GMV NGV A3 Installation, Use And Maintenance Manual

Valve manual available with tank type gl, f1, t2, t3, t4, mrl-t, mrl-h

Hide thumbs

Also See for NGV A3:

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for GMV NGV A3

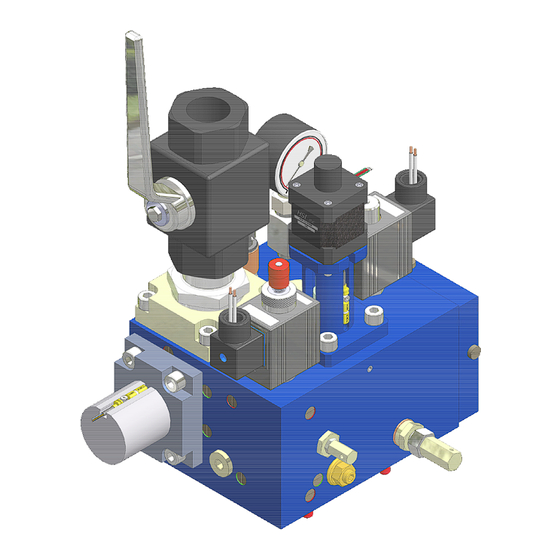

- Page 1 English NGV A3 VALVE NGV A3 V ALVE ANUAL NSTALLATION SE AND AINTENANACE 1 0991 483 EN VAILABLE WITH TANK TYPE GL, F1, T2, T3, T4, MRL-T, MRL-H GMV SPA UNI EN ISO 9001 FLUID DYNAMICS EQUIPMENTS Certified Company AND COMPONENTS FOR LIFTS...

-

Page 2: Table Of Contents

ONNECTIONS TO THE CARD 2.8 C ONNECTION OF HYDRAULIC PIPES 2.8.1 C ONNECTION WITH FLEXIBLE HOSE 2.8.2 C ONNECTION WITH A RIGID PIPE 3 NGV A3 CONTROL BOARD 3.1 E LECTRICAL FEATURES 3.2 P ERFORMANCES 3.2.1 S IGNALLERS 3.3 C ONNECTIONS 3.3.1 C... - Page 3 All rights reserved. Any kind of exploitation in any form and by any means is forbidden without a written permission of GMV Spa. GMV Spa, within technical or manufacturing progress, reserves the right to modify parts or this manual without notice.

- Page 4 Interface box (NGVA3 / Control panel) Chamber of the VRP Inlet chamber VB outlet chamber Chamber of the VRP pilot spool CARD NGV A3 control card Downward signal Downward Filter Inspection gauge fitting Jack Non-return valve Spool of the VRP...

-

Page 5: General Section

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 5 / 46 NSTALLATION SE AND AINTENANCE 1.05 0 GENERAL SECTION 0.1 INTRODUCTION INFORMATIONS 0.1.1 DEFINITIONS In this manual are used the definitions in EN81-1, EN81-2: Safety rules for the construction and installation of... -

Page 6: G Eneral Orders

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 6 / 46 1.05 NSTALLATION SE AND AINTENANCE 0.5 GENERAL ORDERS The valves shall be maintained in good working order in accordance with the European Standards. To this effect, regular maintenance of the installation shall be carried out, to ensure, in particular, the safety of the installation. -

Page 7: Features And Requirements

* Compared to a traditional valve 1.2 THE FLUID GMV use and recommend an hydraulic fluid ISO VG 46 that : · Thanks to classification as category HEES, as rule ISO-UNI 6743-4 and its biodegradability index > 90%, according to standard CEC L33-A- 93, is acceptable from an environmental point of view. - Page 8 SE AND AINTENANCE 1.3 HOW THE NGV A3 WORKS The valve NGV is made with a non-return valve VR, a control spool VB controlled by a stepping motor and by a system with pilot operated non-return valve VRP - P...

-

Page 9: The Double Safety

Needful prerequisite of the control panel, when the system is outside of the doors unlocking zone, is that it does not send commands to the card and/or the motor / pump. 1.5 MAIN FEATURES Valve Type NGV A3 Minimum operating pressure 12 bar Maximum operating pressure 45 bar Test speed 1 m/s Temperature operating range 5°C - 70°C... -

Page 10: Installation Operations

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 10 / 46 1.05 NSTALLATION SE AND AINTENANCE 2 INSTALLATION OPERATIONS ATTENTION During the installation never exclude the safety devices and never connect the motor/pump directly to the power supply 2.1 HYDRAULIC CONNECTIONS... -

Page 11: I Nput And Output - Power Unit Side

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 11 / 46 NSTALLATION SE AND AINTENANCE 1.05 2.1.2 INPUT AND OUTPUT -POWER UNIT SIDE " 1" 12x8 1" PAM 12x8 IN 1” ¼ OUT 1” ¼ OUT ¾” OUT M8 2.2 HYDRAULIC CIRCUIT... -

Page 12: E Lectrical Connections

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 12 / 46 1.05 NSTALLATION SE AND AINTENANCE 2.3 ELECTRICAL CONNECTIONS 2.3.1 CONTROL PANEL REQUIREMENTS The control panel must send to the power unit at least the following signals: Mark... -

Page 13: Fault S Chemas

1.05 2.3.3 FAULT SCHEMAS A control panel installed with the valve NGV A3 must continuously monitor the signals RDY and RUN (UP) that it receives from the card NGVA3-xx. The control panel should go in error status, stop the system and do not send commands to the valve and / or the motor / pump when, for more than 2s, signals RDY and RUN are simultaneously in the same condition. -

Page 14: Schemas Of The Connections To Control Panels

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 14 / 46 1.05 NSTALLATION SE AND AINTENANCE 2.5 SCHEMAS OF THE CONNECTIONS TO CONTROL PANELS In the following pages the schemas of the connections between valve / NGVA3 card and control panels 2.5.1 MAIN SCHEMA... -

Page 15: C Onnection Schemas For S Ignals

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 15 / 46 NSTALLATION SE AND AINTENANCE 1.05 2.5.2 CONNECTION SCHEMAS FOR SIGNALS Schema S00 Schema S48 CARD CARD D+ D- E+ E- D+ D- E+ E- A+PE A- A- A+PE A- A- 10...48 V... -

Page 16: C Onnections To The Terminal

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 16 / 46 1.05 NSTALLATION SE AND AINTENANCE 2.6 CONNECTIONS TO THE TERMINAL U1-W2 150 mm V1-U2 W1-V2 150 mm 2.7 CONNECTIONS TO THE CARD D- E+ E- T+ T- P+ P-... -

Page 17: C Onnection Of Hydraulic Pipes

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 17 / 46 NSTALLATION SE AND AINTENANCE 1.05 2.8 CONNECTION OF HYDRAULIC PIPES ñ 8 ÷ 36 3/4" x 3/4" 3/4" 3/4" x 3/4" 3/4" 3/4" 3/4" 42 ÷ 52 3/4"... -

Page 18: Ngv A3 Control Board

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 18 / 46 1.05 NSTALLATION SE AND AINTENANCE 3 NGV A3 CONTROL BOARD 3.1 ELECTRICAL FEATURES The hardware features of the card NGV-A3 are: DESCRIPTION VALUE Standard supply voltage 24V=, ±10% Extended supply voltage 12...42Vdc... -

Page 19: C Onnections

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 19 / 46 NSTALLATION SE AND AINTENANCE 1.05 3.3 CONNECTIONS 3.3.1 CONTROL PANEL INTERFACE The input circuits are divided in two groups, both isolated from the card power supply: · V0,V1,V2,VS with common V- ·... -

Page 20: V Alve Interface

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 20 / 46 1.05 NSTALLATION SE AND AINTENANCE Jumper J6 (to set connector X6 D+ D-) Pos. Description Input and downward command VMD 12…48Vdc Input and downward command VMD 60…180Vdc... -

Page 21: U Ser Interface

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 21 / 46 NSTALLATION SE AND AINTENANCE 1.05 3.3.3 USER INTERFACE Connector X13, step 2,54 mm - (AUX 2 x 13) õ Connector for extensions (Encoder, …) Slot J1, µSD (serial SPI) õ... -

Page 22: S Ignals And Commands Sequence

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 22 / 46 1.05 NSTALLATION SE AND AINTENANCE 3.4 SIGNALS AND COMMANDS SEQUENCE 3.4.1 UPWARD DIAGRAM [m/s] [mm] Close VB/SM Open ø ø ï ï ÷ RAL,S 3.4.1.1 UPWARD SIGNALS AND COMMANDS SEQUENCE Start travel sequence : RDY=ON + RUN=OFF ð... -

Page 23: D Ownward Diagram

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 23 / 46 NSTALLATION SE AND AINTENANCE 1.05 3.4.2 DOWNWARD DIAGRAM [m/s] [mm] Close VB/SM Open ø ð ï ï ÷ RAL,D 3.4.2.1 DOWNWARD SIGNALS AND COMMANDS SEQUENCE Start travel RDY=ON+RUN=OFF ð... -

Page 24: D Eceleration Distances

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 24 / 46 1.05 NSTALLATION SE AND AINTENANCE 3.5 DECELERATION DISTANCES [m/s] RAL,S Upward Extra Slow Slow Standard Fast 0,00 < V ≤ 0,15 0,19 0,15 0,13 0,12 0,15 < V ≤ 0,40... -

Page 25: Adjustments And Test

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 25 / 46 NSTALLATION SE AND AINTENANCE 1.05 4 ADJUSTMENTS AND TEST 4.1 ADJUSTMENT OF THE OVERPRESSURE VALVE (OPP/MPS) NGVA3 ALVE ï VSMA To adjust the overpressure valve: 1. Refer to the hydraulic circuit of the NGV valve 2. -

Page 26: R Am Pressure On The Vsma Adjustment

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 26 / 46 1.05 NSTALLATION SE AND AINTENANCE 4.2 RAM PRESSURE ON THE VSMA ADJUSTMENT NOTE Adjustment possible only with systems 2:1 To adjust the ram pressure on the VSMA : 1. -

Page 27: T Est In Up Direction

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 27 / 46 NSTALLATION SE AND AINTENANCE 1.05 4.4.2 TEST IN UP DIRECTION E00.001 Cod.10911309 E00.001 C od.10911309 For safety it’s required that the test take place behind closed doors. Then proceed as follows: 1. -

Page 28: T Est Of The Double S Afety System

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 28 / 46 1.05 NSTALLATION SE AND AINTENANCE 4.5 TEST OF THE DOUBLE SAFETY SYSTEM 4.5.1 SIMULATION OF THE VRP FAULT This test allow to verify that the system stay stopped in event of failure of the VRP. -

Page 29: S Imulation Of The Vb F Ault

The test is ended 4.5.3 TEST OF THE MONITORING SYSTEM The NGV A3 card, each travel, automatically perform a check of the monitoring system and in event of fault goes into alarm/fault. To test of the monitoring system is therefore sufficient, at the end of any travel, make sure that (2.1 Alarm) there is no one among the following faults: 06, 07, 13 ÷... -

Page 30: F Ault Simulation On Output Rdy And Run

1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 30 / 46 1.05 NSTALLATION SE AND AINTENANCE 4.6 FAULT SIMULATION ON OUTPUT RDY AND RUN The test verifies the correct behaviour of the control panel when it receives signals RUN and/or RDY not corrects. - Page 31 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 31 / 46 NSTALLATION SE AND AINTENANCE 1.05 5 PROGRAMMING It is possible to dialog with the NGV01 control board by the programmer PT01. The connection between the programmer and the board is made by a network UTP RJ45 straight cable.

- Page 32 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 32 / 46 1.05 NSTALLATION SE AND AINTENANCE 5.2 COMPLETE MENÙ ◄ ▼ NGV-A3 VX.XRXXHX NGV-A3 VX.XRXXHX NGV-A3 VX.XRXXHX ► 5 ► 8 DIAGNOSTICS SETTINGS OUTPUT FUNC Pressure // xx.x bar...

- Page 33 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 33 / 46 NSTALLATION SE AND AINTENANCE 1.05 5.3 MENÙ - 1 - DIAGNOSTICS NGV VER XX.XXX 1-DIAGNOSTICS Ý Þ 1.1 PRESSURE Pressure gauge [bar] read by the pressure transducer XX.X bar...

- Page 34 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 34 / 46 1.05 NSTALLATION SE AND AINTENANCE - 4 - ADJUSTMENTS NGV VER XX.XXX Optimal car motion Real car motion 4-ADJUSTMENTS Ý Þ 4.1 START UP MIN UPWARD start adjustment (-99 ÷ +99) ±XX.X...

- Page 35 35 / 46 NSTALLATION SE AND AINTENANCE 1.05 - 5 - SETTINGS Data entered by GMV, run control during the installation of the system NGV VER XX.XXX 5-SETTINGS Ý Þ 5.1 LIFT RATIO Ratio of the lift system (1:1; 2:1; 3:1) Ý...

- Page 36 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 36 / 46 1.05 NSTALLATION SE AND AINTENANCE - 6 - UPWARD PARAMETERS NGV VER XX.XXX 6-UP PARAMETERS Ý Þ 6.1 NOM.SPEED V0 Nominal speed [m/s] referred to the nominal pump flow, piston diameter X.XX m/s...

- Page 37 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 37 / 46 NSTALLATION SE AND AINTENANCE 1.05 - 8 - OUTPUT FUNCTIONS NGV VER XX.XXX 8-OUTPUT FUNC. Ý Þ 8.1 OUTPUT 11-12 Active function on output 11-12. Every function is identified by a code...

- Page 38 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 38 / 46 1.05 NSTALLATION SE AND AINTENANCE 9.5 VB TEST DOWN Start the routine to check if the VRP working well in event of VB breaking ENT=Start at downward end. To use this function see chapter Simulation of the VB fault.

- Page 39 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 39 / 46 NSTALLATION SE AND AINTENANCE 1.05 5.5 CHART OF FAILURES S3 (VB Open) S2 (VB Close) S1 (VRP) Fault Description 00: NO ALARM No alarm 01: SUPPLY LOW Low power supply <...

- Page 40 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 40 / 46 1.05 NSTALLATION SE AND AINTENANCE 6 MAINTENANCE AND FAULT ANALYSIS 6.1 PROGRAMMED MAINTENANCE For a correct and safe lift use, it is necessary to make a preventive programmed maintenance, following a fixed plan.

- Page 41 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 41 / 46 NSTALLATION SE AND AINTENANCE 1.05 Motor protection functionality Disconnect one terminal of the thermistors, and check that the motor protection working properly. Filter Check the main filter (FIL) mounted inside the silencer and clean it if is necessary.

- Page 42 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 42 / 46 1.05 NSTALLATION SE AND AINTENANCE 6.4 FAULT ANALYSIS Fault Possible cause Possible solution Increase power voltage by 01: SUPPLY LOW Low power supply adjustment or replace power supply...

- Page 43 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 43 / 46 NSTALLATION SE AND AINTENANCE 1.05 6.4.1 TROUBLESHOOTING Fault Possible cause Possible solution 1 The system The card do not receive the Verify in the Menu 1.4 if the card receive...

- Page 44 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 44 / 46 1.05 NSTALLATION SE AND AINTENANCE 9 The system The signal VS or D do not Verify (menu 1.4 S0123DICA) that the - do not stops at landing...

- Page 45 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 45 / 46 NSTALLATION SE AND AINTENANCE 1.05 6.5 ADJUSTING THE SENSORS S3 (VB Open) S2 (VB Close) The adjusting of the sensors should be done with the S1 (VRP) system stopped.

- Page 46 1 0991 483 EN - 21.12.2011 NGV A3 VALVE ANUAL 46 / 46 1.05 NSTALLATION SE AND AINTENANCE 7 CERTIFICATES ¥ "...

- Page 47 ¥ "...

- Page 48 APPARECCHIATURE FLUIDODINAMICHE E COMPONENTI PER ASCENSORI GMV SPA , 10 - 20016 PERO – M Azienda NOCCHI ILANO TALY TEL. +39 02 33930.1 - FAX +39 02 3390379 ERTIFICATA UNI EN ISO 9001 HTTP MAIL INFO...

Need help?

Do you have a question about the NGV A3 and is the answer not in the manual?

Questions and answers