Subscribe to Our Youtube Channel

Summary of Contents for Spearhead AGRICUT 180

- Page 1 8999129: v1 11/09/2018 AGRICUT 180 Page 1.1 of 1.11 pages Original instructions (ENGLISH) Website: www.spearheadmachinery.com...

- Page 2 The information given throughout this manual is correct at the time of publication. However, in the course of constant development of Spearhead machines, changes in specification are inevitable. Should you find the information given in this book to be at variance with the machine in your possession, you are advised to contact the Spearhead Service department where up-to-date information will be provided.

- Page 3 8999129: v1 11/09/2018 EC DECLARATION OF CONFORMITY Conforming to EU Directive 2006/42/EC & ISO 9001:2015 Of SPEARHEAD MACHINERY LIMITED, Station Road, Salford Priors, Evesham, Worcestershire, WR11 8SW, Declare that under our sole responsibility the product (type); Rotary Mower Product Code...

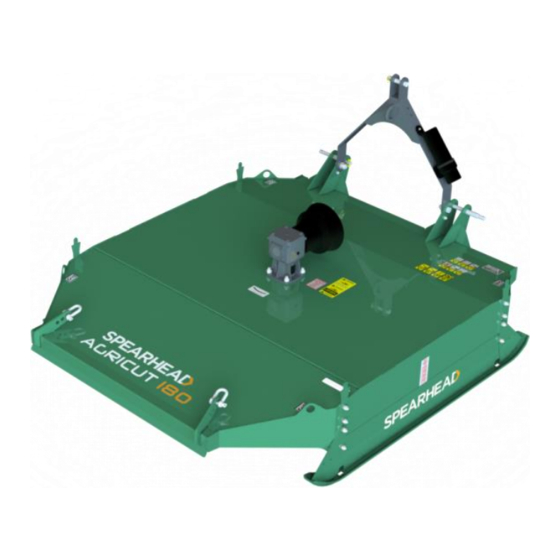

- Page 4 Agricut 180: 1.80m Cut, 540 PTO, In-line Topper This manual covers the Agricut 180 series of topper mowers which are 1.80m cut, rear mounted, 540 PTO, in-line machine, perfect for grasslands and paddocks. These efficient, small farm machines consist of a main deck, A- frame linkage system and individual swinging blades.

-

Page 5: Table Of Contents

8999129: v1 11/09/2018 Contents List Machine Description ..........................7 Intended usage ......................... 7 General arrangement ........................ 8 Machine rotation convention ..................... 9 Machine general specification....................9 Safety ..............................1 Safe operation ........................... 1 Safety warnings ......................... 1 Stopping in an emergency ......................6 Dangers due to overhead power lines .................. - Page 6 8999129: v1 11/09/2018 Power Take Off (P.T.O.) Shaft ....................2 8.4.1 Seasonal slip clutch maintenance. (If fitted) ............... 2 Driveline ............................ 3 8.5.1 Gearbox Mountings Bolts .................... 3 8.5.2 Oil Level ........................3 8.5.3 Draining & Refilling ...................... 3 Blade bar ........................... 4 8.6.1 Blade bar Maintenance ....................

-

Page 7: Machine Description

The Spearhead Agricut has a 1.80 metre cutting width that is suitable for use with tractors from 30 to 70 HP. The cutting height of the machine is manually adjustable and features a ‘self-levelling’ system to ensure the deck remains parallel irrespective of the cutting height. -

Page 8: General Arrangement

8999129: v1 11/09/2018 General arrangement The layout and naming convention used throughout this manual are shown in Figure 1.2 below A-Frame PTO Shaft Transport strap Literature Holder Central Gearbox Deck Lifting Points Lifting Points (Both sides) Blade Carrier Blade Rotor Hub Skid Figure 1.2 Page 1.8 of 1.11 pages... -

Page 9: Machine Rotation Convention

Shredder Blade Kit Notes: (1) Spearhead Machinery constantly reviews and improves product designs and reserve the right to change this information. As a consequence actual machines may vary from specification. Contact your Spearhead Sales representative if you have any queries. - Page 10 8999129: v1 11/09/2018 Figure 1.3 Cut and Deck dimensions Page 1.10 of 1.11 pages Original instructions (ENGLISH) Website: www.spearheadmachinery.com...

- Page 11 8999129: v1 11/09/2018 Figure 1.4 Transport position Figure 1.5 Shipping position Lifting Lifting points points Lifting Lifting points points Figure 1.6 Lifting points Page 1.11 of 1.11 pages Original instructions (ENGLISH) Website: www.spearheadmachinery.com...

-

Page 13: Safety

8999129: v1 11/09/2018 Safety Safe operation This user manual should be considered as part of the machine. The operator should read the following pages carefully and become familiar with the contents before starting work. Familiarity with the instruction manual is an essential part of training for a competent user. - Page 14 8999129: v1 11/09/2018 DANGER! AVOID WIRE. It can be extremely dangerous if wire catches in the blades of the machine, and every care must be taken to ensure this will not happen. Inspect the working area before commencing. Remove all loose wire and obstructions and clearly mark those that are fixed so that you can avoid them.

- Page 15 8999129: v1 11/09/2018 DANGER! Operate the mower only with a tractor equipped with an approved ‘roll over protection system (ROPS). Always wear your seat belt. Serious injury or even death could result from falling off the tractor – particularly during a turnover when the operator could be pinned under the ROPS or the tractor.

- Page 16 WARNING! Never operate the machine with any parts missing. Check the machine regularly for loose or damaged parts. Pay attention to the condition of all safety guards. Always use genuine Spearhead replacement parts in the interest of safety. Failures caused by the use of unapproved replacement parts will not be covered by our warranty, nor will any liability be accepted for damages or injury thus incurred.

- Page 17 CAUTION! When driving on public roads, respect all road rules in force. CAUTION! Spearhead Machinery will not be held responsible for failure caused by the use of incorrect lubricants. For further information, refer to the lubrication section of this manual.

-

Page 18: Stopping In An Emergency

8999129: v1 11/09/2018 Stopping in an emergency In an emergency bringing the blades to a stop requires familiarity with the controls fitted to the tractor. To stop the blades in an emergency, use the tractor ‘ENGINE STOP’ control. NOTE: The use of the tractor ‘ENGINE STOP’... -

Page 19: Noise

8999129: v1 11/09/2018 Figure 2.1 - Minimum heights for overhead power lines Figure 2.2 - Absolute Minimum Exclusion Zones for Specific Overhead Power Lines Figure 2.3 - Definitions of Exclusion Zones Noise The equivalent daily personal noise exposure from this machine, measured at the operator's ear, is within the range of 80-85dB when used in conditions where the load fluctuates between zero and maximum. -

Page 20: Personal Protective Equipment

Spearhead Machinery disclaim all responsibility for any damage or injury arising as a result of guards being removed, or of guards other than of Spearhead manufacture having been fitted, or of operation of the machine other than in accordance with these instructions. -

Page 21: Working On Inclined Ground

When working on top of embankments it is very important to have sufficient forward stability to ensure rapid steerage control. Spearhead recommend 20% forward stability. This means that at least 20% of the total vehicle weight is acting on the steering axle under normal level conditions. -

Page 23: Safety Decals

8999129: v1 11/09/2018 Safety Decals Safety decals are located on various points of the machine. To identify the correct location, refer to the serial number specific Parts book supplied with your machine. Safety decals can be identified by the yellow upper panel depicting the hazard, and the lower white panel indicating means of avoidance or precautions to be taken. -

Page 25: Lubricants

Use oils compatible with classification API GL-5, see Figure 4.1. WARNING! Only use oil which is compatible with the above classification. Recommended Machine type Gearbox Capacity (Litres) oil type Agricut 180 EP 80W-90 90-degree blade drive box in-line Figure 4.1 Page 4.1 of 4.1 pages Original instructions (ENGLISH) -

Page 27: Installation

8999129: v1 11/09/2018 Installation Unpacking the machine Check that the machine instruction manual is in the document holder attached to the machine. The operator’s manual should be regarded as part of the machine. Suppliers of both new and second-hand machines are advised to retain documentary evidence that this manual was provided with the machine. -

Page 28: Tractor Preparation

Ensure that the tyres fitted to the tractor are correctly rated for the total working weight. NOTE: When the cutting unit is fully side shifted the load on the rear tyre on the cutting side increases. Spearhead does not endorse the use of water ballast within tyres as this can have adverse effects on fore aft stability at speed. -

Page 29: Attaching The Machine

8999129: v1 11/09/2018 Attaching the machine Attachment of the machine should be performed on a firm level site - the procedure for attachment is as follows; Cat II link Cat link ‘A’ frame Cat II link pins pins pins 3pt linkage lift strap Figure 5.3 5.3.1.1... -

Page 30: Setting The Cutting Height

8999129: v1 11/09/2018 5.3.2 Setting the cutting height WARNING: Before attempting to access the underside of the machine, ensure it is adequately and safely supported. Do not rely on the tractor’s hydraulics. Use safety supports that are capable of supporting the machine mass indicated in Section 1.4 Machine general specification. -

Page 31: Shortening The Pto Length

Apply the parking brake and stop the tractor. If any faults are identified, refer to ‘Trouble shooting’ section. If a solution is still not found, consult your local Spearhead dealer for assistance. Page 5.5 of 5.6 pages Original instructions (ENGLISH) -

Page 32: Checking Head Float

Checking Head float All Spearhead machines have head float fitted as standard. Head float allows the cutting unit to pitch fore - aft around the lower link pins, smoothing out undulating ground. To check the head float operation, adjust the top link to slacken off the transport strap and allow approximately 50.0 mm of play when the machine is lowered onto... -

Page 33: General Operation

The Spearhead Agricut range is primarily designed for the topping of grass pasture land after grazing, or for thistle and weed control on agricultural land and must not be used for any other purpose. The Spearhead Agricut range is not designed for grass mowing, set-aside cutting or brush/woodland clearance. Use in any other way than stipulated above is considered as contrary to the intended use. -

Page 34: Operator Use And Adjustment

8999129: v1 11/09/2018 Operator use and adjustment WARNING! Before use ensure that all operators have read and thoroughly understood all the safety procedures. For further information refer to the relevant sections of this manual. 6.4.1 Machine Settings and Adjustments WARNING! Before working on any piece of attached machinery, ensure that the tractor engine is turned off and the starter key removed to prevent anyone else from starting the tractor while it is being worked on. -

Page 35: Shear Bolt Protection (If Fitted)

‘A’ frame or the headstock gearbox mounting plate. Ensure the bolt is correctly tightened, see Figure 6.3. CAUTION: Only use the size and grade of shear bolt as supplied by Spearhead Machinery. For further information refer to the Serial number specific parts book supplied with your machine. -

Page 36: Transportation To Work Site

8999129: v1 11/09/2018 6.4.5 Transportation to work site With the PTO shaft correctly connected, raise the machine to a safe transport position. Lock the lift arm stop in this position. Check that there is no lateral movement on the machine when it is in the raised position. Adjust the tractor stabiliser chains (or bars) if required. -

Page 37: Start-Up

8999129: v1 11/09/2018 Lower the machine so that the skids are on the ground, apply tractor hand brake, and turn off engine. If possible set the lift arms to float to allow the skids to follow side to side undulations in the ground. If necessary, adjust the top link to slacken the transport strap to allow for 50mm of play. -

Page 39: Removal, Storage And Disposal

8999129: v1 11/09/2018 Removal, Storage and Disposal Before removing the machine from the tractor, a thorough check of the machine should be made. Preparation for Storage At the end of the season the machine should be readied for winter storage. Carry out the following: 7.1.1.1 Clean the machine thoroughly. -

Page 40: Removal

Children are never allowed to play close to the machine. Disposal When Spearhead equipment reaches the end of its economic working life it should be disposed of responsibly, either through an approved recycling centre or by compliance with all applicable regulations in force in its final destination territory. -

Page 41: Maintenance

8999129: v1 11/09/2018 Maintenance Regular Maintenance chart Regular maintenance carried out at the intervals specified in the maintenance chart will ensure that the machine operates correctly and safely and minimise operational down time. Maintenance intervals Component type and maintenance guideline P.T.O. -

Page 42: Power Take Off (P.t.o.) Shaft

8999129: v1 11/09/2018 8.3.1.1 Avoid excessive skin contact with used lubricating oils and always adhere to the health protection precautions. 8.3.1.2 Avoid prolonged and repeated contact with oils, particularly used engine oils. 8.3.1.3 Wear protective clothing, including impervious gloves where practicable. 8.3.1.4 Avoid contaminating clothes with oil (particularly those next to the skin). -

Page 43: Driveline

8999129: v1 11/09/2018 Driveline 8.5.1 Gearbox Mountings Bolts Check the gearbox mounting nuts and bolts at the intervals stated in the regular maintenance chart, see section 0 and retighten if required. Locations of the mounting nuts and bolts are indicated in Figure 8.2. 8.5.2 Oil Level Check the gearbox oil level at the intervals stated in the regular maintenance chart. -

Page 44: Blade Bar

8999129: v1 11/09/2018 Blade bar WARNING! Ensure that the machine is safely supported using suitable lifting and support equipment before attempting to work beneath a machine – never use or rely on the tractor’s hydraulic system to support the machine 8.6.1 Blade bar Maintenance Check the rotor hub for slack. -

Page 45: Fastener Torque Guidelines

CAUTION: This table refers to bolts that MUST be tightened to the figure shown. Where a specific torque setting is given it should be used instead of the information shown in the Figure 8.6. Specific Torque settings for Agricut models (Nm) Agricut 180 Fastener in-line... -

Page 47: Trouble Shooting

Trouble shooting Trouble shooting – Rotary mower issues Symptom Possible cause Remedy Missing Blades Replace opposite blades as pairs Broken Blades Replace opposite blades as pairs Machine vibration. Check that a 540rpm machine is not run Wrong PTO speed at 1000rpm Blades touching one Re index the blades but check that there Blades are out of timing... -

Page 49: Warranty Information

All spare parts supplied by Spearhead Machinery and purchased by the end user are warranted to be free from defects in material and workmanship from the date of sale to the original purchaser for a period of 6 months. All parts warranty claims must be supported by a copy of the failed part invoice to the end user. -

Page 50: 10.1.3 Remedies And Procedures

Any fault must be reported to an authorised Spearhead Machinery dealer as soon as it occurs. Continued use of a machine, after a fault has occurred, can result in further component failure for which Spearhead Machinery cannot be held liable. -

Page 51: How To Make A Claim

In the event of a warranty claim being made, the process of making a claim will be carried out entirely by your selling agent. This is an arrangement that exists between Spearhead Machinery and its agents. All claims will be made via the Spearhead Machinery web site. - Page 52 Page 11.2 of 11.1 pages Original instructions (ENGLISH) Website: www.spearheadmachinery.com...

Need help?

Do you have a question about the AGRICUT 180 and is the answer not in the manual?

Questions and answers