Sylvac -SCAN 52 REFLEX-CLICK User Manual

Optical measuring system

Hide thumbs

Also See for SYLVAC-SCAN 52 REFLEX-CLICK:

- Instruction manual quick start version (8 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Sylvac SYLVAC-SCAN 52 REFLEX-CLICK

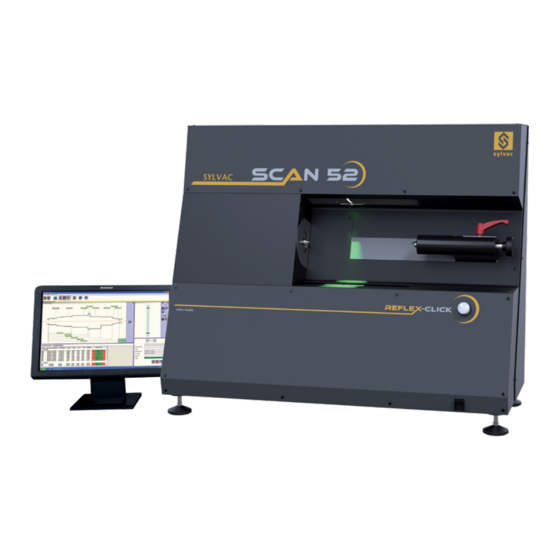

- Page 1 User’s Guide SYLVAC-SCAN REFLEX-CLICK 52 Optical Measuring System...

-

Page 2: Table Of Contents

CONTENTS Introduction General Safety rules and precautions 1.2.1 Strict adherence to the User’s Guide 1.2.2 User’s liabilities 1.2.3 Personnel liabilities 1.2.4 Physical and material risks 1.2.5 Intended use of the machine 1.2.6 Guarantee and liability 1.2.7 Individual protection 1.2.8 Safety guards and covers 1.2.9 Informal safety precautions 1.2.10 Personnel training 1.2.11 Operating the machine... -

Page 3: Introduction

This User’s Guide provides the needed information on the system along with all specifi cations. The SYLVAC-SCAN 52 REFLEX-Click has been designed with safety in mind. However, incorrect handling during Safety rules and installation or operation may be a source of damages for the machine. All safety rules and precautions stated herein precautions must be observed to ensure effective use of the machine. -

Page 4: Intended Use Of The Machine

The machine is to be used for non-contact measurement solely. Any other use will be regarded as improper use and Intended use SYLVAC shall not be responsible for any incurred damages. Furthermore, the use as intended involves that: of the machine •... -

Page 5: Operating The Machine

1.2.15 • No modification, add-on or transformation can be made to the machine without previous approval of SYLVAC SA. Changes to the • Any intention to make drastic changes to the machine requires the written consent of SYLVAC SA. -

Page 6: Description Of The Machine

The SYLVAC-SCAN 52 REFLEX-Click designed by SYL- Description of VAC is aimed at providing Users with the best solution the machine for fast and easy measurement of turned parts. The machine is made to inspect any measurable feature statically (length, diameters, angles, radii and the like) or dynamically (e.g. -

Page 7: Specifications

Specifications SPECIFICATIONS Metric Inches Overall Dimensions Machine (H x L x P) 840 x 1000 x 435 mm 33.1 x 39.4 x 17.1 in Mass Machine with centres ≈ 105 kg ≈ 230 lbs Packed Machine ≈ 165 kg ≈ 360 lbs Operating temperature Storage temperature 5 to 45 °C... -

Page 8: Installation

Check that all listed components are present. If so, Avoid high humidity (over 80%) or extreme tempe- report any damage to SYLVAC SA immediately. rature (below 5°C or above 45°C). Should the whole system be temporarily stored be- fore installation, make sure that it is safely packed... -

Page 9: Establishing Cable Connections

All cable connections are made with the machine A Mains power Establishing switched off. cable connections B RS232 serial port (control of the motors) The wiring plan showing a typical environment may vary according to the PC used. C USB cable (connected to the machine) The physical position of each connection to the PC D Monitor connection depends on the properties of the PC type. -

Page 10: Tailstock

The tailstock is mounted on the carriage, and then precisely centred thanks to the guiding rails on the granite machine’s base. Tailstock The clamp system has been specially designed to eliminate any play and to ensure optimum centring. The tailstock position can be changed to accommodate workpieces having different lengths. 1 Move the tailstock until the whole length of the part is matched, while turning the handle toward the right. -

Page 11: Quick Operation Guide

Windows 7 Professional ope- rating system. Once Windows has initialised, the SYLVAC-REFLEX Scan icon appears on the desktop. Double click this icon to let the application be loaded and get the tool bars ready for use once entirely loaded. -

Page 12: Measuring

1 The user’s interface as shown opposite will not ap- Measuring pear unless SYLVAC-REFLEX Scan has been booted up and the calibration process completed. REFLEX-Click is the default mode 2 Load a workpiece in the workholding and press again the REFLEX-Click button on the machine’s front face. -

Page 13: Maintenance

If the tailstock becomes loose instead of fixed into position, the mechanism needs to be appropriately set. For this purpose, raise the clamp handle vertically and twist it until optimum setting is achieved. 6. TROUBLESHOOTING All SYLVAC-SCAN have been designed for ease of use and trouble-free operation. In case of failure This section described problems that might occur when starting up the system, whilst also listing some error mes- sages appearing when running the software. -

Page 14: Problems At Start Up

The periodic check-ups, the adjustments or the maintenance Sylvac SA owns all parts removed from repaired products. If Sylvac SA repairs or replaces a part of a product, its war- ranty term is not extended. In case of replacement the new component has a warranty of 1 year, without effect on the initial warranty period. -

Page 15: Declaration Of Conformity

8 DECLARATION OF CONFORMITY Name of the manufacturer SYLVAC SA Address of the manufacturer Chemin du Closalet 16 CH-1023 Crissier Suisse who declares herein, that the product Product SYLVAC-SCAN 52 Optical Measuring System for turned parts Order number Description Stock Software 902.5520... - Page 16 Changes without prior notice Sous réserve de toute modification Änderungen vorbehalten Edition : 2015.09 / 681.101.06-120...

Need help?

Do you have a question about the SYLVAC-SCAN 52 REFLEX-CLICK and is the answer not in the manual?

Questions and answers