Table of Contents

Advertisement

The Level Best Service Guide

has been organized to facilitate

quick and easy diagnostics and

trouble shooting for the most

common installation problems and

serviceable part failures.

Each segment of the Service

Guide, labeled 1-6, begins with a

diagnostics flow chart illustrating

the steps involved in the trouble

shooting process. The flow charts

are divided into alphabetical

sections that correspond to the

instructions that immediately

follow the chart.

How to use the

Service Guide:

1. Use the Table of Contents

to locate a topic area that

best matches the

symptoms.

2. Examine the flow chart at

the beginning of the

segment you select.

3. Review the system checks

and maintenance

procedures that

correspond to the

problem.

4. Follow the recommended

steps to repair the system.

5. If system failure continues

after completing the

diagnostics and

recommended repairs,

call 1-800-738-9961.

LEVEL BEST

Service

Guide

Table of Content

1.

Erractic leg operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.

Park brake

3.

Electrical wiring/connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.

Function:

-- Inspection

-- Connections

-- Testing

-- Routing

4.

Pump motor/manifold assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

Solenoid valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.

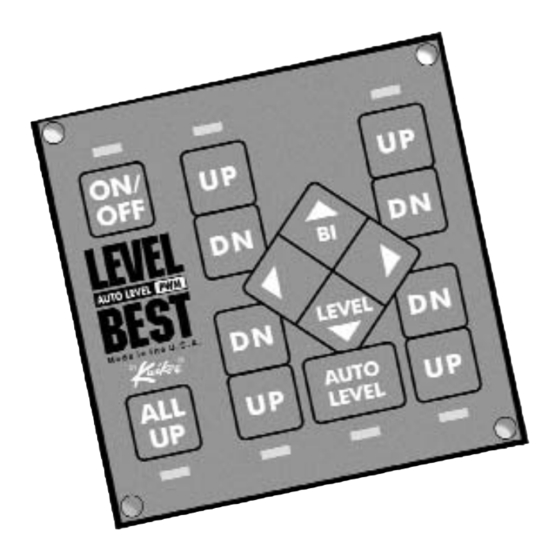

Control touchpad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Products Company, Inc.

Cottage Grove, Oregon 97424

(541) 942-3888

www.kwikee.com

Service

Guide

June 2 2 003

Page

3

6

10

12

15

18

© 2003 Kwikee Products Co., Inc.

Kwikee Doc #KSG002

Advertisement

Table of Contents

Summary of Contents for Kwikee Level Best

-

Page 1: Table Of Contents

Service Guide June 2 2 003 LEVEL BEST The Level Best Service Guide has been organized to facilitate Service quick and easy diagnostics and trouble shooting for the most common installation problems and Guide serviceable part failures. Each segment of the Service... - Page 2 Kwikee will pay for the labor required to repair or replace its products on claims submitted within 2 years of the date of purchase. The warranty on repaired or replaced parts shall be limited to the unexpired duration of the original warranty.

- Page 3 SEGMENT Erractic Leg Operation Diagnostics Chart Level Best Service Guide Page 3...

-

Page 4: Segment

2. Manually Bleeding. Most cylinders will bleed themselves, however if you have diffi- culty with a particular cylinder during the bleeding process, it is possible to manually bleed a cylinder. Level Best Service Guide Page 4... -

Page 5: Incorrect Hose Installation

Left Front Extend LF1T Right Front Extend RF2T Left Rear Extend LR3T Right Rear Extend RR4T Left Front Retract LF1B Right Front Retract RF2B Left Rear Retract LR3B Right Rear Retract RR4B Figure 1a Level Best Service Guide Page 5... - Page 6 SEGMENT Control Diagnostics Chart (1 of 2) Level Best Service Guide Page 6...

- Page 7 SEGMENT Control Diagnostics Chart (2 of 2) Level Best Service Guide Page 7...

-

Page 8: Control

This connection is located on the same terminal as the battery cable from the vehicle battery. Power for the control system is derived from this connection. The Level Best control requires a minimum of 12 volts for proper operation (Figure 2b.) -

Page 9: Leg Extended Indicator

Check the connection at the signal source. This is normally located at or near the parking brake assembly. The Level Best control is designed for a ground signal when the park brake is set. For a 12-volt signal a “mini relay”... - Page 10 SEGMENT Electrical Wiring/Connections Diagnostics Chart Level Best Service Guide Page 10...

-

Page 11: Electrical Wiring/Connections

Electrical Wiring / Connections SEGMENT Function Power for the Level Best leveling system is derived from the battery cable connection at the pump motor solenoid. The power lead for the control module also originates from this connection (Figure 3a.) Check all ground connections. - Page 12 SEGMENT Pump Motor/Manifold Assembly Diagnostics Chart Level Best Service Guide Page 12...

-

Page 13: Pump Motor/Manifold Assembly

If power is detected and the solenoid does not operate replace the solenoid (Figure 4a.) When no voltage is detected at the solenoid control terminal the control module will require replacement. Refer to Segment 6: Control. Level Best Service Guide Page 13... -

Page 14: By-Pass Valve

The By-pass valve controls the pressure at which the leveling system operates. The Level Best system operates at a pressure of 1500 to 1800 pounds per square inch. The By-pass valve is located on the side of the pump motor mounting block (Figure 4b.) Pump motor runs but leveling legs do not operate. - Page 15 SEGMENT Solenoid Valves Diagnostics Chart Level Best Service Guide Page 15...

-

Page 16: Solenoid Valves

Test valve actuation on the workbench using a battery or a regulated 12-volt power supply. Check for bent valve assembly. Check the valve orifices for any obstructions or contaminates. c. Replace valve. Level Best Service Guide Page 16... -

Page 17: Shorted Coils

Next test between the two coil terminals, the meter should read between 8.5 and 10 ohms, if not replace coil. If after replacing the coil the problem still persists refer to Segment 6: Control Touchpad. Level Best Service Guide Page 17... - Page 18 SEGMENT Control Touchpad Diagnostics Chart Level Best Service Guide Page 18...

-

Page 19: Control Touchpad

SEGMENT Function The Control is the heart of the Level Best electronic control system. Note: Extreme care should be exercised when working with this device. Disconnect batteries, as any short circuit or inadvertent grounding will damage the control. The Control microprocessor handles all of the Level Best switching functions, including the motor solenoid, 4-way valve, and cylinder / leg valves. -

Page 20: Auxiliary Dash Light And/Or Air Dump Does Not Work

Check the same for Pin 2, Pin 3, etc. If there is not continuity between the pins, the cable is bad. Replace the cable. Check function again. If the unit still does not work replace the level sensor module. Check function. If the unit does not function, call Kwikee Customer Service at 800-736-9961. Products Company, Inc.

Need help?

Do you have a question about the Level Best and is the answer not in the manual?

Questions and answers