Summary of Contents for Backfire F5F

- Page 1 ACKFIRE Petr Janku Hermanice 72 Nova Paka 50901 Mail: ing.petr.janku@gmail.com f5b@f5b.cz Web: http://www.f5b.cz Phone: +420 728 304 793 BackfireF5F Page 1...

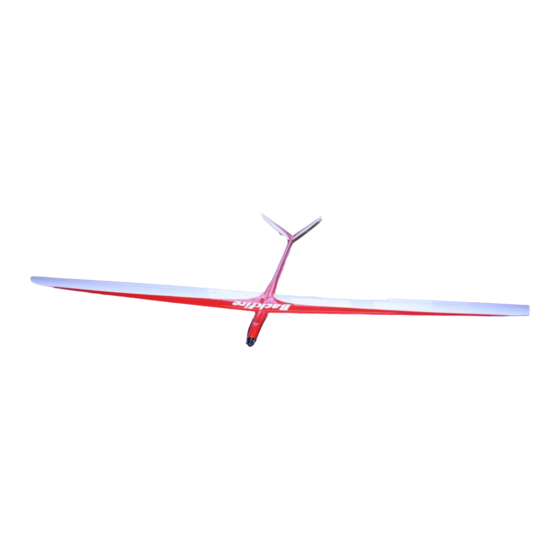

- Page 2 Thank You for buying the model of Backfire F5F. Backfire F5F is a full-carbonic model, it is made by lamination into negative forms. Backfire F5F is suitable for the competitive league , F5B/7, and for the hobby flying as well. The model was designed for competitive flying and its design results from the latest innovation of the F5F category.

- Page 3 Crapping strips 4 pc Picture 1: Accessories 1.2 The fittings needed for completing The cone – diameter 38mm Second glue – medium Activator for the second glue The epoxide R+G L-285 The consolidator R+G 285 Micro-ballons + Aerosil Utility knife Transparent cellotape which does not leave a glue behind Soldering unit Turn-bench Dremel...

-

Page 4: Recommended Components

280g. Hacker B50 F5B B40 F5F Kontronik Fun 500 Kira 600 Neu Motors 1509 F5F 1512 Plettenberg HP 220/30/A1 P6 5:1 HP 220/25/A1 P6 7:1 HP 220/30/A1 P6 7:1 HP 220/25/A1 P6 5:1 1.3.2 Propeller... - Page 5 1.3.5 Receiver batteries Intellect AAA-750 mAh A-1400 mAh X Cell AAA-1000mAh A-1100 mAh A-1300mAh 2 Fuselage 2.1 Cooling hole First we mark the place of the cooling air´s entrance with the felt tip and we cut through the carbonic fuselage by using a knife. We press down the cut cooling entrance under the fuselage level and we fix it with help of balsa –...

- Page 6 It is possible to make the cooling air´s entrance in the wing with help of a carbonic tubule with the 14 mm diameter. The place for leaks is marked on the wing. BackfireF5F Page 6...

- Page 7 2.2 V-tail shoulder The carbonic pins must be ground at their ends with help of a turn-bench and so their edges are flicked off. Those pins that will be sticked up in the fuselage must be roughened, so the pins will hold to fuselage well. We glue everything with the epoxide. Next we cut throught the holes for the butterfly-lever.

- Page 8 Obr. 4: The carbonics pulls for V-tail We screw the servos into prepared barrier and we glue their bolts with the fusing gun so that we could unloose the bolts in case we suffuse them by the epoxide. We secure the servos cables in the same way.

- Page 9 We give the barrier into the fuselage and set the servos´ neutrals. At the end of fuselage we screw the next boll cups. It is absolutely necessary that the pulls are put through the guide tubule in the middle of the fuselage!!! Picture 6: Putting in the servos and setting up the neutrals We apply the epoxide with microballons thickened by aerosil on the barrier in the way that the mixture do not slump.

- Page 10 Picture 7: Glueing V-tail servos Next we can put two balsa-battens with 1mm thickness between ball pivots on the servo and the fuselage-bottom. The battens ensure the space needed for ball pivots movement. We check the quality of glued joint. It is necessary to fix the butterfly to the fuselage before the test flying.

- Page 11 Picture 8: Control of the glued barrier 2.4 Motor Barrier On circuit we make kerfs by using the saw or the milling machine. We screw the barrier to the engine and protect the engine by using the cellotape against the possible epoxide- pollution with.

- Page 12 Picture 9: The glued-in of the engine-barrier BackfireF5F Page 12...

- Page 13 3 Wing 3.1 Horns and Pulls We glue the levers belonging in the flap in the distance of 7,3mm from the axis of rotation and the levers for wings in the distance of 4,4mm from the axis of rotation. The lever of the flap´s servo will have the hole in the distance of 7,3mm from the axis of rotation and the lever of the butterfly´s servo in the distance of 3,0mm...

- Page 14 Picture 10: Levers and pulls of the wing BackfireF5F Page 14...

- Page 15 3.2 Cabels of servos and servoholder We shorten the servos´cabels up to 4cm of distance. We solder the pins from the crushing bar on the servos´cabels pulled through the wing. Or we can crimpen the original pins from the servo-connector. We prepare the septa from plywood 1,5mm for each servo. Picture 11: The cables of servos and septa of servos 3.3 Connectors Wing/Fuselage In case we work with the three-piece wing, we have to solder the connectors into wings...

- Page 16 The length of cables to the receiver should be c. 9cm. We strip cables, tin-plate them and we put the shrink- spaghetti insulation on them. We solder cables to the connector MPX, strip the isolation with the hot-air gun and fix all with the fusing gun. We use the same work procedure while soldering the connector MPX in the wing.

- Page 17 3.4 Sticking up the servos into wing First we set the neutrals to all servos. We stick up the servos into wings with an epoxide. We ensure the ailerons and flaps to the wing in zero deflection by using a cellotape and we set the neutrals of all servos again.

- Page 18 Picture 14: Sticking the servos into wing Picture 15: The servos´caps BackfireF5F Page 18...

- Page 19 It is necessary to use the external voltage supply for power supply. It is more reliable to use the connector 2mm instead of switch. The connector 2mm has a better contact. The conductors to the battery have the cross section 0,5mm Picture 16: Voltage supplies for the deck equipment 4 Others picture BackfireF5F...

- Page 20 Picture 17: Input and output of the cooling air BackfireF5F Page 20...

- Page 21 Picture 18: The tail piece of the fuselage, the divided wing 5 Deck Equipment We place the receive batteries tight behind the engine with help of nails Dual-lock. We place the receiver in front of butterfly´s servos. We hold the regulator also with nails Dual- lock on the top of the front part of fuselage.

- Page 22 6 Setting of deflections, adjustment of phases and centre of gravity 6.1 Setting of servos´ deflections The adviced setting as an informative one. Every pilot has different deflections habits and you can change this deflection after you get familiar with the model. V-tail -4mm +4mm...

-

Page 23: Technical Parameters

Rekreation Hacker B50-9S+6,7 TopFuel 3800- 15x13 Master Basic 70-SB Competetion Hacker B50- TopFuel 5000- 17x18 Master 195-O-F5B 55m/s 5M+6,7-FAI Show Hacker B50-5L+6,7- 4S 3700, 30C 17x18 Master 195-O-F5B 65m/s 8 Technical parameters Wingspan 2440 mm Lenght 1230 mm Area 36,2 dm Aspect ration Airfoil DP 7,81...

Need help?

Do you have a question about the F5F and is the answer not in the manual?

Questions and answers