Summary of Contents for Spearhead Rollicut 500

- Page 1 Spearhead Rollicut 500 & 600 Rollicut 500 & 600 Rotary Mower Edition 1.0 – January 2015 Part No. 8999092...

- Page 2 VERIFICATION OF WARRANTY REGISTRATION DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION It is imperative that the selling dealer registers this machine with Spearhead Machinery Limited before delivery to the end user – failure to do so may affect the validity of the machine warranty.

- Page 3 1.02. All spare parts supplied by Spearhead Machinery Limited are warranted to be free from defects in material and workmanship from the date of sale to the original purchaser for a period of 6 months.

- Page 4 Machinery web site and confirms the registration to the purchaser by completing the confirmation form in the operator’s manual. 2.02. Any fault must be reported to an authorised Spearhead Machinery dealer as soon as it occurs. Continued use of a machine, after a fault has occurred, can result in further component failure for which Spearhead Machinery Ltd cannot be held liable.

- Page 5 Spearhead Rollicut 500 & 600 CE Declaration of Conformity, Conforming to EU Machinery Directive 2006/42/EC We, Spearhead Machinery Ltd, Green View, Salford Priors, Evesham, Worcestershire, WR11 8SW hereby declare that: Product ……………………………………………..………………………… Product Code ……………………………………………..………………………… Serial No ……………………………………………..……..…………………. Type ……………………………………………..…………………………...

-

Page 6: Table Of Contents

Spearhead Rollicut 500 & 600 Contents Safety Recommendations Safety Stickers Safety Decal Location Introduction Machine Specification Serial Number Plate Location Tractor Requirements Setting up your Machine Attaching to the Tractor Drawbar Length Shortening the Input PTO Drive Shaft Connecting PTO Shaft... -

Page 7: Safety Recommendations

Spearhead Rollicut 500 & 600 SAFETY RECOMMENDATIONS Beware of the following Potential Dangers associated with the use of this machine Becoming trapped when hitching or unhitching Getting caught on rotating power take off (PTO) Being hit or caught by any moving parts, e.g. belts, pulleys, arms and cutting body ... - Page 8 Spearhead Rollicut 500 & 600 Ensure that the tractor meets the minimum weight recommendations of the machine manufacturer Check that machine fittings and coupling are in good condition Follow the manufacturers instructions for attachment and removal of the machine from the tractor ...

-

Page 9: Safety Stickers

Spearhead Rollicut 500 & 600 Machine Safety Stickers A B C Warning Warning Warning Warning Danger – flying objects Shut off engine and Avoid fluid escaping Stay clear of falling keep safe distance from remove key before under pressure. Consult... -

Page 10: Safety Decal Location

Spearhead Rollicut 500 & 600 Safety Decal Location B, E, F B, E, F A, C, H D, G B, E, F... -

Page 11: Introduction

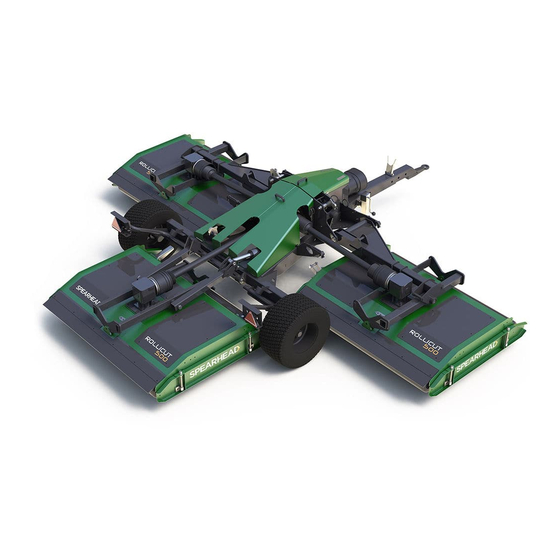

Spearhead Rollicut 500 & 600 Introduction to the Machine The Rollicut Rotary mower is a very robust high capacity roller mower that is easy to operate and maintain. The machine consists of three individual roller mower bodies mounted to a chassis and towed by a tractor. This results in a machine that can mow a wide area quickly and efficiently but also able to fold up to a compact size to travel on the road. -

Page 12: Machine Specification

Spearhead Rollicut 500 & 600 Machine Specification... - Page 13 Spearhead Rollicut 500 & 600 Options Wheels we offer an option of low ground pressure wheels, ideal for turf, or alternatively a road wheel which is ideal for road transport, especially for a machine which is used between several sites.

-

Page 14: Serial Number Plate Location

The operator’s manual is located on the centre chassis by the serial plate in the manual holder. Tractor Requirements Spearhead recommended 70 – 80HP tractor for the Rollicut 500 80 – 90HP tractor for the Rollicut 600. Fixed clevis drawbar minimum height (17”) 430mm, at maximum extension (14”) 355mm. -

Page 15: Setting Up Your Machine

Spearhead Rollicut 500 & 600 Setting Up Your Machine Attaching to the Tractor It is advisable to remove the tractor rear link arms. However, if this is not convenient, lift the link arms to their highest position or lower them to their lowest position so they do not contact the PTO shaft or drawbar when turning. -

Page 16: Drawbar Length

Spearhead Rollicut 500 & 600 Drawbar Length The drawbar is adjustable to set both the height and length of the hitch. The drawbar length may need to be lengthened if wide turf tyres are fitted to the tractor. To adjust the drawbar remove the two bolts and adjust as required. Set the drawbar... -

Page 17: Shortening The Input Pto Drive Shaft

Spearhead Rollicut 500 & 600 Shortening the Input PTO Shaft Before fitting the PTO for the first time, it may be necessary to adjust the length. There should be maximum engagement of the sliding tubes without bottoming at the shortest operation position. -

Page 18: Connecting Pto Shaft

Spearhead Rollicut 500 & 600 Connecting Input PTO Shaft To fit the PTO, first clean and grease. Press pins on the yoke and simultaneously push the PTO drive shaft onto the PTO shaft of the tractor until the pins engage. Pull back on the shaft to check the shaft is securely attached The PTO shaft is fitted with a non-rotating safety guard. -

Page 19: Storage Jack

Spearhead Rollicut 500 & 600 Storage Jack The jack can be stored when not in use in the tool box at the front of the machine. ... -

Page 20: Lights

Spearhead Rollicut 500 & 600 Lights The lights are connected to the tractor with a 7 pin plug. When the lights are connected they should be checked to make sure all functions work correctly before road work is undertaken. -

Page 21: Transport Release Rope

Spearhead Rollicut 500 & 600 Transport Lock Release Rope The transport lock release rope should be secured in the tractor cab in a location where it is able to be pulled whilst operating the auxiliary hydraulic controls. Ensure that the rope stays away from the input shaft and any other moving parts. It must also be ensured that the rope does not come tight when travelling over undulating ground or turning. - Page 22 Spearhead Rollicut 500 & 600 OPERATOR PULLING ROPES TO RELEASE THE TRANSPORT LOCKS AS THE OPERATOR PULLS THE ROPES TO RELEASE THE TRANSPORT LOCKS THEY ALSO NEED TO PRESSURISE THE WING AND REAR BODY LIFT RAMS...

- Page 23 Spearhead Rollicut 500 & 600 PRESSURISE LIFT RAM AND PRESSURISE LIFT RAM AND PULL ROPE TO LIFT HOOK PULL ROPE TO LIFT HOOK CLEAR OF LOCKING BAR CLEAR OF LOCKING BAR ON WING ARM ON WING ARM ONCE HOOK IS CLEAR, OPERATE SPOOL LEVER TO LOWER WINGS.

-

Page 24: Uncoupling Machine

Spearhead Rollicut 500 & 600 Uncoupling the Machine To uncouple the machine park the machine on level ground either with wings in transport position or lowered to the ground. If in transport position ensure that the transport lock are taking the weight of the wings. - Page 25 Spearhead Rollicut 500 & 600 Unplug the lights, hydraulic pipes and remove the transport release rope from cab. Disconnect the input PTO shaft and place on the PTO stand. PTO STAND...

- Page 26 Spearhead Rollicut 500 & 600 Fit the jack and slightly raise the mowers towing eye off the tractor drawbar. Remove the drawbar pin and check there is nothing connected between the tractor and mower before pulling the tractor forward.

-

Page 27: Before Operating Machine

Spearhead Rollicut 500 & 600 Before Operating Machine Daily Checks Daily checks must be carried out before starting work. Check all nuts and bolts are tight Check tyres for any damage Check blades are not broken or bent ... -

Page 28: Cutting Height

Spearhead Rollicut 500 & 600 Cutting Height The Rollicut roller mower is fitted with rollers front and rear of the mowing body. The height off these rollers are used to adjust the cut height of the machine. The rollers and skid combination makes the cutting operation very safe as the blades are all enclosed. -

Page 29: Travelling Between Jobs

Spearhead Rollicut 500 & 600 Traveling Between Jobs 1. Disengage PTO drive. 2. Raise mowing body’s insuring transport locks engage 3. Turn on headlights and warning lights. Starting Mowing Job Engage the PTO only when the tractor engine is at low revs to prevent shock load damage to machine. -

Page 30: General Operation

Spearhead Rollicut 500 & 600 General Operating Tips Running PTO at speeds over 540rpm the blades over speed causing undue stress, this can result in blades breaking and coming off causing risk of injury or death. For best mowing results mow in dry conditions, the finish achieved will vary with several factors: grass length, terrain, moisture. -

Page 31: Servicing & Maintenance

Spearhead Rollicut 500 & 600 Service and Maintenance WARNING Never carry out any servicing or maintenance work without first disengaging the PTO, stopping the engine and removing the key. Safety First Never leave the tractor seat without first disengaging the PTO and stopping the engine. -

Page 32: Transmission Covers

Spearhead Rollicut 500 & 600 Transmission Covers On the top of each of the mowing bodies there are two covers, these are to guard the operator from the moving parts inside and also to keep grass and debris away from the transmission. -

Page 33: Blades

The blades can be removed with only one spanner/tool due to the bolt being located into the blade carrier by a square location shoulder. WARNING Genuine Spearhead Blades must be used due to Safety reasons or otherwise Warranty will also be void... -

Page 34: Greasing

Spearhead Rollicut 500 & 600 Greasing PTO Shaft Maintenance & Greasing Primary Drive The primary drive shaft has fitted a combined overrun and slip clutch; this should be stored in the dry. After a long period of storage/use it may be necessary to disassemble the clutch to check its condition. -

Page 35: Spindle Greasing

Spearhead Rollicut 500 & 600 Spindle Greasing The rotor spindles are greased form the factory, so should only need additional grease as the grease is used during operation. To grease the spindles on each body, there are a bank of 3 grease nipples at the rear of the body on the top face. - Page 36 Spearhead Rollicut 500 & 600 WARNING It is imperative the grub screws are checked on the pulley taper locks fitted to the output shaft of the gearboxes and the top shaft on the spindles (once bedded in, loctite glue may prove useful).

-

Page 37: Roller Greasing

Spearhead Rollicut 500 & 600 Roller Greasing The roller bearings are greased form the factory, so should only need additional grease as the grease is used during operation. There are grease nipples located in the end skids of each body which are used to grease the roller bearings. -

Page 38: Gearboxes

Spearhead Rollicut 500 & 600 Gearbox Before first use check gearbox oil level, thereafter check every 8 hours. - Page 39 Spearhead Rollicut 500 & 600 After the first 50 hours drain and replace the gearbox oil, There-after, annually. Replace with EP90. Regularly inspect gearbox seals. If oil is leaking replace immediately. It is your responsibility to maintain a long and reliable working life.

-

Page 40: Tyres And Wheels

Spearhead Rollicut 500 & 600 Tyres and Wheels Check wheel nuts for tightness (140Nm) Tyre pressures: Turf Tyres – 39psi max Road Tyres – 60psi... -

Page 41: Cleaning The Mower

Spearhead Rollicut 500 & 600 Cleaning the Mower WARNING Do not direct water jets from high pressure hoses directly at any electrical components or bearing or belt components If debris gathers around these parts remove it by brushing or low pressure compressed air. -

Page 42: Service Schedule

Spearhead Rollicut 500 & 600 Service Schedule The following service schedule is layout as a record to maintenance carried out on your machine. This service schedule covers 4 weeks of operation. Please copy this page to continue your record. DATE HOURS SERVICED BY... -

Page 43: Trouble Shooting

Spearhead Rollicut 500 & 600 Trouble shooting Problem Cause Solution Oil level incorrect Check oil level Gearbox Overheating Oil grade incorrect Check oil grade Implement overloaded Reduce forward speed Wrong P.T.O. speed Ensure tractor P.T.O. speed matches implement Belt and Pulley condition... -

Page 44: Transporting Mower

Spearhead Rollicut 500 & 600 Transporting Mower First disengage the PTO drive and fully raise the machine. Fold the wings to fully upright and ensure the locking hooks engage. Lift rear mower to maximum and ensure the locking hooks engage fully. - Page 45 Spearhead Rollicut 500 & 600...

- Page 46 Spearhead Rollicut 500 & 600 Spearhead Machinery Limited Green View, Salford Priors, Evesham, Worcestershire, WR11 8SW Tel: 01789 491860 Fax: 01789 778683 www.spearheadmachinery.com enquiries@spearheadmachinery.com...

Need help?

Do you have a question about the Rollicut 500 and is the answer not in the manual?

Questions and answers