Table of Contents

Advertisement

Quick Links

Published 01/11

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

®

RHINO

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

E-mail: parts@servis-rhino.com

OPERATOR'S MANUAL

©2011 Alamo Group Inc.

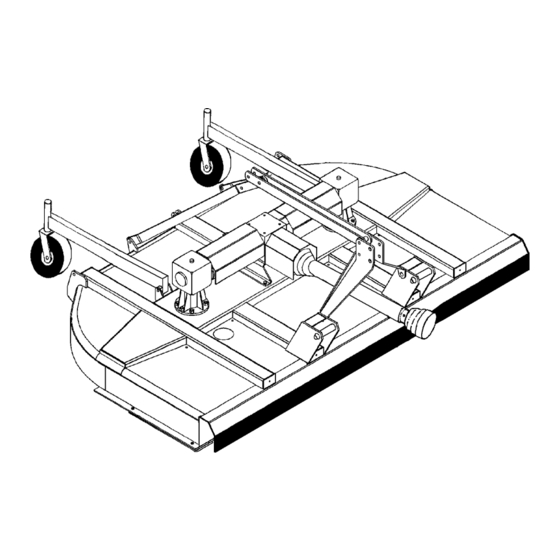

TW120

ROTARY CUTTER

Part NO. 00762120C

$0.00

Advertisement

Chapters

Table of Contents

Summary of Contents for RHINO TW120 FC-0024

- Page 1 Published 01/11 OPERATOR’S MANUAL This Operator's Manual is an integral part of the safe operation of this machine and must be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment. C01- Cover ®...

- Page 2 To the Owner/Operator/Dealer This Operator's Manual is an integral part of the safe operation of this machine and must be maintained with the implement at all times. A Manual canister is provided on the implement where this manual can be properly stored. If you lose or damage this manual a free replacement manual can be obtained from an authorized Rhino dealer or by down loading the manual from the Rhino website www.servis-rhino.com BEFORE YOU START! READ, UNDERSTAND, and FOLLOW the information provided in this manual, the AEM...

-

Page 3: Osha Training Requirements

In order to reduce accidents and enhance the safe operation of mowers, Alamo Group Ag Division, in cooperation with other industry manufacturers has developed the AEM/FEMA Industrial and Agricultural Mower Safety Practices video and guide book. The video will familiarize and instruct mower-tractor operators in safe practices when using industrial and agricultural mowing equipment. - Page 4 Alamo Group Ag. Division will provide one (1) AEM Mower Safety Practices Video Please Send Me: VHS Format – AEM/FEMA Mower Operator Safety Video DVD Format – AEM/FEMA Mower Operator Safety Video Mower Operator’s Manual AEM Mower Operator’s Safety Manual Requester Name:______________________________________Phone: Requester Address:___________________________________________ City:_______________________________...

- Page 5 DEALER to CUSTOMER Pre-Delivery/ Operation Instructions Dealer should inform the Purchaser of this product of Warranty terms, provisions, and procedures that are applicable. Dealer should inform Purchaser to review the contents of the Operator’s Manual including safety equipment, safe operation and maintenance, to review the Safety Signs on the implement (and tractor if possible) and of Purchaser’s responsibility to train his/her operators’s of safe operation procedures.

-

Page 6: Table Of Contents

Table of Contents SAFETY SECTION ... 1-1 GENERAL SAFETY INSTRUCTIONS AND PRACTICES ... 1-2 OPERATOR SAFETY ... 1-3 CONNECTION OR DISCONNECTING IMPLEMENT SAFETY ... 1-4 CRUSHING HAZARDS ... 1-5 THROWN OBJECTS HAZARDS ... 1-6 THROWN OBJECTS HAZARDS (CONTINUED) ... 1-7 RUN OVER HAZARDS ... - Page 7 ROPS and Seat Belt ... 4-4 Tractor Safety Devices ... 4-5 Tractor Horsepower ... 4-5 3-Point Hitch ... 4-5 Drawbar-Pull Type Mower ... 4-6 Front End Weight ... 4-6 Power Take Off (PTO) ... 4-7 Tire Spacing ... 4-7 GETTING ON AND OFF THE TRACTOR ... 4-8 Boarding the Tractor ...

- Page 8 MAIN CV DRIVELINE SAFETY SHIELD (FIGURE Mnt-R-0032) ... 5-9 DRIVELINE TAPER CONE YOKE REMOVAL INSTRUCTIONS ... 5-10 BLADE SERVICING ... 5-10 BLADE SHARPENING ... 5-11 BLADE CARRIER REMOVAL ... 5-11 BLADE REMOVAL ... 5-13 Blade Bolt Inspection ... 5-14 BLADE TIMING AND ROTATION ... 5-15 BLADE TIMING PROCEDURE ...

-

Page 9: Safety Section

SAFETY SECTION Safety Section 1-1 © 2011 Alamo Group Inc. -

Page 10: General Safety Instructions And Practices

GENERAL SAFETY INSTRUCTIONS AND PRACTICES A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to the owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings, and observing certain precautions. The first section of this manual includes a list of Safety Messages that, if followed, will help protect the operator and bystanders from injury or death. -

Page 11: Operator Safety

OPERATOR SAFETY TO AVOID SERIOUS INJURY OR DEATH DO THE FOLLOWING: • READ, UNDERSTAND and FOLLOW Operator's Manual instructions, Warnings and Safety Messages. • WEAR SAFETY GLASSES, safety shoes, hard hat, hearing protection and gloves when operating or repairing equipment •... -

Page 12: Connection Or Disconnecting Implement Safety

CONNECTION OR DISCONNECTING IMPLEMENT SAFETY TO AVOID SERIOUS INJURY OR DEATH FROM BEING CRUSHED BY TRACTOR OR IMPLEMENT: WHEN BACKING tractor to implement hitch: • DO NOT ALLOW BYSTANDERS between tractor and implement BEFORE connecting and disconnecting implement hitch: • STOP TRACTOR ENGINE, place transmission into park, engage parking brake and remove key. -

Page 13: Crushing Hazards

CRUSHING HAZARDS TO AVOID SERIOUS INJURY OR DEATH FROM FALLING OFF TRACTOR, EQUIPMENT RUN OVER, ROLLOVER AND CRUSHING BY FALLING WING OR IMPLEMENT: • USE ROPS and SEAT BELT equipped tractors for mowing operations. • KEEP ROPS lock in up position. •... -

Page 14: Thrown Objects Hazards

THROWN OBJECTS HAZARDS ROTARY MOWERS CAN THROW OBJECTS 300 FEET OR MORE UNDER ADVERSE CONDITIONS. TO AVOID SERIOUS INJURY OR DEATH TO OPERATOR OR BYSTANDERS FROM THROWN OBJECTS: • KEEP bystanders 300 feet away STOP MOWING IF PASSERSBY ARE WITHIN 300 FEET UNLESS: •... -

Page 15: Thrown Objects Hazards (Continued)

THROWN OBJECTS HAZARDS (CONTINUED) MOWER OPERATION: • DO NOT exceed mower's rated Cutting Capacity or cut non-vegetative material. • USE ENCLOSED TRACTOR CABS when two or more mowers are operating in mowing area. • ADJUST mower sections or wing close and parallel to ground without exposing blades •... -

Page 16: Run Over Hazards

RUN OVER HAZARDS TO AVOID SERIOUS INJURY OR DEATH FROM FALLING OFF TRACTOR OR EQUIPMENT RUN OVER: • USE ROPS and SEAT BELT equipped tractors for mowing operations. • KEEP ROPS locked in UP position. • ONLY start tractor while seated in tractor seat. •... -

Page 17: Pto Entanglement Hazards

PTO ENTANGLEMENT HAZARDS KEEP AWAY FROM ROTATING DRIVELINES AND ELEMENTS TO AVOID SERIOUS INJURY OR DEATH: hands, feet and body AWAY from rotating blades, drivelines and parts until all moving STAY AWAY KEEP elements have stopped. • STOP, LOOK and LISTEN before approaching the mower to make sure all rotating motion has stopped. •... -

Page 18: Mower Blade Contact Hazards

MOWER BLADE CONTACT HAZARDS KEEP AWAY FROM ROTATING BLADES TO AVOID SERIOUS INJURY OR DEATH FROM BLADE CONTACT: • STAY AWAY and KEEP HANDS, FEET and BODY AWAY from rotating blades, drivelines and parts until all moving elements have stopped. •... -

Page 19: High Pressure Oil Leak Hazards

HIGH PRESSURE OIL LEAK HAZARDS TO AVOID SERIOUS INJURY OR DEATH FROM HIGH PRESSURE HYDRAULIC OIL LEAKS PENERATING SKIN: • DO NOT OPERATE equipment with oil or fuel leaks. • KEEP all hydraulic hoses, lines and connections in GOOD CONDITION and TIGHT before applying system pressure. -

Page 20: Electrical & Fire Hazards

ELECTRICAL & FIRE HAZARDS TO AVOID SERIOUS INJURY OR DEATH FROM ELECTRICAL CONTACT WHEN WORKING AROUND ELECTRICAL POWER LINES, GAS LINES AND UTILITY LINES: • INSPECT mowing area for overhead or underground electrical power lines, obstructions, gas lines, cables and Utility, Municipal, or other type structure. •... -

Page 21: Transporting Hazards

TRANSPORTING HAZARDS TO AVOID SERIOUS INJURY AND DEATH WHEN TOWING OR TRANSPORTING EQUIPMENT: • KEEP transport speed BELOW 20 mph to maintain control of equipment. • REDUCE SPEED on inclines, on turns and in poor towing conditions. • DO NOT TOW with trucks or other vehicles •... -

Page 22: Hazards With Maintenance Of Implement

HAZARDS WITH MAINTENANCE OF IMPLEMENT AVOID SERIOUS INJURY OR DEATH FROM COMPONENT FAILURE BY KEEPING IMPLEMENT IN GOOD OPERATING MAINTENANCE. BEFORE PERFORMING SERVICE, REPAIRS AND MAINTENANCE ON THE IMPLEMENT: • STOP ENGINE AND PTO, engage parking brake, lower implement, allow all moving parts to stop and remove key before dismounting from tractor. -

Page 23: Parts Information

PARTS INFORMATION Rhino mowers use balanced and matched system components for blade carriers, blades, cuttershafts, knives, knife hangers, rollers, drivetrain components, and bearings. These parts are made and tested to Rhino specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce mower performance, void warranties, and present a safety hazard. -

Page 24: Decal Location - Lift Type

SAFETY Decal Location - Lift Type NOTE: Rhino supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Rhino cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 25 ITEM PART NO. D389 D388 00756004 00756005 D137 D138 D454 00771283 99102 00787406 00785891 00785892 D302 03200347 00760657 D401 1458392 1458393 00776031 00762120C 10058000 00024100 02959924 D614 D534 D629 D608 Provided by Tractor Manufacturer Provided by Driveline Manufacturer DECAL SHEETS Dual Spindle Decal Sheet D442 TW 120 Decal Sheet D483 TW120 01/11...

-

Page 26: Decal Location - Pull Type

SAFETY Decal Location - Pull Type NOTE: Rhino supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Rhino cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 27 ITEM PART NO. D389 D390 D388 00756004 00756005 D137 D138 D454 00771283 99102 00787406 00785891 00785892 D302 03200347 00760657 D401 1458392 1458393 00776031 00762120C 10058000 00024100 02959924 D614 D534 D629 D518 D608 Provided by Tractor Manufacturer Provided by Driveline Manufacturer DECAL SHEETS Dual Spindle Decal Sheet D442 TW120 Decal Sheet D483...

-

Page 28: Decal Description

SAFETY Decal Description TW120 01/11 Safety Section 1-20 © 2011 Alamo Group Inc. - Page 29 SAFETY TW120 01/11 Safety Section 1-21 © 2011 Alamo Group Inc.

- Page 30 SAFETY TW120 01/11 Safety Section 1-22 © 2011 Alamo Group Inc.

- Page 31 SAFETY TW120 01/11 Safety Section 1-23 © 2011 Alamo Group Inc.

- Page 32 SAFETY TW120 01/11 Safety Section 1-24 © 2011 Alamo Group Inc.

- Page 33 SAFETY TW120 01/11 Safety Section 1-25 © 2011 Alamo Group Inc.

- Page 34 SAFETY TW120 01/11 Safety Section 1-26 © 2011 Alamo Group Inc.

- Page 35 SAFETY TW120 01/11 Safety Section 1-27 © 2011 Alamo Group Inc.

- Page 36 SAFETY TW120 01/11 Safety Section 1-28 © 2011 Alamo Group Inc.

-

Page 37: Federal Laws And Regulations

This section is intended to explain in broad terms the concept and effect of federal laws and regulations concerning employer and employee equipment operators. This section is not intended as a legal interpretation of the law and should not be considered as such. Employer-Employee Operator Regulations U.S. - Page 40 We wish to acknowledge the contributions of the members of AEM’s Industrial/Agricultural Mower Manufacturers Council Copyright, 2010, by the Association of Equipment Manufacturers. All rights reserved. This work may not be reproduced or disseminated in whole or in part by any means This safety manual is intended to point out some of the basic safety situations that may be encountered during the normal operation and maintenance of your machine...

-

Page 41: Safety Alerts

Symbol This Safety Alert Symbol means: “ATTENTION! STAY ALERT! YOUR SAFETY IS INVOLVED!” The Safety Alert Symbol identifi es important safety messages on equipment, safety signs, in manuals or elsewhere. When you see this symbol, be alert to the possibility of death or personal injury. Follow instructions in the safety message. -

Page 42: The Industrial/Agricultural Mower

The Industrial/Agricultural Mower Industrial/Agricultural Mower Types Mowers are used for pasture clipping, crop residue shredding, heavy brush cutting, waterways, right-of- ways, roadside or highway mowing. Also, these mowers are used for cutting grass and other growth in public areas such as parks and cemeteries. Folding Wing Rotary The Industrial/Agricultural Mower Agricultural Disc Mower Types... -

Page 43: Follow A Safety Program

Follow A Safety Program Protect Yourself Wear personal protective clothing and Personal Protective Equipment (PPE) issued to you or called for by job conditions. You must ALWAYS wear safety glasses with side shields. You may also need: — Hard hat —... - Page 44 Follow A Safety Program Avoid Injury From Raised Equipment Avoid possible crushing injury from falling mower or other raised equipment. Avoid Crushing – Securely Support Before working near or under raised mower or equipment parts: — Securely support or block up raised mower or equipment parts according to the operator’s manual.

- Page 45 Follow A Safety Program Be Alert! Know where to get assistance. Know how to use a fi rst aid kit and fi re extinguisher/fi re suppression system. Be Aware! Take advantage of training programs offered. Be Careful! Human error is caused by many factors: carelessness, fatigue, overload, preoccupation, unfamiliarity of operator with the machine, drugs, and alcohol to name a few.

- Page 46 Follow A Safety Program Some Rules You Must Work By (continued) — Only qualifi ed and authorized individuals may operate this equipment. — Never allow children to play on, ride on or operate the equipment. Children are not qualifi ed to operate this equipment.

-

Page 47: Prepare For Safe Operation

Prepare For Safe Operation Check The Mower And Tractor Equipment Before beginning your work day inspect the machine and have all systems in good operational condition. WARNING! Prevent possible crushing injury from falling equipment. Hydraulic system or part failure could cause unsupported equipment to fall. - Page 48 Prepare For Safe Operation Know The Work Area Before you operate the mower thoroughly inspect the work area. Walk around the area and inspect the surfaces you will travel on when using the mower. Locate and avoid: — Deep mud —...

- Page 49 Prepare For Safe Operation Tractor And Mower Controls Safety Test Start the tractor following the specifi c procedures in the manufacturer’s operator’s manual. These procedures normally include: — Fasten and adjust seat belt on your ROPS-equipped tractor. — Check parking brake for engagement. —...

- Page 50 Prepare For Safe Operation Hitching Mower To Tractor Three-point hitch-mounted mowers: — Refer to mower and tractor manufacturers’ manuals. — Place tractor’s hydraulic power lift (rockshaft) selector lever in down position to avoid unexpected movement. — Explain the hitching procedures to those operators who cannot read.

-

Page 51: Start Safely

Make The Right Start Mow only in daylight or good artifi cial light conditions. Avoid serious injury or death from mower-thrown objects or blade contact: — Keep chain shields, fl exible or solid defl ector shields or discharge chutes in place and in good repair. —... - Page 52 Mower-Thrown Objects (continued) Disc Mowers — When using a disc mower it is important to know the area to be mowed. If the operator has mowed the fi eld before and is familiar with all obstacles that may be present, it is suffi cient to watch ahead of the mower path for any additional objects that may have entered the fi eld.

- Page 53 Under Mount Mower Safety Practices When mowing with an under mount mower: — Keep removable discharge chute in place and over discharge opening. — Never stand on a mower housing when the tractor engine is operating. — Distribute grass clippings with discharge chute facing mowed area.

- Page 54 Wing And Side Mount Mowers Safety Practices Raised wing positions reduce shielding protection and increases the thrown object and blade contact hazard risks. Avoid possible serious injury or death by thrown objects or blade contact from raising and lowering wings during mowing operations: —...

- Page 55 Uneven Terrain Mowing Safety Practices (continued) — Use extreme care to maintain control over the equipment when operating in these conditions. — Increase tractor stability by adding wheel weights, ballast and increasing wheel spacing to maximum. Refer to operator’s manual for recommendations. —...

-

Page 56: Park Safely

Parking Safety Practices — Use designated or out-of-traffi c areas. — Use fi rm level ground locations. — Set parking brake. — Lower raised equipment to ground. Shut down the mower and tractor using proper equipment shut down practice before dismounting tractor. -

Page 57: Perform Maintenance Safely

Dismounting Properly — Never dismount from moving equipment. — Never jump from any machines. — Dismount carefully. — Check for slippery steps. — Keep feet and hands away from controls. — Use handholds and steps during dismount. — Face machine and use three-point contact (2 hands and 1 foot or 2 feet and 1 hand). - Page 58 Perform Maintenance Safely Prepare Yourself Wear personal protective clothing and Personal Protective Equipment (PPE) issued to you or called for by job conditions. You must ALWAYS wear safety glasses with side shields. You may also need: — Hard hat — Safety shoes —...

- Page 59 Perform Maintenance Safely Prepare The Machine Stored energy sources (electrical, mechanical, hydraulic, pneumatic, chemical, thermal, etc.) must be controlled or reduced to a practical minimum before performing any maintenance, repair or service procedures. Safety practices to prevent potential injuries from energy-releasing sources: —...

- Page 60 Perform Maintenance Safely Perform Maintenance Safely Use Proper Ventilation If it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. If you do not have an exhaust pipe extension, make sure you open the doors and get outside air into the area.

- Page 61 Perform Maintenance Safely Hydraulic System Hazards The hydraulic system is under pressure whenever the engine is operating and may hold pressure even after the engine is shut off. Cycle all hydraulic controls including the auxiliary hydraulic control after the engine is shut down.

- Page 62 Perform Maintenance Safely Avoid Explosion WARNING! Avoid possible serious injury from explosion. Lead-acid batteries produce extremely explosive gases especially when being charged. Keep arcs, sparks, fl ames and lighted tobacco away. — Do not smoke near batteries. — Keep arcs, sparks and open fl ames away from batteries.

- Page 63 Perform Maintenance Safely Tire And Wheel Maintenance (continued) WARNING! The types of wheels and tires usually found on this equipment require special care when servicing to prevent death or serious injury. Do not infl ate the tires above the recommended pressure.

-

Page 64: Final Word To The User

Perform Maintenance Safely Mower Blade Maintenance (continued) — How are mower blades made? Mower blades are made of high strength alloy spring steel. They are hot-forged and shaped to meet the manufacturer’s individual specifi cations, then heat treated and tempered to a high strength, ductile state to reduce the possibility of breaking while mowing. -

Page 66: Introducción

Contenido Reconocimiento Deseamos reconocer las contribuciones de los miembros del Consejo de Fabricantes de Cortadoras de Césped Industriales/para Agricultura para la preparación de este Manual de seguridad. Copyright, 2010, por la Asociación de Fabricantes de Equipos (Association of Equipment Manufacturers). Todos los derechos reservados. Queda prohibida la reproducción o difusión parcial o total de este trabajo por cualquier medio sin consentimiento previo por escrito de la Asociación de Fabricantes de Equipos. -

Page 67: Alertas De Seguridad

Alertas de seguridad Símbolo Este símbolo de alerta de seguridad signifi ca: “¡ATENCIÓN! ¡MANTÉNGASE ALERTA! ¡SU SEGURIDAD ESTÁ EN RIESGO!” El símbolo de alerta de seguridad identifi ca mensajes de seguridad importantes sobre el equipo, sobre letreros de seguridad, en manuales u otros lugares. Cuando vea este símbolo, manténgase alerta ante la posibilidad de muerte o lesiones personales. -

Page 68: Cortadora De Césped Industrial/Para Agricultura

Cortadora de césped industrial/para agricultura Tipos de cortadora de césped industrial/para agricultura Las cortadoras de césped se usan para recortar pasturas, desmenuzar residuos de cultivos, cortar arbustos, realizar desbroce pesado, cortar la hierba en vías de agua, derechos de paso, costados de caminos o autopistas. Además, estas cortadoras se usan para cortar la hierba y otras plantas en zonas públicas como parques y cementerios. -

Page 69: Cumplimiento Del Programa De Seguridad

Cumplimiento del programa de seguridad Protéjase a sí mismo Use la ropa de protección personal y los equipos de protección personal (PPE) que se le proporcionen o que requieran las condiciones del trabajo. SIEMPRE debe usar gafas de seguridad con escudos laterales. Puede necesitar también: —... - Page 70 Cumplimiento del programa de seguridad Evite las lesiones provocadas por equipos elevados Evite posibles lesiones de aplastamiento por caídas de la cortadora u otros equipos elevados. Evite ser aplastado – con seguridad la Antes de trabajar cerca o debajo de partes levadas de la cortadora o de los equipos: —...

- Page 71 Cumplimiento del programa de seguridad ¡Manténgase alerta! Sepa dónde obtener asistencia. Sepa cómo usar un equipo de primeros auxilios y un extintor de incendios/ sistema de supresión de fuego. ¡Manténgase informado! Aproveche los programas de capacitación que se ofrecen. ¡Tenga cuidado! El error humano es causado por muchos factores: descuido, fatiga, sobrecarga, preocupación, desconocimiento de la máquina por parte del operador, fármacos y alcohol,...

- Page 72 Cumplimiento del programa de seguridad Algunas reglas que debe cumplir al trabajar (continuación) — Únicamente personas cualifi cadas y autorizadas pueden manejar estos equipos. — Nunca permita que los niños jueguen en los equipos, viajen en ellos o los hagan funcionar. Los niños no están cualifi cados para manejar estos equipos.

-

Page 73: Preparación Para Una Operación Segura

Preparación para una operación segura Revise los equipos de la cortadora de césped y el tractor Antes de comenzar la jornada de trabajo, inspeccione la máquina y asegúrese de que todos los sistemas estén en buenas condiciones operacionales. ¡ADVERTENCIA! Evite posibles lesiones por aplastamiento producidas por equipos que caen. - Page 74 Preparación para una operación segura Familiarícese con la zona de trabajo Antes de hacer funcionar la cortadora de césped, inspeccione cuidadosamente la zona de trabajo. Recorra a pie alrededor de la zona e inspeccione las superfi cies sobre las cuales se desplazará cuando utilice la cortadora. alrededor del lugar Localice y evite: —...

- Page 75 Preparación para una operación segura Prueba de seguridad de los controles del tractor y de la cortadora de césped Arranque el tractor siguiendo los procedimientos específi cos del manual del operador del fabricante. Estos procedimientos normalmente incluyen: — Colóquese y ajústese el cinturón de seguridad en el tractor equipado con ROPS.

- Page 76 Preparación para una operación segura Enganche de la cortadora de césped al tractor Cortadoras montadas en enganche de tres puntos: — Consulte los manuales de los fabricantes de la cortadora y del tractor. — Coloque la palanca selectora de elevación de potencia hidráulica del tractor en la posición descendida para evitar movimientos imprevistos.

-

Page 77: Arranque Con Seguridad

Arranque con seguridad Cómo realizar un arranque correcto Corte la hierba únicamente con luz diurna o en condiciones de buena luz artifi cial. Evite lesiones graves o muerte producidas por objetos arrojados por la cortadora o por el contacto con las hojas: —... - Page 78 Operación con seguridad Objetos arrojados por la cortadora de césped (continuación) Cortadoras de disco — Cuando se usa una cortadora de disco, es importante conocer la zona donde se va a cortar. Si el operador ha realizado cortes en el terreno antes y está...

- Page 79 Operación con seguridad Prácticas de seguridad para la cortadora de césped de montaje inferior Cuando se traslada con una cortadora de césped de montaje inferior: — Mantenga la rampa de descarga extraíble en su lugar y por encima de la abertura de descarga. —...

- Page 80 Operación con seguridad Prácticas de seguridad para cortadoras de césped con laterales y montaje lateral Las posiciones elevadas de los laterales reducen la protección de los escudos y aumentan los riesgos de objetos arrojados y contacto con las hojas. Evite la posibilidad de lesiones graves o muerte por objetos arrojados o contacto con las hojas causados por la elevación y el descenso de los laterales durante las operaciones de corte:...

- Page 81 Operación con seguridad Prácticas de seguridad para trabajos de corte en terrenos desparejos (continuación) — Use extremo cuidado para mantener el control de los equipos cuando trabaja en estas condiciones. — Aumente la estabilidad del tractor agregando pesos o lastre en las ruedas y aumentando al máximo la separación entre las ruedas.

-

Page 82: Estacionamiento Seguro

Estacionamiento seguro Prácticas de seguridad para el estacionamiento — Use las zonas designadas o alejadas del tránsito. — Use lugares con suelo fi rme y nivelado. — Aplique el freno de estacionamiento. — Descienda el equipo de la cortadora de césped hasta el suelo. -

Page 83: Realización De Mantenimiento Con Seguridad

Apagado con seguridad Descenso correcto — Nunca descienda de equipos en movimiento. — Nunca baje de una máquina saltando. — Descienda con cuidado. — Verifi que que no haya peldaños resbaladizos. — Mantenga los pies y las manos lejos de los controles. —... - Page 84 Realización de mantenimiento con seguridad Preparación personal Use la ropa de protección personal y los equipos de protección personal (PPE) que se le proporcionen o que requieran las condiciones del trabajo. SIEMPRE debe usar gafas de seguridad con escudos laterales. Puede necesitar también: —...

- Page 85 Realización de mantenimiento con seguridad Preparación de la máquina Deben controlarse o reducirse las fuentes de energía almacenada (eléctricas, mecánicas, hidráulicas, neumáticas, químicas, térmicas, etc.) al mínimo practicable antes de realizar cualquier procedimiento de mantenimiento, reparación o servicio. Prácticas de seguridad para prevenir posibles lesiones por fuentes que liberan energía: —...

- Page 86 Realización de mantenimiento con seguridad Use ventilación adecuada Si es necesario hacer funcionar un motor en una zona cerrada, elimine del área las emanaciones de escape con una extensión del caño de escape. Si no tiene esa extensión, asegúrese de abrir las puertas y dejar entrar aire del exterior.

- Page 87 Realización de mantenimiento con seguridad Riesgos del sistema hidráulico El sistema hidráulico se encuentra bajo presión siempre que el motor está funcionando; puede conservar presión incluso después de apagar el motor. Haga funcionar todos los controles hidráulicos incluyendo el control hidráulico auxiliar después de que el motor esté...

- Page 88 Realización de mantenimiento con seguridad Evite explosiones ¡ADVERTENCIA! Evite posibles lesiones graves por explosiones. Las baterías de plomo-ácido producen gases sumamente explosivos, especialmente durante la carga. Mantenga alejados los arcos, las chispas, las llamas y el tabaco encendido. — No fume cerca de las baterías. —...

- Page 89 Realización de mantenimiento con seguridad Mantenimiento de neumáticos y ruedas (continuación) ¡ADVERTENCIA! Los tipos de ruedas y neumáticos que generalmente se encuentran en estos equipos requieren cuidados especiales al realizar servicios para evitar lesiones graves o la muerte. No infl e los neumáticos por encima de la presión recomendada.

-

Page 90: Palabras Fi Nales Para El Usuario

Realización de mantenimiento con seguridad Mantenimiento de las hojas de la cortadora (continuación) — ¿Cómo están hechas las hojas de la cortadora de césped? Están hechas acero para resortes de aleación de alta resistencia. Se forjan en caliente y se les da forma para cumplir con las especifi caciones individuales del fabricante;... -

Page 91: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1 © 2011 Alamo Group Inc. - Page 92 We are pleased to have you as a Rhino customer. Your Rotary Cutter has been carefully designed with care and built with quality materials by skilled workers to give maximum service with minimum down time. This manual is provided to give you the necessary operating and maintenance instructions for keeping your rotary cutter in top operating condition.

-

Page 93: Equipment Specifications

The Rhino TW120 Rotary Mower is designed for medium duty applications such as weed, grass, corn stalks, and light brush to 2" diameter. These mowers are single spindle with two free-swinging blades. Free swinging blades reduce the shock of impact when a stationary object is hit. Additional protection is provided by a slip clutch on the gearbox input shaft. -

Page 94: Operating Noise Level/Sound Pressure

• Cutting performance and distribution are best when cutter is level from side to side and front to rear. • In extra heavy material, rear chains will allow better discharge and better distribution than solid rear bands. • Never operate the Mower below full PTO speed of 540 or 1000 rpm. •... -

Page 95: Rhino Limited Warranty

RHINO LIMITED WARRANTY LIMITED WARRANTIES 1.01. Rhino warrants for one year from the purchase date to the original non-commercial, governmental, or municipal purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser (“Purchaser”) that the goods purchased are free from defects in material or workmanship. -

Page 97: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1 © 2011 Alamo Group Inc. -

Page 98: Dealer Setup Instructions

DEALER SETUP INSTRUCTIONS The mower as received from the factory is partially assembled and requires minimum time to complete assembly and is ready for sale. This mower is shipped vertically with shipping brackets. These shipping brackets are intended for use in transporting the mower from the factory to dealer. - Page 99 ITEM DESCRIPTION A-Frame - RH A-Frame - LH Brace Brace Bushing 1-1/8OD x 9/16 Lg Spacer Bolt Bolt Bolt Washer Spacer Bolt Bolt Clip Bushing 1 1/4 x 2 1/8 Lg Bolt TW120 01/11 © 2011 Alamo Group Inc. ASSEMBLY Assembly Section 3-3...

-

Page 100: Tail Wheel Assembly - Lift Type

TAIL WHEEL ASSEMBLY - LIFT TYPE 1. Attach Beam Support Weldments (2) to the Main Frame Assembly with 1/2” x 1-1/2” Bolts (6) & Locknuts(7). 2. Slide the Beam Weldment (1) through Bracket (3) and attach to the Mower Lugs with 5/8” x 4-1/2” Bolt(4) and Locknut(5). -

Page 101: Axle Assembly - Pull Type

ASSEMBLY AXLE ASSEMBLY - PULL TYPE Attach the Rear Axle to the lugs on the rear of the Mainframe using (4) 3/4 x 3-1/2 bolts (#1), (1) 3/4 x 3 bolt (#2), (5) bushings (#3), (5) Locknuts (#4) and (4) Flatwashers. See Figure Asm-R-0184. Attach the Axle Arms to the Main Axle maintaining Dim. -

Page 102: Cutter Leveling

ASSEMBLY CUTTER LEVELING Often when the unit is first assembled and placed on a horizontal surface, the cutter is not level front to rear or side to side. Proper leveling must be obtained in order to prevent skid shoes from plowing in the dirt and to obtain a clean, level cutting performance. -

Page 103: Hydraulic Or Manual Lift

ASSEMBLY HYDRAULIC OR MANUAL LIFT Attach the Spring Assembly option (FIGURE Asm-R-0186) to the lug on the cutter deck behind the Center Gearbox. Retain using 3/4 x 3 capscrew and locknut. Install the Hydraulic Cylinder (FIGURE Asm-R-0187) or the manual Ratchet Lift Screw 1"x2 3/4 (FIGURE Asm-R-0187) between the Axle Center Lug and the Lug directly behind the Center Gearbox. -

Page 104: Shield Assembly

DRIVELINE ATTACHMENT Before starting assembly, make certain that all paint, dirt, and grease are removed from gearbox shaft (1). To ease assembly apply a light coat of grease to splines and assemble. Do not assemble a driveline without a shield. 1. -

Page 105: Jackshaft Bearing Support Assembly

JACKSHAFT BEARING SUPPORT ASSEMBLY Attach the Jackshaft bearing support bracket (1) to the tongue. Loosely attach bearing support by using pivot bolt (3) with bushing (6). Install Bearing and housing assembly (4). Install spacers (5) and bolt (2) leaving installed loosely. Tighten bolt (2) NOTE: Do not tighten to point of collapsing spacer (5). -

Page 106: Driveline Clamp Cone Yoke Operating Instructions

DRIVELINE CLAMP CONE YOKE OPERATING INSTRUCTIONS Loosen the yoke clamp cone with a 11/16” (17mm) wrench and remove the cone from yoke. Slide yoke onto the shaft and align hole for clamping cone with annular groove of gearbox shaft. Reinstall cone and tighten (75 lb.-ft. -

Page 107: Chain Guard (Extra Equipment)

ASSEMBLY Rear Deflector Attach the rear rubber Deflectors (1) to the Cutter with bracket Straps (2), 1/2” x 1-1/4” Bolts (3), Flatwashers (4) and Locknuts (5) CHAIN GUARD (EXTRA EQUIPMENT) CHAIN GUARDS: Front and Rear Chain Guards (Optional Equipment) are recommended for higher than normal usage (100 hours or more per year) and will provide protection from thrown objects with careful operation. -

Page 108: Check Chains (Extra Equipment) For Lift-Models

Rear Chain Guards Attach the right and left Chain Guard assemblies (1) to the Cutter with 1/2” x 1-1/4” Bolts (2), Flatwashers (3), and Locknuts(4). CHECK CHAINS (EXTRA EQUIPMENT) FOR LIFT-MODELS Check Chains are available for attachment to front of Cutter as an accessory. Check chains are used to control cutting height and especially to allow Cutter to be lowered to the same preset cutting height effortlessly. -

Page 109: Operation Section

OPERATION SECTION Operation Section 4-1 © 2011 Alamo Group Inc. - Page 110 RHINO TW120 ROTARY MOWER OPERATION INSTRUCTIONS Rhino rotary mowers are manufactured with quality material by skilled workers. These mowers are designed to cut grass, weeds, small brush and other vegetative material up to 2” diameter in areas such as pastures, industrial areas, and roadsides.

-

Page 111: Operator Requirements

1. OPERATOR REQUIREMENTS Safe operation of the unit is the responsibility of a qualified operator. A qualified operator has read and understands the implement and tractor Operator’s Manuals and is experienced in implement and tractor operation and all associated safety practices. In addition to the safety messages contained in this manual, safety signs are affixed to the implement and tractor. -

Page 112: Tractor Requirements And Capabilities

2. TRACTOR REQUIREMENTS The tractor used to operate the mower must have the power capacity to lift, pull, and operate the Power Take Off (PTO) at the mower’s rated speed while traveling at a ground speed between 2 and 5 MPH. Operating the mower with a tractor that does not meet the following requirements may cause tractor or mower damage and be a potential danger to the operator and passersby. -

Page 113: Tractor Safety Devices

2.2 Tractor Safety Devices If transporting or operating the tractor and implement near a public roadway, the tractor must be equipped with proper warning lighting and a Slow Moving Vehicle (SMV) emblem which are clearly visible from the rear of the unit. -

Page 114: Drawbar-Pull Type Mower

2.5 Drawbar-Pull Type Mower For pull type mowers (540 and 1000 RPM) equipped with an equal-angle driveline, the tractor drawbar must be positioned at a 14” distance from the hitch point to the PTO shaft end for proper operation and minimal wear to the driveline and tractor. -

Page 115: Power Take Off (Pto)

2.7 Power Take Off (PTO) This mower is designed to operate at a PTO speed of 540. Most tractors operate at either 540, or a combination of 540 and 1000 RPM PTO speeds. The operating speed of the mower and tractor can be determined by the number of splines on the driveline yoke and PTO output shaft. -

Page 116: Getting On And Off The Tractor

3. GETTING ON AND OFF THE TRACTOR Before getting onto the tractor, the operator must read and completely understand the implement and tractor operator manuals. If any part of either manual is not completely understood, consult an authorized dealer for a complete explanation. -

Page 117: Starting The Tractor

BEFORE leaving the tractor seat lower the implement, set the parking brake and/or set the tractor transmission in parking gear, disengage the PTO, stop the engine, remove the key, and wait for all moving parts to stop. Place the tractor shift lever into a low range or parking gear to prevent the tractor from rolling. -

Page 118: Connecting The Mower-Lift Type And Semi-Mount Type

5. CONNECTING THE MOWER TO THE TRACTOR Use extreme caution when connecting the mower to the tractor. The mower should be securely resting at ground level or setting on blocks. Keep hands and feet from under the mower deck and clear of pinch points between the tractor hitch arms and mower pins. -

Page 119: Connecting Mower - Lift Type (Quick Hitch)

5.2 3-Point Quick Hitch Our 3-Point Quick Hitch is designed to connect to a Quick-Attach Coupler making dismounting your mower easier. The 3-Point Quick Hitch is also designed to connect the cutter to a tractor’s three-point linkage without the use of a Quick-Attach Coupler. -

Page 120: Connecting The Mower-Pull Type

5.4 Safety Tow Chain If the mower is towed on a public roadway, a safety chain with tensile strength equal to or greater than the gross weight of the mower must be connected between the tractor and mower. This will help control the implement in the event the tongue becomes disconnected from the drawbar. -

Page 121: Setting Mower Height- Lift Type

7. If using a hydraulic cylinder, connect hydraulic hose ends into tractor hydraulic ports. 8. If the mower has been attached to a 3-point hitch drawbar, adjust any tractor equipped lower link check chains, guide blocks, or sway blocks to prevent the hitch and mower from swaying side to side. Note: Never raise the 3-point lift with the mower attached as catastrophic driveline damage will occur. -

Page 122: Setting Mowing Height-Pull Type

5. Level the mower side to side by manipulating one lower lift arm length. On most tractors, at least one of the lift arms is designed to allow for manipulation of its length. Shortening or extending will allow for deck leveling from side to side. -

Page 123: Driveline Attachment

OPERATION 6.3 Setting Deck Pitch Lower Horse Power - Better Fuel Efficiency To increase fuel efficiency and lower horsepower requirements for mower operation, the mower should be operated with the deck approximately 3/ 4" LOWER IN THE FRONT THAN THE REAR. Operating the mower at this pitch will allow the mower to cut the grass only once and requires less work from the tractor. -

Page 124: Driveline Length Check

When attaching the Implement input driveline to the Tractor PTO, it is important that the connecting yoke spring activated locking collar slides freely and the locking balls are seated securely in the groove on the Tractor PTO shaft. Push and pull the driveline back and forth several times to ensure it is securely attached. - Page 125 Shorten the driveline profiles as follows: • Remove the driveline from the tractor. • Position the mower (Lift and Semi-Mount Type - Raise and lower/ Pull Type - Turn sharply) to the point with the shortest distance between the tractor PTO shaft and cutter gearbox. Shut down the tractor and securely block the mower in this position.

-

Page 126: Constant Velocity (Cv) Driveline

7.2 Constant Velocity (CV) Driveline Mowers are equipped with a Constant Velocity (CV) driveline, the maximum turning angle between the tractor and mower must be determined to ensure the joint angle does not over-extend which can cause CV joint damage. Constant Velocity joints enable the driveline to operate smoothly with no vibrations and clattering at angles up to 80°. -

Page 127: Pre-Operation Inspection And Service

8. PRE-OPERATION INSPECTION AND SERVICE Before each use, a pre-operation inspection and service of the implement and tractor must be performed. This includes routine maintenance and scheduled lubrication, inspecting that all safety devices are equipped and functional, and performing needed repairs. DO NOT operate the unit if the pre-operation inspection reveals any condition affecting safe operation. -

Page 128: Tractor Pre-Operation Inspection/Service

8.1 Tractor Pre-Operation Inspection/Service Refer to the tractor operator’s manual to ensure a complete pre-operation inspection and scheduled service performed according manufacturers recommendations. are some of the items that require daily service and inspection: • Tire condition/air pressure • Wheel lug bolts •... -

Page 129: Mower Pre-Operation Inspection/Service

8.2 Mower Pre-Operation Inspection/Service Before each mower use, a complete inspection and service is required to ensure the mower is in a good and safe working condition. Damaged and/or broken parts should be repaired and/or replaced immediately. To ensure the mower is ready for operation, conduct the following. OPS-R-0007 The operator’s manual and safety signs affixed on the unit contain important instructions on the safe and proper use of the equipment. - Page 130 All Safety Shields, Guards and Safety devices including (but not limited to) - the Deflectors, Chain Guards, Steel Guards, Gearbox Shields, PTO integral shields, and Retractable Door Shields should be used and maintained in good working condition. devices should be inspected carefully at least daily for missing or broken components.

- Page 131 • Inspect the gearbox oil level. A low oil level is a warning sign that the gearbox may be cracked or its seal is damaged and needs replacement. • Ensure the gearbox vent is in place and free from clogs. OPS-R-0040_C •...

-

Page 132: Cutting Component Inspection

OPERATION 8.3 Cutting Component Inspection Inspect blade pan and blade assembly for the following: OPS-U-0031 TW120 01/11 Operation Section 4-24 © 2011 Alamo Group Inc. - Page 133 Operating the mower with loose blade hardware will damage the blade holder or blades and can result in blade breakage or blade fastener failure. Broken blades or bolts can be thrown out from under the mower for distances up to 300 feet. When the blades are replaced, the fastening hardware must be replaced.

-

Page 134: Blade Bolt Inspection

8.4 Blade Bolt Inspection Inspect Blade Bolt Head daily for wear as followed: Inspect the Blade Bolt Heads daily for abnormal wear. REPLACE BOTH BLADE BOLTS on the Blades IMMEDIATELY if either blade bolts has: • Visible cracks or • If the recessed area on blade bolt is worn off or •... - Page 135 Tractor PRE-OPERATION Inspection Tractor ID#________________ Date: Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged. Make sure the mower is resting on the ground or securely blocked up and all hydraulic pressure has been relieved.

- Page 136 Rotary Mower PRE-OPERATION Inspection Mower ID#________________ Date: Before conducting the inspection, make sure the tractor engine is off, all rotation has stopped and the tractor is in park with the parking brake engaged. Make sure the mower is resting on the ground or securely blocked up and all hydraulic pressure has been relieved.

-

Page 137: Driving The Tractor And Implement

9. DRIVING THE TRACTOR AND IMPLEMENT Safe tractor transport requires the operator possess a thorough knowledge of the model being operated and precautions to take while driving with an attached implement. Ensure the tractor has the capacity to handle the weight of the implement and the tractor operating controls are set for safe transport. -

Page 138: Brake And Differential Lock Setting

9.1 Starting the Tractor The procedure to start the tractor is model specific. Refer to the tractor operator’s manual for starting procedures for your particular tractor. Consult an authorized dealer if the starting procedure is unclear. Ensure the 3-point control lever is in the lowered position and the PTO is disengaged before starting the tractor. -

Page 139: Driving The Tractor And Mower

9.3 Raising the Mower Using the tractor 3-point hitch control lever-lift type or hydraulic remote lever-pull and semi-mount type, raise the mower high enough to clear all ground obstacles. When raising the mower, make sure all connection points are securely attached and at least 1”... -

Page 140: Crossing Ditches And Steep Inclines

9.5 Crossing Ditches and Steep Inclines When crossing ditches with steep banks or going up sharp inclines, it is possible that the main driveline inner profile will penetrate into the outer housing to its maximum depth until the assembly becomes solid (driveline is at its extreme shortest length). -

Page 141: Operating The Tractor And Implement

Inclines and ditches should be approached along a line which is at an angle as shown. This type of path will reduce the possibility of over-collapse of the driveline and resulting damage. If the gradient is so steep that such an approach increases the possibility of a tractor roll-over, select an alternate crossing path. -

Page 142: Bystanders/Passersby Precautions

Many varied objects, such as wire, cable, rope, or chains, can become entangled in the operating parts of the mower head. These items could then swing outside the housing at greater velocities than the blades. Such a situation is extremely hazardous and could result in serious injury or even death. -

Page 143: Engaging The Power Take Off (Pto)

Rotary Mowers are capable under adverse conditions of throwing objects for great distances (300 feet or more) and causing serious injury or death. Follow safety messages carefully. STOP MOWING IF PASSERSBY ARE WITHIN 300 Feet UNLESS: -Front and Rear Deflectors, Chain Guards, or Bands are installed and in good, workable condition;... -

Page 144: Pto Rpm And Ground Speed

10.4 PTO RPM and Ground Speed Ground speed for mowing will depend upon the height, type, and density of vegetation to be cut. Recommended speed for efficient mower performance is between 2 and 5 mph(3-8 kph). Operate the mower at its full rated PTO speed to maintain blade speed for a clean cut. Refer to the tractor operator’s manual or the tractor instrument panel for the engine speed and gear to provide the required PTO and desired ground speed. - Page 145 Do not mow with two machines in the same area except with Cab tractors with the windows closed. (SGM-11) Mow only in conditions where you have clear visibility in daylight or with adequate artificial lighting. Never mow in darkness or foggy conditions where you cannot clearly see at least 300 feet (90 m) in front and to the sides of the tractor and mower.

- Page 146 Do not let the Blades turn when the Mower Deck is raised for any reason, including clearance or for turning. Raising the Mower deck exposes the Cutting Blades which creates a potentially serious hazard and could cause serious injury or even death from objects thrown from the Blades.

-

Page 147: Right Of Way (Highway) Mowing

10.6 Right of Way (Highway) Mowing • USE DOUBLE CHAIN GUARDS for highway, right-of-way, parks, greenbelt mowing, or all other mowing where human dwellings, vehicles, or livestock could be within 300 feet of the mower. • No shielding is 100% effective in preventing thrown objects. To Reduce Possibility of Injury: 1. -

Page 148: Disconnecting The Mower From The Tractor

10.7 Shutting Down the Implement To shut down attached mower head, first bring the tractor to a complete stop. Decrease engine RPM to idle then disengage cutterhead. The mower head will come to a complete stop within a suitable amount of time. Do not engage or disengage the cutterheads at a high RPM unless there is an emergency situation. - Page 149 Always shut the Tractor completely down, place the transmission in park, and set the parking brake before you or anyone else attempts to connect or disconnect the Implement and Tractor hitches. Never unhitch without using the Tongue Jack. The Tongue is very heavy. Attempting to lift the Tongue without using the Tongue Jack could cause strains or other injury.

-

Page 150: Transporting The Tractor And Implement

12. MOWER STORAGE Properly preparing and storing the mower at the end of the season is critical to maintaining its appearance and to help ensure years of dependable service. The following are suggested storage procedures: • Thoroughly clean all debris off the mower to prevent damage from rotting grass and standing water. -

Page 151: Transporting On Public Roadways

Before transporting the tractor and mower, idle the tractor engine, disengage the PTO and wait for all mower moving parts to come to a complete stop. Once all mower parts are completely stopped, raise the mower to transport height. raising the mower, maintain 1” clearance between the driveline and mower deck. - Page 152 The SMV (Slow-Moving Vehicle) emblem is universal symbol used to alert drivers of the presence of equipment traveling on roadways at a slow speed. SMV signs are a triangular bright orange with reflective red trim for both easy day and night visibility. Make sure the SMV sign is clean and visible from the rear of the unit before transporting the tractor and implement on a public...

-

Page 153: Hauling The Tractor And Implement

Reduce speed before turning or applying the brakes. Ensure that both brake pedals are locked together when operating on public roads. OPS-U- 0023 13.2 Hauling the Tractor and Implement Before transporting a loaded tractor and implement, measure the height and width dimensions and gross weight of the complete loaded unit. -

Page 154: Troubleshooting Guide

14. TROUBLESHOOTING GUIDE Problem Possible Cause Uneven Cut Excessive ground speed. Blades worn, dull, or bent. Mower not level side to side. Improper height adjustment. Low tractor tire pressure on one side Turning too fast. Tractor tires push grass down. Damaged Mower pan. - Page 155 Blade Bolts Working Loose Bolts not tightened. Bolt hole elongated or oversized. Locknut worn out. Gearbox Noisy Low Lubricant. Rough gears. Worn Bearing. Gearbox Leaking Damaged Oil Seal. Bent Shaft. Oil Seal Race rough. Oil Seal installed wrong. Oil Seal not sealing in the housing. Oil level too high.

-

Page 157: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1 ©2011 Alamo Group... -

Page 158: Hazards With Maintenance Of Implement

HAZARDS WITH MAINTENANCE OF IMPLEMENT AVOID SERIOUS INJURY OR DEATH FROM COMPONENT FAILURE BY KEEPING IMPLEMENT IN GOOD OPERATING MAINTENANCE. BEFORE PERFORMING SERVICE, REPAIRS AND MAINTENANCE ON THE IMPLEMENT: • STOP ENGINE AND PTO, engage parking brake, lower implement, allow all moving parts to stop and remove key before dismounting from tractor. -

Page 159: Lubrication

Rhino mowers use balanced and matched system components for blade carriers, blades, cuttershafts, knives, knife hangers, rollers, drivetrain components, and bearings. These parts are made and tested to Rhino speci- fications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce mower performance, void warranties, and present a safety hazard. - Page 160 MAINTENANCE TW120 01/11 Maintenance Section 5-4 ©2011 Alamo Group...

- Page 161 MAINTENANCE TW120 01/11 Maintenance Section 5-5 ©2011 Alamo Group...

-

Page 162: Drivelines

GEARBOX The Gearbox has been filled with lubricant to the Test Plug Level prior to shipment. However, you should check the oil level at Test Plug before operating, and frequently thereafter. The gearbox should not require additional lubricant unless the box is cracked or a seal is leaking. It is recommended that the oil level plug be removed after every 8 to 10 hours of operation and oil added until it runs out Test Plug hole. - Page 163 LOCATION Cross & Bearings Telescoping Tube Shield Bearings End Spider Hub CV Center Housing TW120 01/11 ©2011 Alamo Group MAINTENANCE EXTENDED LUBE INTERVAL 8 Hours 8 Hours 50 Hours 20 Hours 8 Hours Maintenance Section 5-7 LEVER ACTION PUMPS 2 - 3 6 - 8 1 - 2 1 - 2...

-

Page 164: Main & Jackshaft Driveline Shields

MAIN & JACKSHAFT DRIVELINE SHIELDS To remove the main inner driveline shield, Remove the locking screws. Align the bearing tabs with the cone pockets. FIGURE Mnt-0026. Remove the half-guard and remove the bearing ring. FIGURE Mnt-R-0012. Inspect the driveline shield for worn areas or cracks. If the shield has any dents or cracks, replace the Shield. While the Shields are off, examine the Driveline for signs of abnormal wear, bent or twisted shafts, or cracks in the shafts or tubes. -

Page 165: Main Cv Driveline Safety Shield (Figure Mnt-R-0032)

MAIN CV DRIVELINE SAFETY SHIELD (FIGURE Mnt-R-0032) To remove the outer CV cone, remove the locking screws from shield cone. Remove cone over yoke. MNT-R- 0038. Remove bearing ring and remove the locking screws from inner shield cone. Mnt-R-0038. Turn inner cone to assembly position and remove half shield. -

Page 166: Driveline Taper Cone Yoke Removal Instructions

DRIVELINE TAPER CONE YOKE REMOVAL INSTRUCTIONS 1. Loosen 11/16” bolt end one revolution. 2. Insert drift punch (max. diameter 0.375) into hole opposite the hex head and impact with hammer. 3. Repeat operations 1 & 2. 4. Remove clamping cone from yoke and yoke from shaft. -

Page 167: Blade Carrier Removal

BLADE SHARPENING Always sharpen both blades at same time to maintain balance. Follow original sharpening pattern as shown in Mnt-R-0008. Always sharpen blades by grinding. DO NOT heat and pound out edge. Do not sharpen blade to a razor edge, but leave a 1/16” blunt edge. Do not sharpen back side of blade. Avoid personal injury. -

Page 168: Blade Carrier Inspection

BLADE CARRIER INSPECTION Blade bolt fit into carrier bushings should be checked every time blades are changed. The blade bolt should fit into carrier bushings as a snug slip fit. If the blade bolt fit appears to be loose or sloppy, measure the square hole in bushing. -

Page 169: Blade Removal

BLADE CARRIER INSTALLATION Clean the splines on both the blade carrier and output shaft. Position carrier on the gearbox output shaft and install special washer, and nut. Tighten nut holding blade carrier to minimum 600 ft. pounds, strike the carrier near the hub several times with a heavy hammer to seat the hub. -

Page 170: Blade Bolt Inspection

Blade Bolt Inspection Inspect Blade Bolt Head daily for wear as followed: Inspect the Blade Bolt Heads daily for abnormal wear. REPLACE BOTH BLADE BOLTS on the Blades IMMEDIATELY if either blade bolts has: • Visible cracks or • If the recessed area on blade bolt is worn off or •... -

Page 171: Blade Timing And Rotation

BLADE TIMING AND ROTATION (FIGURE Mnt-R-0102) Blades on multi-spindle mowers overlap cutting paths to ensure a complete cut across the width of the mower and to compensate for blade tip wear. If a gearbox has been repaired, a blade carrier or side driveline has been removed, or other maintenance performed which altered the factory set blade carrier timing, the blades must be re-timed to ensure they will not collide while rotating. -

Page 172: Slip Clutch

MAINTENANCE SLIP CLUTCH A slip clutch is incorporated in the PTO driveline. It is designed to slip, absorb the shock load, and protect the driveline. After the first hour of operation, the slip clutch should be checked for overheating. After this first check, the slip clutch should be checked weekly or anytime there is overheating. -

Page 173: Proper Torque For Fasteners

STORAGE Your rotary cutter represents an investment from which you should get the greatest possible benefit. Therefore, when the season is over, the cutter should be thoroughly checked and prepared for storage so that a minimum amount of work will be required to put it back into operation for the next season. - Page 174 MAINTENANCE TW120 01/11 Maintenance Section 5-18 ©2011 Alamo Group...

- Page 175 372-9529 (830) contacto ponerse seguridad seccion 1-20 pagina RHINO partes seguridad. peligro puede auténticas partes Partes RHINO. especificaciones línea componentes rodillos, portadores para seleccionado 1-14 Seguridad Sección Fax: 78155; Seguin, Street favor español completamente referirse porfavor español DISTRIBUIDOR CONTACTE seguridad. economía (SPRM-1 presentar...

- Page 176 reproductivos. HM01 California estado plomo, componentes reproductivos. daños otros nacimiento agentes emiten contienen vehículo elementos gastado. antideslizantes. caja cubiertas acero, protectores cadena, SEGURIDAD: rígidas. superficies suelde nuevas. cuchillas movimiento. desgaste. filtraciones, sueltos ajustes rotas, DESCRIBEN MANTENIMIENTO componentes fallas vibraciones equipos. componentes químicos.

- Page 177 curvas. TH02 uniformes, poco irregulares superficies cortadora. vuelco. puede determinar para curvas TERRENO CARRETERAS hora millas PARA IMPLEMENTO TRACTOR central. SEGURIDAD: CADENA cortadora. para clara visión tener para implemento implemento, cabina tractor, operación adecuada para advertencia adecuadas. condiciones funcionamiento segura. forma dirección mantener...

- Page 178 cortadora, conducción calentamiento excesivo deslizamiento objetos contacto entre cortadora quemadas bastidor vegetación: cortadora servicio reparación subterráneos. municipales. servicios cables todos distancia tipo. otro subterráneos, eléctricos alimentación SERVICIOS: LÍNEAS ELÉCTRICO CONTACTO 1-11 Seguridad Sección combustible. EF02 cambios. líneas alrededor acumulado residuo evitar para DESLIZANTES...

- Page 179 médico inmediato hidráulico. fluido eyección boquillas HIDRÁULICOS: SISTEMAS VISIBLES. verifique distribuidor sistema. trabajar antes AJUSTADAS ESTADO BUEN combustible. FILTRACIONES PENETRACIÓN PRESIÓN ALTA HIDRÁULICO MB01 cortadora acercarse antes SONIDOS alas cortadora detenido. líneas giratorias, cuchillas CUERPO GRAVES LESIONES EVITAR PARA CORTADORA 1-10 Seguridad Sección...

- Page 180 trabajo longitud aumento cuchillas fallas objetos, coincide implemento semanal. conducción. línea caer hacer PTO. romper soporte solidificará. deslizará cambios caja operaciones: mantenimiento. reparación tareas faltan. colocados cubiertas conducción IMPLEMENTO: OPERAR PTO. cortadora acercarse antes SONIDOS detenido. líneas giratorias, cuchillas MUERTE: ELEMENTOS OTROS CONDUCCIÓN...

- Page 181 detengan espere implemento, detenidos. equipos. para SEGURIDAD CINTURONES ATROPELLO TRACTOR CAÍDA Seguridad Sección tractor. bajarse antes RO01 descienda mano, freno coloque estén móviles partes éste implemento. tractor tractor. asiento sentado tractor operar seguridad tractor. asiento vertical. posición trabado (ROPS) ANTIVUELCO SISTEMA MUERTE GRAVES...

- Page 182 dañadas TO02-X vibración EXCESIVA: transporte. posición cortadora adelante. CUCHILLAS. dañado. está gran arrojados pueden objetos pesados, objetos contacto transporte. fijas. obstrucciones sólidos, objetos CUCHILLAS cuchillas exponer suelo mismo operando cortadoras vegetación. sean elementos Seguridad Sección dobladas CUCHILLAS dañada fuente detectar para tractor.

- Page 183 como SÓLIDOS OBJETOS CONTACTO OBJETOS riesgo posible ELIMINAR cuchillas antideslizantes zapatas pro- posibilidad reducir Para arrojados. cortadora. donde verde cinturón cortes parques dañados. están éstos faldones bandas, acero, protectores entre cortadora, operar funcionamiento gran plataforma desprendidos área. extraños OBJETOSQUE POSIBILIDAD DETECTAR residuos.

- Page 184 equipo. alejarse alrededores. EQUIPO: equipo. alejarse debajo cuerpo pies manos, poner elevados. componentes implementos componentes debajo palanca inesperado movimiento aplastamiento. accidentes tractor tracción barra ajustada ajustado. seguridad cinturón equipos. operaciones para SEGURIDAD IMPLEMENTO: APLASTAMIENTO, TRACTOR, Seguridad Sección CH02 operador. lesión gato pesados.

- Page 185 CD02 tractor. transmisión enredo riesgo implica conducción opera- velocidad duplicación consecuencia tractor: coincide PTO. romper solidificará. deslizará implemento. cambios caja para implemento tractor FUERZA(PTO) sobre libremente operación: lengüeta movimiento controlar llave. saque mano freno TRACTOR APLASTAMIENTO IMPLEMENTO Seguridad Sección conectada directamente línea desprotegidas...

-

Page 186: Operación

OS01 fallas conducción línea roturas PROTECTORAS PRENDAS obstrucciones desniveles, pozos, empinadas, altura densidad césped, tipo obstrucciones desniveles, pozos, (100 metros más nítida visibilidad DESCANSE. PAUSA HAGA sentidos. sobre medicación alcohol. drogas equipo. lesión. causar giratorias contraer evitar polvorientas equipo reparar operar guantes Mensajes... - Page 187 ruso. alemán, francés, GS01 372- (830) Fax: 78155; Seguin, idiomas, siguientes alguno evitar para común graves lesiones Manual este Seguridad. eficiente más reparación operación accesorios maquinaria, destrucción observarse que, específicos OCASIONAR PODRÍA evitada, OCASIONAR PODRÍA evitada, OCASIONARÁ evitada, seguras. prácticas puede USTED Sólo...

- Page 188 Inc. Group Alamo 2011 © Seguridad Sección SEGURIDAD SECCIÓN...

- Page 190 Cortadora Seguridad (entregado Cortadora ADMA Conducción Línea (instalada) seguridad operación) (instalación necesario) (instalado (instalado) tractor (entregado) (colocados) seguridad ajuste) (limitador conducción instalación) SEGURIDAD ajustadas bien montaje altura) (ajuste máx.) giro radio (verificar C.V. elevación operación (verificar centro) nivel (ajustar montaje pre-operación (ajustar) iguales)

- Page 191 distribuidor: distribuidor: serie: Teléfono: formato – AEM/FEMA formato – AEM/FEMA Cortadoras Video suministrar AEMVideo@alamo-group.com Dirección Vendedor Número Cortadora Operador Cortadora Cortadoras Operador para Cortadoras Operador para para Seguridad dispuesto está cortadora electrónico correo 372-9529 (830) 78155 Seguin, Street Walnut 1502 Services Video correo...

- Page 192 implicado estará esté, practicas implemento eso, después anualmente pieza código Operador. asistir puede Operador Manual comprender cortadora), VHS. versión solicite 78155, encuentra formulario AEMVideo@alamo- electrónico Group Alamo acerca pregunta alguna comprende nueva. cortadora video, mire video: copia entregado haya importante. aprendizaje advertencia mensajes...

- Page 193 compra: adquirido. RHINO seguridad. maximizar presentar garantía anular especificaciones. estas cumplen según prueban fabrican ganchos hojas, corte, ejes cuchillas, utilizan Rhino cortadoras Partes. correctamente implemento abajo arriba trasero, frontal, cabalmente comprender para desempeño satisfacción comprendido haya manual. este totalidad comprendido antes manual este...

- Page 194 $0.00 C01-Cover equipo. operar Instrucciones SIGA máquina esta segura operación 00762120C nº. Parte GIRATORIA CORTADORA/TRITURADORA TW120 Inc. Group Alamo 2011 antes manual este contenidas ENTIENDA, LEA, siempre. unidad esencial parte OPERADOR MANUAL © parts@servis-rhino.com 800-446-5158 60936 Ave. Sangamon Operación Seguridad mantener debe Operador...

Need help?

Do you have a question about the TW120 FC-0024 and is the answer not in the manual?

Questions and answers

Looking for wheels for tw120 rhino

Where is the serial number located? I do not have an owners manual, it was bought used.