Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for UAS SMOG-HOG PSH

- Page 1 OWNER’S MANUAL SMOG-HOG ELECTROSTATIC AIR CLEANER ® MOdEL: PSH...

- Page 2 Should you need assistance, call the United Air Specialists, Inc. customer service number shown below. To expedite your service, have the following information available when contacting UAS. UAS ORDER #: ________________________________________________________________ UNIT MODEL #:________________________________________________________________...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Page Safety PrecautionS ..................v 1. introDuction ....................1 Description of operation ................1 System Definitions ..................1 unit nomenclature ..................1 Description of components ...............5 1.4.1 Power Packs ..................5 1.4.2 ionizers ..................5 1.4.3 collector cells ................5 1.4.4 filters .....................5 1.4.5 Junction Boxes ................5 1.4.6 other equipment ................5 2. - Page 4 4.1.8 Power Pack enclosure Push rod and Ground Bar ......13 4.1.9 in-Place cleaning................13 4.1.10 Placing PSH on Line..............14 4.1.11 uaS on Site Start up Visit ............14 5. Maintenance ....................14 recommended Maintenance ..............14 5.1.1 check Power Pack enclosure indicator Light(s) ......14 5.1.2 ionizer and collector cell(s) Weekly Visual inspection ....14...

- Page 5 TABLE OF CONTENTS Page 9. Part rePLaceMent ProceDureS anD aDJuStMentS ......17 ionizer Wire replacement ................17 Door feed through insulator replacement..........17 indicator Light replacement ..............17 component access Door Gasket replacement ........17 Power Pack enclosure Push rod adjustment .........18 Blower Lubrication ..................18 10.

- Page 6 this page intentionally left blank...

-

Page 7: Safety Precautions

SAFETY PRECAUTIONS We have provided many important safety messages in this manual on your Smog-Hog PSH. always read and obey all safety messages. this is the safety alert symbol. this symbol alerts you to potential hazards that can kill or hurt you and others. all safety messages will follow the safety alert symbol and the word “DanGer”... - Page 8 this page intentionally left blank...

-

Page 9: Introduction

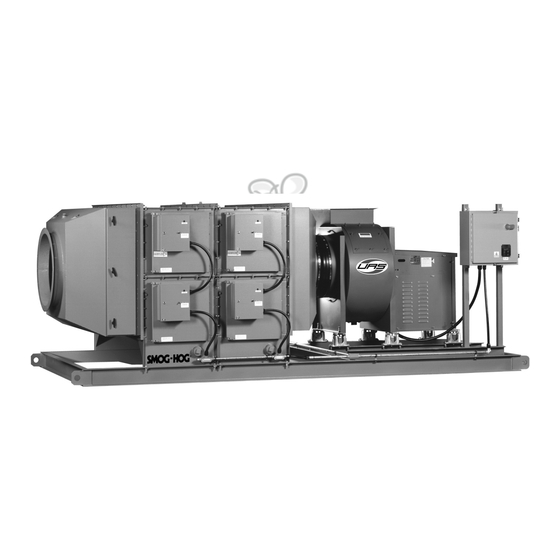

PSH systems may include various combinations of by united air Specialists, inc. (uaS). reading this features connected in series in the direction of airflow. manual is important to the successful installation and the PSH’s configuration code is defined with a series... - Page 10 Smog-Hog revised 10/09 PSH Series Model ITEM NAME Prefilter ionizer collector cell afterfilter Power Pack enclosure component Door electrical Junction Box Lifting eye (4 places, not provided on skidded systems) 3’’ fPt Drain (1 side, 1 bottom on PSH 12 thru 52; 1 each side, 1 bottom on PSH 24 thru 64) Lifting eye...

- Page 11 Smog-Hog revised 10/09 PSH Series Model Figure 4 PSH System Components...

- Page 12 Smog-Hog revised 10/09 PSH Series Model ITEM NAME attach nut to Screw on ionizer Wire Support Bar ionizer ionizer Standoff insulator ionizer contact Spring 4 per assembly ionizer Door feed thru insulator ionizer Standoff insulator attach nut to Screw install Spring to Mate ionizer Wire on ionizer Wire Support Bar...

-

Page 13: Description Of Components

Main electrical Panel or a uaS Blower Panel. refer to uaS 2.2.3 BOTTOM WORKING CLEARANCE... -

Page 14: Supports

2.3.3 UTILITIES/dRAINS Mechanical, electrical service requirements and system entry points are clearly marked on the uaS System CRUSH ANd ELECTROCUTION HAzARd Layout Drawing and uaS electrical Drawings. the PSH main drain pipe should be have a drain trap. refer Use adequate safety measures when lifting and to figure 6. -

Page 15: Receiving Inspection

Most can be handled by forklift truck Lifting eye but final placement may require a crane refer to uaS (two Per SMoG-HoG® unit System Layout Drawing for weights, sizes and notes unit Side) detailing responsibilities of the installing contractor. -

Page 16: Unit Storage/Delay To System Installation

3.5.6 ORdER OF INSTALLATION Where the PSH is to be suspended, refer uaS System When the PSH is shipped in sections refer to the uaS Layout Drawing. Do not support ducting, plumbing or System Layout Drawing for proper installation. -

Page 17: Leveling

3.5.9 dRAIN PIPE CONNECTIONS WARNING the PSH modular cabinet is supplied with drain connections. (refer to uaS System Layout Drawing.) The PSH unit should be secured with appropriate the number of drain connections will depend on the hardware by the installing contractor. -

Page 18: Wash Water Supply Connection

Hazardous live and moving parts are exposed others an electrical interlock should be provided during the troubleshooting procedures. for the power pack circuit to the Smog-Hog PSH and the system exhaust blower. This provides safe operation of the PSH. do not operate the... -

Page 19: Operation

PSH inlet plenum, if supplied belt occurs which requires a belt tension adjustment. by uaS, will have baffle filters or aluminum media. if this tension adjustment is not completed the belt will the inlet plenum should be inspected that all baffle wear prematurely, requiring a replacement. -

Page 20: Blower Current Measurement

number. -

Page 21: Power Pack Enclosure Push Rod And Ground Bar

Smog-Hog revised 10/09 PSH Series Model 4.1.8 POWER PACK ENCLOSURE PUSH ROd ANd GROUNdING BAR each power pack enclosure has a captive, spring loaded “push rod” extending into the module. factory-set, the push rod serves the following purposes: 1. High voltage Dc power is automatically shut down with the collector cells removed from the module. -

Page 22: Placing Psh Online

Service for a start-up request form. the completion of of contaminant build-up for ground contact. the request form is required before scheduling a uaS field Service technician. the on site start up consist inspect the collector cell, noting the condition of the... -

Page 23: Perform An In-Place Cleaning Wash Cycle

“Detergent frequency Selection” required when changing detergents. can be increased up to everyday. the auto wash cycle is initiated by a uaS time clock, with the wash cycle sequencing, wash cycle times, and detergent frequency 6.3 Water Temperature through the uaS PLc. -

Page 24: Dry-Out Time

Smog-Hog revised 10/09 PSH Series Model 6.7 dry-Out Time 7.4 Other Cleaning Considerations ionizer(s), collector cell(s) and filter media should be the previous methods address the cleaning of collector dry before the PSH is placed into operation. Startup cells and filter media. the PSH cabinet should also of a wet system will cause dead short conditions to be periodically cleaned (i.e., during normal planned the ionizer and collector cell circuits. -

Page 25: Cabinet

Smog-Hog revised 10/09 PSH Series Model 8.4 Cabinet 1. Door feed-thru insulators are cleaned and white. 2. Door gaskets are cleaned and intact. 3. component tracks are free of contaminant build up (for ionizer and collector cell grounding). 4. Module drain sumps are cleaned and free-flowing. 5. -

Page 26: Power Pack Enclosure Push Rod Adjustment

Smog-Hog revised 10/09 PSH Series Model TO CHANGE GASKET 10. TROUBLESHOOTING 1. remove existing gasket, making sure to scrape off any residual silicone sealant. CAUTION 2. trim one edge of gasket neatly and evenly. 3. the door gasket should be formed to the complete Troubleshooting should only be completed by cabinet lip edge before applying silicone sealant. -

Page 27: Tools Required

• High voltage test cables (2), 3’ in length with test clips at each end • Basic hand tools • One power pack* (UAS Part Number 21-1216) for bench testing. • AC cable with three prone plug (for the wall... -

Page 28: Step 1 Checking The Power Pack

Smog-Hog revised 10/09 PSH Series Model all connectors on the power pack are identified with 2. there are “run away” voltages to the power pack name and wire number with the exception of the ground requiring power pack replacement, above 12.0 connector (green wire to this connection). -

Page 29: Step 2 Checking The Ionizers And Collector Cells

Smog-Hog revised 10/09 PSH Series Model Figure 20 Power Pack Enclosure Wiring diagram (a) Place the toggle switch in the off position, and open the power pack has two terminals for the indicator light, identified as #9 (+), and #2 (-). the factory wiring power pack lid door. -

Page 30: High Voltage Probe Measurements

• Contaminant build up and or cracked ionizer stand • Warped cell plate (s) which could be due to high off insulators and or high voltage feed through duct operating temperature, consult uaS. insulators. • Carbon tracking to the cell high voltage door feed •... -

Page 31: Bench Test Procedure

Smog-Hog revised 10/09 PSH Series Model 4. engage the interlock switch and place the tip this procedure can be utilized to determine an electrical of the high voltage probe to the collector cell problem with the ionizers and collector cells or a power door feed through insulator. - Page 32 Smog-Hog revised 10/09 PSH Series Model teStinG coLLector ceLL 1. Select one collector cell to be tested. 2. connect one high voltage wire to the collector cell contact spring and to the power pack connector identified as “collector #7”. 3. connect the other high voltage wire (use as a ground wire) to the metal frame of the collector cell and to the ground stud on the power pack.

-

Page 33: Troubleshooting Guide

Power pack enclosure(s) push rod refer to Section 9.5. assembly is not properly adjusted. fuses have failed to the power pack replace fuses. circuit. air volume (acfM) is not within Measure air volume, call uaS customer specifications. Service for specifications. -

Page 34: Ordering Parts

11.3 Freight Cost freight cost on returned parts must be prepaid by the sender. freight cost on parts shipped from uaS is prepaid by uaS and added to the cost of the parts. - Page 35 Smog-Hog revised 10/09 PSH Series Model this page intentionally left blank...

-

Page 36: Power Pack Enclosure Illustration And Parts List

Smog-Hog revised 10/09 PSH Series Model 12. POWER PACK ENCLOSURE ASSEMBLY 12 13 10 11 32 33 POWER PACK ENCLOSURE ILLUSTRATION... - Page 37 Smog-Hog revised 10/09 PSH Series Model 12.1 POWER PACK ENCLOSURE ASSEMBLY PARTS LIST ITEM NO. PART NO. dESCRIPTION QUANTITY REQUIREd 20-1396 Power Pack enclosure 21-1216 Power Pack 02-1651 Shorting out assembly 42-10063-0001 Gasket for Lid cover 20-2835 terminal Block 10-11034-0001 terminal Bracket 41-2435-5 terminal Label...

-

Page 38: Replacement Parts For Ionizer And Collector Cell

Smog-Hog revised 10/09 PSH Series Model IONIZER SUPPORT BAR IONIZER STANDOFF IONIZER WIRE SPRING INSULATOR CELL DOOR FEED THRU INSULATOR COMPONENT SECTION THROUGH IONIZER AIRFOIL ACCESS DOOR IONIZER DOOR IONIZER CONTACT FEED THRU SPRING INSULATOR ATTACH NUT TO SCREW ON ALL IONIZER WIRE SUPPORT BARS IONIZER WIRE 9 PER ASSEMBLY COMPONENT... - Page 39 Smog-Hog revised 10/09 PSH Series Model CELL CONTACT SCREW WITH WASHER INSTALL SPRING TO MATE WITH CENTER CELL CONTACT SPRING POST IN ADJACENT CELL TRIANGLE INSULATOR IONIZER DOOR FEED THRU INSULATOR CELL DOOR FEED THRU INSULATOR COMPONENT DOOR COLLECTION CELL COLLECTOR CELL ASSEMBLY COLLECTOR CELL ASSEMBLY ITEM...

- Page 40 UAS is limited to furnishing replacement parts F.O.B. UAS’ factory or making repairs at UAS’ factory of any parts that are determined, upon inspection by UAS, to be defective. In no event will UAS be responsible for labor or transportation charges for the removal, reshipment or reinstallation of the parts.

Need help?

Do you have a question about the SMOG-HOG PSH and is the answer not in the manual?

Questions and answers