Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Merrylock MK 4055

- Page 1 INSTRUCTION BOOK INSTRUCTION BOOK INSTRUCTION BOOK...

- Page 2 PREFACE Thank you for your purchase of this Combination Overlock, Chain Stitch and Cover Stitch Sewing Machine. This machine, that is intended for household use will provide you with excellent performance in sewing from light to heavy material (lawn to denim). Please refer to this Instruction Book for proper use and optimum service.

- Page 3 “IMPORTANT SAFETY INSTRUCTIONS“ When using an electrical appliance, basic safety precautions should always be followed, including the following: Read all instructions before using this overlock sewing machine. “DANGER“___ To reduce the risk of electric shock: 1. The appliance should never be left unattended when plugged in. 2.

- Page 4 17. If oil gets in eyes, immediately, rinse the oil out with water. If you swallow oil by mistake, immediately consult a medical doctor. 20. To reduce risk of injury, switch off before servicing. Close looper cover before operating. “SAVE THESE INSTRUCTIONS“ “This overlock sewing machine is intended for household use only.”...

- Page 5 CONSIGNES DE SECURITE Lors de l’utilisation de cette machine, les précautions élémentaires de sécurité doivent être pris es. Lisez attentivement toutes les consignes de sécurité suivantes avant de l’utiliser : DANGER - Pour reduire le risque de décharges électriques : * Ne laissez pas la machine sans surveillance lorsqu’elle est sous tension.

-

Page 6: Table Of Contents

TABLE OF CONTENTS PAGE PAGE 1. PRINCIPAL PARTS 13. NEEDLE THREADER (1) MACHINE OVERVIEW 14. HOW TO CHANGE THREADS : TIE ON METHOD (2) FREE ARM 15. STITCH LENGTH ADJUSTMENT (3) MAIN PARTS BEHIND THE LOOPER COVER 16. SELECTION OF STITCHES 2. -

Page 7: Principal Parts

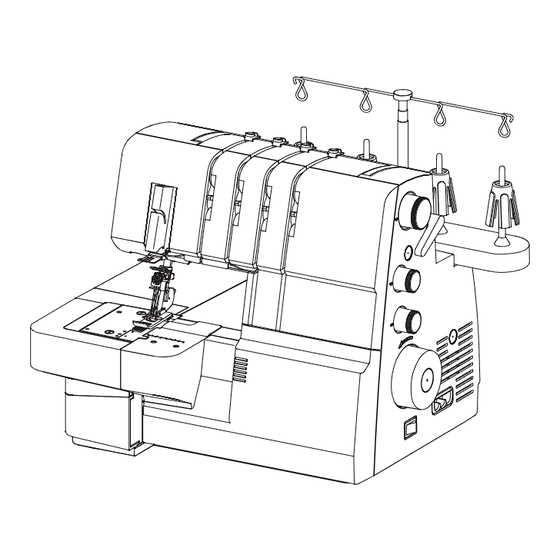

1. PRINCIPAL PARTS (1) MACHINE OVERVIEW 1. Thread guides and holder 2. Handle 3. Left needle thread tension fine tuning (orange) 4. Right needle thread tension fine tuning (blue) 5. Upper looper thread tension fine tuning (green) 6. Chain stitch looper thread tension fine tuning (brown) 7. -

Page 8: Free Arm

21. Foot pressure adjusting dial 22. Thread cutter (2) FREE ARM 1. Attached extension table * The attached extension table can be removed to expose the free arm. * To remove pull to the left. * To attach press firmly to the right until it engages. * The free arm is ideal for sewing tubular items such as ribbing, trousers and sleeve hems. -

Page 9: Main Parts Behind The Looper Cover

(3) MAIN PARTS BEHIND THE LOOPER COVER 1. Cover stitch looper thread take-up lever (D) 2. Cover stitch looper thread take-up lever (E) 3. Chain looper thread guide set 4. Cover looper protect board 5. Spring 6. Cover looper autothreader 7. -

Page 10: Optional Accessories

3. OPTIONAL ACCESSORIES Optional presser feet specially prepared for this machine are available at your dealer. The snap-on type presser foot used on this machine allows easy removal and replacement. (1) COVER STITCH PRESSER FOOT Elastic Foot G20804A The Elastic Foot guides and stretches narrow elastic (6-12mm, 1/4~1/2”) wear lingerie and other elastic insertion techniques Cording Foot Set H10793... -

Page 11: Needle Information

4. NEEDLE INFORMATION This overlock uses a flat shank industrial needle that eliminates the possibility of inserting the needle backwards. Do not attempt to use a standard household sewing machine needle of any size or type in this overlock. ELx705 Overlock needle Needle ELx705 size 14/90 is finished with the machine. -

Page 12: Telescopic Thread Stand

6. TELESCOPIC THREAD STAND * Place the thread spools over the cone holders on the spool pin. * If the machine is already threaded, straighten the threads to prevent tangling. 7. PREPARATION FOR THREADING (1) SETTING UP THE THREAD GUIDE HOLDER * This machine is shipped with the thread guide holder on the top of Styrofoam. -

Page 13: Spool Cap

(3) SPOOL CAP * When using a regular thread spool, fit the spool cap supplied with the machine onto the thread Press in spool as shown at right. Spool cap Thread spool 8. HOW TO OPEN AND CLOSE LOOPER COVER Be sure to turn off power switch. -

Page 14: How To Remove And Insert Needles

9. HOW TO REMOVE AND INSERT NEEDLES (1) NEEDLE POSITION * With this machine, five needles can be inserted to the needle clamp as shown in the drawing but only one or two or three needles are to be used for cover stitch sewing. -

Page 15: To Insert Needles (S)

(3) TO INSERT NEEDLES (S) * Hold the needle with the flat surface to the back. * Insert the needle into the needle socket as far as it will go. To tighten * When inserting a needle, if you first lower it down into the hole in the stitch plate it will line up with the needle socket. -

Page 16: General Threading Information

12. GENERAL THREADING INFORMATION Thread the machine in the order 1 to 4 as shown at right. Note : Threads go through the take-up lever cover for Chain stitching as shown. Tip : Your new machine is threaded to sew a standard “Triple Cover Stitch”. - Page 17 * While holding thread with fingers, pass it between the tension discs and pull thread down to make certain it is properly located in between the tension discs 3. * Turn the hand wheel toward you until the cover stitch looper extends out 10mm from the stitch plate edge.

-

Page 18: To Thread Cover Stitch Right Needle

(2) TO THREAD COVER STITCH RIGHT NEEDLE (GREEN) (E ON NEEDLE CLAMP) Thread the right needle as indicated 1~10. * Raise Presser foot to release Tension discs. * Pass thread from back to the front through the thread guide 1. * Thread the top cover thread guide by pulling the thread towards the right until it slips under guide. -

Page 19: To Thread Cover Stitch Middle

* Continue to thread points 4~9. * Slip the thread into the rear slot on the thread guide (5) and into the slot on the take-up lever cover (6). Then slip the thread into the right slot on the thread guides (7) and (8). * Before threading the eye of the needle, make sure thread is in front of thread guide located on the bottom of the needle clamp (9). - Page 20 * While holding thread with fingers, pass it between the tension discs and pull thread down to make certain it is properly located in between the tension discs 3. * Continue to thread points 4~9. * Slip the thread into the rear slot on the thread guide (5) and into the slot on the take-up lever cover (6).

- Page 21 * Pass thread from back to the front through the thread guide 1. * Thread the top cover thread guide by pulling the thread towards the right until it slips under guide. Then pull thread along the right side of button as illustrated.

-

Page 22: Needle Threader

13. NEEDLE THREADER * To make threading the needles easier, use the needle threader included with the accessories. * Turn the handwheel so the needles are in their highest position and lower the presser foot. Make sure one of the rectangular markings of the needle threader is pointing upwards. -

Page 23: How To Change Threads : Tie On Method

14. HOW TO CHANGE THREADS : TIE ON METHOD To change thread type or color, clip thread near the spool. * Place new thread on stand. * Tie new thread and old thread ends together with a square knot. Clip thread tails to 2~3cm (1 inch) length. -

Page 24: Selection Of Stitches

16. SELECTION OF STITCHES This machine is capable of producing various types of stitches according to the combination of needle positions, threading methods, tension adjustment and the use of convertible right looper/ converter. Reference Stitch Type Chain looper Cover stitch right needle Cover stitch left needle Cover stitch middle needle Page... -

Page 25: Cover Stitch Sewing

18. COVER STITCH SEWING * The Cover stitch can be used for covering, binding or top-stitching necklines and for hemming the bottom of T-shirts and sweat suits, etc. in addition to flat joining seams (plain seaming). The Cover stitch is most suitable for stretchy fabrics. It can also be used for woven fabrics. -

Page 26: Presser Foot Pressure Adjustment

19. PRESSER FOOT PRESSURE ADJUSTMENT The presser foot pressure for sewing based on normal conditions should be set to N. Adjustments some instances may be necessary. Increase or decrease the pressure until you are satisfied with result. Always test sew on a sample of your fabric before sewing on your garment. -

Page 27: How To Sew A Cover Stitch

21. HOW TO SEW A COVER STITCH * This machine can produce a 3-thread 5.6 mm wide bottom cover stitch. * The cover stitch can be used for covering, binding or top-stitching necklines and for hemming the bottom, of T-shirts and sweat suits, etc. in addition to flat joining seams (plain seaming). -

Page 28: Additional Information About Cover

(2) ADDITIONAL INFORMATION ABOUT COVER STITCH At start of sewing * Raise presser foot. (a) Place fabric under presser foot behind the needle. (b) Lower presser foot. (c) Note : When you start to sew from the middle of the fabric, place the fabric at the desired of starting point of sewing. -

Page 29: Suggested Tension Setting

22. SUGGESTED TENSION SETTING (1) Chain stitch Tension settings are effected by : * Type and thickness of fabric * Needle size Cover stitch middle * Size, type and fibre content of thread needle Chain stitch looper (1) CHAIN STITCH thread * Stitch length for chain stitch should be set at over... -

Page 30: Cover Stitch, Triple

(4) COVER STITCH, TRIPLE (4) Cover Stitch, Triple * Stitch length for cover stitch should be set at over (2.5 mm). Cover stitch right needle thread Cover stitch middle * Set auto tension dial to J shown at right and test needle thread sew on a sample of your fabric. -

Page 31: Storage

(2) STORAGE When the machine is not in use, be sure to keep it unplugged. Cover the machine with the dust cover to protect it from the dust. Store the machine, so it is not exposed to direct sunlight or humidity. (3) SERVICING Have your cover stitch machine serviced regularly by your local authorized dealer! If you have followed the trouble shooting information. -

Page 32: Specifications

Problem Solution * Check for tangled or caught thread. Fabric Jams * Compress thick layers of fabric with conventional machine before sewing with cover stitch. Machine Does Not Operate * Connect machine to power source correctly. 25. SPECIFICATIONS Sewing speed Maximum 1300 stitches/min Stitch length 1.0 - 5.0 mm... - Page 33 J1P17...

Need help?

Do you have a question about the MK 4055 and is the answer not in the manual?

Questions and answers