Table of Contents

Advertisement

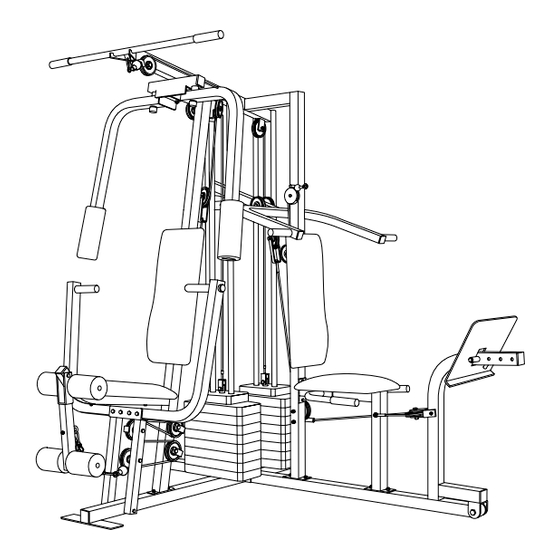

Model No. WESY39310

Serial No.

Write the serial number in the

space above for reference.

Serial Number Decal (Under Seat)

QUESTIONS?

As a manufacturer, we are com-

mitted to providing complete

customer satisfaction. If you have

questions, or if there are missing

parts, we will guarantee complete

satisfaction through assistance

from our factory.

TO AVOID UNNECESSARY

DELAYS, PLEASE CALL DIRECT

TO OUR TOLL-FREE CUSTOMER

HOT LINE. The trained techni-

cians on our customer hot line

will provide immediate assis-

tance, free of charge to you.

CUSTOMER HOT LINE:

1-800-999-3756

Mon.–Fri., 6 a.m.–6 p.m. MST

CAUTION

Read all precautions and instruc-

tions in this manual before using

this equipment. Save this manual

for future reference.

USER'S MANUAL

Visit our website at

www.weiderfitness.com

new products, prizes,

fitness tips, and much more!

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Weider WESY39310

- Page 1 Model No. WESY39310 Serial No. Write the serial number in the space above for reference. Serial Number Decal (Under Seat) QUESTIONS? As a manufacturer, we are com- mitted to providing complete customer satisfaction. If you have questions, or if there are missing...

-

Page 2: Table Of Contents

Note: A PART IDENTIFICATION CHART and a PART LIST/EXPLODED DRAWING are attached at the center of this manual. Remove the PART IDENTIFICATION CHART and the PART LIST/EXPLODED DRAWING before beginning assembly. WEIDER is a registered trademark of ICON Health & Fitness, Inc. -

Page 3: Important Precautions

IMPORTANT PRECAUTIONS WARNING: To reduce the risk of serious injury, read the following important precautions before using the weight system. 1. Read all instructions in this manual and in the accompanying literature before using the weight system. Use the weight system only as described in this manual. -

Page 4: Before You Begin

(excluding holidays). To help us assist you, please note the product model number and serial number before calling. The model number is WESY39310. The serial number can be found on a decal attached to the weight system (see the front cover of this manual). -

Page 5: Assembly

ASSEMBLY Before beginning assembly, carefully read the following information and instructions: • Due to the many features of the weight system, assembly will require about six hours. By setting aside plenty of time and by deciding to make the task enjoyable, assembly will go smoothly. You may want to assemble the weight system over a couple of evenings. - Page 6 2. Slide the Rear Upright (74) and the Leg Press Upright (56) onto the indicated 5/16” x 2 1/2” Carriage Bolts (1) in the Stabilizer (5). The high side of the brackets on the Rear Upright and Leg Press Upright should be on the side shown. Hand tighten four 5/16”...

- Page 7 4. Press a 2” Square Inner Cap (27) into the end of the Top Frame (55). Press a 1 3/4” Square Inner Cap (44) into each end of the crossbar on the Top Frame. Press two Round Inner Caps (75) into the top of the crossbar.

- Page 8 7. Press a Weight Tube Bumper (64) into the end of a Weight Tube (63). Insert the Weight Tube into the front stack of Weights (25). Be sure that the pin on the Weight Tube is sitting in the pin grooves in the top Weight.

-

Page 9: Arm Assembly

9. Attach the upper ends of the Short Weight Guides (73) to the Top Frame (55) with a 5/16” x 6” Bolt (60), two 1/2” x 3/4” Spacers (61), and a 5/16” Nylon Locknut (3). Attach the upper ends of the Long Weight Guides (62) to the Top Frame (55) with a 5/16”... - Page 10 12. Press a 1” Round Inner Cap (49) into one of the Press Arms (46). Press a 1 3/4” Square Inner Cap (44) into the Press Arm. Attach the Press Arm (46) to one side of the Press Frame (17) with two 5/16” x 2 1/2” Bolts (22) and two 5/16”...

-

Page 11: Cable Assembly

15. See the inset drawing. Attach the Military Press Arm (84) to the Pivot Arm (80) with two 5/16” x 2 1/4” Bolts (33) and two 5/16” Nylon Locknuts (3). Press two 1 1/2” Square Inner Caps (32) into the indicated end of the Military Press Arm (84). - Page 12 18. Wrap the High Cable (58) around a “V”-Pulley (50). Attach the “V”-Pulley and a Long Cable Trap (31) to the indicated bracket on the Front Upright (42) with a 3/8” x 2 1/2” Bolt (86) and a 3/8” Nylon Locknut (21).

- Page 13 22. See the inset drawing. Attach a 3 1/2” Pulley (15) and a Cable Trap (66) to the upper hole in a Long “U”-Bracket (57) with a 3/8” x 2” Bolt (12) and a 3/8” Nylon Locknut (21). Be sure that the Cable Trap is inside the Long “U”-Bracket.

- Page 14 25. Locate the Low Cable (23) and the bag labeled “LOW PULLEY.” Route the Low Cable under the 3 1/2” Low Pulley (76). Attach the Pulley and the 5/8” x 9/16” Spacer (7) to the Press Frame (17) with a 3/8” x 3 3/4” Bolt (88), 3/8” Washer (9), and a 3/8” Nylon Locknut (21).

- Page 15 29. Attach the end of the Low Cable (23) to the Long “U”-Bracket (57) with a 1/4” Nylon Locknut (2) and a 1/4” Washer (10). Do not completely tighten the Nylon Locknut. It should be threaded onto the end of the Cable so only a couple of threads are showing above the Nylon Locknut, as shown in the inset drawing.

- Page 16 32. Wrap the Military Press Cable (72) around a 3 1/2” Pulley (15). Attach the Pulley and a Cable Trap (66) to the Pivot Arm (80) with the 3/8” x 5” Bolt (101). Be sure the Bolt is on the side shown, and that the Cable Trap is positioned to hold the Cable in place.

- Page 17 35. Locate the Leg Press Cable (78). Attach the end of the Leg Press Cable to the Long “U”-Bracket (57) with a 1/4” Nylon Locknut (2) and a 1/4” Washer (10). Do not completely tighten the Nylon Locknut. It should be threaded onto the end of the Cable only a couple of turns, as shown in the inset drawing.

-

Page 18: Seat Assembly

SEAT ASSEMBLY 37. Locate and open the parts bag labeled “SEAT ASSEMBLY.” Insert a 1/4” x 2 1/2” Carriage Bolt (92) through the center hole in a Seat Plate (37). Attach the Seat Plate to the Leg Press Backrest (85) with two 1/4” x 3/4”... - Page 19 41. Press a 1 1/2” Square Inner Cap (32) into the Leg Lever (29). Lubricate the 5/16” x 2 1/4” Bolt (33). Attach the Leg Lever (29) to the Front Seat Frame (36) with the Bolt and a 5/16” Nylon Locknut (3). Insert the 5/16”...

- Page 20 44. Remove the adhesive backing from the PRO 9400 decal and apply it to the Front Upright (42). 45. Make sure that all parts have been properly tightened. The use of the remaining parts will be explained in ADJUSTMENTS, beginning on page 21 of this manual. Before using the weight system, pull each cable a few times to be sure that the cables move smoothly over the pulleys.

-

Page 21: Adjustments

ADJUSTMENTS The instructions below describe how each part of the weight system can be adjusted. Refer to the exercise guide accompanying this manual to see how the weight system should be set up for each exercise. IMPOR- TANT: When attaching the lat bar or nylon strap, make sure that the attachments are in the correct start- ing position for the exercise to be performed. - Page 22 ATTACHING AND REMOVING THE SEAT To attach the Seat (13), set the bracket on the Front Seat Frame (36) onto the indicated pin on the Front Upright (42). Attach the Front Seat Frame to the Front Upright with the 5/16” x 2 3/4” Carriage Bolt (14), 5/16”...

-

Page 23: Weight Resistance Chart

WEIGHT RESISTANCE CHART This chart shows the approximate weight resistance at each weight station. “Top” refers to the 6.5 lb. top weight. The other numbers refer to the 12.5 lb. weight plates. The butterfly arm resistance listed is the resistance for each butterfly arm. -

Page 24: Trouble-Shooting And Maintenance

TROUBLE-SHOOTING AND MAINTENANCE TIGHTENING THE CABLES Woven cable, the type of cable used on the weight system, can stretch slightly when it is first used. If there is slack in the cables before resistance is felt, the cables should be tightened. If any slack is felt when using the front weight stack, both the High Cable (58) and the Low Cable (23) will need to be tightened. -

Page 25: Cable Diagrams

CABLE DIAGRAMS The cable diagrams on these pages show the proper routing of the High Cable (58), the Low Cable (23), the Military Press Cable (72), and the Leg Press Cable (78). Use the diagrams to be sure that the four cables and the cable traps have been assembled correctly. - Page 26 Military Press Cable (72) and Leg Press Cable (78) Military Press Cable (72) Ball End 1—Long “U”-Bracket Rear Weight Stack—1 4—Rear Seat Frame Leg Press Cable (78)

- Page 27 EXPLODED DRAWING—Model No. WESY39310 3/8" Washer (9) 5/16" Washer (8) 1/4" Washer (10) 1/4" x 3/4" Screw (18) 1 1/8" x 2 1/2" Plastic Bushing (89) "V"-Pulley (50) (Not shown to scale) 1/4" x 2" Machine Screw (81) 3/8" Nylon Locknut (21) 3/8"...

- Page 28 3/8" x 2 1/2" Bolt (86) 5/16" x 2 1/2" Carriage Bolt (1) 5/16" x 2 1/2" Bolt (22) 5/16" x 2 3/4" Bolt (11) 1/4" x 2 1/2" Carriage Bolt (92) 5/16" x 2 3/4" Carriage Bolt (14) 1/4" x 2 1/2" Screw (43) 3/8"...

- Page 29 5/16" x 2" Eyebolt (35) 1" Round Cover Cap (70) 3/4" Round Inner Cap (34) Round Inner Cap (75) 1" Round Inner Cap (49) 1/2" x 3/4" Spacer (61) 5/8" x 9/16" Spacer (7) 1" Square Inner Cap (6) 2" Square Inner Cap (27) 1 1/2"...

- Page 30 PART LIST—Model No. WESY39310 Key No. Qty. Description 5/16” x 2 1/2” Carriage Bolt 1/4” Nylon Locknut 5/16” Nylon Locknut Base Stabilizer 1” Square Inner Cap 5/8” x 9/16” Spacer 5/16” Washer 3/8” Washer 1/4” Washer 5/16” x 2 3/4” Bolt 3/8”...

- Page 31 EXPLODED DRAWING—Model No. WESY39310 R1101A...

-

Page 32: Ordering Replacement Parts

Friday, 6 a.m. until 6 p.m. Mountain Time (excluding holidays). To help us assist you, please be prepared to give the following information: 1. The MODEL NUMBER of the product (WESY39310) 2. The NAME of the product (WEIDER 3. The SERIAL NUMBER of the product (see the front cover of this manual) 4.

Need help?

Do you have a question about the WESY39310 and is the answer not in the manual?

Questions and answers