Summary of Contents for NSK Megatorque Motor System

- Page 1 ® Megatorque Motor System User’s Manual (Supplement to the EDC Driver Unit System) Document Number: C20169-03 EC-T...

- Page 2 Ltd. is notified of in writing within, which comes first, one (1) year of shipment or 2400 total operation hours. NSK Ltd., at its option, and with transportation charges prepaid by the claimant, will repair or replace any product which has been proved to the satisfaction of NSK Ltd. to have a defect in material and/or workmanship.

-

Page 3: Table Of Contents

Contents 1. Introduction ------------------------------------------------------------ 1-1 1.1. Precaustions for Use ----------------------------------------------------------------1-1 2. Reference Number and Coding --------------------------------- 2-1 2.1. PN Series Megatorque Motor-------------------------------------------------------2-1 2.2. EDC Driver Unit for PN Series Megatorque Motor ----------------------------2-1 2.3. Cable Set --------------------------------------------------------------------------------2-3 2.4. HandyTerminal -------------------------------------------------------------------------2-3 3. Name of Each Part--------------------------------------------------- 3-1 4. -

Page 4: Introduction

This is the supplementary of the instruction manual “EDC Driver Unit System (Document Number: C20158).” This supplement describes the Megatorque Motor System composed of the EDC Driver Unit and the PN series Megatorque Motor. Please refer to the above mentioned instruction manual (Document No.C20158) for items not described in this document. -

Page 5: Reference Number And Coding

2. Reference Number and Coding 2. 1. PN Series Megatorque Motor Fig.2-1: PN Motor M-PN 2 012 K N 201 Megatorque Motor PN Series Design number Motor size code KN: Standard Motor Notor maximum troque [N・m] 2. 2. EDC Driver Unit for PN Series Megatorque Motor Fig. -

Page 6: Cable Set

Fig.2-5: EDC Driver Unit for PN4135, and PN4180 types Motor M-EDC – PN4135 A B 5 02 – 01 -01: Bundled with connectors, fixing brackets and a Japanese EDC Driver Unit -02: Bundled with connectors, fixing Motor type brackets and an English manual. Design serial number 02: standard Power voltage: A: 200 to 230 [VAC] (single phase) -

Page 7: Name Of Each Part

3. Name of Each Part Fig 3-1: PN 2012 type Motor Hollow Cover (Rotating part) (Stationary part) Rotor (Rotating part) Mounting surface Resolver connector Motor connector g. 3-2: PN3045, 4135, and 4180 type Motor Hollow Cover (Stationary part) (Stationary part) Rotor (Rotating part) Motor connector Mounting surface... -

Page 8: Combination Of Motor And Driver Unit

4. Combination of Motor and Driver Unit Table4-1: Combination of PN2012 type Motor and Driver Unit Driver Unit Motor Power voltage Motor reference number Cable diameter Remarks [VAC] reference number : Code for specification reference number [mm] of bundled items. M-C0 SCP03 (Fixed type cable) -

Page 9: Motor Specifications

5. Motor Specifications Table 5-1: PN series Megatorque Motor Reference number M-PN2012KN201 M-PN3045KN001 M-PN4135KN001 M-PN4180KN001 Item [Unit] Motor outside diameter [mm] ø176 ø210 ø280 Maximum output torque [N•m] Rated output torque [N•m] Motor height [mm] Motor hollow diameter [mm] Maximum velocity Rated velocity Resolution of position [Count/rev.]... -

Page 10: Externel Dimensions

6. External Dimensions 6.1. PN Series Megatorque Motors ! Caution: Bending radius of the outgoing lines of Motor cable (ø7) and resolver cable (ø7) shall be R30 [mm] or less. ! Caution: Do not use outgoing lines of Motor cable and Resolver cable as a part of the flexible cable. - Page 11 Fig 6-3: PN4135 type Motor Fig 6-4: PN4180 type Motor — 6-2 —...

-

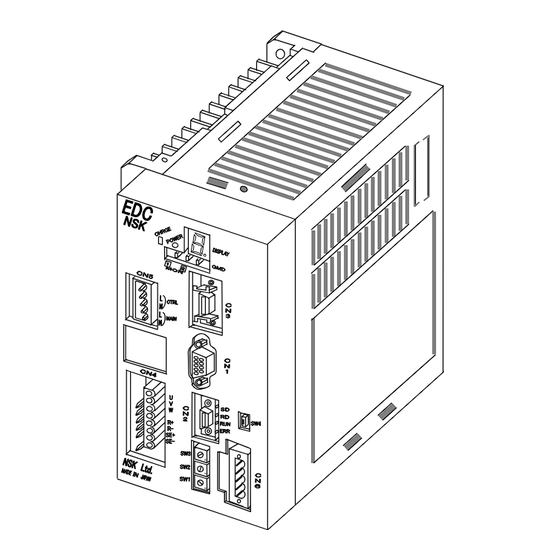

Page 12: Driver Unit

6.2. Driver Unit : Fig.6-5 EDC Driver Unit for PN2012 type Motor Fig. 6-6: CC-Link Compatible EDC Driver Unit for PN2012 type Motor — 6-3 —... - Page 13 Fig. 6-7 EDC Driver Unit for PN3045, PN4135 and PN4180 Megatorque Motors Fig. 6-8 CC-Link Compatible EDC Driver Unit for PN3045, PN4135 and PN4180 Megatorque Motors — 6-4 —...

-

Page 14: Driver Unit Specifications

7. Driver Unit Specifications Table 7-1: EDC Driver Unit Item PN2012 PN3045 PN4135 PN4180 Rated output [Arms] Output current Maximum output [Arms] 14.9 14.9 14.9 Rated capacity [kVA] Max. capacity [kVA] Power Single phase 100 to 115 [VAC] Control power source input Single phase 200 to 230 [VAC] Single phase 200 to 230 [VAC]... -

Page 15: Installation

8. Installation 8.1. Environmental Conditions of Motor Use the Motor in the indoor conditions free from dust and corrosive gas. The operating ambient temperature of the Motor shall be 0 to 40°C. The PN type Megatorque Motors are neither dust-proof nor waterproof. Do not expose the Motor to water or oil from any source. - Page 16 8.3. Confirmation of Use Conditions In case of the Megatorque Motor system, the moment of inertia of load is extremely higher than that of the rotor. The table bellow shows the allowable moment of inertia for each Motor type. :...

-

Page 17: Appendix 1: How To Check Motor Condition

1. ± 30% of the value in the left PN3045 2. Variation between each phase UV, VW, and WU PN4136 is less than 15% PN4180 Please ask NSK for a Motor with special winding specifications or a Cable longer than 4 m. — A-1 —... - Page 18 (ABS・COM) (ABS-C) (ABS・COM) * Please ask NSK for the specifications of the Motor with special winding, and the Cable longer than 4 [m]. Fig A-5: Connection of the Motor with the absolute position sensor [Reference only] Driver unit connector Motor connecter...

- Page 19 3. Insulation resistance check of Motor winding ! Caution: Disconnect the Motor from the Driver Unit when checking insulation resistance of the Motor. ! Caution: Checking voltage must be 500[ VDC] or less. Fig A-6: Check with the Cable PN3 or PN4 Tester Fig A-7: Check the Motor only PN3 or PN4...

- Page 20 (Blank Page) — A-4 —...

- Page 21 ® MEGATORQUE MOTOR SYSTEM PN Motor Series EDC Driver Unit User’s Manual Document Number: C20169-03 Nov 1, 2007 1st Edition Sep 30, 2009 2nd Edition Mar 1, 2012 3rd Edition NSK Ltd.

Need help?

Do you have a question about the Megatorque Motor System and is the answer not in the manual?

Questions and answers