Advertisement

English

3010 ¾" VALVE

3010 ¾" V

I

NSTALLATION

A

VAILABLE WITH TANK TYPE

HL, HL DRY, HL 50 DRY, HLV, HLV 40 e GL

GMV SPA

FLUID DYNAMICS EQUIPMENTS AND

COMPONENTS FOR LIFTS

M

ALVE

ANUAL

, U

SE AND

S

T

W

ELL

ECH

ORK

M

AINTENANCE

1 0991 497 EN

UNI EN ISO 9001

Certified Company

C

U

UST

SER

ENG

1.01

Advertisement

Table of Contents

Summary of Contents for GMV 3010

- Page 1 English 3010 ¾” VALVE 3010 ¾” V ALVE ANUAL NSTALLATION SE AND AINTENANCE 1 0991 497 EN VAILABLE WITH TANK TYPE HL, HL DRY, HL 50 DRY, HLV, HLV 40 e GL GMV SPA UNI EN ISO 9001...

- Page 2 All rights reserved. Any kind of exploitation in any form and by any means is forbidden without a written permission of GMV Spa. GMV Spa, within technical or manufacturing progress, reserves the right to modify parts or this manual without notice.

-

Page 3: General Section

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 3 / 16 1.01 NSTALLATION SE AND AINTENANCE Support and informations: FLUID DYNAMICS EQUIPMENTS AND UNI EN ISO 9001 COMPONENTS FOR LIFTS Certified Company GMV SPA Via Don Gnocchi, 10 - 20016 PERO – Milano (Italy) TEL. -

Page 4: R Ules Reference

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 4 / 16 NSTALLATION SE AND AINTENANCE 1.01 0.1.2 RULES REFERENCE For all definitions not included in this manual please refer to rules and local laws in force, following, particularly: EN 81-2: Safety rules for the construction and installation of lifts, UNI–EN-ISO-14121: Safety of machinery - Principles for risk assessment,... -

Page 5: L Iability And Warranty

GMV's warranty is voided if you install any components or parts not original, if you make unauthorized changes or modifications or made by unauthorized or unqualified personnel. -

Page 6: Features And Requirements

Any use of the facility, which is different from the original proposal situation should be discussed with GMV. An application or use not permitted by GMV (patent legal reasons, technical or otherwise) is under the installer responsibility and may affect the warranty. -

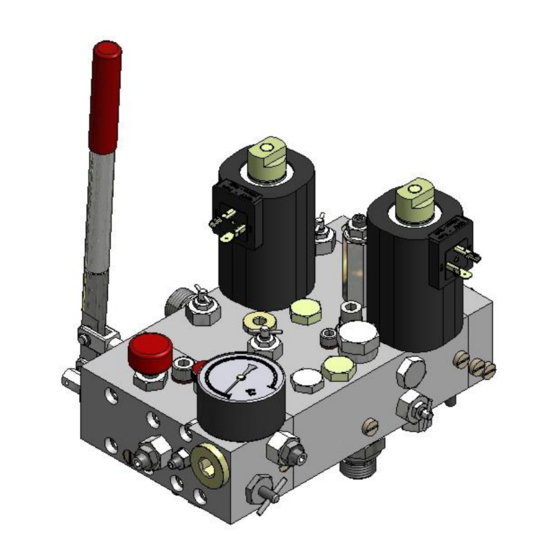

Page 7: ¾" Valve Dimensions

SE AND AINTENANCE Remove the spilled oil, remove the oil leaks, keeping equipment clean so leaks can be detected and easily removed. 2.2 3010 ¾” VALVE DIMENSIONS 2.3 HYDRAULIC CIRCUIT Pressure safety valve adjustment (p/max) Levelling / slow speed adjustment (up/down) -

Page 8: D Eceleration Distances And Signals

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 8 / 16 NSTALLATION SE AND AINTENANCE 1.01 2.4 DECELERATION DISTANCES AND SIGNALS DISTANCE DISTANCE CAR SPEED [m/s] DOWN 0 < 0.15 0.10 0.15 0.10 < 0.15 0.15 0.20 0.16 <... -

Page 9: H Ydraulic C Onnections

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 9 / 16 1.01 NSTALLATION SE AND AINTENANCE 2.7 HYDRAULIC CONNECTIONS ¾” ¾” X ¾ ½ X ¾ 3010 ¾” 12 ÷ 23 1/2” 3/4” ¾” X M30 ½... -

Page 10: A Djustment Of The Upward Acceleration – N ° 4

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 10 / 16 NSTALLATION SE AND AINTENANCE 1.01 Loosen the screw (1) two or three turns. Start the motor-pump (refer to the controller manual). Tighten screw (1) till get the desired maximum pressure (see technical report of the lift). -

Page 11: P Ipe Rupture Valve ( Vc ) Test ( In The Valve Block ) – N ° 5

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 11 / 16 1.01 NSTALLATION SE AND AINTENANCE Tighten the lock nut (3). The adjustment is finished. 3.9 PIPE RUPTURE VALVE (VC) TEST (IN THE VALVE BLOCK) – N° 5... -

Page 12: Maintenance And Fault Analysis

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 12 / 16 NSTALLATION SE AND AINTENANCE 1.01 4 MAINTENANCE AND FAULT ANALYSIS 4.1 PROGRAMMED MAINTENANCE For a correct and safe lift use, it is necessary to make a preventive programmed maintenance, following a fixed plan. - Page 13 1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 13 / 16 1.01 NSTALLATION SE AND AINTENANCE Check for the exclusion shut-off pressure gauge Pressure gauge shut off (RUB) Close the ball valve (S), open the pressure gauge shut off (RUB) and fully discharge the pressure using electro- valve (VMD).

-

Page 14: F Ault A Nalysis

1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 14 / 16 NSTALLATION SE AND AINTENANCE 1.01 4.4 FAULT ANALYSIS Fault Possible cause Possible solution The car doesn’t DEVICES : VRP, keep the floor VMD, VSMA, PAM Remove the spool and check the cleanliness of the closure. - Page 15 1 0991 497 EN - 24.03.2017 3010 ¾” V ALVE ANUAL 15 / 16 1.01 NSTALLATION SE AND AINTENANCE...

- Page 16 Via Don Gnocchi, 10 - 20016 PERO – Milano (Italy) UNI EN ISO 9001 Certified Company TEL. +39 02 33930.1 - FAX +39 02 3390379 http://www.gmv.it - e-mail: info@gmv.it Doc. n° 1 0991 497 Rev. 1.00 - 24.03.2017 File: 3010 3_4_10991497EN.doc...

Need help?

Do you have a question about the 3010 and is the answer not in the manual?

Questions and answers