Unigas IDEA Series Manual Of Installation - Use - Maintenance

Hide thumbs

Also See for IDEA Series:

- Manual of installation - use - maintenance (89 pages) ,

- Installation, use and maintenance instruction manual (48 pages) ,

- Manual (48 pages)

Summary of Contents for Unigas IDEA Series

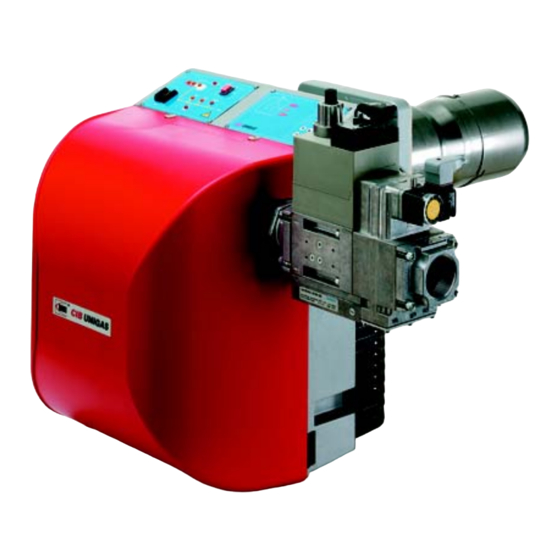

- Page 1 LG550 NG550 NGX550 IDEA Series Gas burners MANUAL OF INSTALLATION - USE - MAINTENANCE BURNERS - BRUCIATORI - BRULERS - BRENNER - QUEMADORES - ГОРЕЛКИ M039119CE Rel. 4.1 06/2010...

-

Page 2: Table Of Contents

TABLE OF CONTENTS WARNINGS ................................5 PART I: INSTALLATION ............................5 GENERAL FEATURES ................................... 5 How to interpret the burner “Performance curve” ........................... 6 Checking the proper gas train size ..............................6 BURNERS SPECIFICATIONS ............................... 7 Matching the burner to the boiler ..............................7 Specifications .................................... -

Page 3: Warnings

WARNINGS THIS MANUAL IS SUPPLIED AS AN INTEGRAL AND ESSENTIAL PART OF THE PRODUCT AND MUST BE DELIVERED TO THE USER. INFORMATION INCLUDED IN THIS SECTION ARE DEDICATED BOTH TO THE USER AND TO PERSONNEL FOLLOWING PRO- DUCT INSTALLATION AND MAINTENANCE. THE USER WILL FIND FURTHER INFORMATION ABOUT OPERATING AND USE RESTRICTIONS, IN THE SECOND SECTION OF THIS MANUAL. - Page 4 DIRECTIVES AND STANDARDS 3b) FIRING WITH GAS, LIGHT OIL OR OTHER FUELS Gas burners GENERAL European directives: The burner shall be installed by qualified personnel and in com- - Directive 90/396/CEE - Gas Appliances; pliance with regulations and provisions in force; wrong installation Directive 2006/95/EC on low voltage;...

-

Page 5: Part I: Installation

C.I.B. UNIGAS - M039119CE PART I: INSTALLATION GENERAL FEATURES This series burners are characterised by high performaces and width in the performance curves, when the pressure in the combustion chamber is high. They are also provided with other important functional features: there are plugs which can be easily connected to the boiler and to the detecting probes, a pressure plug in the combustion chamber, all mechanical components are mounted on a plate which can be quickly taken off for maintenance. -

Page 6: How To Interpret The Burner "Performance Curve

C.I.B. UNIGAS - M039119CE How to interpret the burner “Performance curve” To check if the burner is suitable for the boiler to which it must be installled, the following parameters are needed: furnace input, in kW or kcal/h (kW = kcal/h / 860);... -

Page 7: Burners Specifications

C.I.B. UNIGAS - M039119CE BURNERS SPECIFICATIONS Burner model identification Burners are identified by burner type and model. Burner model identification is described as follows. Type NG550 Model NG - Natural gas burner (1) BURNER TYPE LG - L.P.G. burner NGX - Low NOx burners... -

Page 8: Specifications

C.I.B. UNIGAS - M039119CE Specifications NG550 NG550 NG550 NG550 LG550 LG550 LG550 LG550 BURNERS M-.TN..0.25 M-.TN..0.32 M-.TN..0.40 M-.TN..0.50 L-.TN..0.25 L-.TN..0.32 L-.TN..0.40 L-.TN...0.50 245 - 570 Output min. - max kW Natural gas L.P.G. Fuel Gas category (see next paragraph) 3B/P 26 - 60 9.4 - 22... -

Page 9: Country And Usefulness Gas Categories

C.I.B. UNIGAS - M039119CE Low NOx burners NGX550 NGX550 NGX550 NGX550 BURNERS M-.xx...0.25 M-.xx...0.32 M-.xx...0.40 M-.xx...0.50 132 - 490 Output min. - max kW Natural gas Fuel Gas category (see next paragraph) 14 - 52 Gas rate min.- max Stm Gas pressure min. -

Page 10: Performance Curves

C.I.B. UNIGAS - M039119CE Performance curves NG550 - LG550 Single stage NG550 - LG550 Double-stage/Progressive 100 150 200 250 300 350 400 450 500 550 600 650 NGX550 Low NOx burner To get the input in kcal/h, multiply value in kW by 860. - Page 11 C.I.B. UNIGAS - M039119CE Pressure in the network/gas rate curves Natural gas burners NG550 Single stage NG550 Double-stage/Progressive R p 1" ( 25) Rp 1" Rp 1"¼ R p 1" ¼ ( 32) Rp 1"½ (40) R p 1" ½ ( 40) Rp 2"...

-

Page 12: Overall Dimensions

Overall dimensions (mm) Standard burners Recommended boiler drilling jig and burner flange A(S*) A(L*) B(S*) B(L*) Omin Omax ±5mm ±5mm NG/LG550 25/32 165 178 384 384 M10 247 NG/LG550 165 178 384 384 M10 247 NG/LG550 165 178 384 384 M10 247 * S = measure referred to burners fitted with standard blast tube L = measure referred to burners fitted with extended blast tube... - Page 13 Low NOx Burner Low NOx burners Recommended boiler drilling jig and burner flangeRecommended boiler drilling jig and burner flange A(S*) A(L*) B(S*) B(L*) Omin Omax ±5mm ±5mm NGX550 25/32 874 176 198 384 241 384 M10 247 NGX550 176 198 384 241 384 M10 247 NGX550 176 198 384 241 384 M10 247 * S = measure referred to burners fitted with standard blast tube...

-

Page 14: Mountings And Connections

C.I.B. UNIGAS - M039119CE MOUNTINGS AND CONNECTIONS Packing urners are despatched in cardboard packages whose dimensions are: 1030mm x 530mm x 570mm (L x P x H) Packing cases of this type are affected by humidity; the maximum number of cases to be stacked is showed outside the packing. -

Page 15: Gas Train Connections

C.I.B. UNIGAS - M039119CE GAS TRAIN CONNECTIONS This paragraph shows the gas train components which are included in the delivery and those which must be fitted by the customer. The diagram complies with regulations in force ATTENTION: BEFORE EXECUTING THE CONNECTIONS TO THE GAS PIPE NETWORK, BE SURE THAT THE MANUAL CUTOFF VALVES ARE CLOSED. -

Page 16: Gas Proving System Vps504 (Option)

C.I.B. UNIGAS - M039119CE MOUNTING POSITIONS Fig. 5 Fig. 6 Fig. 7 Fig. 8 MULTIBLOC DUNGS MB-DLE 415..420 Mounting 1. Loosen screws A and B do not unscrew (Fig. 5 - Fig. 6). 2. unscrew screws C and D (Fig. 5 - Fig. 6). - Page 17 C.I.B. UNIGAS - M039119CE Fig. 13 Fig. 14 When wishing to monitor the test, install a pressure gauge ranged to that of the pressure supply point PA (Fig. 14). If the test cycle is satisfactory, after a few seconds the consent light LC (yellow) comes on. In the opposite case the lockout light LB (red) comes on. To...

-

Page 18: Electrical Connections

C.I.B. UNIGAS - M039119CE ELECTRICAL CONNECTIONS Respect the basic safety rules. make sure of the connection to the earthing system. do not reverse the phase and neutral connections. fit a differential thermal magnet switch adequate for connection to the mains. - Page 19 C.I.B. UNIGAS - M039119CE Single stage burner connectors: Fig. 18 - 7-poles connector Fig. 19 - Electric motor 3-pole connector Progressive burner connectors Fig. 20 - 7-poles and 4-poles connectors Fig. 21 - Electric motor 3-poles connector BURNER IN LOW FLAME SIGNALLING LAMP...

-

Page 20: Power Supply Without Neutral

C.I.B. UNIGAS - M039119CE LOW FLAME TIME METER LINE FUSE FOR FAN MOTOR LINE FUSE AUXILIARY FUSE BURNER LINE SWITCH FAN MOTOR LINE SWITCH FAN MOTOR REMOTE CONTACTOR SIEMENS RWF40 MODULATION REGULATOR BURNER LOCKOUT SIGNALLING LAMP BURNER IN LOW FLAME SIGNALLING LAMP FAN MOTOR SD-0÷10V... -

Page 21: Combustion Head Pressure Curves Vs. The Gas Flow Rate

C.I.B. UNIGAS - M039119CE Combustion head pressure curves vs. the gas flow rate Curves are referred to pressure= 0mbar in the combustion head! The curves referred to the gas pressure in the combustion head, depending on the gas flow rate, are referred to the burner in the com- bustion stage (percentage of residual O in the flues as shown in the “Recommended combustion values”... -

Page 22: Gas Pressure In Combustion Head Vs. Gas Flow Rate Curves

C.I.B. UNIGAS - M039119CE Gas pressure in combustion head vs. gas flow rate curves NG550 NGX550 Gas rate Stm LG550 L.P.G. L.P.G. rate Stm ATTENTION: before starting the burner up, be sure that the manual cutoff valves are open and check that the pres- sure upstream the gas train complies the value quoted on paragraph “Technical specifications”. -

Page 23: Startup Output

C.I.B. UNIGAS - M039119CE Startup Output The start-up heat output shall not exceed 120 kW (single stage burners) or 1/3 of nominal output (double-stage, progressive or fully modulating burners). In order to comply with these requirements, burners are provided with butterfly valve and/or slow-opening safety valve. -

Page 24: Fully Modulating Burners

C.I.B. UNIGAS - M039119CE go on adjusting air and gas flow rates: check, continuosly, the flue gas analisys, as to avoid combustion with little air; dose the air according to the gas flow rate change following the steps quoted below;... -

Page 25: Calibration Of Air And Gas Pressure Switches

C.I.B. UNIGAS - M039119CE Adjusting the combustion head The burner is factory-set with the combustion head at the position that refers to the "MAX" output. The maximum output setting refers to the “fully-ahead” position of the combustion head, as far as standard models (Fig. 29), and to “fully-backward” position for low NOx bur- ners (Fig. -

Page 26: Calibration Of Air Pressure Switch (Double-Stage, Progressive And Fully-Modulating)

C.I.B. UNIGAS - M039119CE Calibration of air pressure switch (double-stage, progressive and fully-modulating) To calibrate the air pressure switch, proceed as follows: Remove the transparent plastic cap. Once air and gas setting have been accomplished, startup the burner. During the pre-purge phase o the operation, turn slowly the adjusting ring nut VR in the clockwise direction until the burner lockout, then read the value on the pressure switch scale and set it to a value reduced by 15%. -

Page 27: Part Ii: Operation

C.I.B. UNIGAS - M039119CE PART II: OPERATION LIMITATIONS OF USE THE BURNER IS AN APPLIANCE DESIGNED AND CONSTRUCTED TO OPERATE ONLY AFTER BEING CORRECTLY CON- NECTED TO A HEAT GENERATOR (E.G. BOILER, HOT AIR GENERATOR, FURNACE, ETC.), ANY OTHER USE IS TO BE CONSI- DERED IMPROPER AND THEREFORE DANGEROUS. - Page 28 C.I.B. UNIGAS - M039119CE Fig. 33 - Progressive burners only Keys Mains switch ON - OFF Lockout signalling lamp Reset button for control box Gas pressure switch consent signalling lamp High flame operation signalling lamp (or air damper opening during pre-purge stage)

-

Page 29: Operation

C.I.B. UNIGAS - M039119CE OPERATION .BEFORE STARTING UP THE BURNER, BE SURE THAT THE MAIN SWITCH IS ON AND THE MANUAL SHUTOFF VALVES ARE OPEN. READ CAREFULLY THE “WARNINGS” NOTES ON THIS MANUAL. Set to ON position the mains switch A on the burner electrical board front panel. -

Page 30: Part Iii: Maintenance

C.I.B. UNIGAS - M039119CE PART III: MAINTENANCE At least once a year carry out the maintenance operations listed below. In the case of seasonal servicing, it is recommended to carry out the maintenance at the end of each heating season; in the case of continuous operation the maintenance is carried out every 6 months. -

Page 31: Removing The Filter In Themultibloc Dungs Mb-Dle 415 - 420

C.I.B. UNIGAS - M039119CE Removing the filter in theMULTIBLOC DUNGS MB-DLE 415 - 420 B01 1” 1/2 - 2” Check the filter at least once a year! Change the filter if the pressure difference between pressure connection 1 and 2 (Fig. 37-Fig. 38) Δp> 10 mbar. -

Page 32: Replacing The Electrodes

C.I.B. UNIGAS - M039119CE scratchbrush. LOCKED UNLOCKED Fig. 41 Fig. 42 Fig. 40 Fig. 43 Fig. 44 Fig. 45 Replacing the electrodes .To remove the electrodes, proceed as follows once the combustion head is removed (see “Removing and cleaning the combustion head”... -

Page 33: Electrodes Position Setting

C.I.B. UNIGAS - M039119CE Electrodes position setting ATTENTION: avoid the ignition and detection electrodes to contact metallic parts (blast tube, head, etc.), otherwise the boiler’s opera- tion would be compromised. Check the electrodes position after any intervention on the combustion head. The gap between the ignition electrode and the ground is 4 ÷... -

Page 34: Troubleshooting

TROUBLESHOOTING TROUBLE CAUSE MAIN SWITCH OPEN LACK OF GAS MAXIMUM GAS PRESSURE SWITCH DEFECTIVE (IF PROVIDED) THERMOSTATS/PRESSURE SWITCHES DEFECTIVE OVERLOAD TRIPPED INTERVENTION AUXILIARIES FUSE INTERRUPTED CONTROL BOX FAULTY DEFECTIVE SERVOCONTROL (IF PROVIDED) AIR PRESSURE SWITCH FAULT OR BAD SETTING MINIMUM GAS PRESSURE SWITCH DEFECTIVE OR GAS FILTER DIRTY IGNITION TRANSFORMER FAULT IGNITION ELECTRODES BAD POSITION... -

Page 35: Spare Parts

C.I.B. UNIGAS - M039119CE SPARE PARTS Desription Code NG550 LG550 NGX550 COVER 1011801 1011801 1011801 CONTROL BOX 2020468 2020468 2020468 DETECTION ELECTRODE 2080108 2080108 2080108 INGNITION ELECTRODE 2080218 2080218 2080270 INGNITION ELECTRODE 2080234 2080234 GASKET 2110056 2110056 2110056 FAN WHEEL... -

Page 36: Burner Exploded View

BURNER EXPLODED VIEW POSITION DESCRIPTION POSITION DESCRIPTION EXTENDED BLAST TUBE CONTROL BOX GENERATOR GASKET IGNITION TRANSFORMER THREADED GAS PIPE ACTUATOR FLANGE AIR PRESSURE SWITCH FLANGE OUTPUT CONTROLLER GAS PROVING SYSTEM PRINTED CIRCUIT BOARD COVER FIXING SCREW FRONT CONTROL PANEL AIR INTAKE FRONT CONTROL PANEL AIR INTAKE LIGHT... -

Page 38: Electrical Wiring Diagrams

C.I.B. UNIGAS - M039119CE ELECTRICAL WIRING DIAGRAMS Wiring diagram 18-163 - Complete key LOW FLAME TIME METER HIGH FLAME TIME METER FLAME DETECTION ELECTRODE EV1,2 GAS ELECTRO-VALVES (OR VALVES GROUP) FAN MOTOR LINE FUSE LINE FUSE LINE FUSE AUXILIARY FUSE... -

Page 46: Appendix

APPENDIX SIEMENS LME11/21/22 CONTROL BOX The series of equipment LME.. is used for the starup and supervisione of START-UP PROGRAM 1- or 2- stage gas burners. The series LME.. is interchangeable with the series LGB.. and LMG.., all diagrams and accessories are interchangea- As far as the startup program, see its time diagram: ble. - Page 47 LME11 control sequence LME21 control sequence B´ B´ SB / R SB / R W / GP W / GP (LR) BV2 7101d05/0206 Control sequence Waiting time LME22 control sequence Purge time B´ TSA Ignition safety time SB / R W / GP Preignition time Postignition time...

- Page 48 LME11 connection diagram Connection diagram Error message (alarm) Fuel valve C control RESET EK2 Remote lockout reset button Flame signal Gas pressure switch Air pressure switch Load controller K2/1 K2/2 Fan motor Control thermostat/pressurestat R / W Safety limit thermostat Limit thermostat /pressure switch Ignition transformer 7101 24 /0606...

- Page 49 CONTROL PROGRAM IN THE EVENT OF FAULT CONTROL BOX LOCKED If a fault occurs, all outputs will immediately be deactivated (in less In the event of lockout, the LME.. remains locked and the red signal lamp than 1s). (LED) will light up.The burner control can immediately be reset. This state After an interruption of power, a restart will be made with the full pro- is also mantained in the case fo mains failure.

- Page 52 C.I.B. UNIGAS S.p.A. Via L.Galvani, 9 - 35011 Campodarsego (PD) - ITALY Tel. +39 049 9200944 - Fax +39 049 9200945/9201269 web site: www.cibunigas.it - e-mail: cibunigas@cibunigas.it Note: Specifications and and data subject to change. Errors and omissions excepted.

Need help?

Do you have a question about the IDEA Series and is the answer not in the manual?

Questions and answers