Trane CVGF Product Manual

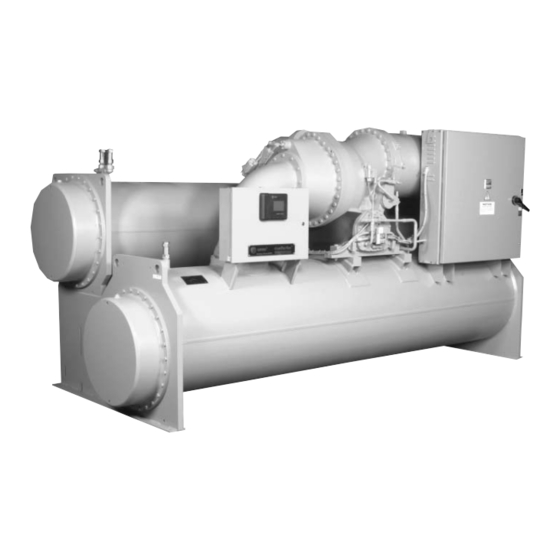

Water-cooled hermetic centrifugal water chillers

Hide thumbs

Also See for CVGF:

- Instruction manual (28 pages) ,

- Installation instructions manual (32 pages)

Summary of Contents for Trane CVGF

- Page 1 Centrifugal Water Chillers Model CVGF Water-Cooled Hermetic Centrifugal Refrigeration Capacities From 400 to 1000 Tons (1400 kW-3510 kW) 50 and 60 Hz CTV-PRC001-GB September 2004...

-

Page 2: Introduction

The Trane Company continues to deliver its reliability and energy fitness commitment on its newest line of gear drive centrifugal water chillers, the Model CVGF . The major advantages of the Model CVGF are: • High reliability • Low sound levels •... -

Page 3: Table Of Contents

CTV-PRC001-GB Contents Introduction Features and Benefits Application Considerations General Data Jobsite Connections Controls Physical Dimensions Mechanical Specifications Conversion Table... -

Page 4: Features And Benefits

• Designed with the retrofit and replacement market in mind • The 400 to 500 NTON sizes can fit through most double-width doors • Small footprint of the CVGF chiller saves valuable equipment room space Simple Installation • Simplified piping; the only water... - Page 5 Microprocessor Controls with CH530 DynaView Operator Interface ™ DynaView is the unit-mounted control panel and also serves as the main processor and operator interface. It has a touch-sensitive overlay on a 1/4 VGA display. DynaView presents information through an intuitive, tabbed- navigation system. Alternate languages can be downloaded to the control panel, which can hold English plus two other languages at...

- Page 6 The Tracer chiller controller will be gradually applied to all Trane chillers. TechView will then serve as a common interface to all Trane chillers, and will customize itself based on the properties of the chiller with which it is communicating. Thus, the service technician learns only one service interface.

- Page 7 Benefits Building Automation and Chiller Plant Control For a preprogrammable and flexible building automation and chiller plant control, Trane has developed the Tracer Summit ™ . It can control the operation of the complete installation: chillers, pumps, cooling towers, isolating valves, air handlers and terminal units.

- Page 8 Tracer Summit building automation system. But the benefits do not stop at the chiller plant. At Trane, we realize that all energy used in your cooling system is important. That is why we worked closely with other equipment manufacturers to predict the energy required by the entire system.

- Page 9 This results in a better balance of forces at low loads and produces a machine with a wider unloading capability. In Trane centrifugal chillers, gas prerotation vanes ahead of the compression stage improve impeller aerodynamic efficiency, resulting in smoother unloading and reducing power consumption.

-

Page 10: Application Considerations

Trane’s CH530 and/ or Tracer system. Chillers are designed to ARI conditions of 29.4°C (85°F), but Trane centrifugal chillers can operate to a five psig pressure differential between the condenser and evaporator at any... -

Page 11: General Data

Table GD-1 – Model CVGF Description Model Nominal Cooling Capacity NTON Heat Exchanger Size Evaporator EVSZ Condenser CDSZ Heat Exchanger Bundles Evaporator EVBS A = Small B = Medium C = Large Condenser CDBS A = Small B = Medium... - Page 12 Table GD-3 – Evaporator and Condenser Flow rates (Minimum and Maximum, liters per second, gallons per minute) High Efficiency Shells - 0.75 inch (19 mm) Int. Enhanced Cu Tube: Condenser: Nominal Shell Bundle Size Small Medium Number of Passes Min Flow lps (gpm) 31 (487) 34 (542) 37 (586)

-

Page 13: Jobsite Connections

CTV-PRC001-GB Jobsite Connections Supply and Motor Lead Wiring and Connections Copper conductors only should be connected to the compressor motor due to the possibility of galvanic corrosion as a result of moisture if aluminum conductors are used. Copper conductors are recommended for supply leads in the starter panel. -

Page 14: Controls

Standard Features Field Connection The field-connected elements are involved in physically turning the chiller on or off. This involves ensuring that the chiller is not in an emergency or external stop condition, starting the pumps, and verifying that flow has been established. -

Page 15: Optional Features

Extended Operation Package Select the extended-operation package for chillers that require external , hot water control, and/or base-loading capabilities. This package also includes a 4-20 mA or 0-10 Vdc analog input for a refrigerant monitor. • External base-loading control input •... - Page 16 Tracer ™ Chiller Controller The chiller controller uses proportional- integral-derivative (PID) control for all limits—there is no dead band. This removes oscillation above and below setpoints and extends the capabilities of the chiller. Some of the standard protection features of the chiller controller are described in this section.

- Page 17 Momentary Power Loss and Distribution Fault Protection Three-phase momentary power loss (MPL) detection gives the chiller improved performance through many different power anomalies. MPLs of 2.5 cycles or longer will be detected and cause the unit to shut down. The unit will be disconnected from the line within 6 line cycles of detection.

-

Page 18: Physical Dimensions

– Recommended clearance (D2) for machine without unit mounted starter is 1219 mm (38”) Unit length is not included for the waterbox. See page 19 for waterbox dimension Physical Dimensions Figure PD-2 – Model CVGF Cooling Only Without Unit Mounted Starter (for Remote Mounted Starter) ” LENGTH Unit Dimensions... - Page 19 CTV-PRC001-GB Physical Dimensions Model CVGF Water Connection Pipe Size Water Passes Metric Pipe Size (mm) DN Evaporator 2 Pass DN 200 (8”) 3 Pass DN 200 (8”) Condenser 2 Pass DN 250 (10”) Evaporator Water Box Length — SI (English)

-

Page 20: Mechanical Specifications

The Trane CVGF packaged centrifugal water chillers using HFC-134a refrigerant consist of a hermetic two stage, gear-drive centrifugal compressor, evaporator, condenser, interstage economizer, unit-mounted microprocessor based control panel and compressor motor starter. The chiller is completely factory assembled. Compressor Two-stage centrifugal compressor with high-strength aluminum alloy fully shrouded impellers. - Page 21 It is a factory-mounted packaged and tested on the CVGF unit. All controls necessary for the safe and reliable operation of the chiller are provided including oil management, interface to the starter, and three phase motor overload protection.

- Page 22 The oil ships in the unit’s sump and the refrigerant ships directly to the jobsite from refrigerant suppliers. Painting All painted CVGF surfaces are coated with two coats of air-dry beige primer- finisher prior to shipment. Insulation The chiller can be ordered with or without factory applied insulation.

-

Page 23: Conversion Table

To Convert From: Length Feet (ft) meters (m) Inches (In) millimeters (mm) Arca Square Feet (ft square meters (m Square Inches (In square millimeters (mm Volume Cubic Feet (ft Cubic meters (m Cubic Inches (In Cubic mm (mm Gallons (gal) litres (l) Gallons (gal) cubic meters (m... - Page 24 Literature Stocking Location Europe Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice. Only qualified technicians should perform the installation and servicing of equipment referred to in this publication.

Need help?

Do you have a question about the CVGF and is the answer not in the manual?

Questions and answers