Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Merrylock MK740DSA

- Page 2 “IMPORTANT SAFETY INSTRUCTIONS“ When using an electrical appliance, basic safety precautions should always be followed, including the following: Read all instructions brfore using this overlock sewing machine. “DANGER“___ To reduce the risk of electric shock: 1. The appliance should never be left unattended when plugged in. 2.

- Page 3 17. If oil gets in eyes, immediately, rinse the oil out with water. If you swallow oil by mistake, immediately consult a medical doctor. 20. To reduce risk of injury, switch off before servicing. Close looper cover before operating. “SAVE THESE INSTRUCTIONS“ “This overlock sewing machine is intended for household use only.”...

- Page 4 CONSIGNES DE SECURITE Lors de l’utilisation de cette machine, les précautions élémentaires de sécurité doivent être pris es. Lisez attentivement toutes les consignes de sécurité suivantes avant de l’utiliser : DANGER - Pour reduire le risque de décharges électriques : * Ne laissez pas la machine sans surveillance lorsqu’elle est sous tension.

-

Page 5: Table Of Contents

TABLE OF CONTENTS 1. DETAILS OF THE MACHINE...... 16. SELECTION OF STITCHES....2. OPTIONAL PRESSER FEET...... 17. HANDY REFERENCE CHART....ACCESSORIES ......... CHAINING OFFAND TEST SEWING..4. NEEDLE INFORMATION......19. FLATLOCK SEWING ......PREPARATION PRIOR TO SEWING ..(1) Standard flatlock stitch ...... -

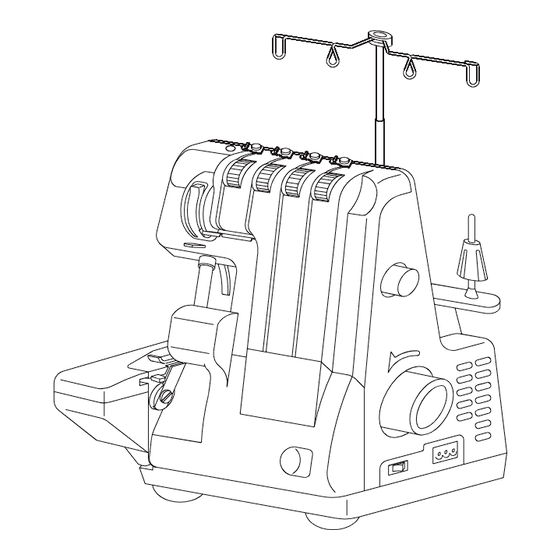

Page 6: Details Of The Machine

1. DETAILS OF THE MACHINE 1 Lower looper tension dial 2. Upper looper tension dial 3. Right needle tension dial 4. Left needle tension dial 5. Thread take up cover 6. Cloth plate 7. Looper cover 8. Lower looper tension dial 9. - Page 7 19. Knife guard 20. Presser foot 21. Cloth plate 22. Stitch plate 23. Handle 24. Bulb cover 25. Presser foot lifter 26. Differential feed dial 27. Accessory box Cutting width dial...

-

Page 8: Optional Presser Feet

2. OPTIONAL PRESSER FEET 1) Elastic Foot his foot is used for attaching elastic tape to the garment and the amount of contraction of the elastic tape can be adjusted as required. 2) Blind Hem Foot * This foot is for sewing cuffs on knit fabrics, skirt and trouser seams where seam should not be visible. -

Page 9: Accessories

3. ACCESSORIES 1. Screwdriver 2. Tweezers 3. Oiler 4. Cleaning brush 5. Set of needles ELx705 6. Net 7. Spool caps 8. Waste collector 9. Hexagon wrench 10. Upper knife 4. NEEDLE INFORMATION * This overlock uses a flat shank industrial needle that eliminates the possibility of inserting the needle backwards. -

Page 10: Reparing The Machine

6. REPARING THE MACHINE Assembling the hread tand Raise the support rod fully, turning slightly until the positioning catches engage. Thread ones The anti-vibration cone should be used with the wider edge to the bottom on the spool holder pin when sewing with cones. -

Page 11: How To Open Looper Cover

7. HOW TO OPEN LOOPER COVER * Push the cover to the right as far as it will go. * Pull cover down toward you. 8. HOW TO REMOVE AND INSERT NEEDLES (1) Needle position * With this machines, two needles can be inserted to the needle clamp as shown in the drawing. -

Page 12: Presser Foot Lifer

9. PRESSER FOOT LIFER To raise the presser foot, raise the lever on the rear of the machine until it engages. 10. OPTIONAL ACCESSORIES * The following optional presser feet specially prepared for this machine are available at extra-charge. Note: Do not use presser foot made for other machines. -

Page 13: Standard Overlock And Rolled Hem Stitching

11. STANDARD OVERLOCK AND ROLLED HEM STITCHING To sew standard overlock * Set seam width finger knob to N to move seam width finger to standard overlock sewing position. lever Note: Be sure to push seam width finger knob as far as it will go in the direction of setting N. -

Page 14: Threading The Upper Looper (Green)

To thread the machine correctly Be sure to turn off power switch. (1) Threading the upper looper (Green) * Thread the upper looper as indicated 1~7. * Raise Presser foot to release tension discs. * Pass thread from back to the front through the thread guide 1. -

Page 15: ( 2) Threading The Lower Looper (Red)

* Thread the looper area of the machine following the green color coded thread guides (4~7). Thread the hole in the upper looper from front to back 7. Note: Make sure thread passes behind lower looper. Note: Use tweezers provided in the accessory case to aid in threading the looper. - Page 16 * While holding thread with finger, pass it between the tension discs and pull thread down to make certain it is properly located in between the tension discs 3. * Turn the hand wheel toward you until the lower looper extends out 5~10mm from the throat plate edge.

-

Page 17: Threading The Right Needle (Blue) (B On Needle Clamp)

(3) Threading the right needle (Blue) (B on needle clamp) * Thread the right needle as indicated 1~9. * Raise Presser foot to release Tension discs. * Pass thread from back to the front through the thread guide 1. Thread the top cover thread guide by pulling the thread towards the left until it slips under guide. -

Page 18: Threading The Threading The Left Needle (Yellow) (A On Needle Clamp)

* Continue to thread points 4~9. Note: Slip thread into the rear slot on the thread guide 5 and bottom slot of take-up lever cover 6. Then slip thread into the right slot on the thread guide 7. * Before threading eye of needle, slip thread behind thread guide located on the bottom of the needle clamp. - Page 19 * Thread the top cover threadguide by pulling the thread towards the left until it slips under guide. Then pull thread along the right side of button as illustrated. * While holding thread with fingers, pass it between the tension discs and pull thread down to make certain it is properly located in between the tension discs 3.

-

Page 20: How To Change Threads: Tie On Method

13. HOW TO CHANGE THREADS: TIE ON METHOD * To change thread type or color, clip thread near the spool. * Place new thread on stand. * Tie new thread and old thread ends together with a square knot. Clip thread tails to 2~3cm (1 inch) length. -

Page 21: Stitch Widthadjustments

15. STITCH WIDTH ADJUSTMENTS * Overlock seam width can be achieved by repositioning the needle position and also with the width adjustment knob. djustment by changing (1) Width a needle position * Overlock seam width can be adjusted by changing the needle position. -

Page 22: Selection Of Stitches

16. SELECTION OF STITCHES This machine is capable of producing various types of stitches according to the combination of needle positions, threading methods, tension adjustment and the use of convertible right looper/ converter. Stitch Type Page 2-needle 4-thread stitch that is ideal for medium to heavyweight stretchy fabrics 1. - Page 23 * Depending on the needle positions used, this machine can sew 2-thread and 3-thread standard width 4 mm overlock and a 6 mm wide overlock seams. Also, for overedging heavyweight fabrics, the seam width can be increased still more by turning the overlock seam width adjustment knob.

-

Page 24: Chaining Offand Test Sewing

18. CHAINING OFF AND TEST SEWING * When the machine is completely threaded, bring all of the threads across the throat plate and slightly to the left under the presser foot. * Hold the threads and apply a slight tension. * Turn the hand wheel toward you 2 or 3 complete turns to start the thread chain. -

Page 25: Flatlock Sewing

19. FLATLOCK SEWING A flatlock stitch is made by sewing the seam and pulling the fabric apart to flatten the seam. The flatlock stitch can be used both as a decorative construction stitch, sewing two pieces together (Standard flatlock stitch), or for embellishment on only one piece of fabric (Ornamental flatlock stitch). -

Page 26: Differential Feed

20. Differential feed * There are two feed dogs one front and one rear. The two feed dogs move independently and the distance each feed dog travels during one complete movement can be adjusted. (1) Stretching effect * To stretch the fabric select a number from N to 5 in the section “... -

Page 27: Suggested Tension Setting

21. SUGGESTED TENSION SETTING (1) 4-Thread overlock Note: * These are suggested tension settings only. NEEDLE POSITION * Tension settings are effected by; 1) Type and thickness of fabric SEAM WIDTH FINGER KNOB 2) Needle size STITCH LENGTH 3) Size, type and fiber content of thread Right Needle thread Correct balance Upper looper thread... -

Page 28: 3-Thread Overlock

(2) 3-Thread overlock Note: * These are suggested tension settings only. * Tension settings are effected by; NEEDLE POSITION 1) Type and thickness of fabric 2) Needle size SEAM WIDTH FINGER KNOB 3) Size, type and fiber content of thread STITCH LENGTH Upper looper thread Correct Balance... -

Page 29: 3-Thread Flatlock

(3) 3-Thread flatlock Note: * These are suggested tension settings only. * Tension settings are effected by; NEEDLE POSITION 1) Type and thickness of fabric 2) Needle size SEAM WIDTH FINGER KNOB 3) Size, type and fiber content of thread STITCH LENGTH Lower looper Upper looper thread... -

Page 30: 3-Thread Rolled Edge

(4) 3-Thread rolled edge Correct balance NEEDLE POSITION * Set each tension dial to settings shown at right and test sew on a sample of your fabric. SEAM WIDTH FINGER KNOB STITCH LENGTH Needle thread Lower looper thread Upper looper thread Topside Underside Tension Dial... -

Page 31: Oiling The Machine

(2) Oiling the machine Before lubricating your machine, disconnect power line plug from the wall receptacle. * The oiling points shown in the diagram, should be oiled periodically. Note: Use only sewing machine oil. Do not use any other oil or damage could result. (3) Replacing the movable upper cutter Turn off the main power switch and unplug the machine. -

Page 32: How To Exchange Light Bulb

(4) How to exchange light bulb Always unplug before re-lamping. * Light bulb is available at your dealer shop. Take old bulb to the dealer shop and ask for same bulb. If voltage indicated on the electrical rating plate of your machine is 120V, ask for light bulb conforming to following specification. -

Page 33: Troubleshooting Chart

23. TROUBLESHOOTING CHART Problem Solution Page Fabric does not feed well - Lengthen stitch length. - Increase presser foot pressure for heavy weight fabric. - Decrease presser foot pressure for lightweight fabric. Needle breaks - Insert needle correctly. - Do not pull fabric while sewing. - Tighten needle set screw. -

Page 34: Relationship Between Cloth, Threadand Needle

24. RELATIONSHIP BETWEEN CLOTH, THREAD AND NEEDLE Type of Fabric Type of Thread Needle ELx705 WOVEN Cotton: #100 Lightweight Silk/ Rayon: #100 #12/80 Spun: #80 ~ #90 Lawn, Organdy, Voile, Polyester: #80 ~ #100 Crepe, etc. Cotton: #60 ~ #80 Medium Weight Silk/ Rayon: #50 #14/90, #12/80... -

Page 35: Specification

25. SPECIFICATION Stitch types: - 2 needles, 4 thread overlock with integrated safety seam - 1 needle. 3-thread overlock, 3 thread rollhem. Needle system: ELx705 Seam width: 3-7mm Stitch length: 1-4mm Presser foot lift: max. 6mm Handwheel: rotates counter-clockwise Sewing speed: up to 1300 s.p.m. - Page 36 B1P24-03...

Need help?

Do you have a question about the MK740DSA and is the answer not in the manual?

Questions and answers