Summary of Contents for Merrylock MK1100

- Page 1 Instruction Book Instruction Book Instruction Book 1-Needle 3-Thread Overlock Sewing Machine...

- Page 2 “IMPORTANT SAFETY INSTRUCTIONS“ When using an electrical appliance, basic safety precautions should always be followed, including the following: Read the instruction carefully before you use the machine. To reduce the risk of electric shock: “DANGER“___ Pour reduire le risque de décharges électriques : 1.

-

Page 3: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS Parts Name................................Standard Accessories............................Specifications................................ Opening and Closing the Looper Cover......................Opening and Closing the Sewing Table......................Opening and Closing the Accessory Box......................Connecting the Machine to the Power Supply....................How to Use Foot Controller and Control the Sewing Speed................How to Turn the Balance Wheel........................... -

Page 4: Parts Name

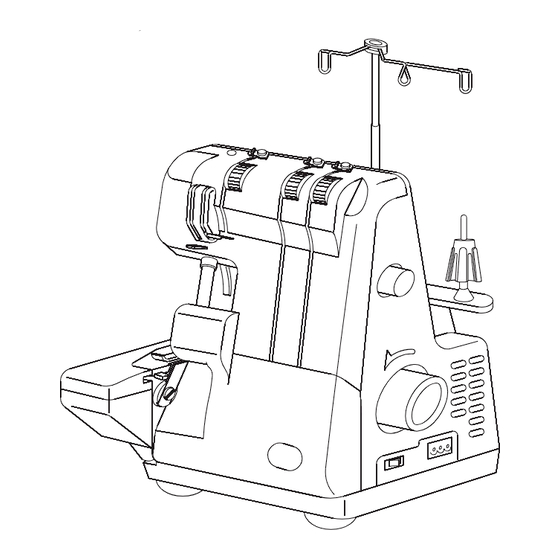

Parts Name Pre-tension thread guide Needle thread tension dial Thread guide bar Thread guide Foot pressure cover Thread take-up lever cover Spool pin Needle thread guide Needle thread guide Spool holder Spool stand Stitch length dial Side Cover Sewing table Balance wheel Power socket Looper cover... -

Page 5: Standard Accessories

Standard Accessories Screw driver Set of Needles Tweezers Nets Lint brush Upper knife Thread stripping discs Hexagon wrench Chip box Specifications Max. speed Up to 1300 r.p.m. Stitch length 1-4mm Stitch width 3-5mm Presser foot height Max. 6mm Differential feed (DF type only) 0.8-2.0 ELx705 # 12 or # 14 Needle... -

Page 6: Opening And Closing The Looper Cover

Opening and Closing the Looper Cover To open: Hold the hollow to the right as far as it will go, then pull looper cover toward you. To close: Lift looper cover and push against the machine. The looper cover snaps into the position automatically. Looper cover Hollow Opening and Closing the Sewing Table... -

Page 7: Connecting The Machine To The Power Supply

Connecting the Machine to the Power Supply Electrical outlet Light and Power Foot controller switch Light and power switch Power socket 1. Turn off the light and power switch. 2. Connect two plugs to power socket and electrical outlet. 3. Turn on the light and power switch. -Caution- Always disconnect the plug from electrical outlet: - when machine is not in use. -

Page 8: Stretch Up The Thread Guide Bar

Stretch up the Thread Guide Bar 1. Pull the thread guide bar up to the top. 2. Turn the thread guide bar to make it comes right above the spool pins and locked into the stopper. Attaching the Thread Stripping Disc and Net Thread stripping disc Spool holder Spool pin... -

Page 9: Raising Or Lowering The Presser Foot

Raising or Lowering the Presser Foot 1. Apply the presser foot lifter to raise or lower the presser foot. Presser foot 2. Always keep the presser foot down when sewing. Presser foot lifter How to Change (Remove) the Presser Foot 1. -

Page 10: How To Thread The Machine

How to Thread the Machine -NOTED- 1. Always thread the upper looper first, then lower looper, needle on the right and needle on the left. A threading chart is placed on the machine body inside the looper cover. 2. Incorrect threading will cause of skipped stitch, broken thread or uneven thread tension. -

Page 11: Threading The Lower Looper

Threading the lower looper (red) - Open the looper cover and sewing table. - Place the spool on right spool holder. - Draw the thread through the pre-tension thread guide (1) from right to left. - Thread from left to right around the thread guide (2) - Thread guides (3, 4, 5, 6) - Turn the balance wheel toward you until the lower looper extending out 5-10mm from the needle plate edge. -

Page 12: Threading The Needle

Threading the needle (orange) - Place the spool on left spool holder. - Draw the thread through the pre-tension thread guide (1) from left to right. - Thread from left to right around the thread guide (2). - Thread guide (3) - Thread behind of the thread take-up lever cover. -

Page 13: Securing Ends

Securing Ends To avoid unravelling, it is necessary to leave a thread chain about 5 cm (2") long at the beginning and end of seam. To secure the beginning and end of a seam choose one of the following methods. At the beginning Separate the end of threads and knot. -

Page 14: Adjustment Of Differential Feed (Df Type Only)

Adjustment of Differential Feed (DF type only) Stretched Gathered How to adjust If the sewn fabric is stretched, turn the dial between the " " section. If the sewn fabric is gathered, turn the dial between the " " section. * When sewing without differential feed, the adjustment dial should be set on the "N"... -

Page 15: Thread Tension Adjusment

Thread Tension Adjustment Thread Tension Dial Correct Tension Wrong side of fabric Upper looper thread Needle thread Tighten Lower looper thread Right side of fabric Loosen Needle thread is loose. Lower looper thread is tight and / Upper looper thread is tight and / or upper looper thread is loose. -

Page 16: Adjustment Of Stitch Length

Adjustment of Stitch Length 1. Larger the number, longer the stitch. Smaller the number, shorter the stitch. 2. The stitch length can be adjusted from 1 to 4mm (approx. 0.04" to 0.15") 3. The position "N" is for normal over lock sewing. Adjustment of Cutting Width Counter- clockwise... -

Page 17: Changing The Needle

Change the Needle Needle clamp screw Needle clamp Flat side Hexagon wrench Presser foot 1. Disconnect the machine from the power supply. 2. Turn the balance wheel to raise the needle above the presser foot. Then apply the hexagon wrench ( in the accessory box) to loose the needle clamp screw for the needle you are going to remove. -

Page 18: Using The Needle Plate

Using the Needle Plate Switch the lever to select the regular or rolled hem and narrow hem sewing. “R” For rolled and narrow hem sewing “N” For regular sewing Lever Lever Fabric, needle and threads Lightweight fabric such as organdy, Fabric crepe de chine, lawn and georgette ELx705 # 12... -

Page 19: Rolled Hemming, Picot Edging And Narrow Hemming

Rolled Hemming, Narrow Hemming and Picot Edging Rolled Hemming Lower looper Wrong side thread of fabric Right side of fabric Upper looper Needle Stitch length: 1.5 - 2 thread thread Narrow Hemming Wrong side of fabric Lower looper thread Right side Upper of fabric looper... -

Page 20: Cleaning And Oiling

Cleaning and oiling -Cleaning the feed dog- Lint brush 1. Open the sewing table and looper cover. 2. Turn the balance wheel toward you until the needle goes up to the highest position. 3. Remove the needle plate and presser foot. 4. -

Page 21: Trouble Shooting

Trouble shooting Before calling for service, check the information below. Reference Problem Cause Correction Page 1. Needle inserted incorrectly - Reset needle 2. Used wrong needle - Use correct needle 3. Needle is bent or blunt - Insert new needle Thread Breaks 4. -

Page 22: Optional Feet

Optional feet ELASTIC FOOT: This special sewing foot is for sewing on elastic tape. In the same operation, the fabric is trimmed, serged and gathered by the constriction of the elastic tape. BLIND HEM/LACE FOOT: One foot for both blind hem and lace sewing. BLIND HEM: The hem is trimmed, serged and sewn in one operation. - Page 23 RECYCLING Do not dispose of electrical appliances as unsorted municipal waste. Use separate collection facilities. Contact your local government for information regarding the collection systems available. If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak into the groundwater and get into the food chain, damaging your health and well-being.

- Page 24 F1P05-01...

Need help?

Do you have a question about the MK1100 and is the answer not in the manual?

Questions and answers