diagenode Bioruptor Pico User Manual

Sonication system

Hide thumbs

Also See for Bioruptor Pico:

- Manual (20 pages) ,

- User manual (28 pages) ,

- User manual (28 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for diagenode Bioruptor Pico

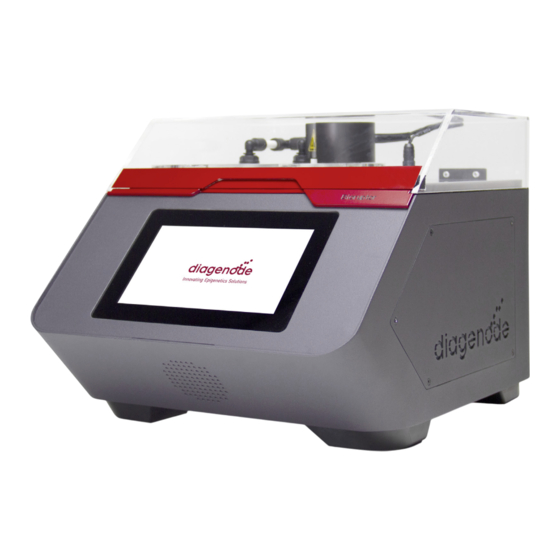

- Page 1 Bioruptor Pico ® Sonication System USER GUIDE Version 3 01_2020...

- Page 2 210 hours of total running time* from the date that the warranty period begins, unless the original quotation or accompanying documentation states a different warranty period. The warranty period begins on the date of delivery and apply only to the first purchaser of the product. The warranty period expires when one of the two above conditions ends (5 years or 210 hours of total running time*). If a manufacturing defect arises and a valid claim is received within the warranty period, Diagenode, at its discretion, will repair or replace the product in accordance with the warranty terms and conditions stated herein. In case of repair or replacement of a product under warranty, Diagenode will cover the expenses to return the repaired or replacement product. This warranty covers only manufacturing defects and does not cover any damage caused by misuse, lack of compliance to recommendations stated in the manual, neglect, accidents, abrasion, or ...

-

Page 3: Table Of Contents

Contents BIORUPTOR PICO ® Critical steps for maintenance and efficient shearing Introduction Technical specifications Getting to know you Bioruptor Pico System Equipment installation Installation System Operation Tube holders & tubes BIORUPTOR COOLER ® Safety Design and functions Operation Maintenance 38 Disposal Technical data ... -

Page 5: Bioruptor ® Pico

BIORUPTOR PICO ®... -

Page 6: Critical Steps For Maintenance And Efficient Shearing

Critical steps for maintenance and efficient shearing General warnings DON’T Turn on the instrument without water Change water at least once every month Exceed 30 min of total sonication Use deionized or distilled water Tilt the sonication unit QC your system with our DNA QC Kit Sonication bath temperature • Optimal temperature for sonication is 4°C. Sample temperature should not exceed 8°C. • The Bioruptor Cooler (Cat. No. B02010010, B02010011, B02010012) has to be used to guarantee the automatic temperature control of the sonication bath during the entire sonication process. Validated tubes for the Bioruptor Pico ®... -

Page 7: Introduction

Introduction Diagenode’s Bioruptor Pico uses a gentle method of sonication to retain the integrity of DNA and/or biological complexes, including chromatin, protein-protein binding, protein- DNA complexes and other biochemical and biological assay systems. The Bioruptor Pico sonication system uses a sonication bath to generate indirect sonication waves, which ... -

Page 8: Technical Specifications

Bioruptor Pico technical specifications BIORUPTOR PICO ® 100 - 240 V Input Voltage Range 50 - 60 Hz Input Frequency Range Maximum Electrical Consumption 4.2 A 20 - 60 kHz Ultrasonic Wave Frequency Unit Dimensions • The sonicator 380 (W) x 315 (D) x 275 (H) mm • The cooler 200 (W) x 390 (D) x 495 (H) mm Weight • The sonicator 9 kg 26.9 kg •... -

Page 9: Getting To Know You Bioruptor Pico System

Getting to know your Bioruptor Pico system Bioruptor Pico components overview Sonication bath Motorized lid Sonication unit Power cable (EU) Power cable (US) Tube holder Bioruptor Cooler (detailed instructions page 21) - Page 10 Sonication bath The sonication bath is a critical component of the instrument. The generators below the tank produce ultrasonic waves which are then transferred through water. The sonication bath requires special handling and care as described below. Handling The sonication unit must remain upright at all times, especially when moved. Tilting the sonication ...

- Page 11 tank. The integrated regulating valve ensures that water will only be replaced during the off cycle to avoid any interference between the water flow and the sonication process. Bioruptor Cooler ® Sonication unit Motorized lid The motorized lid, along with the gear plate accessory, keeps the sample tubes in constant rotation and ensures optimal position in the sonication bath during sonication. Avoid the immersion of the motor into the water. Tube holders Several sizes of tubes can be used with the Bioruptor Pico. The minimum and maximum sample volume to be used with each tube is given in the table below. TUBE SIZE MINIMUM MAXIMUM 0.2 ml 20 µl 100 µl 0.65 ml 100 µl 100 µl 1.5 ml 100 µl 300 µl 15 ml 500 µl 2 ml...

-

Page 12: Equipment Installation

Equipment installation The following pages contain information on installing your particular Bioruptor Pico model. This equipment must only be installed by personnel after reading this section. Consider all hazards even though no particular hazards have been identified during installation. Before starting installation work, turn the main switch off and secure the unit against being re- energized. No special tools are required. One square meter is needed to set-up the Bioruptor Pico. Devices are designed to be safe under the following conditions: • I ndoor use • Power plug must be grounded • A ltitude up to 2,000 meters • POLLUTION DEGREE 2 (Normally only non-conductive pollution occurs. However, • Operating external temperature 15°C to 25°C occasionally a temporary conductivity caused (do not install the Bioruptor in a cold room) by condensation is expected) • ... - Page 13 Installing the Bioruptor Pico system Before starting the installation, turn the main switches off and make sure that the unit is not plugged into an electrical outlet. 1. Open the boxes and unpack all components. Bioruptor ® Pico Bioruptor ® Cooler 2. P lace the Bioruptor on a bench. • Important Note: Please make sure that the Bioruptor Pico is always placed on a level surface. 3. P lace the Bioruptor Cooler on the bench or below the Bioruptor. 4. C onnect the Bioruptor Pico to the Bioruptor Cooler with the cooling long red and blue isolated tubing by inserting them into the connectors (Optional: Cut the length you need for the output and input flow. Make sure there is enough slack). 5. F ill the tank of the Bioruptor Cooler with 2 - 3 liter and the sonication bath of the ...

-

Page 14: System Operation

System operation Touch screen: Allows the user to easily program the sonication of samples. PICO MANUAL BIORUPTOR ®... - Page 15 Brightness: Adjust the brightness of the recommendations for your applications screen Good Practices: Critical steps for Language: Choose your voice language Bioruptor maintenance and efficient shearing Diagenode dots: Go back to the top Maintenance: Access for administrators menu Information: General information about Technical Support: Diagenode contact information for technical questions your Bioruptor Pico Commercial Support: Diagenode contact Edit: Edit the parameter information for commercial questions Question mark: Some notes to guide you LED LIGHT BAR The LED light bar allows the tracking of the processing of your samples. The blue light means the system is waiting for the operator. progressive green light indicates the progression of the shearing process. green light indicates the end of the shearing process. The orange light means the protocol is on pause. light indicates an alert message.

- Page 16 START SHEARING EXPERIMENT ‘ ’ PROTOCOLS C lick on Protocols icon of the top menu. 2. C lick on ‘Go & Shear’ icon to start a new protocol or click on ‘User Protocols’ icon to find your pre-recorded shearing protocol. GO AND SHEAR 3. S elect your mode. Find validated parameters on the Easy Mode or optimize your protocol with ...

- Page 17 PREPARE SAMPLES 1. F ill the sonication tubes with same volume of sample. Use the recommended tubes and sample volumes for optimal shearing efficiency. Visit our Guidelines folder for more information. 2. V ortex and then spin your samples. 3. F ill all positions of the tube holder with your samples (or with water of same volume) and place it on the motorized lid. 4. C lose the lid to start the run. The sonication only starts ...

- Page 18 START PROCESSING & MONITOR PROGRESS 1. C lick “Go” to start the shearing process. You GO AND SHEAR (easy mode) will then be asked to check water temperature and right setting of your samples. seconds seconds cycles seconds 2. O nce the run started, the running screen appears. The running screen indicates SHEARING PROCESS the ...

-

Page 19: Tube Holders & Tubes

Tube holders & tubes The holder is made up of a tube holder and its specific dock. Tube holder To guarantee homogeneity of chromatin or DNA shearing, the tube holders should always be completely filled with Dock tubes. Never leave empty spaces in the tube holder. Fill the empty spaces with tubes containing the same volume of distilled water. 15 ml sonication 0.2 ml Bioruptor Tube holder for 0.2 ml tubes ®... -

Page 21: Bioruptor ® Cooler

BIORUPTOR COOLER ®... -

Page 23: Safety

Safety General safety instructions • The equipment must only be operated for the intended use under the conditions stated in this operating manual. Any other type of operation is considered to be not-intended use and can impair the protection provided by the device. • The operating manual is part of the device. The information in this operating manual must therefore be available in close vicinity to the device. Also store this copy of the operating manual carefully. Any hazards (electrical shock, fire, contact with movable parts, etc.) caused by the use of the device must be eliminated as much as possible by the design in accordance with the appropriate standards. Residual hazards are reduced using any of the following measures: • If relevant, there are safety devices for the device. These devices are essential for the safety of the device. Their functionality must be ensured with appropriate maintenance activities. • If relevant, there are warning symbols on the device. These symbols must always be observed. • There are safety instructions in this operating manual. These instructions must always be observed. • There are additional specific requirements for the personnel and for the personal protective equipment. Intended use The present device is exclusively permitted to be used for tempering and delivering non- flammable heat transfer liquids to the Bioruptor... - Page 24 • I ncorrect connection of tubes. Modifications to the device Any technical modifications to the machine are prohibited. Service works may be carried out only by qualified personal. Heat transfer liquid The device is exclusively designed for nonflammable heat transfer liquids in Class I according to DIN 12876-1. Heat transfer liquids are used for the temperature control. In each case, the heat transfer liquids cover a specific temperature range. This temperature range must match the temperature range of your application. The use of heat transfer liquids can cause hazards from high or low temperatures and fire if certain temperature thresholds are exceeded or undercut or if the container breaks and there is a reaction with the heat transfer liquid. The heat transfer liquid safety data sheet specifies all possible hazards and appropriate safety measures for handling the liquid. The safety data sheet must therefore be consulted for the intended use of the device. Materials All parts coming into contact with the heat transfer liquid are made of high quality materials suitable for the operating temperature. Stainless steel and temperature-resistant plastics are used. Hoses When selecting suitable hoses for the application, the permissible temperature range and ...

- Page 25 Personnel qualification Operating personnel Operating personnel are employees that have been instructed by technical staff in the intended use of the device according to the operating manual. Personal protective equipment Protective clothing • Protective clothing is required for certain activities. This protective clothing must comply with the legal requirements for personal protective equipment. Protective clothing should have long sleeves. Safety footwear is additionally required. Protective gloves • CE protective gloves are required for certain activities. These protective gloves must comply with the legal requirements for personal protective equipment of the European Union. Protective goggles • Protective goggles are required for certain activities. These protective goggles must comply with the legal requirements for personal protective equipment of the European Union. Structure of the safety instructions Danger • A safety instruction of the type “Danger” indicates an immediately hazardous situation. • ...

-

Page 26: Design And Functions

Unpacking Personnel: Operating personnel 1. Unpack the device. Keep the original packaging of the device for later transport. 2. Inspect the device and the accessories immediately after delivery for completeness and transport damage. If there is unexpected damage to the device or accessories, inform the carrier immediately so that a damage report is produced and a check of the transport damage can be made. Design and function Design of the circulation chiller - Front side Top handle Filler neck with cover Top cover Level indicator Control panel Overflow tube Drain connection Front panel with ventilation openings Four support feet PICO MANUAL BIORUPTOR ®... - Page 27 Design of the circulation chiller - Back side Supply water connection (blue) Return water connection (red) Mains power socket with fuse 24Vdc socket (to be connected to the Bioruptor ® Back handle Ventilation openings Controls Mains power switch The mains power switch can be put in the following positions: • In position [I], the device is switched on. • In position [O], the device is switched off. Control Panel and display buttons Display LEDs UP arrow button ENTER button DOWN arrow button Mains power switch...

- Page 28 Function elements LEDs for function display Yellow LED: valve Blue LED: refrigeration Red LED: fault Each device has three LEDs with the following functions: • The yellow LED lights if the 24 Vdc signal from the Bioruptor is present (open solenoid valve). • The blue LED indicates whether the refrigeration unit is active. • The red LED lights in the event of device faults. PICO MANUAL BIORUPTOR ®...

- Page 29 Hydraulic circuit Hydraulic circuit The hydraulic circuit designates the circuit through which the heat transfer liquid flows. The circuit basically consists of the following components: • • internal storage bath with heat transfer liquid • • pumps for conveying the heat transfer liquid into the external consumer via the pumps connections Pumps The devices are equipped with a pressure pump for the supply and a membrane suction pump for the return. Level indicator The fill level of the heat transfer liquid in the circuit can be read using the level indicator.

- Page 30 3.4 Rating plate The rating plate information is explained in detail in the following table. SPECIFICATION DESCRIPTION Type Device type Order No. Order number of the device Serial number of the device Serial No. (Manufacturing year indicated with two digits after the letter “S”) Device must only be connected to this voltage and Voltage frequency Refrigerant that is used in the compressor of the device Refrigerant I (GWP-value indicated in brackets) Fill quantity of the refrigerant Fill quantity I (tons of CO2 equivalent in brackets) maximum permitted operating pressure on the refrigerant PS high pressure I high pressure side (compressor, condenser) maximum permitted operating pressure on the refrigerant PS low pressure I low pressure side (expansion, evaporation) Current consumption Current consumption of the device during operation Protection class IP protection class of the device Fuse Fuse used in the device Class according to DIN German standard for electrical laboratory equipment 12876-1 PICO MANUAL BIORUPTOR ®...

- Page 31 Before commissioning EMC classification Approval of the equipment according to EMC classification COUNTRIES EMC CLASS Class B, oder? Europe This classification has been made according to the EMC standard DIN EN 61326-1 (corresponds to VDE 0843-20-1). Class A This classification has been made according to the FCC (Federal Communications Com- mission) regulations, Section 15. Class A Canada This classification has been made according to the ICES-003 (Interference Causing Equipment Standards) and NMB-003 regulations. Instructions for machines, Europe EMC classification of the equipment: • Class A: Operation only on mains power supplies without connected residential areas. • • Class B: Operation on mains power supplies with connected residential areas. In the case of unfavorable mains conditions, disruptive voltage fluctuations can occur. Instructions for Class A digital device, USA “This equipment has been tested and found to comply with the limits for Class A digital device, pursuant to Part 15 of the FCC (Federal Communication Commission) Rules. These ...

- Page 32 Instructions for Class A digital device, Canada This Class A digital apparatus complies with Canadian ICES-003” (ICES = Interference Causing Equipment Standards). « Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada ». Device Placement Very specific placement conditions are applicable for the equipment. These placement conditions are specified in the technical data of the device for the most part. Additional placement conditions are described below. • Toxic vapors can be produced depending on the heat transfer liquid used and type of operation. Ensure sufficient extraction of the vapors. • Observe the requirements of the device for electromagnetic compatibility (EMC). • Do not cover the ventilation openings. WARNING! Rolling away, falling over of the device Impact, crushing • ...

- Page 33 Commissioning Heat transfer liquids Note the following: • The heat transfer liquids each cover a recommended temperature range and must be suitable for the temperature range of your application. • Never use contaminated or degenerated heat transfer liquid. Heat transfer liquid water • The alkaline earth ions content (hardness) of the water must be between 0.71 mmol/l and 1.42 mmol/l (equivalent to 4.0 and 8.0 °dH). Harder water results in lime deposits in the device. • The pH value of the water must be between 6.0 and 8.5. • Distilled, deionized, demineralized (DM) water or seawater must not be used due to the corrosive properties. Ultra-pure water and distillates are suitable as medium after addition of 0,1 g soda (Na2CO3, sodium carbonate) per liter of water. • Any chlorine content in the water must be strictly avoided. Do not add any chlorine to the water. Chlorine is contained, for example, in cleaning agents and disinfectants • The water must be free of impurities. Water containing iron is unsuitable due to rust formation and untreated river water is unsuitable due to algae formation.

- Page 34 Switching on device and filling with water Filling mode The device has a software program (starting from and including software version 61.15) that supports the operator for filling the temperature control device. If the fill level is too low, the Fill mode is started immediately after switching on the device. FILL is shown on the display and the level indicator is illuminated. The pumps and the refrigerant unit are not started. When the minimum level has been reached, the pumps are automatically started. Personnel: Operating personnel NOTICE! Overheating of the compressor Device damage • Never operate water cooled device without cooling water. DANGER! Use of incorrect heat transfer liquid Fire • Select a heat transfer liquid with a temperature range 20 K above the temperature range of the application WARNING! Overflow of heat transfer liquid Electric shock • Ensure that the device is not overfilled. Note the level indicator and the thermal volume expansion of the heat transfer liquid WARNING! Spraying of heat transfer liquid Electric shock...

- Page 35 Fill level sufficient 1. Switch on the device using the mains power switch. A signal tone sounds. The software version is shown on the display. The actual temperature is shown on the display afterwards.The temperature control device starts operation; the pumps are started. Depending on the specified set point temperature, the refrigerant unit is started after 2 minutes at the earliest. The blue LED lights if the refrigerant unit is activ Fill level too low (Low Level) 2. S witch on the device using the mains power switch. A signal tone sounds. The software version is shown on the display. FILL is shown on the display afterwards. In the case of Low Level, the pumps and the refrigerant unit are not started. Fill the device with heat transfer liquid. 3. C arefully pull up the cover of the filler neck; do not turn. 4. F ill the heat transfer liquid into the filler neck carefully. Monitor the level indicator. Fill the device up to the maximum fill level. The pumps start when the minimum level is reached. If necessary, use a funnel for the filling. The level indicator must not be above the max- imum fill level. Fill level drops 5. T op up the heat transfer liquid carefully as the consumer is now being filled. If the fill level drops too far, the device automatically goes into the FILL mode and the pump and refrigerant unit are switched off. Continue with the filling until operation without problems is possible. Monitor the level indicator for this. 6. P ress the cover carefully into the filler neck.

-

Page 36: Operation

Operation Switching on the device Personnel: Operating personnel NOTICE! Overheating of the compressor Device damage • Never operate water cooled device without cooling water. 1. Switch on the device using the mains power switch. A signal tone sounds. The software version is shown on the display. The actual temperature is shown on the dis- play afterwards. The temperature control device starts operation; the pumps are started. Depending on the specified set point temperature, the refrigerant unit is started after 2 minutes at the earliest. The blue LED lights if the refrigerant unit is active. - Page 37 compressor and the pumps turn off again when the set point is reached. If a display button is pushed during Standby mode, the device goes into normal operation mode. Sleep mode The Display shows: “SLEP” alternating with the bath temperature. The device goes into Sleep mode if no 24V signal from the Bioruptor is received for a period of time of more than 16 hours. In Sleep mode the compressor and the pumps are turned off. If a display button is pushed during Sleep mode, the device goes into normal operation mode.

-

Page 38: Maintenance

Maintenance General safety instructions DANGER! Contact with live or moving parts Electric shock, impact, cutting, crushing • The device must be disconnected from the mains power supply before any maintenance work. • Repairs must only be carried out by specialists. CAUTION! Contact with hot / cold device parts, accessories and heat transfer liquid. Burns, scalding, frostbite • Ensure device parts, accessories and heat transfer liquid are at room temperature before touching them Also note the following: Before all maintenance work, you should ensure that decontamination of the device has been performed if it came into contact with hazardous materials. Maintenance intervals The maintenance intervals described in the following table must be complied with. The following maintenance work is mandatory before every longer unsupervised operation. ... - Page 39 Cleaning the device Personnel: Operating personnel WARNING! Ingress of cleaning agents in the device Electric shock • Use a moist cloth for cleaning. Also note the following: Only clean the control panel with water and detergent. Do not use acetone or solvents. The consequence would be permanent damage of the plastic surfaces. Cleaning air-cooled condenser Personnel: Operating personnel 1. Switch off the device. 2. Remove the front cover by holding underneath with both hands and pulling the grating to the front. Remove the front cover slowly and carefully to prevent damage. 3. Brush off or vacuum the condenser. 4. Remount the front cover carefully. Checking the heat transfer liquid Soiled or degenerated heat transfer liquid must be replaced. Replace fuse 1. Switch off the device. 2. Remove power cord from the main power socket at the back of the device. 3. Remove fuse holder from the main power socket at the back of the device. 4. Replace fuse T10AH (10 ampere time delay fuse with high breaking capacity). 5.

- Page 40 Cleaning the mesh filter 1. Switch off the device. 2. Remove the top cover by dismounting the top handle and unscrewing the two screws at the back of the device. 3. Unscrew mesh filter holder (counter-clockwise). 4. Remove the metallic mesh filter and clean it. 5. Mount the mesh filter back in the holder and screw it back in the by-pass block (clockwise). 6. Mount top cover and top handle back in the device. PICO MANUAL BIORUPTOR ®...

- Page 41 Faults Alarms, errors and warnings Any alarms, error signals and warnings triggered on the device are shown on the display as 7-segment text. Procedure in the event of alarms Alarms can be cancelled using the ENTER button after rectification of the cause of the fault. Procedure in the event of warnings Warnings can be cancelled using the ENTER button after rectification of the cause of the fault. Procedure in the event of errors A two-tone signal is output if any error occurs. The red LED on the device also lights. In the case of an error, switch off the device at the mains power switch. If the error occurs again after restarting the device, note the error code and contact the Service partner. Errors are symbolized with an E and a sequential three- digit number. ...

- Page 42 Decommissioning Draining the device Personnel: Operating personnel WARNING! Contact with cold heat transfer liquid Frostbite • Bring the heat transfer liquid to room temperature before draining. Also note the following: Observe the regulations for disposal of the used heat transfer liquid. 1. Switch off the device. 2. Connect the end of an 8 mm exterior diameter pipe to the self-closing drain connector of the device. Place the other end of the pipe in a container with appropriate capacity under the level of the device. 3. Let the water flow until the device is completely empty. PICO MANUAL BIORUPTOR ®...

-

Page 43: Disposal

Disposal Disposing of refrigerant The refrigerant must be disposed of in accordance with EC Directive 303/2008/EC in combination with 842/2006/EC. CAUTION! Uncontrolled escape of refrigerant. Impact, cutting • Do not dispose of any pressurized refrigerant circuit. • The decommissioning is only permitted by a specialist. Global Warming Potential (GWP), comparisons CO2 =1.0 according to IPCC IV - time horizon 100 years - also basis for EU Fluoride Gases Directive 517/2014/EC Type and fill quantity of the refrigerant can be seen on the rating plate. Device disposal The following applies for Europe: The device must be disposed of according to EU Directive 2012/19/EC. Disposing of packaging The packaging must be disposed of in accordance with EU Directive 94/62/EC. -

Page 44: Technical Data

Technical data General data The device sound pressure level is below 70 dB. According to EC Directive 2006/42/EC the sound pressure level of the devices is therefore not specified further. SPECIFICATION VALUE UNIT Placement Indoor areas Placement height above sea level up to 2,000 Humidity Maximum relative humidity 80% Ambient temperature range 15 - 25 °C IP protection rating IP 32 Degree of soiling Clearance from surroundings (front and rear sides) Overvoltage category II and transient overvoltages Overvoltage according to category II Protection class for electrical operating equip- ment DIN EN 61 140 (VDE 0140-1) Classification according to DIN 12 876-1 I/NFL (non-flammable liquids, only) (class designation / identification) Display... - Page 45 Cooling capacity BC 100 Cooling capacity (at 20 °C) Cooling capacity (at 4 °C) Refrigerant R-134A The cooling capacity is measured for a specified temperature of the heat transfer liquid. Information is provided in brackets. The ambient temperature for the measurement is 20 °C; water was used as heat transfer liquid. Hydraulic circuit BC 100 Fill capacity 2 - 3 Maximum flow rate l/min (water 20 °C) Supply and return connections Quick connector (ext. hose diameter in mm) Drain connector Self-closing quick connector (ext. hose diameter in mm) Overflow tube Tube (int. hose diameter in mm) Maximum power consumption BC 100 230 V; 50 Hz 0.29 115 V; 60 Hz 0.29 100 V; 50/60 Hz 0.29...

- Page 48 www.diagenode.com...

Need help?

Do you have a question about the Bioruptor Pico and is the answer not in the manual?

Questions and answers