Table of Contents

Advertisement

HIGH EFFICIENCY CONDENSING GAS BOILER

USER'S INFORMATION MANUAL

WARNING:

If the information in this

manual is not followed

exactly, a fire or explosion

may result causing property

damage, personal injury or

loss of life.

- Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

California Proposition 65 Warning: This product contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

Heating Contractor

Address

Phone Number

This manual must be left with owner and should be

hung on or adjacent to the boiler for reference.

VGH-80-CH / VGH-100-CH / VGH-120-CH / VGH-150-CH /

59.0 °F

FULL TABLE OF CONTENTS............................................................. 3

1.0 SAFETY GUIDELINES ................................................................... 5

2.0 INTRODUCTION. ........................................................................... 8

3.0 HOW TO USE YOUR BOILER .......................................................... 11

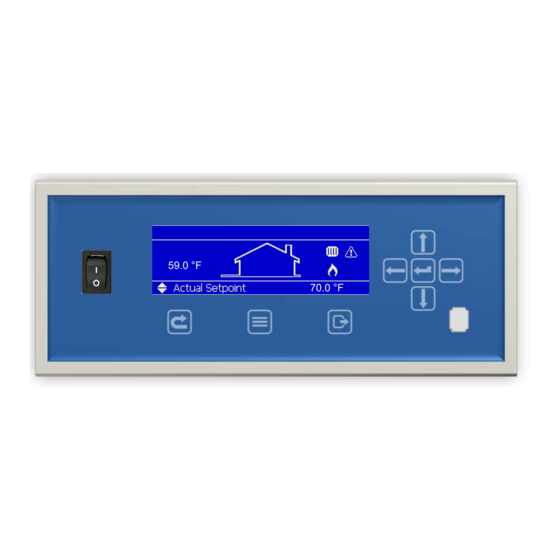

4.0 DISPLAY AND BUTTONS ............................................................. 12

5.0 ERROR INFORMATION .................................................................. 20

- WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any

•

phone in your building.

Immediately call your gas supplier from a neighbor's

•

phone. Follow the gas supplier's instructions

If you cannot reach your gas supplier, call the fire

•

department.

- Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

RESIDENTIAL BOILER MODELS

VGH-180-CH

VGH-90-CO / VGH-150-CO / VGH-200-CO

70.0 °F

Boiler Model Number

Boiler Serial Number

Installation Date

Advertisement

Table of Contents

Summary of Contents for Slant/Fin VGH-80-CH

-

Page 1: Table Of Contents

This manual must be left with owner and should be hung on or adjacent to the boiler for reference. RESIDENTIAL BOILER MODELS VGH-80-CH / VGH-100-CH / VGH-120-CH / VGH-150-CH / VGH-180-CH VGH-90-CO / VGH-150-CO / VGH-200-CO HIGH EFFICIENCY CONDENSING GAS BOILER USER’S INFORMATION MANUAL... -

Page 3: Quick Contents Full Table Of Contents

TABLE OF CONTENTS SAFETY GUIDELINES ..........................5 INTRODUCTION ............................8 ....................... 8 ERMS AND ABBREVIATIONS ......................9 AINTENANCE AND INSPECTION On a Continuous basis ......................9 On a Monthly basis ......................9 On an Annual basis (every 12 months) ................9 ............ - Page 4 IMPORTANT READ ALL OF THE FOLLOWING WARNINGS AND STATEMENTS BEFORE READING THE INSTALLATION INSTRUCTIONS DANGER Danger Sign: indicates the presence of an imminently hazardous situation that will cause death, serious personal injury or substantial property damage. WARNING Warning Sign: indicates the presence of a hazardous situation which can cause death, serious personal injury or substantial property damage.

-

Page 5: Safety Guidelines

SAFETY GUIDELINES E95.1901EN032 User manual Slant Fin VGH-CH / CO... - Page 6 CONSIGNES DE SÉCURITÉ. E95.1901EN032 User manual Slant Fin VGH-CH / CO...

- Page 7 This boiler is equipped with a pressure switch. In the event of a blocked vent the boiler will lockout. No attempt by the user/owner may be made to put the boiler back into operation. A qualified service technician must be notified of the issue. The boiler may only be reset by a qualified service technician after they have diagnosed and corrected CAUTION the issued that caused the safety lockout of the boiler.

-

Page 8: Introduction

INTRODUCTION This manual is written for the User. Slant/Fin is not accountable for any damage caused by failure to correctly follow these instructions. For service and repair purposes use only original Slant/Fin spare parts. All documentation produced by the manufacturer is subject to copyright law. This manual is subject to change without notice. -

Page 9: Maintenance And Inspection

Maintenance and inspection Maintenance and inspection of the boiler must be carried out at the following occasions: • When a number of similar error codes and/or lock-outs appear. • At least every 12 months maintenance must be done to ensure safe and efficient operation. Damage caused by lack of maintenance will not be covered under warranty ONTINUOUS BASIS •... -

Page 10: For Installations In The Commonwealth Of Massachusetts

WARNING: Crystalline Silica - Certain components in the combustion chamber may contain this potential carcinogen. Improper installation, adjustment, alteration, service or maintenance can cause property damage, serious injury (exposure to hazardous materials) or death. Refer to Section 19 for information on handling instructions and recommended personal protective equipment. -

Page 11: How To Use Your Boiler

HOW TO USE YOUR BOILER Functional introduction The VGH boilers are central heating/combi boilers with a maximum high efficiency. Such a performance can be reached by, amongst other things, using a special heat exchanger made of stainless steel. This allows the flue gases to cool down below the condensation point, thus releasing extra heat. This has an immediate positive impact on the efficiency. -

Page 12: Display And Buttons

DISPLAY AND BUTTONS 100 °F 170 °F Figure 4.1 ON/OFF. On/off switch. Switches electrical power to the boiler COMPUTER. Connector for computer cable RESET. Reset lockout error MENU. Enter the main menu ESCAPE. Escape / Return to the status overview RIGHT. -

Page 13: Screens And Settings

Screens and settings When the appliance is started the following screen is displayed: Figure 4.3 This screen is active during power up and will remain active until communication with the Main Control (the AL- BUS) has been established. After communication has been established the following Status overview appears: Heating Only boiler (VGH-CH) Heating &... -

Page 14: Control Panel Menu Structure

Control panel menu structure Press menu button Select ‘Central Heating (CH) and Select ‘CH setpoint’ and press Press ENTER or RIGHT to select and UP/ DOWN to change the value, press ENTER or RIGHT ENTER or RIGHT and ENTER or RIGHT to confirm. -

Page 15: Set Actual Setpoint/Dhw Setpoint Directly Via The Status Overview

/DHW CTUAL SETPOINT SETPOINT DIRECTLY VIA THE TATUS OVERVIEW When CH is active, you can adjust the Actual setpoint directly on the bottom of the Status overview. When DHW is active, you can adjust the DHW setpoint directly on the bottom of the Status overview. This means that when CH is active, you cannot set the DHW setpoint directly via the Status overview. -

Page 16: Protected Menu Items

ROTECTED MENU ITEMS Some menu items are protected and only accessible via a password*. The following password screen will appear: Figure 4.12 Users are only allowed to change parameters not needing a password. Changing protected/safety parameters may only be conducted by experienced, licensed boiler operators and mechanics. -

Page 17: Service Reminder

Service reminder The Service reminder will remind you that the appliance needs to be serviced. The "Service_Interval" is factory set at 2000 burn hours. When service is not done within this time, a service reminder will be shown: • on the screen: "Service is required!" is displayed, alternating with the normal status display; If the message “Service is required”... - Page 18 3.2 Boiler status min. max. Default unit Access Description: level Flow Temperature °F (°C) User Actual supply flow temperature Flow 2 Temperature °F (°C) User Actual supply 2 flow temperature Return Temperature DHW Temperature °F (°C) User Actual DHW temperature DCW Temperature °F (°C) User...

- Page 19 4 Settings min. max. Default unit Access Description: level 4.1 General Settings User Enter the General Settings menu 4.2 Boiler Settings User Enter the Boiler Settings menu 4.1 General settings min. max. Default unit Access Description: level 4.1.1 Language User Enter the Language menu 4.1.2 Unit Type User...

-

Page 20: Error Information

ERROR INFORMATION General Errors can be divided in three groups: • Manual reset locking errors (can only be reset by the reset button). • Blocking errors (will disappear when error is gone). • Warnings (will disappear when the warning is gone, not stored in the controls e2prom). The boiler circulator will continue to run during most locking and blocking error codes. -

Page 21: Error Logging

Error logging Errors will be logged for a stand-alone system or for a complete cascade system (based on the cascade settings). Thedisplay will monitor the error codes it receives from the boiler(s) and if an error code is a new error code the error will be stored in the error log. -

Page 22: Boiler History

Boiler history The last 15 lockouts and 15 blocking errors are stored in the boiler control. This boiler history can be shown via the Boiler History screen via the installer boiler status menu in one of the advanced displays. • Successful ignitions •... - Page 23 Lock Error Description Cause Solving code ROM_ERROR Internal software error wrongly programmed If the boiler does not start BCU or PB after Reset, contact your installer APS_NOT_ Air pressure switch not electrical circuit is If the boiler does not start OPEN opening during pre-purge short circuited or...

- Page 24 Lock Error Description Cause Solving code too many filing also check expansion attempts vessel on internal leak FILL_TIME_ Filling takes too long if output is Check if there is a leak in ERROR programmed as filing the central heating system valve and filling takes or if the boiler is leaking more than 10...

-

Page 25: Blocking Codes

Blocking codes If you cannot restart your boiler with the reset button, contact your installer. Maintenance and repairs must be carried out by a certified technician/installer. WARNING Blocking Error Description Cause Solving code WD_ERROR_ Internal software error wrongly If the boiler does not start programmed BCU after Reset, contact your or PB... - Page 26 Blocking Error Description Cause Solving code WD_COMM_ Watchdog communication wrong If the boiler does not start ERROR error programmed BCU after Reset, contact your or PB installer RETURN_ Return sensor open malfunctioning If the boiler does not start OPEN return sensor or after Reset, contact your not connected installer...

-

Page 27: Warnings

Blocking Error Description Cause Solving code LOWEXFLOW_ Flow is too low, demand not enough water If the boiler does not start PROTECTION needs to be stopped with flow through heat after Reset, contact your fan at ignition speed*, but exchanger installer no error needed to be stored at this time... - Page 28 E95.1901EN032 User manual Slant Fin VGH-CH / CO...

- Page 32 ©Slant/Fin Corp. 2019 • 1019 • PUBLICATION VGHR-UIM SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600 FAX: (516) 484-5921 • Canada: Slant/Fin , Mississauga, Ontario LTD/LTEE 400 Ambassador Drive Mississauga, Ontario L5T 2J3Phone: (905) 677-8400 www.slantfin.com...

Need help?

Do you have a question about the VGH-80-CH and is the answer not in the manual?

Questions and answers