. Unscrew the drive gear housing fixing bolts and remove the drive gear assembly. DE08TS Diesel Engines Maintenance... -

Page 38: Timing Gear Case

3. In order for the disassembled crankshaft to be pre- vented from bends or damage, put it on the spe- cial lathe and store. 4. Disassemble the metal bearings in turn and store them. DE08TS Diesel Engines Maintenance... -

Page 39: Inspection And Measurement On Major Parts

Disassemble the cotter pin, spring, spring seat pushing valve spring by a special tool. c. Pull out the intake and exhaust valves. d. The disassembled parts are kept laid in turn. e. Disassemble the valve stem seal. DE08TS Diesel Engines Maintenance... - Page 40 3. Inspection of valve and valve guide Intake valve 2.7 mm 1 mm or less a. Valve Exhaust valve 2.2 mm 1 mm or less After cleaning valve with fuel, check it. End of stem EFM2036I DE08TS Diesel Engines Maintenance...

- Page 41 • Assemble the valve at the valve seat of the cylinder head, and check the amount of depression of the valve from the lower portion of the cylinder head using a dial gauge. DE08TS Diesel Engines Maintenance...

- Page 42 • Assemble the valve by inserting the valve cotter pressing the valve spring with a special tool. • After installing the valve, check whether the valve is correctly installed or not tapping it lightly with ure- thane hammer. DE08TS Diesel Engines Maintenance...

-

Page 43: Rocker Arm Assembly

If the clearance exceeds the limit, replace either bushing or shaft, whichever worn more. Standard Limit 0.020 ~ 0.093 mm 0.3 mm or less DE08TS Diesel Engines Maintenance... -

Page 44: Camshaft

• Push the thrust plate toward the cam gear • With a feeler gauge, measure the clearance between the thrust plate and camshaft journal. • If the end play is excessive, replace the thrust plate. Standard Limit 0.28~ 0.43 mm 0.6 mm DE08TS Diesel Engines Maintenance... -

Page 45: Crankshaft

• By means of magnetic particle test and color check, check the crankshaft for any crack and if found, replace it. EA0M4063 a. With an outside micrometer, measure the camshaft journal diameter. b. Measure the inside diameter of the camshaft DE08TS Diesel Engines Maintenance... - Page 46 N 70.971 ~ N 70.990 N 70.000 mm WARNING In case of regrinding, the grinding the “R” part of bearing end should be correctly done and keep in mind to remove any jaws or coarse surface absolutely. DE08TS Diesel Engines Maintenance...

- Page 47 • Assemble the crankshaft on the cylinder block and the oil clearance. put plastic gauge on the journal and pin of crank- DE08TS Diesel Engines Maintenance...

- Page 48 • Crankshaft bearing crush • Assemble the crankshaft to the cylinder block. • With a dial gauge, measure crankshaft end play. Standard Limit 0.15 ~ 0.325 mm 0.5 mm EAMD063I Install the bearing and cap in the cylinder block, DE08TS Diesel Engines Maintenance...

- Page 49 BDC) in a direction at an angle of 45°. Take the mean value with the largest and small- est values excepted. Standard Limit 111 ~ 111.022 mm 111.122 mm DE08TS Diesel Engines Maintenance...

- Page 50 If the connecting rod is found distorted, never re-use it but replace with a new one. EA0M4031 Measure the amount of wear on the piston pin at the DE08TS Diesel Engines Maintenance...

-

Page 51: Fuel Injection Nozzle Projection

If the measured values are fixing bolts using the spray nozzle jig. beyond the limit, replace the seal ring. Torque 7 kg • Standard 3.5 L 0.1 mm (Thickness of seal ring) 2.43 ~ 2.80 mm (Projection of nozzle) DE08TS Diesel Engines Maintenance... -

Page 52: Tappet And Cam Shaft

2. Heat the crankshaft gear for at least 10 minutes to 120°C, then apply sealant (Loctite # 641) to the inside wall of the heated crankshaft gear evenly before inserting it to the end of crankshaft. 4. Check to see that the camshaft rotates smoothly. DE08TS Diesel Engines Maintenance... - Page 53 • Tighten the bearing cap in the sequence of 4-3-5-2- 6-1-7. EAMD077I • Check to see that the assembled crankshaft turns 5. Install the bearing and thrust washers to the bear- smoothly with hand. ing cap and apply oil to the bearing and thrust washers. DE08TS Diesel Engines Maintenance...

-

Page 54: Flywheel Housing

Do not allow the temperature of the ring gear to exceed 200 °C (390 °F). 2. By means of mandrel, assemble pilot bearing to the flywheel. 3. By means of mandrel, press in the wear ring at the backward face. DE08TS Diesel Engines Maintenance... -

Page 55: Magnetic Pick-Up Sensor

3. After the cleaning operation, make the cylinder liner M16 x 1.5 dried up and push it into the cylinder block by hand. 4. Wet the liner inside diameter with engine oil. EPM2030I DE08TS Diesel Engines Maintenance... -

Page 56: Piston And Connecting Rod

9. Install the bearing by aligning it with the connecting tion with the narrow margin of the combustion rod key groove and apply oil to the bearing and pis- chamber. ton. DE08TS Diesel Engines Maintenance... -

Page 57: Timing Gear Case

(Particularly around dowel pin). 3. Tighten the bolts for assembling to the specified torque. However, in case of tightening the bolts, tighten pri- marily the bolts of both end parts and then do the rest. DE08TS Diesel Engines Maintenance... -

Page 58: Timing Gear And Idle Gear Pin

4. After adjusting the injection timing of fuel injection pump drive gear, tighten the fixing bolts in the Mark "2" direction of fuel injection pump. Fuel injection Camshaft gear pump drive gear Idle gear Mark "1" Crank shaft Mark "0" gear EA9M3015 DE08TS Diesel Engines Maintenance... -

Page 59: Fuel Injection Pump

After turning slowly the coupling of injection pump until the fuel will drop from #1 plunger at the rate of a drop for 6 ~ 8 sec., tighten the dri- ving gear fixing bolt of fuel pump. DE08TS Diesel Engines Maintenance... -

Page 60: Oil Pump And Oil Pipe

4. Tighten the fixing bolts beginning with the oil pan 4. Connect a water pipe to the expansion tank. fitting face. WARNING In the assembling, be careful not to be damaged by the crankshaft. DE08TS Diesel Engines Maintenance... -

Page 61: Vibration Damper

Torque 2.2 kg • Be careful for the gasket pieces not fall into the engine during the work. 2. Apply engine oil to the oil filter cartridge o-ring and assemble the cartridge using a filter wrench. DE08TS Diesel Engines Maintenance... -

Page 62: Oil Cooler

4. Tap the valve stem lightly with a rubber hammer to check that the valve is assembled correctly. 1. Assemble the starter in position on the flywheel housing. Torque 8.0 kg • DE08TS Diesel Engines Maintenance... -

Page 63: Cylinder Head

If the dowel pin is not in alignment, lift the above steps. cylinder head again and then remount it. 7. Coat the push rod with engine oil and insert it into the push rod hole. DE08TS Diesel Engines Maintenance... -

Page 64: Rocker Arm Assembly

3. Install the spring, rocker arm, bracket, rocker arm, spring, washer, and snap ring in the described sequence. 4. Install the rocker arm and bracket in the same direction. 5. Adjust the valve clearance as following guide. DE08TS Diesel Engines Maintenance... - Page 65 Turn it to the direction of engine rotation, but do not use the installing bolts at the turn. c. The cylinder no. and the order of intake and exhaust can be determined from the crank shaft pulley. DE08TS Diesel Engines Maintenance...

-

Page 66: Intake Manifold

3. Assemble them by tightening the assembling bolts. The tightening order of bolts is from the mid- dle to left and right alternately. WARNING For upper and lower bolts differ in the length, so use the correct bolts. DE08TS Diesel Engines Maintenance... -

Page 67: Cooling Water Pipe

1. Install the alternator mounting bracket and sup- porter to the cylinder block, then tighten the fixing bolts. 2. Install the alternator with fixing bolts to the mount- ing bracket. DE08TS Diesel Engines Maintenance... -

Page 68: Fuel Filter

2. Assemble the cylinder head cover to the cylinder head by tightening the cap bolts for fixing the cylinder head cover. Torque 1.2 kg • 3. Assemble the breather and breather hose. 4. Fit the oil filler cap on the cylinder head cover. DE08TS Diesel Engines Maintenance... -

Page 69: Cooling Fan

1. Assemble by connecting the other oil and fuel pulley hoses. Crank pulley V-belt EA9O2006 1. Install the V-belt on the crank pulley, alternator pulley and water pump pulley.. 2. Adjust the V-belt tension using the tension adjust- ing support. EB5O6001 DE08TS Diesel Engines Maintenance... -

Page 70: Breaking In

4. Abrupt start and stop of the engine should be avoided. DE08TS 18.5 API CH-4 above 5. Engine speed must be under 70% of its maximum speed. 6. Maintenance and inspection must be accom- plished thoroughly. DE08TS Diesel Engines Maintenance... -

Page 71: Maintenance Of Major Components

At the radiator, the heat absorbed in the coolant is radiated to cool down and the coolant recirculates to the water pump. Thermostat Cooling water pipe Thermostart Cylinder head Cylinder block Oil cooler Water pump EQM4001I DE08TS Diesel Engines Maintenance of Major Components... -

Page 72: Specifications

One is named c. Replacing thermostat by 71 °C , 79°C type and the other is 83 °C. If the thermostat is detected defective, replace with a new one. DE08TS Diesel Engines Maintenance of Major Components... -

Page 73: Diagnostics And Troubleshooting

Water pump bearing defective Replace bearing • • Fan loosely fitted or bent Retighten or replace fan • • Fan out of balance Replace fan • • Fan belt defective Replace fan belt DE08TS Diesel Engines Maintenance of Major Components... -

Page 74: Lubrication System

실린더 헤드 Crankshaft bearing 크랭크 축 베어링 Rocker arm shaft 록커암 축 Connecting rod 컨넥팅 로드 베어링 bearing Rocker arm bush 록커암 부쉬 Relief valve 릴리이프 밸브 10 bar 10 bar 오일 팬 EB5M4001 DE08TS Diesel Engines Maintenance of Major Components... -

Page 75: Oil Pump

Disassemble the drive gear and driven gear. Clearance 0.032 ~ 0.077 mm 2. Inspection and correction 3. Reassembly a. For reassembly, reverse the disassembly sequence. Steel plate Feeler gauge EQM4008I DE08TS Diesel Engines Maintenance of Major Components... -

Page 76: Diagnostics And Troubleshooting

Various bearings worn Replace • • 3. Oil deteriorates quickly Restriction in oil filter Replace filter element • • Gases leaking Replace piston rings and cylinder liner • • Wrong oil used Use suggested oil DE08TS Diesel Engines Maintenance of Major Components... -

Page 77: Fuel Injection Pump

Make sure that servicing should be performed at the professional maintenance shop as authorized by Bosch or Zexel Company. For adjustment of fuel injection volume, refer to the ‘Specifications of fuel injection pump’ described on the following pages. DE08TS Diesel Engines Maintenance of Major Components... - Page 78 1. DE08TS (D100/120) a. Injection pump ass’y : 65.11101-7388 (101609-904F) - Injection pump : KP-PES6AD95B410RS2 (101062-8240) - Governor : KP-EPRSV200-1300AQ39C311 (105411-215A) - Fuel feed pump : KP-FP/KE-ADS (105210-5610) - Plunger & barrel : 131153-1720 - Delivery valve : 131160-3620 b. Nozzle holder assembly : 65.10101-7088 (Y430 K02 049) c.

- Page 79 2. Governor adjustment (D100/120) BOO. COM STRDKE: 0.7 11.4 10.2 IDLE SUB SPRING 1220 (1170) 1190 Injection pump speed(rpm) Boost adjustment(DE08TS) N= 550rpm -10.2) -0.7) Boost pressure (mmHg) DE08TS Diesel Engines Maintenance of Major Components...

- Page 80 3. DE08TS (D150) a. Injection pump ass’y : 65.11101-7388 (101609-904F) - Injection pump : KP-PES6AD95B410RS2 (101062-8240) - Governor : KP-EPRSV200-1300AQ39C311 (105411-215A) - Fuel feed pump : KP-FP/KE-ADS (105210-5610) - Plunger & barrel : 131153-1720 - Delivery valve : 131160-3620 b. Nozzle holder assembly : 65.10101-7088 (Y430 K02 049) c.

- Page 81 4. Governor adjustment (D150) BOO. COM STRDKE: 0. 12.7 11.4 1120 (1170) 1190 Injection pump speed(rpm) 2. Boost adjustment(DE08TS) N= 550rpm -11.4) -0.7) Boost pressure (mmHg) DE08TS Diesel Engines Maintenance of Major Components...

-

Page 82: Fuel Feed Pump

(B). If the feeding pressure increases abnormally, the spring is compressed, resulting in interrupting further delivery of fuel as shown in (C). Priming pump Check valve Check valve Outlet Inlet side side Tappet Piston Cam shaft EQM4019I DE08TS Diesel Engines Maintenance of Major Components... - Page 83 In addition, a strainer is fitted into joint bolt on the inlet side of the fuel feed pump to filtrate any foreign EB1M4003 substances possibly mixed in fuel. DE08TS Diesel Engines Maintenance of Major Components...

- Page 84 Replace the push rod if excessively worn, and replace together with the pump housing if required. The inspection for wear should be per- formed in the same procedure as for suction pressure test described below. DE08TS Diesel Engines Maintenance of Major Components...

- Page 85 Make a test with the feed pump mounted on a pump tester as illustrated. Operate the pump at the rate of 1,000 rpm and check to see if the pump delivery is more than 405 cc/15 seconds. DE08TS Diesel Engines Maintenance of Major Components...

-

Page 86: Injection Nozzle

Remove the nozzle nut and components inside. b. Replace all the seal rings with new ones. c. Assemble the parts and tighten them to speci- fied torque 4. Inspection a. Visually inspect the disassembled components for damage. DE08TS Diesel Engines Maintenance of Major Components... - Page 87 After adjusting the injection pressure, tighten the cap nut to specified torque. Normal Abnormal Abnormal EFM2057I f. Re-check the injection pressure and see if the spray pattern is normal. Spray pattern should be uniform and free of spattering. DE08TS Diesel Engines Maintenance of Major Components...

-

Page 88: Diagnostics And Troubleshooting

Adjust • exhaust smoke Nozzle spring broken Replace • Nozzles not working normally Replace • Plungers worn excessively Adjust • Delivery valves seat defective Replace • Supply of fuel excessively Check feed pump DE08TS Diesel Engines Maintenance of Major Components... - Page 89 Governor defective Disassemble, correct • 8. Engine idling unstable Movement of control rod Disassemble, correct • sluggish Operation of plungers unsmooth Disassemble, correct • Control pinions not engaged Disassemble, correct with control rod correctly DE08TS Diesel Engines Maintenance of Major Components...

-

Page 90: Turbocharger

9.5 kg 2. Construction EA05008I 1. Impeller casing A. Air inlet 2. Turbine casing B. Gas outlet 3. Bearing casing C. Gas inlet 4. Impeller D. Oil supply 5. Turbine E. Oil return DE08TS Diesel Engines Maintenance of Major Components... -

Page 91: General Descriptions

As explained, the compressing of air to supply into the cylinders is called “Supercharging” and the making use of the energy of exhaust gas discharged from the combustion chamber to charge the compressed air into the cylinders is called “Turbocharging”. DE08TS Diesel Engines Maintenance of Major Components... -

Page 92: Functions

Sealing-Compressor shaft The compressor is of a dual construction type com- posed of seal plate and seal ring to prevent the leak of compressed air or lubricating oil. DE08TS Diesel Engines Maintenance of Major Components... -

Page 93: Precaution For Operation

When stopping transmitted to the bearing portion the engine and burns oil to cause seizure of the bearing metal and rotating shaft. DE08TS Diesel Engines Maintenance of Major Components... -

Page 94: Walk-Around Check And Servicing

Besides of it, if spray pattern from the fuel injection nozzles is bad or the injection timing is incorrect, temperature of exhaust gas rises up to affect the turbocharger adversely. To avoid such trouble, be sure to make a nozzle test. DE08TS Diesel Engines Maintenance of Major Components... -

Page 95: Periodical Checking And Servicing

Standard : 0.075~0.11mm in both directions Limit of wear : 0.12mm simultaneously Oil inlet EA8M4004 c. If the measured axial and radial plays are beyond the limit of wear, replace or repair the tur- bocharger. DE08TS Diesel Engines Maintenance of Major Components... - Page 96 Do not interchange them with ordinary steel bolts and nuts when performing reassem- bly operation. Apply anti-seizure coating to the bolts and nuts. • Assemble each joint on the exhaust pipes securely to prevent gas leaks. DE08TS Diesel Engines Maintenance of Major Components...

-

Page 97: Diagnostics And Troubleshooting

4. Unusual sound or 1) Rotor assembly coming in contact Disassemble/repair vibration or replace 2) Unbalanced rotation of rotor Disassemble/repair or replace 3) Seized up Disassemble/repair or replace 4) Each joint loosened Check and correct DE08TS Diesel Engines Maintenance of Major Components... -

Page 98: Special Tool List

(From 2000. may.) EF.123-052 Oil seal puller ass’y (Front) EF.123-048 Oil seal puller ass’y (Rear) EU.2-0530 Cylinder pressure tester adapter EU.123-086 Cylinder liner puller ass’y EF.123-179 Valve stem seal punch EU.2-0131 Valve clearance adjust ass’y EB1M70 DE08TS Diesel Engines Special Tool List... - Page 99 Part No. Figure Tool Name Remark EF.123.-065 Valve spring press EU.2-0647 Crankshaft gear punch D1146/TI EF.123-064 DE08TIS Piston sleeve All engine EF.120-208 60.99901-0027 Feeler gauge T7610001E Snap ring plier T7621010E Piston ring plier DE08TS Diesel Engines Special Tool List...

- Page 100 • Injection pump coupling bolt 6.0 ~ 6.5 kg • Injection pump driving gear nut 8.8T 25.0 kg • Injection pipe nut 8.8T 3.0 kg • Injection pump delivery valve holder 11.0 ~ 12.0 kg • DE08TS Diesel Engines Appendix...

- Page 101 For example, a screw coated with MoS2 should be tightened to 60% or so of the standard value. 4. Tightening torque for hollow screw (4-hole) Material SM25C 13.0 18.0 30.0 *SUM22L 11.0 16.0 20.0 35.0 STS304 11.0 16.0 20.0 35.0 * : Adopted in DOOSAN engine DE08TS Diesel Engines Appendix...

- Page 102 0.05~0.085 0.15 Cross Install by Direction of ring gap 120˚ Outer diameter of piston 41.994 ~ 41.94 Replace piston pin Piston Clearance between Replace one worn 0.003 ~ 0.015 0.08 piston pin and its bush more DE08TS Diesel Engines Appendix...

- Page 103 Diameter of cam shaft 57.86~ 57.88 57.52 journal Clearance between cam 0.12~0.17 0.24 Replace cam bush shaft and cam bush shaft Replace thrust End play of camshaft 0.28~0.43 washer Correct or replace Run-out of camshaft 0.05 the cam shaft DE08TS Diesel Engines Appendix...

- Page 104 (along free 1.5° Exhaust length valve direction) spring D1146/TI : 71 Free length DE08TIS : 77.7 Tension force(when D1146/TI : 62.7~69.3 Replace pressed to DE08TIS : 71~79 valve spring 41mm)kg Squreness (along free 1.5° length direction) DE08TS Diesel Engines Appendix...

- Page 105 Replace gear shaft 17e7 Diameter of driving gear 28.000 ~ 28.033 Replace bush 28e7 bush Between crank gear & idle 0.15 ~ 0.25 gear Backlash Adjust back-lash Between oil pump drive 0.15 ~ 0.25 gear & idle gear DE08TS Diesel Engines Appendix...

- Page 106 ˚C Thermostat Type- ˚C opening temp. Replace - Opening temp. : 83˚C Thermostat (under atmospheric pressure) - Full opening temp. : Replace if defective ˚C Full opening temp. 95˚C Stroke min. 8mm DE08TS Diesel Engines Appendix...

- Page 107 Running-in the engine “running-in” Inspection Compression pressure of 24 or 24 ~ 28 Correct more Cylinder cylinder (kg/cm at 200rpm or more completion pressure Compression pressure 10% or less ˚C more(20 difference of each Correct against average cylinder DE08TS Diesel Engines Appendix...

Need help?

Do you have a question about the DE08TS and is the answer not in the manual?

Questions and answers