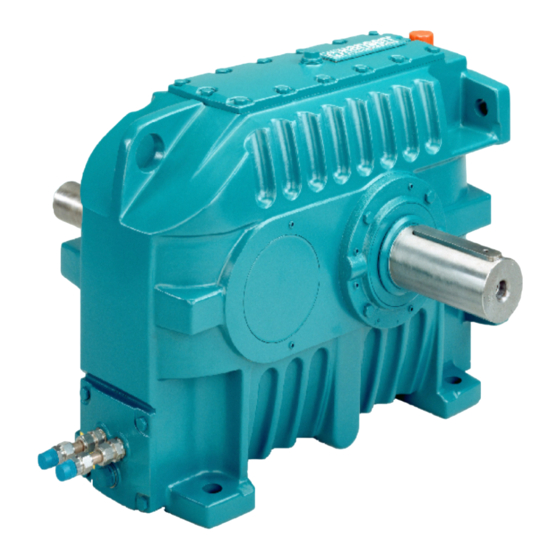

Hansen P4 Installation Manual

Standardized gear units

Hide thumbs

Also See for P4:

- Service manual (36 pages) ,

- Service manual (47 pages) ,

- Service manual (44 pages)

Need help?

Do you have a question about the P4 and is the answer not in the manual?

Questions and answers