Summary of Contents for Tractel derope Series

- Page 1 derope ® emergency escape/controlled descent devices use and Meets or exceeds standards requirements established by maintenance ANSI Z359.4-07 instructions CSA Z259.2.3, type 1E...

-

Page 2: Table Of Contents

ALL instructions contained herein must be carefully read and strictly followed for proper use and maintenance of the equipment. Alterations or misuse of this product, or failure to follow instructions can result in serious injury or death. If you have any concerns or questions, please contact your distributor or Tractel ®... -

Page 3: First Read The Following Warnings

This includes all parts that constitute the rescue equipment, especially the harness and connecting equipment. Tractel denies liability for any incident due ® to non compliance of components not sold or not recommended by Tractel ® TRAINING AND QUALIFICATION Do not use the derope emergency escape/controlled descent device unless properly ®... - Page 4 ® ® repair having been carried out beyond its control. Except for the operations described in this manual, the maintenance and repair of Tractel ® xvii equipment, must be exclusively performed by authorised (written approval) Tractel service ®...

- Page 5 Hazardous situation leading to serious injuries or death. NOTICE Possibly dangerous situation leading to damage to equipment or surroundings. Always concerned to improve the quality of its products, Tractel reserves ® the right to modify the specifications of the equipment described in this manual.

-

Page 6: Function And Description

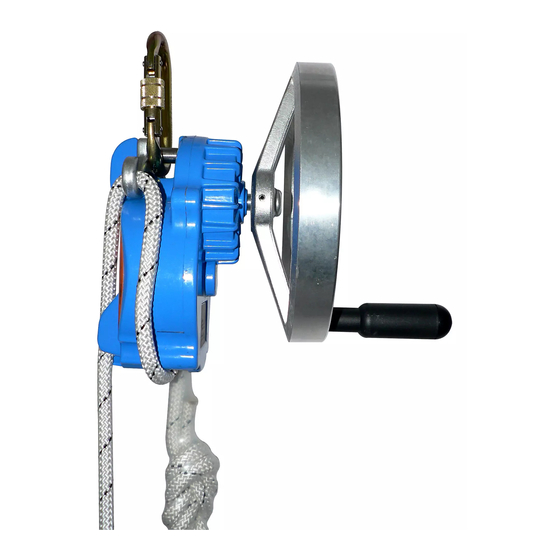

Pig tails and a jamming cleat give with a bracket designed exclusively for the users even more control on the descent speed. Tracpode™ positioning tripod from Tractel ® Cooling fins ensure that the unit is rapidly This bracket must be fastened to one of the legs available for consecutive descents. - Page 7 Adjustable lanyard to secure the system Rope adjuster Carabiner Pig tail Carabiners Pig tail Upper clamp jaw Casing Jamming cleat Anchor Kernmantle rope ® (Descent extremity) Lower clamp jaw Kernmantle rope ® (Ascending Knurled extremity) knob Self-locking snap hook Knurled knob derope Fig. 3 ®...

-

Page 8: Limitation Of The Equipment

Following each use, whether for a single descent DANGER or repeated descents, the derope descent device ® Only the Tractel Kermantle that comes with must be inspected by a technician trained and ® ® the device is authorized for use with the derope qualified for this operation. -

Page 9: System Component Requirements

Exposure to chemicals may cause equipment malfunction. If your equipment will be exposed to chemicals and you are unsure of the effects Make sure there is no obstacle on your equipment, please contact Tractel ® in the evacuation path Moving machinery Take extreme caution when working near or around moving machinery. -

Page 10: Installation

of supporting the worker. For rescue purposes, the anchorage point must support a minimum of 3,100 lbs. (13.8 kN) per attached worker. Consult local, state, federal and provincial regulations as revisions occur. 3.2.1 Every anchorage point must be selected with care. - Page 11 4.3.4 When the derope Up R descent device is ® WARNING installed on the bracket used with the Tractel ® tracpode tripod: The derope Up E descent device must always be ™ ®...

-

Page 12: Operation

f) Lock the fastening pin using the safety pin WARNING (Figure 12b, page 12). Always use a self-locking snap hook for an g) Fully unfold the three legs of the tracpode ™ attachment in any personal rescue system. tripod. h) Remove the ball pin located above the idler pulley at the top of the tracpode tripod Evacuation function... - Page 13 g) Descent may be interrupted by firmly WARNING grasping the free end of the lifeline. Ensure that the free end of the Kenmantle rope is ® h) Once the person has reached the ground, inserted in the jamming cleat. unfasten the person from the harness.

-

Page 14: Marking And Labeling

D-ring to his own frontal Cleaning attachment point using a 1 ft. (0.3 m) lanyard. Upon ensuring of the proper connection holding Most of Tractel ’s equipment can be washed ® the victim to the rescuer frontal attachment with a solution of cold water and mild point, the rescuer can cut the victim’s lanyard... - Page 15 Fig. 15...

-

Page 16: Performance Data

Inspection schedule hardware, bracket and housing should be A thorough inspection of the working components inspected for rough or sharp edges, corrosion, is required by Tractel or an authorized service burrs, cracks dents and distortion. Ensure ® center upon meeting one of the following critiria: the presence of all screws and that they are a) One person: up to 3,280 ft. -

Page 17: Warranty Information

10.5 Any defect in this equipment must immediately WARNING be brought to the attention of Tractel . The ® distributor will make arrangements with the Any equipment that fails to meet the above factory for repairs or replacements of the parts inspection requirements shall be removed from within the terms of this warranty. - Page 18 derope decent device model: ® Lot number of the manufacturer: Serial number of the manufacturer: Owner/User: Date of purchase: First use: Date of inspection Inspection results, details of identified defects Signature of competent person...

- Page 19 derope decent device model: ® Product serial number: Owner/Training facility: Evacuation Hoisting height Result of visual Trainer’s Date of use Trainer/User height and and weight inspection signature weight of trainee of trainee Maximum number of repeated descents < 165 ft. < 410 ft. <...

- Page 20 CONTACT THE NEAREST TRACTEL OFFICE. ® UNITED STATES CANADA BOSTON LOS ANGELES MONTREAL 1.800.421.0246 1.800.675.6727 1.800.561.3229 tractel.usa-east@tractel.com tractel.usa-west@tractel.com tractel.canada@tractel.com 51 Morgan Drive 168 Mason way Unit B2, 11020 Mirabeau St. Norwood, MA 02062 City of Industry, CA 91746 Montreal, Quebec H1J 2S3 Tel.

Need help?

Do you have a question about the derope Series and is the answer not in the manual?

Questions and answers