Table of Contents

Summary of Contents for GMV DLV-A3

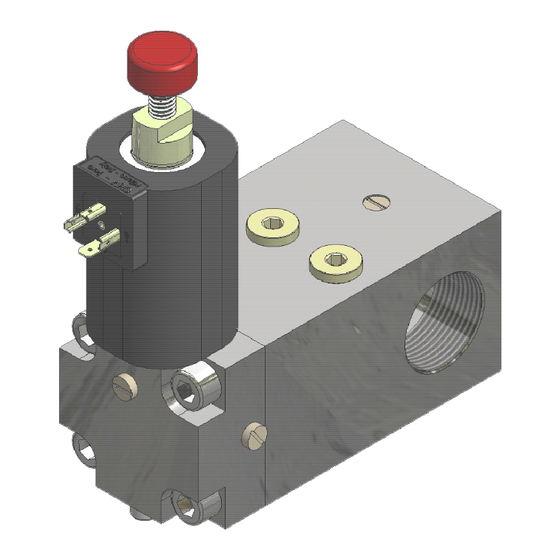

- Page 1 English DLV VALVE DLV-A3 VALVE MANUAL NSTALLATION AND 1 0991 486 EN VAILABLE WITH VALVE TYPE 3010 ¾”,1 1/4”, 1 ½”, 2”, NGV ¾” GMV SPA UNI EN ISO 9001 FLUID DYNAMICS EQUIPMENTS Certified Company AND COMPONENTS FOR LIFTS...

-

Page 2: Table Of Contents

1 0991 486 EN - 29.09.2016 VALVE MANUAL 2 / 11 NSTALLATION SE AND AINTENANCE INDEX 0 GENERAL SECTION 0.1 INTRODUCTION 0.2 INSTALLATION RELATED DOCUMENTS 0.3 SAFETY PRECAUTION DURING INSTALLATION 0.4 GENERAL ORDERS 0.5 LIABILITY AND WARRANTY 1 FEATURES AND REQUIREMENTS DLV A VALVE DELIVERY PACKAGING... -

Page 3: Eng

1 0991 486 EN - 29.09.2016 VALVE MANUAL 3 / 11 NSTALLATION SE AND AINTENANCE 0 GENERAL SECTION 0.1 INTRODUCTION Assembling,installation,start-up and hydraulic lift maintenance should be performed by experienced personnel.Before starting any work on the hydraulic components,personnel showld carefully read these instructions,particularly referring to 0.3 chap. -

Page 4: General Orders

These instructions are intended for people with experience in installation, adjustment and maintenance of hydraulic lifts. GMV disclaims any liability for damage caused by improper or different use from what described in these instructions or inexperience or carelessness of those responsible to assemble, adjust or repair hydraulic components. -

Page 5: Delivery Packaging

1 0991 486 EN - 29.09.2016 VALVE MANUAL 5 / 11 NSTALLATION SE AND AINTENANCE DLV are manifactured in different sizes and can be used for the following range(see the tab. 1). Nominal Working Working Emerg. Type Viscosity Tens.DLV Power interv.flow flow press. -

Page 6: Cleaning And Safety Protections

NSTALLATION SE AND AINTENANCE GMV use and recommend an hydraulic fluid ISO VG 46 that : • Thanks to classification as category HEES, as rule ISO-UNI 6743-4 and its biodegradability index > 90%, according to standard CEC L33-A-93, is acceptable from an environmental point of view. -

Page 7: Hydraulic Scheme

1 0991 486 EN - 29.09.2016 VALVE MANUAL 7 / 11 NSTALLATION SE AND AINTENANCE 2. Timed The DLV A3, respect to the main downward solenoid valve VMD, is energized about 1 second before and de-energized almost 2 seconds after the arrival at landing. In this way the DLV A3 is not an element working to control the lift and consequently does not require any kind of monitoring. -

Page 8: Installation

1 0991 486 EN - 29.09.2016 VALVE MANUAL 8 / 11 NSTALLATION SE AND AINTENANCE 3 INSTALLATION ATTENZIONE During the installation:nvere exclude safety devices and never power-on the motor pump. 3.1 HYDRAULIC CONNECTION SAMPLES DLV A3 - 3010 – MR with cabinet up to 150 lt DLV A3 - 3010 –... -

Page 9: Dimensions

1 0991 486 EN - 29.09.2016 VALVE MANUAL 9 / 11 NSTALLATION SE AND AINTENANCE 3.2 DIMENSIONS M8x1.25 ¾” ≈6,5 ¾” G 1” ¼ 153,5 ≈13 1” ¼ G 67,5 28,5 1” ½ ≈9 1” ½ G 2” ≈15 2” G 57,5 89,25 39,5... -

Page 10: Electrical Getting Started:icons

1 0991 486 EN - 29.09.2016 VALVE MANUAL 10 / 11 NSTALLATION SE AND AINTENANCE 4.1 ELECTRICAL GETTING STARTED:ICONS 0 - OFF 0 - OFF 5 TEST AND ADJUSTMENTS 5.1 MONITORING SYSTEM CHECK To assure the correct working of the monitoring system of the DLV A3 the control panel should perform a check operation behind closed doors, at least once a day. -

Page 11: Certificates

1 0991 486 EN - 29.09.2016 VALVE MANUAL 11 / 11 NSTALLATION SE AND AINTENANCE In the same way,is energized only the main valve VMD,holding the DLV A3 valve de-energized.If all the components work correctly,the car must stop at landing position.A timed check starts for two sec.to verify a car movement.In case of movement detection without landing,the system must go into alarm and put the lift out of service.In case of back-landing,another 2 seconds timed check starts,energizing the VMD.If the relevelling does not start,the system is ok.Otherwise,a DLV failure is confirmed (VMD de-energized). - Page 12 All rights reserved. Any kind of exploitation in any form and by any means is forbidden without a written permission of GMV Spa. GMV Spa, within technical or manufacturing progress, reserves the right to modify parts or this manual without notice.

Need help?

Do you have a question about the DLV-A3 and is the answer not in the manual?

Questions and answers