Summary of Contents for rada Meynell V8/3

- Page 1 Rada Meynell V8/3 Thermostatic Mixing Valve Important! This Manual is the property of the customer and must be retained with the product for maintenance and operational purposes. Product Manual...

- Page 3 INTRODUCTION The Meynell V8/3 is a Thermostatic Mixing Valve specified to meet the highest standards of safety, and reliability as demanded by today’s users. All Meynell products are designed, manufactured and supported in accordance with accredited BS EN ISO 9001: 2000 Quality Systems.

-

Page 4: Safety Warnings

SAFETY : WARNINGS Warning! Products manufactured by us are safe provided they are installed, used and maintained in good working order in accordance with our instructions and recommendations. Caution! Read all of these instructions. Retain this guide for later use. Pass on this guide in the event of change of ownership of the installation site. -

Page 5: Pack Contents

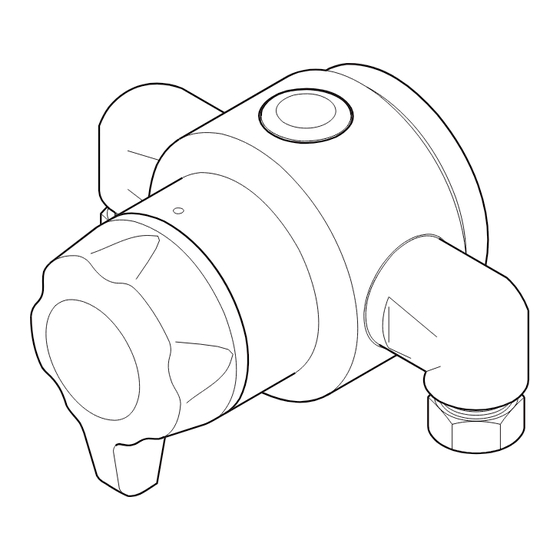

PACK CONTENTS Tick the appropriate boxes to familiarize yourself with the part names and to confirm that the parts are included. Exposed Models 1 x V8/3 1 x Hexagonal Key 3 x Fixing Screws 1 x V8/3 L 2 x 6 L/M Flow Regulators (Note! see section: Type 2 and Type 3... - Page 6 Built-in Models 1 x Hexagonal Key 1 x V8/3 B 3 x Fixing Screws 2 x 6 L/M Flow Regulators (Note! see section: Type 2 and Type 3 Valves - Application) 1 x V8/3 BL 1 x Foam Seal 1 x Concealing Plate 1 x Rubber Grommet 1 x TMV3 Requirements Manual...

-

Page 7: Specifications

SPECIFICATIONS Normal Operating Conditions are considered as: • inlet maintained pressures are nominally balanced • daily usage 1-6 hours • installation and usage environment not subject to extremes of temperature, unauthorised tampering or wilful abuse. Operating Parameters For Type 3 installations, the supply conditions specified in the TMV3 Requirements Manual take precedence over the operating parameters which follow. - Page 8 The performance specification outlined below is achieved with outlet blend temperature set between 35 - 45°C and supplies of 15°C cold and 65°C hot with nominally equal pressures. • Outlet blend temperature is maintained within 2°C with a 10°C change in hot or cold supply.

-

Page 9: Installation Requirements

Tempering Valve Overflow Indicator Mini Expansion Vessel Pressure Reducing Valve The Meynell V8/3 Thermostatic Mixing Valve is compatible with the following systems: Gravity fed system The Mixing Valve MUST be fed from a cold water cistern and hot water cylinder providing nominally equal pressure. - Page 10 Unvented mains pressure system The Mixing Valve can be installed with a unvented, stored hot water cylinder. Mains pressurised instantaneous hot water system (thermal store) The Mixing Valve can be installed with systems of this type with balanced pressures. Pumped system The Mixing Valve can be installed with an inlet pump (twin impeller).

-

Page 11: Installation

INSTALLATION General Installation must be carried out in accordance with these instructions, and must be conducted by designated, qualified and competent personnel. The installation must comply with the “Water Supply (Water Fittings) Regulations or Scottish Byelaws” or any particular regulations and practices, specified by the local water company or water undertakers. -

Page 12: Reverse Outlet Connector

11. Decide on a suitable position for the Mixing Valve. The position of the Mixing Valve and the Shower Fittings must provide a minimum gap of 25 mm between the spill-over level of Hose Retaining Ring the shower tray/bath and the handset. This is to prevent back-siphonage. -

Page 13: Exposed Models

1. Exposed Models Wall Plugs 1.1 Decide on a suitable position for the (not supplied) Thermostatic Mixing Valve where all users can operate it. 1.2 Remove the Wall Bracket from the rear of the Mixer Valve Body by loosening the Wall Bracket Grubscrew with a 2.5 mm hexagonal key (supplied). - Page 14 2. Built-in Models 2.1 Decide on a suitable position for the Thermostatic Mixing Valve where all users can operate it. Outlet 2.2 Determine the routes of the incoming hot and cold supply pipework. They can be rising or falling supplies. 2.3 Determine the route for the outlet pipework.

- Page 15 2.11 Plaster and tile up to the Thermostatic Foam Seal Mixing Valve, leaving a maximum diameter hole around the Mixing Valve Concealing of 125 mm. Plate 2.12 Fit the Sealing Grommet to the inner diameter of the Concealing Plate. Remove the protective backing from one side of the Foam Washer and fix to rear of the Concealing Plate.

-

Page 16: Operation

OPERATION Temperature selection (not lockshield model). The mixer has one control to set temperature and works in a sequence: Off → Cold → Tepid → Pre-set Maximum Preset Maximum Temperature... -

Page 17: Exercising The Thermostat

This should be no more than 2°C change). Note! Causing thermal shutdown of the Meynell V8/3 by full closure of the cold supply may not adequately indicate the practical capability of the Meynell V8/3, nor its service condition. -

Page 18: Maximum Temperature Setting

The maximum blend temperature obtainable by the user should be limited, to prevent accidental selection of a temperature that is too hot. The Meynell V8/3 is fully performance tested, and the maximum temperature is preset to approximately 42°C under ideal installation conditions at the factory. -

Page 19: Fault Diagnosis

FAULT DIAGNOSIS Symptom Cause/Rectification Only hot or cold Inlet supplies reversed (hot supply to cold supply). water from mixer No hot water reaching mixer. outlet. Check strainers and inlet/outlet fittings for blockage. Installation conditions continuously outside operating parameters, refer to section: ‘Specifications’ and 2.e below. -

Page 20: Maintenance

Periodic attention is given, when necessary, to maintain the product in good functional order. The Rada Meynell V8/3 is designed for the minimum of maintenance in normal use. The only serviceable parts are the inlet filters which should be checked and cleaned every 12 months. - Page 21 SPARE PARTS...

- Page 22 SPARE PARTS SPKB0016P Control Knob (Stub Lever) SPLR0012P Control Knob (Long Lever) SPSL0006J Cartridge Sleeve Assembly - Components identified 1 SPPE0007P Concealing Plate (Chrome) SPSK0319.1J V8 Seal Kit - Components identified ‘A’ 147.48 Non Return Valve (Lockshield Only) - Not Illustrated 457.04 Bezel 1531.056...

- Page 23 SPKB0016P SPLR0012P 457.04 1551.185 SPPE007P...

-

Page 24: Customer Care

● For shower fi ttings or consumable items we You have the assurance of a fully trained Technician, reserve the right to supply replacement parts only. genuine Rada spare parts and a 12 month guarantee on any chargeable work done. The guarantee does not cover: ●...

Need help?

Do you have a question about the Meynell V8/3 and is the answer not in the manual?

Questions and answers