Table of Contents

Advertisement

Quick Links

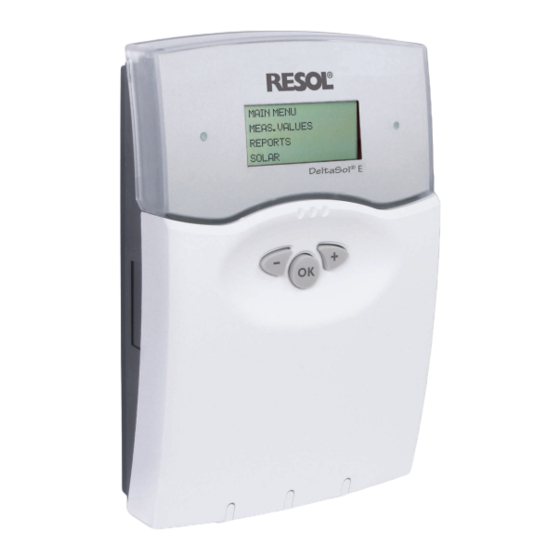

RESOL DeltaSol

Mounting

Connection

Operation

Troubleshooting

The Internet portal for easy and secure access

to your system data – www.vbus.net

Thank you for buying this RESOL product.

Please read this manual carefully to get the best performance from this unit.

®

E

(Version 2)

en

Manual

www.resol.com

Advertisement

Table of Contents

Summary of Contents for Resol DeltaSol E

- Page 1 Mounting Connection Operation Troubleshooting The Internet portal for easy and secure access to your system data – www.vbus.net Manual Thank you for buying this RESOL product. Please read this manual carefully to get the best performance from this unit. www.resol.com...

-

Page 2: Table Of Contents

CE mark. The • ATTENTION means that damage to the appliance can Declaration of Conformity is available upon re- occur. quest, please contact RESOL. Note: Notes are indicated with an information symbol. Note: Strong electromagnetic fields can impair the func- Î... - Page 3 4 weather-compensated heating circuits. For data communication and remote maintenance, the controller is equipped with the RESOL VBus , which ® 12,0...

-

Page 4: Installation

DeltaSol ® 1. Installation 1.1 Montage Electric shock! WARNING! push-push locking mechanism Upon opening the housing, live parts are push to open exposed! push to close ÎAlways disconnect the controller from power supply before opening the housing! Note: Strong electromagnetic fields can impair the func- display tion of the controller. -

Page 5: Electrical Connection

DeltaSol ® 1.2 Electrical connection 1.2.1 Overview of electrical connections ESD damage! ATTENTION! Electrostatic discharge can lead to damage to electronic components! ÎTake care to discharge properly before touching the inside of the device! To do so, touch a grounded surface such as a radiator or tap! Electric shock! WARNING! -

Page 6: Actuators (Pumps, Valves Etc.)

“ (either polarity). One or more RESOL VBus ® VBus modules can be connected via this data bus: • RESOL WMZ, calorimeter • RESOL large display / Smart Display • RESOL Datalogger • RESOL heating circuit modules HKM (up to 3 modules) VBus terminals... -

Page 7: Sensors

klemme benutzen! Use ground common Vor Öffnen Gerät spannungslos terminal block! schalten! Isolate mains before removing cover! R1-R6 1 (1) A (100 ... 240) V~ DeltaSol ® 4 (1) A (100 ... 240) V~ Masse-Sammelklemme benutzen OK / Set Use the ground common terminal block IP 20 L' L N 1.2.4 Sensors... -

Page 8: Operation And Function

DeltaSol ® 2. Operation and function 2.1 Buttons for adjustment The controller is operated via the 3 push buttons below the display. The forward-button (1) is used for scrolling forward through the menu or to increase the adjustment values.The control lamp backward-button (2) is similarly used for scrolling backwards and reducing values. -

Page 9: Menu Structure

DeltaSol ® 2.3 Menu structure Adjustment and control of the controller are carried out main menu via the menu.When the controller is commissioned, the meas. values display level is in the main menu. In the first line of each reports submenu you will find the option “back”, by means of which it is possible to get to the former menu level. -

Page 10: Menu Overview

DeltaSol ® 2.5 Menu overview Main menu Meas. values Reports Chimney sweeper Solar Solar (s. 4.1) Arrangement Adj. values Balance values Manual operation (s. 4.5) Options User code ( s. 2.4) Expert Expert Arrangement (s. 4.2) Adj. values Adj. values Heat. -

Page 11: Commissioning

DeltaSol ® 3. Commissioning When the hydraulic system is filled and ready for opera- tion, connect the controller to the mains. The controller runs an initialisation phase in which the product name and the version number are indicated. When the controller is commissioned or when it is reset, it will run a commissioning menu after the initialisation phase. - Page 12 DeltaSol ® Beginning with system 2, different hydraulic variants are possible (pump or valve control): system 1 system 2 variant 1 system 2 variant 2 system 3 variant 1 system 3 variant 2 system 3 variant 3 system 4 variant 1 system 4 variant 2 system 4 variant 3 system 4 variant 4...

-

Page 13: Function Blocks

DeltaSol ® 3.2 Function blocks Depending on the selected system/variant and other op- Each function block provides 4 functions: tions e.g. internal heating circuit module, certain relays are 1 temperature differential function already assigned. Relays which are not assigned can be allo- 2 thermostat functions cated to one of the 5 function blocks other uses e.g.(extra 1 timer (with 21 time frames) - Page 14 DeltaSol ® For the use of a further heat source (e.g. solid fuel boiler), one or two thermostat functions can be activated addition- ally to the differential function, in order to allocate a mini- mum temperature to the boiler or to limit the maximum store temperature.

-

Page 15: Adjusting The Controller Step-By-Step

DeltaSol ® 3.3 Adjusting the controller step-by-step The following points are optional to suit the system requirements, points 16. and 17. should be adjusted before the system is handed over to the operator. 1. Activate internal heating circuit module if needed 7. -

Page 16: Overview Of Relay And Sensor Allocation

DeltaSol ® 3.4 Overview of relay and sensor allocation System 1 sensor allocation sen.1 sen.2 sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Th 3 Th 4 Th 1 Th 2 Th 5 Th 6 Th 7 Th 8 Th 9 Th 10 Tstb T2-DT5... - Page 17 DeltaSol ® System 2 variant 2 S1 S6 sensor allocation sen.1 sen.2 sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Th 3 Tcol2 Th 5 Th 4 Th 10 Th 7 Th 8 Th 9 Tstb T1-AH- T1-DT6 Th 6 Tcol T1-DT8 T2-DT8...

- Page 18 DeltaSol ® System 3 variant 2 sensor allocation sen.1 sen.2 sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Th 3 Th 4 Th 9 Th 10 Tstb Th 5 Th 6 Th 7 Th 8 Tcol Tst2b T1-DT9 T2-DT9 T-HE T1-DT6 T2-DT6 T1-DT8...

- Page 19 DeltaSol ® System 4 variant 1 S1 S6 sensor allocation sen.1 sen.2 sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Th 1 Th 2 Tcol2 Th 9 Th 10 Tstb Th 5 Th 7 Th 8 Tcol Tst2b Th 6 T1-DT9 T2-DT9 T-HE...

- Page 20 DeltaSol ® System 4 variant 3 sensor allocation sen.1 sen.2 Sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Tcol2 Th 9 Th 10 Tstb Th 5 Th 7 Th 8 Tcol Tst2b Th 6 T1-DT9 T2-DT9 T1-DT7 T1-DT8 T2-DT8 T2-DT7 T1 WMZ T2 WMZ relay allocation...

- Page 21 DeltaSol ® System 5 variant 1 sensor allocation sen.1 sen.2 sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Th 1 Th 2 Th 9 Th 10 Tstb Th 7 Th 8 Tcol Tst2b Tst3b T1-DT9 T2-DT9 T-HE T1-DT8 T2-DT8 T2-DT5 T1 WMZ T2 WMZ T1-DT5...

- Page 22 DeltaSol ® System 6 Variante 1 sensor allocation sen.1 sen.2 sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Th 1 Th 2 Th 9 Th 10 Tstb T1-DT5 Tcol T2-DT5 Tst3b Tcol2 T1-DT9 T2-DT9 Tst2b T1 WMZ T2 WMZ T-HE relay allocation relay 1 relay 2...

- Page 23 DeltaSol ® System 6 variant 3 sensor allocation sen.1 sen.2 sen.3 sen.4 sen.5 sen.6 sen.7 sen.8 sen.9 sen.10 Th 9 Th 10 Tspu Tkol Tsp2u Tsp3u Tkol2 T1-DT9 T2-DT9 DVGW T1 WMZ T2 WMZ relay allocation relay 1 relay 2 relay 3 relay 4 relay 5...

- Page 24 AH suppress. ext. HE Abbreviations - sensors sensor denomination sensor location sensor location Tcol temperature-collector DeltaSol E 1. HKM (S6) Tcol2 temperature-collector 2 DeltaSol E Flow 1. HKM Tstb temperature-store 1 base DeltaSol E 2. HKM (S1) Tst2b temperature-store 2 base DeltaSol E 2.

-

Page 25: Functions And Options

DeltaSol ® Abbreviations - relay relay denomination pump col. 1 (2) solar pump collector field 1-2 Solar Pumpe Sp 1-4 solar pump store 1-4 2 PV St 1-4 2-port valve store 1-4 3 PV St 1-3 3-port valvel store 1-3 func. - Page 26 DeltaSol ® Bypass: In order to prevent energy from being extracted from the store when starting store loading, this function makes sure Solar/Options/Bypass that the cold fluid in the pipes is diverted past the store via selection: „Yes“, „No“ a bypass (valve or pump). Once the pipe is warm enough, factory setting: „No“...

- Page 27 DeltaSol ® Tube collector function: This function helps overcome the non-ideal sensor posi- tion with some tube collectors. Solar/Options/tube col. This function operates within a given time frame (“tube selection: „Yes“, „No“ init“ and “tube-final“). It activates the collector circuit factory setting: „No“...

- Page 28 DeltaSol ® The collector cooling function starts, when the adjusted Collector cooling function: maximum collector temperature is reached. If this tem- Solar/Options/col. cooling perature is underrun by 5 K, this function is switched off. selection: „Yes“, „No“ The collector is cooled via the heat transfer to the next factory setting: „No“...

- Page 29 DeltaSol ® As soon as the temperature at the collector is 4 °C, the Frost protection: frost protection function operates the loading circuit be- Solar/Options/Frost prot. tween the collector and the 1 store in order to protect selection: “Yes“, “No“ the medium in the loading circuit against freezing or co- factory setting: „No“...

- Page 30 DeltaSol ® A collector is considered to be blocked, if either the sen- collector blocked sor is defective or the emergency shutdown temperature is reached. Collector minimum limitation: This is the minimum temperature which must be exceeded for the solar pump to switch on. If the adjusted minimum Solar/Expert/Tcolmin temperature is not exceeded or the condition “collector adjustment range: -25 …...

-

Page 31: Menu: Arrangement

DeltaSol ® Priority logic and store sequence control: Priority logic is used in multi-store systems only. If St1, St2, St 3, St4 are set to 1, the stores with a tempera- Solar/adj. values/priority St1 (...St4) ture difference to the collector are loaded in parallel as adjustment range: 1 …... - Page 32 DeltaSol ® Store loading: In order to carry out afterheating of a store within a cer- tain store volume (store zone), this function uses 2 sensors Arrangement/Options/store load. to monitor the switch-on and switch-off level. selection: „Yes“, „No“ The switch-on and -off temperatures Th7on and Th7off are factory setting: „No“...

- Page 33 DeltaSol ® Thermostat function The relay allocated to the function block is switched on, when the adjusted switch-on temperature (Th(x)on) is (Function block 1 … 5): reached. It is switched off when the adjusted switch-off Arrangement/Options/Thermo1 (...10) temperature (Th(x)off) is reached. The switching condi- selection: „Yes“, „No“...

-

Page 34: Heating Circuits

The controller can control up to 4 independent weather- compensated heating circuits. One heating circuit can be controlled via the internal control functions and the oth- ers via an additional external module RESOL HKM3 each. Internal heating circuit control: The internal heating circuit is activated in this menu. - Page 35 DeltaSol ® Heating curve: The heating curve used by the controller can be increased or decreased to suit the building heating load as shown in Arrangement/Heat. circuit/hc/heat. curve the family of curves below. Increasing this value has the ef- adjustment range: 0,3 … 3,0 fect of raising the flow set temperature, reducing the value factory setting: 1,0 will lower the flow set temperature.

- Page 36 DeltaSol ® Timer: The timer determines whether day correction or night correction (set back ) is used for changing the set flow Arrangement/Heat. circuit/hc/timer/Mode temperature. 21 different time frames (3 for each day) can selection: “Night / Day“, “Off / Day“, “Without“ be set for night correction of the heating circuit.

- Page 37 DeltaSol ® Sensor 1 store With this parameter, the 1 reference sensor for heating circuit afterheating can be selected. Arrangement/Heat. circuit/hc/Expert/S1 Store adjustment range: 1 … 10 factory setting: 4 Sensor 2 store With this parameter, the 2 reference sensor can be se- lected for store-dependent afterheating.

- Page 38 ® factory setting: “Off“ Arrangement/heat. circuit/Hc-Module/... The displays and functions are comparable to those of the internal heating circuit (see also manual „RESOL HKM3“). Screed drying option This function is used for time- and temperature-controlled Screed heat screed drying in selectable heating circuits.

- Page 39 DeltaSol ® DHW heating option The DHW heating function can be used to heat the DHW (available only when the heating circuit afterheating has store by demanding an afterheating. been activated) The allocated demand relay of the heating circuit is Arrangement/Heat.

-

Page 40: Menu: Heat Quantity Measurement

1 … 10 factory setting: 10 Heat quantity measurement without flowmeter The heat quantity measurement calculation (estimation) RESOL V40 uses the difference between flow and return temperature and the user entered flow rate. The flow rate should be WMZ/Options/WMZ to „Yes“... -

Page 41: Menu: Expert

DeltaSol ® 4.4 Menu: Expert This message is shown, if solar loading has been carried out System warning “DT too high“ for a period of 20 minutes with a differential higher than 50 K. Expert/DT too high selection: „Yes“, „No“ The message function can be deactivated by selecting “No“. -

Page 42: Menu: Vbus

DeltaSol ® Maximum speed In the „Max speed“ channel, a maximum pump speed can be adjusted for the corresponding output. Expert/Relay/Max speed1 (...3) Adjustment range: 30 … 100% Factory setting: 100 % Pump speed control With this parameter, the pump control type can be ad- justed. -

Page 43: Troubleshooting

DeltaSol ® 5. Troubleshooting In the case of an error, a message is shown on the display of the controller: fuse T4A operating control lamp Control lamp flashes red. Control lamp off. Sensor defect. An error code instead of If the light is off, check the power supply a temperature is displayed in the sensor of the controller.. - Page 44 DeltaSol ® Pump is overheated, but no heat transfer from the collec- Pump starts for a short moment, switches-off, switches- tor to the store, flow and return have the same tempera- on again, etc. ture; perhaps also bubble in the lines. Air in the system? Temperature difference Air the system;...

- Page 45 DeltaSol ® Stores cool down at night Control the non-return Further pumps which valve in warm water are connected to the circulation - o.k. solar store must also be checked. Collector circuit pump runs in the night? Clean or replace it The gravitation circula- Check controller tion in the circulation...

-

Page 46: Accessories

Smart Display SD3 / Large Display GA3 The RESOL Smart Display is designed for simple connec- tion to RESOL controllers with RESOL VBus . It is used ®... -

Page 47: Interface Adapters

VBus.net The Internet portal for easy and secure access to your sys- tem data. VBus.net is all about the data of your RESOL controller. Live data of your system, customized fi lter settings and much more await you. DL2 Datalogger This additional module enables the acquisition and storage 6.3 Interface adapters... - Page 48 Another use outside the copyright requires pleteness of the drawings and texts of this manual - they the approval of RESOL – Elektronische Regelungen only represent some examples. They can only be used at GmbH. This especially applies for copies, translations, mi- your own risk.

Need help?

Do you have a question about the DeltaSol E and is the answer not in the manual?

Questions and answers