Table of Contents

Advertisement

Quick Links

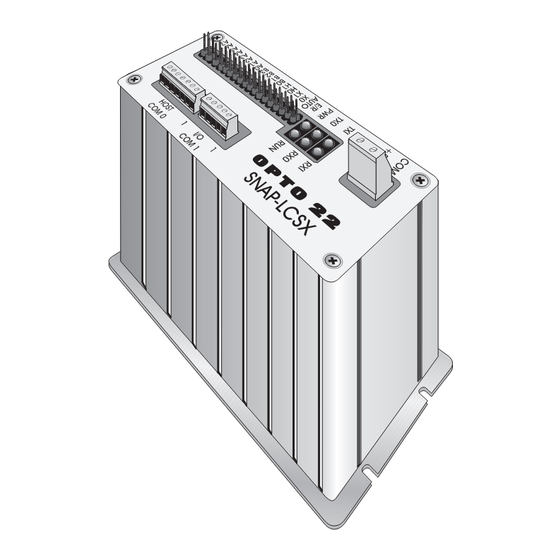

SNAP-LCSX AND LCSX-PLUS

INSTALLATION GUIDE

Form 1061-191112—November 2019

43044 Business Park Drive

Temecula

CA 92590-3614

•

•

Phone: 800-321-OPTO (6786) or 951-695-3000

Fax: 800-832-OPTO (6786) or 951-695-2712

www.opto22.com

Product Support Services

800-TEK-OPTO (835-6786) or 951-695-3080

Fax: 951-695-3017

Email: support@opto22.com

Web: support.opto22.com

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the LCSX-PLUS and is the answer not in the manual?

Questions and answers