Alcatel ONETOUCH POP 3 Series Repair Documentation

Tcl communication

Hide thumbs

Also See for ONETOUCH POP 3 Series:

- User manual (64 pages) ,

- Quick start manual (21 pages) ,

- Quick start manual (21 pages)

Table of Contents

Advertisement

Quick Links

See also:

User Manual

TCL

L2 Repair Document

Communication Ltd.

Pixi3-5 3G

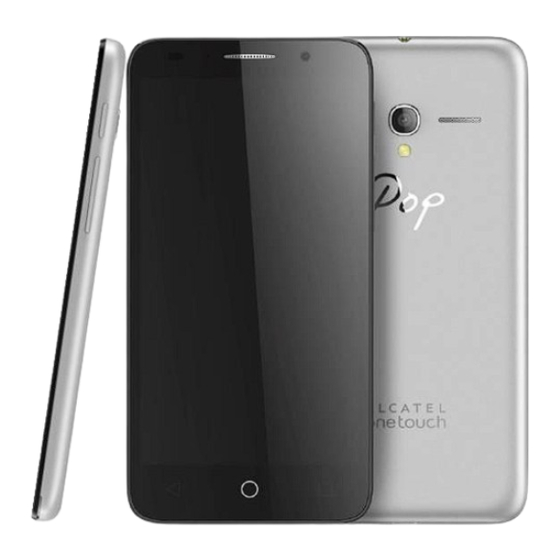

ALCATEL ONETOUCH POP 3 (5)

5015D/X/A/E_5016A/J

POP 3 (5) = Pixi3-5 3G

Note: this manual is non-contractual and TCL Communication Ltd. can modify it without prior

notice on the characteristics of described equipments.

Rev.

Page

1.0

1/42

5015D/X/A/E_5016A/J Level 2 Repair Document

All rights reserved. Transfer, copy, use or communication of this file is prohibited without authorization.

Advertisement

Table of Contents

Need help?

Do you have a question about the ONETOUCH POP 3 Series and is the answer not in the manual?

Questions and answers