Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Zmorph 2.0 S

- Page 1 PERSONAL FABRICATOR VERSION 2.0 S USER MANUAL...

-

Page 2: Table Of Contents

TABLE OF CONTENT OVERVIEW THE ZMORPH SAFETY MACHINE OVERVIEW CHAMBER PANEL OVERVIEW ACCESSORIES GET STARTED PRINTER CONNECTION USB CONNECTIVITY LAN CONNECTIVITY CALIBRATION TESTING THE AXIS BED CALIBRATION EXTRUDER TEST PLASTICS STUCK FIRST PRINT YOUR FIRST PRINT SOFTWARE BASICS GENERATING GCODES... - Page 3 VOXELIZER G-CODES IN VOXELIZER SOFTWARE WORKING WITH VOXELS G-CODE AND PRINTING MAINTENANCE AND FUNCTION TOOLHEADS TOOLHEAD FEATURES CLEANING THE NOZZLE NOZZLE REMOVAL LUBRICATION EXCHANGE AND REPLACEMENT OF TOOLHEAD EXCHANGING THE TOOLHEADS MAKING THE PLASTIC PRINT STICK TO THE PRINTBED CNC-MILLING THE CNC-MILLING FEATURE THE FILE FORMAT: LOADING DFX SETTING WORKING PARAMETERS...

-

Page 4: Safety

OVERVIEW / THE ZMORPH SAFETY Before using the machine, You need to read the instructions carefully. Improper use of the device might cause fire, electric shock or damage to the mechanical and electronic parts. This machine is not a toy. Small children and pet animals should not be allowed to interfere with it. - Page 5 If fumes make You feel unwell, switch the machine off and allow fresh air in. The machine shall not be covered during operation. The machine must be supervised at all times. ZMorph extruders and toolheads should be used only with materials they were designed for. Other use is prohibited and will void warranty.

- Page 6 ZMORPH 3D PRINTER FIRST STEPS...

-

Page 7: Machine Overview

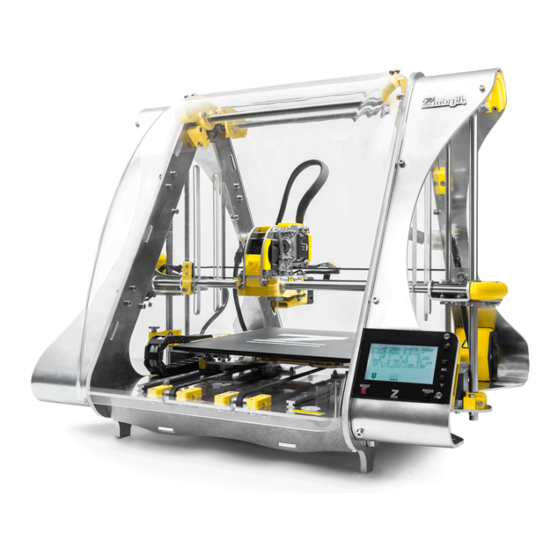

OVERVIEW / THE ZMORPH MACHINE OVERVIEW Chamber Extruder Navigation panel X Axis motor Reset button Z Endstop Glass heated bed MOST IMPORTANT ZMORPH PARTS... -

Page 8: Chamber

OVERVIEW / THE ZMORPH CHAMBER Zmorph has two covers that creates a closed heat chamber. This enables the machine to print in ABS, which otherwhise would crack and warp due to uneven temperature. The covers add extra safety when the machine is running, which is desirable for educational use and public exhibitions. -

Page 9: Panel Overview

OVERVIEW / THE ZMORPH PANEL OVERVIEW RESET PLAY/PAUSE DOWN... -

Page 10: Accessories

OVERVIEW / THE ZMORPH ACCESSORIES ZMorph personal fabricator 100 ml of ABS juice HEX keys set (optional) Micro SD card with config files Micro SD card adapter Spool stand (installed in the machine) Micro drill with handle Extruder servicing tool... -

Page 11: Get Started

GET STARTED / PRINTER CONNECTION USB CONNECTIVITY Driver and software installation instructions for Windows. From March 2014 ZMorph personal fabricators don’t require drivers. The new firmware supports USB communication (as HID device) and internal SD drive natively, without any necessary files. Just... - Page 12 GET STARTED / PRINTER CONNECTION Important: please copy all contents of the SD card drive as soon as you can (backup). After that, you can connect to the machine using Voxelizer, which can be downloaded from: http://voxelizer.com/ In Voxelizer, select connection method as HID.

-

Page 13: Lan Connectivity

Connect the machine to a router in your network using the cable provided. If your network has DHCP active (most networks do), ZMorph will get it’s IP address and display it on front panel. Type this address to Voxelizer. Click ‘Connect’. - Page 14 GET STARTED / PRINTER CONNECTION If you want, you can drive the ZMorph using any Telnet client, or even (!) a web browser. To do so, just type machine’s IP as: http://192.168.1.5 (example). This allows you to drive it also via mobile devices.

- Page 15 - Smoothie Virtual Serial Port - Smoothie DFU Simply right click on them, and choose ‘uninstall’. Make sure that driver files get removed (tick an option). Then, unplug the USB-cable and plug it again. You should see ‘ZMorph HID’ appear.

-

Page 16: Calibration

ZMORPH 3D PRINTER CALIBRATION... -

Page 17: Testing The Axis

GET STARTED / CALIBRATION TESTING THE AXIS Important : Before you start testing the axis, make sure that endstop for Z axis is in correct position (approximately). It might have moved during transport. It must be positioned in a way, that allows contact with the tactile switch, when in lowest possible position. - Page 18 Z button (or use the panel) and watch the entire horizontal axis go down. To make sure that tactile switch works, press it with finger few times - the motors should now stop. If it doesn’t happen, contact ZMorph support team at: support@zmorph3d.com...

- Page 19 GET STARTED / CALIBRATION After successful testing of X, Y and Z endstops, you can click A button (ALL) or select: Calibrate >> Home To Center on the panel.

-

Page 20: Bed Calibration

GET STARTED / CALIBRATION WORKING TABLE (BED CALIBRATION) The machine always comes as calibrated. No calibration is usually necessary to start printing. If your machine got miscalibrated in transport, follow the instructions below. In order to work with 3d printing, it is essential to properly calibrate the print surface. To calibrate the print surface, you should position the nozzle in the... - Page 21 Calibration should be run with a hot machine - as elements change dimensions with temperature. To heat everything up choose on the ZMorph panel: Filament Menu >> Preheat [ABS/PLA] Or click ‘heater’ in Voxelizer. White LEDs on the toolhead should light up, marking that the heating process is started.

- Page 22 GET STARTED / CALIBRATION After setting the right temperatu- re, you should move the nozzle to the working areas 4 corners (black squ- are) and make sure that the clearance is the same (as a paper sheets thickness). Use: Calibrate >> Check ... If it’s not, regulation can be run in two ways: Re-balancing the X-axis made by adjusting vertical threaded rods on the side of the machine.

- Page 23 If you are experiencing any problems with balancing the table or X axis of the machine, Touch Probe. consider purchasing the clip-on add-on for the ZMorph called It will make calibration much easier and is available in our shop. Video tutorial demonstrating this can be found here:...

-

Page 24: Extruder Test

GET STARTED / CALIBRATION EXTRUDER TEST Before you start printing, the extruder needs to be tested. To do that, move the nozzle up by 20mm. In the panel you should go to: OK >> Move Axis >> Z axis (press two times for 20mm). And heat it to 235-245°C - if using ABS, or... - Page 25 GET STARTED / CALIBRATION If you have no filament loaded, you should feed it in, as shown in the video: https://www.youtube.com/watch?v=zZigNKNwppI...

- Page 26 GET STARTED / CALIBRATION The speed and length of test extrusions is defined underneath the E and R buttons in Voxelizer. E and R refer to Extrude and Reverse. Extrude pushes filament out of the nozzle, reverse moves it back. Both values (amount and speed) relate to both buttons.

-

Page 27: Plastics Stuck

GET STARTED / FIRST PRINT EXTRUDER JAMS Important: The extruder comes calibrated, and is always tested before the machine is shipped. If you don’t get proper extrusion, play with temperatures first - this is usually the primary cause of uneven flow. If the plastic doesn’t progress, despite motor movement, you need to check the following: Temperature of the nozzle. -

Page 28: Your First Print

GET STARTED / FIRST PRINT YOUR FIRST PRINT To test the printer, you should: Make sure your table is sticky enough (apply „ABS juice” in case of ABS plastic, or paper glue in case of PLA. You can also use Kapton or blue masking tape - PLA only. - Page 29 GET STARTED / FIRST PRINT Heat the nozzle to: · 235-245°C - if using · 185-200°C - if using PLA. Heat the bed to: · 100°C for ABS · 60°C for PLA. Extrude some filament.

- Page 30 GET STARTED / FIRST PRINT In Panel menu choose: OK >> PLAY >> SD >> examples and select one of test files (for example Wolf_6cm_175_PowerRaft.gcode) and press OK the first print layer sticks Important: It is essential to pay attention how to the bed.

- Page 31 VOXELIZER SOFTWARE GCODES...

-

Page 32: Generating Gcodes

SOFTWARE / BASICS GENERATING GCODES To turn a 3D model into something that can be easily printed, the models geometry needs to be saved into STL file format. Most CAD programs supports STL export. You can also download print ready projects as STL files from the internet: (for example www.designfutures.club using your web browser or... -

Page 33: Preparing Gcodes

SOFTWARE / BASICS PREPARING GCODES The print preparation process can be illustrated with the diagram below: Creation of a 3D GEOMETRY saving as STL-format model. VOXELIZATION - conversion from mesh based STL-model to volumetric- pixel data. Generating horizontal slices of the object, and plastic extrusion paths as G-CODES, instructions for machine to move in space and deposit plastic. -

Page 34: Setting Gcodes

SOFTWARE / BASICS SETTING GCODES Recommendations for G-code generation for ZMorph personal fabricator: Print speed: 40 mm/s (normal quality) Layer height 0.25mm when using 0.4mm nozzle: First layer height 0.3mm when using 0.4mm nozzle: Nozzle temperature for ABS: 225-245°C Nozzle temperature for PLA: 185-200°C... -

Page 35: G-Codes In Voxelizer Software

SOFTWARE / VOXELIZER G-CODES IN VOXELIZER SOFTWARE To start working you should first load your model, which you will prepare for print. Voxelizer is able to import files in STL-format, which is the most used 3D model format. You can download plenty of STL-files on the internet, or you can use CAD- software of your preference, most CAD-programs support STL-file export. - Page 36 SOFTWARE / VOXELIZER When you have imported your STL model you have access to tools like scale and rotation. To make these modifications click on the object you would like to manipulate and use sliders in mesh transformations window. You can also move your objects through the printing area which is represented by a light grey color.

-

Page 37: Working With Voxels

SOFTWARE / VOXELIZER WORKING WITH VOXELS The Voxelizer software allows you to work with an innovative technique: VOXELIZATION. Nowadays most programs use 3D objects represented as surfaces forming closed volume. Voxelizer interprets models as voxels - similarly to atoms, representing it as finite number of blocks in space. - Page 38 SOFTWARE / VOXELIZER 3D printer creates objects by placing layers starting from bottom to top of the model. For this reason every overhanging model part needs support material. In support settings you will find settins connected with support parts. To enable support click 'generate sup- port' button.

-

Page 39: Gcode And Printing

There are many ways to connect printer to your personal computer. Basic method: you will propably use is USB connection. If you are user of ZMorph printer and you have newest firmware. (If unsure - check: http://zmorph3d.com/firmware/) you only need to plug the machine to your PC - no drivers are required. - Page 40 SOFTWARE / VOXELIZER Before starting print it is important to prepare printer. There are four most important parameters, you shouldn’t forget: Head homing (resetting coordinate system) Heating extruder (235-245°C for ABS plastic/ 185-200°C for PLA) Heating bed (100°C for ABS plastic/ 60°C for PLA) Beds sticky surface (can be covered with ABS juice, special glue, kapton or paper masking tape, or other special surfaces like Build Tak) Then use one of three printing methods:...

- Page 41 SOFTWARE / VOXELIZER Save the file to SD card and start print using LCD panel (you can unplug the printer afterwards). Note: This option is only available when connecting via HID mode Copy the file to external SD card (behind LCD panel), insert it to the machine and start using PLAY command (you can unplug the cable).

- Page 42 ZMORPH EXTRUDERS EXTRUDERS AND TOOLHEADS...

-

Page 43: Maintenance And Function

MAINTENANCE AND FUNCTION / TOOLHEADS EXTRUDERS FEATURES A classic extruder for mono material prints. Made of aluminium and stainless steel. • VERY PRECISE SINCE IT EXTRUDES THINNER FILAMENT THUS HAVING MORE CONTROL • ABLE TO EXTRUDE ABS, PLA, NYLON AND OTHER MATERIALS •... - Page 44 MAINTENANCE AND FUNCTION / TOOLHEADS Plastic extruder for two materials (1.75mm) application. Driven by two independent stepper motor drivers, uses two heated nozzles and temperature sensors. • ALLOWS MULTICOLOR AND MULTIMATERIAL PRINTS • ALLOW DISSOLVING SUPPORT MATERIAL, PVA IN WATER AND ABS IN ACETONE.

- Page 45 MAINTENANCE AND FUNCTION / TOOLHEADS Experimental laser toolhead. Available in ZMorph online store. • SUITABLE FOR CREATING ARCHETECTURAL MODELS IN THIN PLYWOOD OR CARDBOARD • ENGRAVING IN METAL, WOOD OR PLASTIC • 2.0 WATT STRENGTH LASER TOOLHEAD (experimental) To find out more about using http://zmorph3d.com/laser-tutorial/...

- Page 46 MAINTENANCE AND FUNCTION / TOOLHEADS Experimental toolhead created for prin- ting with ceramics. Equipped with pla- netary gears and a powerful motor, uses large pushing power to drive the piston. Can extrude thick mass that solidifies quickly afterwards. Nozzle size is approximately 1.5mm.

- Page 47 MAINTENANCE AND FUNCTION / TOOLHEADS Experimental chocolate and cake extruder. Can extrude semi-liquid masses. Used for decorative purposes and experimental builds. Utilizes Moineau pump, also known as a 'progressive cavity pump', driven by a powerful motor with planetary gears. Does not use a piston and can be refilled during operation.

- Page 48 MAINTENANCE AND FUNCTION / TOOLHEADS An experimental toolhead, designed to host a variety of add-ons. Can work as 5d milling machine, or 5D extruder. Allows the use of custom-designed add-ons (tips). 5 AXIS MILLING TOOLHEAD Watch video below: https://www.youtube.com/watch?v=tSFiK9q_Ers&list=UUyyeCKyWMN-zZsrSrbNaHDA...

- Page 49 MAINTENANCE AND FUNCTION / TOOLHEADS Connect your camera to Voxelizer and create amazing time lapses of your 3D-prints. THE SET INCLUDES: • MINI-FIT PLUG FOR CONNECTING THE CABLES TO THE MACHINE (USING RIGHT EXTRUDER SOCKET) • MODULE WITH MINI-JACK PLUG AND 24V CONTACT SWITCH, THAT WILL INFORM CAMERA ABOUT SHUTTER RELEASE •...

- Page 50 ZMORPH 3D PRINTER SERVICING...

-

Page 51: Cleaning The Nozzle

MAINTENANCE AND FUNCTION / TOOLHEADS CLEANING THE NOZZLE There are situations when your extruder nozzle will get blocked. This happens either when a foreign object enters your nozzle or if you have the wrong temperature settings for your filament. If a foreign object enters the nozzle with the filament a blockage may occur. - Page 52 MAINTENANCE AND FUNCTION / TOOLHEADS If you experience a blockage while using ABS, just place the nozzle in acetone for one night, then clean it carefully. Check if you can see through the nozzle. If not - repeat the above steps. Re-insert the nozzle back to the heating block (it’s easier to screw it in when it's heated).

-

Page 53: Nozzle Removal

MAINTENANCE AND FUNCTION / TOOLHEADS NOZZLE REMOVAL The nozzle of the extruder has to be removed in two cases: If it needs to be cleaned When you want to change it (when it is blocked). to different size. In both cases, the procedure is the same. Start with heating the nozzle to about 200°C. -

Page 54: Lubrication

If you experience high friction on Y axis (linear rails for heated bed), they should be cleaned with water and soap or WD40 fluid. EXCHANGE AND REPLACEMENT OF EXTRUDER ZMorph allows exchange of different toolheads and accessories: • EXTRUDERS • DREMELS •... -

Page 55: Exchanging The Toolheads

MAINTENANCE AND FUNCTION / TOOLHEADS EXCHANGING THE TOOLHEADS Exchanging extruder is shown in the video: https://vimeo.com/119830882 RELEASE CURRENT TOOLHEAD Unscrew the nut with the provided hex key. The USB cable might remain plug- ged (display will be active), but motors and heaters will be shut down, so electronics stays safe. - Page 56 MAINTENANCE AND FUNCTION / TOOLHEADS CHOOSE A NEW TOOLHEAD And put it in place. SECURE THE TOOLHEAD By screwing the nut with provided hex key. If You are using regular extruder insert the plug to left socket. If you’re using dual extruder, or 5-axis toolhead, insert plugs in left and right sockets. Turn the power on after making sure that plugs are positioned correctly.

- Page 57 MAINTENANCE AND FUNCTION / TOOLHEADS If you exchange extruder to another device that measures temperature (is equipped with thermistor), make sure to verify BETA values of this thermistor. They are specified on the device, or in it's documentation. If unsure - ask us. If beta is different, you have to change it in config file, and restart the machine.

-

Page 58: Making The Plastic Print Stick To The Printbed

MAINTENANCE AND FUNCTION / TOOLHEADS MAKING PLASTIC STICK TO PRINTBED To keep the print hold firmly to the table while printing, we can use measure described below: Heating the bed table - especially important for ABS plastic. Usual temperature is 100-120°C. With higher temperatures plastic sticks better, and deforms less during printing (especially for large objects). - Page 59 HEATER for the CHAMBER. ZMorph personal fabricator, bed works also as a Heating the bed to 100°C and keeping the chamber closed increases internal air tempera- ture to about 50°C, which has positive effect to ABS plastic. Protective atmosphere prevents cracks between layers, curling up the edges, saves energy and keeps the smells inside.

- Page 60 MAINTENANCE AND FUNCTION / TOOLHEADS You can print with PLA just on pure glass (cleaned with acetone), more information here: https://vimeo.com/17064268...

-

Page 61: The Cnc-Milling Feature

MAINTENANCE AND FUNCTION / CNC MILLING THE CNC MILLING FEATURE (AND DXF FILE IMPORT IN VOXELIZER SOFTWARE) Before you start we recommend to download newest release from our website: http://voxelizer.com/download/ Important: Voxelizer imports only lines and polylines composed of lines on "geometry"... -

Page 62: Setting Working Parameters

MAINTENANCE AND FUNCTION / CNC MILLING SETTINGS WORKING PARAMETERS After loading DXF file "milling tool" window will apear. You can also open it from "Toolbars" menu. There you will set machine working parameters: Set travel Z This value is used when printer moves head to new place without doing any job. It should be enough high to avoid printer and material collision. -

Page 63: Preparing The Dremel Tool

MAINTENANCE AND FUNCTION / CNC MILLING PREPARING THE DREMEL TOOL Normally printer is calibrated to use plastic extruder. If you want to use other device you should keep in mind that its end probably will be at different height creating the possibility of collision with bed. Be careful! To install device move head to central area of machine, and increase it’s height to provide enough space. -

Page 64: Upgrades Software Upgrades

UPGRADES / SOFTWARE UPGRADES SOFTWARE UPGRADES ZMorph uses SunBeam electronics. It is inspired by Smoothie electronics (it’s compatible) and works on open-source firmware Smoothieware. To find out more about its capabilities check http://smoothieware.org Make sure you backup all the files (especially config and firmware.cur). - Page 65 ZMORPH 3D PRINTER QUESTIONS AND ANSWERS...

-

Page 66: Troubleshooting

MAINTENANCE AND FUNCTION / TROUBLESHOOTING AND ADJUSTMENTS TROUBLESHOOTING Symptom: no connection with the machine. Reason: dropped USB connection Solution: insert/remove USB cable. Voxelizer should reconnect automatically. If it doesn’t , run the program again and repeat the steps. If this doesn’t help, reset the machine. Symptom: plastic doesn’t flow, even though extruder pulley is rotating normally. - Page 67 MAINTENANCE AND FUNCTION / TROUBLESHOOTING AND ADJUSTMENTS Symptom: uneven layer height, cracks between layers. Reason: uneven layer height, cracks between layers. Solution: make sure that spool rotates freely. Symptom: layers are shifted, machine loses position from time to time. Reason: friction on one or two axis is too strong, or speeds are too high. Solution: find cause of high friction. Usually smooth rails are covered in sticky substances that prevent it from moving freely.

-

Page 68: Faq

What is ZMorph? Zmorph is a device designed to materialize physical objects using digital fabrition techniques, such as 3D printing or CNC milling. ZMorph 3D personal fabricator is designed to be user friendly, easy to setup and straightforward to use. It marks its uniqueness innovative interchangeable toolheads. - Page 69 What is a filament ? It's consumable for 3D printers ( in technology ABS, PLA , PVA ) - like traditional ink for printers. What colors of filament are available in ZMorph’s store? On our website you can find: blue, green , red, black and yellow filament. http://shop.zmorph3d.com/index.php/pl/kategorietop/filament Which operating systems do you support ? Windows Vista, Windows 7, Windows 8 , and Linux and OSX soon.

- Page 70 X, Y and Z axis, as well as stepper motors. In case of technical fault caused by material wear or improper assembly, if still in warranty period, user can send faulty module to ZMorph headquaters, where it will be exchanged and shipped back as soon as possible.

- Page 71 What is in a jar? 100 ml solution of ABS dissolved in acetone. Often calles 'ABS juice' makes prints stick to the table. I would like to be a reseller of ZMorph, is it possible? Of course , please contact sales at: sales@zmorph3d.com What determines the quality of the prints ? Method for generating gcodes ( height of the layer , the amount of plastic) and nozzle size .

- Page 72 MAINTENANCE AND FUNCTION / TROUBLESHOOTING AND ADJUSTMENTS What is a recommended temperature of print? Recommended temperature (heads): 235-245°C (ABS) 185-200°C (PLA) Recommended temperature (table): 100-120°C (ABS) 60 - 70°C (PLA) 135°C (NYLON) Which elements require most maintenance during normal use ? Depending on quality of the plastic, users might experience nozzle clogging in the extruder, which needs to be cleaned ocassionally.

- Page 73 MAINTENANCE AND FUNCTION / TROUBLESHOOTING AND ADJUSTMENTS Do I need a special training if I want to use ZMorph personal fabricator? ZMorph was designed to be as easy and intuitive as possible. However, it requires certain amount of skill. Start with reading the manual, watch video tutorials, and try for yourself.

-

Page 74: Advanced Servicing And Machine Hacking

ZMorph has many capabilities to extend boundaries of modern digital fabrication. To truly be a part of this revolution, you can take advantage of software and hardwa- re openness and use your technical skills to improve your ZMorph experience. CONFIG FILE SD card delivered with your ZMorph contains small text file named ‘config’... - Page 75 MAINTENANCE AND FUNCTION / TROUBLESHOOTING AND ADJUSTMENTS Each entry needs three lines: status (enable=true/false), name (text field), and G-Code command In the last one, multiple commands can be separated by | symbol. It’s also important to give each entry separate descriptor (this doesn’t matter to the user, but it matters to the firmware). For example custom_menu.myDescriptor1.enable true...

-

Page 76: Design Your Own Toolheads

MAINTENANCE AND FUNCTION / TROUBLESHOOTING AND ADJUSTMENTS DESIGN YOUR OWN TOOLHEADS If you’re experienced enough to create and build your own toolhead, please read information here: http://zmorph3d.com/custom-toolhead/ If you want to design your own toolhead, check specifications of the mount and wiring at: www.zmorph3d.com You can download CAD files, technical drawings and working examples. -

Page 77: Specifications

MAINTENANCE AND FUNCTION / SPECIFICATIONS SPECIFICATIONS 250x235x165mm, working area expandable to 300x235x165mm with special table 0.3mm-0.05mm (ABS) recommended layer height 0.3-0.01mm (PLA) 40mm/s - normal speed 75mm/s - high speed 200mm/s - extreme speed. Works only for simple geometries, no re- traction, large builds. - Page 78 MAINTENANCE AND FUNCTION / SPECIFICATIONS firmware Smoothieware recommended host software Voxelizer X and Y – 500mm/s Z – 5mm/s Maximum axis speeds extruder 6mm/s (extrusion) and 40mm/s (retractions) watercut aluminium 6mm frame construction cnc-cut policarbonate 6mm ABS printed parts 3mm laser cut other elements and computer-bent aluminium...

- Page 79 MAINTENANCE AND FUNCTION / SPECIFICATIONS hardened glass 5mm, heated bed dimensions 250x235mm 150W heater, max 150°C...

- Page 80 MAINTENANCE AND FUNCTION / SPECIFICATIONS detachable, modular, parameters: heating: 40W heater extruder thermistor: 100K NTC nozzle size: 0.4mm, exchangeable lighting (heated bed, X AXIS bracket, heater’s indicators): white LED...

-

Page 81: Warranty

WARRANTY WARRANTY ZMorph personal fabricator is designed to be modular, and easy to service. In case of technical difficulty with any of the parts, it can be easily removed and shipped to us for maintenance. Warranty covers following components: • STANDARD PLASTIC EXTRUDER MODULE WITH HEATED NOZZLE,... -

Page 82: Contact

CE Conformity Hereby, zmorph sp. z o. o. declares that this device is in compliance with the essential safety requirements and other relevant provisions set out in the Europen Directive. Environmental Statement Zmorph has a strong commitment to environment and taking care ecolo- gy in line with European Union Directive on waste electrical and electronic pro- ducts (Directive 2002/96/EC ), which enteres into force on 13th August 2005. - Page 83 You will be receiving information about the new version of Voxelizer and its amazing modern possibilities. To be up to date with Zmorph Team & New Staff/Toolheads: Just subscribe on our website www.zmorph3d.com (you can do that at the down of the main page).

Need help?

Do you have a question about the 2.0 S and is the answer not in the manual?

Questions and answers