Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for CALEFFI DIRTMAGCLEAN

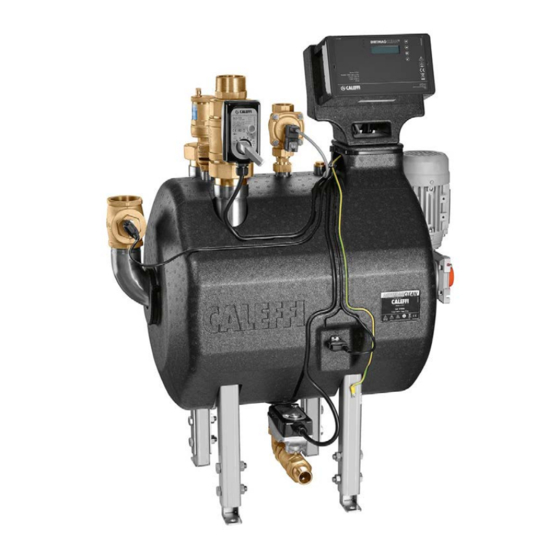

- Page 1 H0006359 Caleffi S.p.A. S.R. 229 no. 25 - 28010 Fontaneto d’Agogna - Italy www.caleffi.com DIRTMAGCLEAN Self-cleaning magnetic dirt separator strainer Code 579000 © Copyright 2018 Caleffi USE AND MAINTENANCE MANUAL ORIGINAL INSTRUCTIONS DATE: 01/07/2018 REVISION: 00...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Contents 1 Introduction 1.1 Purpose of the manual 1.2 Requirements for use 1.3 Symbols 1.4 Definitions 2 General information 3 Characteristic components 3.1 Package composition 3.2 Technical features of the device and valves 3.3 Regulator and actuator technical features 3.4 Sizing 4 General description of the operation 4.1 Operating principle... -

Page 3: Introduction

1 Introduction Dear Installer, Thank you for choosing the self-cleaning magnetic dirt separator strainer, which we hope will always satisfy you; this product has been manufactured in compliance with the most stringent safety regulations in force. To ensure the safety of personnel, the self-cleaning magnetic dirt separator strainer referred to in this use and maintenance manual must be handled, installed, used, maintained and dismantled/eliminated by carefully following the instructions provided in this use and maintenance manual in compliance with the applicable law. -

Page 4: Definitions

Person in charge of installing, operating, regulating and cleaning the machine. QUALIFIED TECHNICIAN Specialized person, specially trained by Caleffi S.p.A. and authorized to carry out extraordinary maintenance or repairs requiring a particular knowledge of the machine, of its operation, of the safety devices and their methods of intervention. -

Page 5: Characteristic Components

3 Characteristic components Performance Medium: water, glycol solutions Maximum percentage of glycol: Maximum working pressure: 10 bar Working temperature range: 5–85°C Hydraulic characteristics: Kv = 45 m Water content: 50 l Strainer mesh size Ø: 30 µm Particle separation rating: down to 2 μm DHW inlet minimum dynamic pressure for 3 bar wash Motor noise:... -

Page 6: Sizing

3.4 Sizing The sizing of the dirt separator strainer must be performed considering the following values: Maximum recommended flow rate: 20 m Hydraulic characteristics p(mm w.g.) p(kPa) 5000 2000 1000 2" Connections 4 General description of the operation The dirt separator strainer consists of a series of elements that make it possible to obtain a product capable of carrying out a constant and continuous filtration of the system water and automatic cleaning. -

Page 7: Filtration

4.2 Filtration During normal operation, the medium coming from the system enters in the strainer body through the motorised ball valve V1. The medium is forced to pass through the filtration discs, then it is conveyed into the central part until it comes out of the device through the clapet check valve. Inlet from the system 579 series Supply: 230V (ac) ±10%... -

Page 8: Circuit Filling And Operating Conditions Reset

During the second cleaning phase (mechanical cleaning with water injection), the two-way solenoid valve V2 (equipped with check valve) is opened injecting water from the water mains. In order to perform an effective cleaning, a minimum dynamic pressure of 3 bar must be guaranteed during washing and the installation of an anti-backflow system is mandatory to protect the aqueduct network (apply according to local regulations in force). -

Page 9: Overall Dimensions

5 Overall dimensions 202,5 6 Adhesive labels location IMPORTANT: product already con gured according to the speci cations indicated in the technical documentation. IS CASE OF NEED, or for technical information related to the operation, please contact the external after-sales serviceat the number 0322 849301... -

Page 10: Electrical Connections Label

6.1 Electrical connections label μ 48 V ˜ 230 V ˜ G. OUT ALARM OUT1 50 Hz serie 638 serie 638 F6 = 2A - 250 Vac F7 = 315 mA - 250 Vac 230 V ˜ 50 Hz 7 Intended use The device is intended for use exclusively in heating systems containing water or water+glycol solutions up to a concentration of 50%. -

Page 11: Packaging, Handling And Transport

8 Packaging, handling, transport The strainer is fixed on a wooden pallet. An external carton with cover protects the strainer in order to prevent damage that could occur during handling. The packaging is single-use and must be disposed of according to the indications provided for by the regulations in force. Before any movement, make sure that the elements used for transport (trolleys, bridge cranes, nylon straps, ropes, etc.) are in perfect working order and can withstand loads of not less than 100 kg. -

Page 12: Handling

8.4 Handling It is advisable to move the strainer using mechanical devices (lift truck, crane, bridge crane, etc.) of adequate capacity. For lifting it is advisable to use standard belts, positioned as indicated in the illustrations aside, taking care to keep them always tensioned so that they do not slip and taking care to keep the strainer parallel to the ground. -

Page 13: Hydraulic Installation

9.1 Hydraulic installation Installation in by-pass with dedicated pump NOTE The strainer regulator does not directly control the activation of the circulation pump. 9.2 Installation in by-pass Provide suitable safety devices to be installed on the system near the appliance to prevent any possible risk due to overpressure. Suitable safety devices must be installed in order to prevent exceeding the maximum pressure declared for the device or pipes, in compliance with current regulations. - Page 14 It is possible to adjust the drain in the most appropriate direction rotating the motorised ball drain valve and its fitting after loosening the cap. Take care not to bend-stress the valve. This operation must be carried out before commissioning, with a completely empty and pressure-free device. The device drains the liquid collected that can be at high temperatures (>...

-

Page 15: Device Reset

9.3 Device reset The "Reset device" function allows to interrupt all the functions in progress and to set to the initial condition. This function cancels the alarms and anomalies present, if any. 1. Press and hold "OK" until the configuration menu is displayed. 2. -

Page 16: Example Of Electrical Connection For Circulator Management

9.6 Example of electrical connection for circulator management Control 230V ac system 24Vac Relay The circulators A (boiler circulator) and B (strainer service circulator) operate simultaneously. When the strainer is in the cleaning phase (OUT1 contact closed), the 24V relay (to be inserted separately) removes electric supply from the pump B, stopping it until the end of cleaning. 9.7 Example of electrical connection with two parallel strainers MAX10 ALARM... -

Page 17: Regulator Description And Operation

10 Regulator description and operation The regulator is provided with several programs to clean the strainers. This can be performed according to a periodic program or it can be directly controlled by an operator. Depending on the type and conditions of the circuit and the system maintenance management, the most suitable operating modes can be selected, see the "controller operation”... - Page 18 Cleaning on instantaneous Dp During normal operation, the device monitors the strainer clogging status, by measuring the differential pressure between inlet and outlet of the strainer elements measured by the probes S1 and S2. When the difference exceeds a value set and modifiable by the user, an automatic strainer cleaning cycle is immediately started.

-

Page 19: Commissioning

11 Commissioning Commissioning must be carried out according to the regulations in force by qualified personnel. Check that the cold water supply pressures are within the operating limits of the device. Check that the temperature of the hot drain water has a value complying with the regulations in force. NOTE. -

Page 20: Maintenance

12 Maintenance Introduction Never perform maintenance and control operations with wet body parts. Wear the accident prevention equipment provided for by the regulations in force. Inspection and maintenance must always be carried out with the strainer stopped and without pressure. All operations must be performed by skilled personnel authorized by the manufacturer to avoid damage to the internal parts. -

Page 21: Important Notice For Correct Disposal Of The Product

13 Important notice for correct disposal of the product It is essential that the disposal is carried out in compliance with the above and in full compliance with the relevant regulations in force in the user's country. Since different regulations to observe are in force in the individual countries, the prescriptions imposed by local laws and by the competent authorities must be observed. -

Page 22: Spare Parts

15 Spare parts Consult the drawing of the spare parts with the relative table where the code and description of the individual parts supplied as spare parts are indicated Ref. Description Code Gearmotor x art. 579000 spare part F0000955 Actuator 230V-90° 2 way- "t" -cable l = 125 638052 Electrical spare part N.C.-Ø1"f.-V.230/50-60 H F0000952... -

Page 23: Manufacturer's Liability And Warranty

(flooding, etc...). 17 Manufacturer's liability and warranty With reference to the indications in this instruction manual, the company Caleffi S.p.A., declines all responsibility in case of: • use of the strainer contrary to national laws on safety and accident prevention •... -

Page 24: Table Of Interventions

18 Table of interventions DATE INTERVENTION LEAVE THIS MANUAL AS A REFERENCE GUIDE FOR THE USER...

Need help?

Do you have a question about the DIRTMAGCLEAN and is the answer not in the manual?

Questions and answers