Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Yardworks YW50DHP

-

Page 2: Table Of Contents

TABLE OF CONTENTS WARRANTY ………………………………………… INTRODUCTION …………………………………….. SPECIFICATIONS ……………………………………. KNOW YOUR PRODUCT ………………………………. PACK CONTENTS ……………………………………. DESCRIPTION OF SYMBOLS …………………………… GENERAL SAFETY INSTRUCTIONS ………………………. ADDITIONAL SAFETY INSTRUCTIONS FOR PUMPS …………. SET-UP & INSTALLATION ……………………………... OPERATION ………………………………………… MAINTENANCE ……………………………………… SPARE PARTS ………………………………………... -

Page 3: Warranty

If the tool shows signs of damage or defects caused by or resulting from abuse, accidents or alterations. • Failure to perform maintenance as set out within the instruction manual. • If the tool is disassembled or tampered with in any way. YARDWORKS Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175 OW12... -

Page 4: Introduction

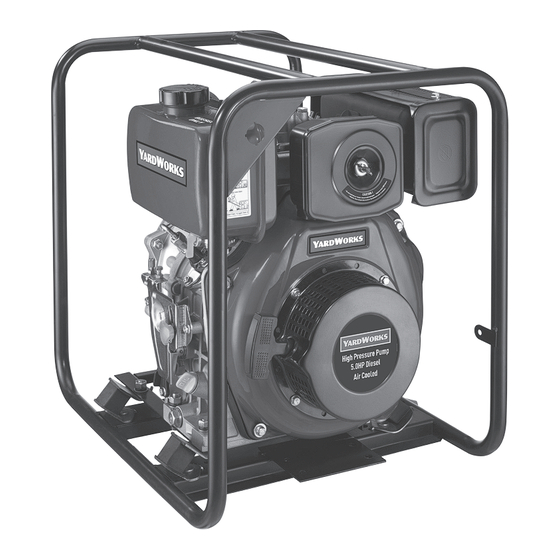

INTRODUCTION Congratulations on purchasing the YARDWORKS 5.0HP Diesel High Pressure Water Pump. We aim to provide quality products at an affordable price. Before using, it is most important that you read and follow the instructions in this manual, even if you feel you are quite familiar with this type of product. -

Page 5: Know Your Product

KNOW YOUR PRODUCT 1. Priming Cap 6. Lockable Throttle Knob 2. Discharge Outlets 7. Recoil Starter 3. Suction Inlet 8. Fuel Pipe 4. Pump Housing 9. Fuel Tap 5. Oil Fill Plug 10. Fuel Cap WARNING! THIS PRODUCT IS NOT SUITABLE FOR USE WITH DRINKING(POTABLE) WATER. - Page 6 KNOW YOUR PRODUCT (cont.) 11. Motor Housing 12. Air Filter 13. Exhaust 14. Decompression Lever...

- Page 7 KNOW YOUR PRODUCT (cont.) 15. 5m Suction Hose 16. 2 x 25.4mm (1”) Outlet Caps 17. 2 x 25.4mm (1”) Collars 18. 2 x 25.4mm (1”) Hose Adaptors 19. 3 x 25.4mm (1”) Hose Clamps 20. 4 x 25.4mm (1”) O-rings 21.

-

Page 8: Pack Contents

PACKED CONTENTS Contents Included 2 x 40mm (1 ") Collars 1 x 5.0HP Diesel High Pressure Water Pump 2 x 40mm (1 ") Hose Adaptors 1 x 5M suction hose 3 x 40mm (1 ") Hose Clamps 2 x 25.4mm (1”) Outlet Caps 3 x 40mm (1 ") O-rings 2 x 25.4mm (1”) Collars... -

Page 9: General Safety Instructions

GENERAL SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS 1) WORK AREA a) Do not operate pump in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Engine may create sparks which may ignite the dust or fumes. b) Never run engine in an enclosed area. Exhaust gases contain deadly, poisonous carbon monoxide, which has no odor or taste. -

Page 10: Additional Safety Instructions For Pumps

ADDITIONAL SAFETY INSTRUCTIONS FOR DIESEL PUMPS 1) Never refuel while engine is running or hot. Fuel spilled on a hot engine could result in a fire or explosion. 2) Use caution when handling diesel fuel. Refuel in well-ventilated area. Do not overfill fuel tank and do not spill fuel. -

Page 11: Set-Up & Installation

SET-UP & INSTALLATION Positioning The Pump Fig. 1 Place the pump close to the water that is required to be pumped (Fig. 1). Note: Ensure the pump is no further than 5m away from the water's edge. 2. Fill the engine crank case with oil (not included). Note: SAE 10W-30 Diesel Oil (ONLY) is recommended, refer to the maintenance section for more information Suction Inlet... - Page 12 SET-UP & INSTALLATION (cont.) 5. Add thread sealant (not included) and/or Teflon tape (not included) on to the suction inlet (3). 6. Align and screw the collar of the assembled inlet adaptor onto the thread on the Fig. 5 suction inlet (3) port of the pump (Fig. 5). Note: Ensure the collar is tightly fastened onto the suction inlet;...

-

Page 13: Operation

SET-UP & INSTALLATION (cont.) Priming Priming the pump prepares the motor for safe operation. Caution: Do not run the pump dry, this may result damage to the pump. 1. Unscrew the priming cap (1) by turning anti-clockwise. Using a hose, fill the pump Fig. - Page 14 OPERATION (cont.) Fuel inspection WARNING! Be sure to stop the engine before re-fueling. WARNING! Do not over fill the fuel tank. WARNING! Do not smoke while re-fueling. Good quality fuel is a major factor for engine reliability. 1. Only use high quality diesel. 2.

- Page 15 OPERATION (cont.) Starting the Engine WARNING! Before starting please ensure all inspections stated above have been made. WARNING! Exhaust gas contains poisonous carbon monoxide. Never use the machine in poorly ventilated locations. Doing so may result in carbon monoxide poisoning. WARNING! Do not touch muffler and muffler cover while the machine is running or hot.

- Page 16 OPERATION (cont.) Note: The decompression lever (14) will automatically reset. Note: If motor does not start repeat steps 4 to 6, if the motor still fails to start refer to the trouble shooting section of the manual (page 18). Fig. 9 7.

-

Page 17: Maintenance

MAINTENANCE Storing the Pump Fig. 12 Before storing the pump, it is recommended to empty the pump body of any water. Turn the drain screw (a) anti-clockwise with the 14mm spanner (28) and remove from the pump body. This will drain any excess water. Replace the drain screw (a) (Fig. 12). Changing the Oil Note: After the first 20 hours of use the engine oil needs to be replaced, and then every 100 hours after that. - Page 18 MAINTENANCE (cont.) Cleaning the Pump Body Use a moist cloth to wipe down the pump housing (4). Allow to dry thoroughly before storing in a dry location that is protected from bad weather conditions. If the pump is not going to be used for a long period of time, it is advisable to rinse with water. Ensure the pump is completely dry before storing.

-

Page 19: Spare Parts

MAINTENANCE (cont.) Recommended Check & Maintenance Chart After 20 hours or After 100 hours or After 300 hours or After 1000 hours Every operation / daily Time Item 1 month 3 months 6 months or yearly Inspect and tighten all nuts and bolts (top up if required and (only required after first Engine Oil... -

Page 20: Troubleshooting

Refer to the maintenance section for the correct oil to be used and replace if required Unit starts but runs and Air Filter clogged Check, clean or replace filter as required performs poorly Engine or carburetor difficulties Contact YARDWORKS customer service...

Need help?

Do you have a question about the YW50DHP and is the answer not in the manual?

Questions and answers