Resol DeltaSol BX Plus Manual

For the specialised craftsman

Hide thumbs

Also See for DeltaSol BX Plus:

- User manual (80 pages) ,

- Manual (48 pages) ,

- Manual (92 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

BX Plus

DeltaSol

®

beginning with firmware version 1.06

Manual for the specialised

craftsman

Mounting

Connection

Operation

Troubleshooting

Application examples

en

Thank you for buying this RESOL product.

Manual

Please read this manual carefully to get the best performance from this unit.

Please keep this manual safe.

www.resol.com

Advertisement

Table of Contents

Summary of Contents for Resol DeltaSol BX Plus

- Page 1 1.06 Manual for the specialised craftsman Mounting Connection Operation Troubleshooting Application examples Thank you for buying this RESOL product. Manual Please read this manual carefully to get the best performance from this unit. Please keep this manual safe. www.resol.com...

- Page 2 Safety advice Target group Please pay attention to the following safety advice in order to avoid danger and These instructions are exclusively addressed to authorised skilled personnel. damage to people and property. Only qualified electricians should carry out electrical works. Initial installation must be effected by the system owner or qualified personnel Instructions named by the system owner.

-

Page 3: Table Of Contents

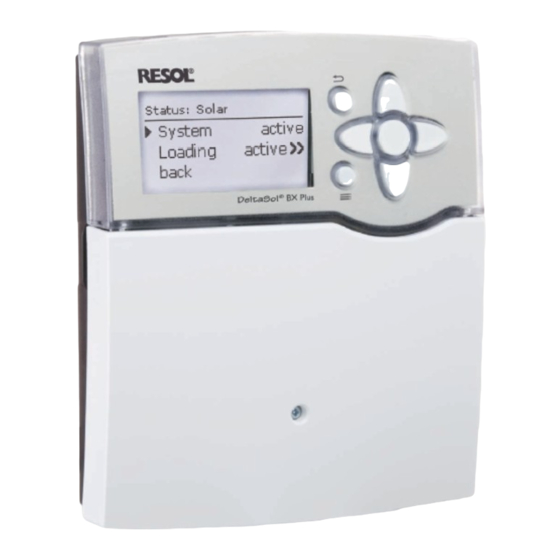

BX Plus DeltaSol ® The DeltaSol BX Plus is a system controller for multi-store solar and heating For an optimum overview, all sensor and relay allocations are listed in the service ® systems. menu. The intuitive commissioning menu leads you through the system configuration by requiring the most important adjustments directly after connecting the controller. -

Page 4: Overview

Overview Technical data Inputs: 8 (9) inputs for Pt1000, Pt500, or KTY temperature sensors, 1 V40 impulse • 8 sensor inputs and 5 relay outputs input, inputs for 2 digital Grundfos Direct Sensors™, 1 input for a CS10 irradiation • Data logging, storing and firmware updates via SD memory card sensor •... -

Page 5: Optional Functions

Optional functions Installation Mounting Solar WARNING! Electric shock! Bypass Upon opening the housing, live parts are exposed! CS-Bypass Î Always disconnect the controller from power supply External heat exchanger before opening the housing! Tube collector Note: Target temperature Strong electromagnetic fields can impair the function of the device. Frost protection Î... -

Page 6: Electrical Connection

Electrical connection WARNING! Electric shock! Upon opening the housing, live parts are exposed! screw Î Always disconnect the controller from power supply before opening the housing! ATTENTION! ESD damage! Electrostatic discharge can lead to damage to electronic components! cover Î Take care to discharge properly before touching the inside of the device! To do so, touch a grounded surface such as a radiator or tap! upper fastening point... -

Page 7: Data Communication / Bus

The mains connection is at the terminals: Different solutions for visualisation and remote parameterisation are availabe on Neutral conductor N the RESOL website www.resol.com. Conductor L On the website, firmware updates are also availabe. Protective earth conductor ⏚ (common terminal block) -

Page 8: Sd Memory Card Slot

SD memory card slot The controller is equipped with an SD card slot. At the end of the commissioning menu, a safety enquiry follows. If the safety en- quiry is confi rmed, the adjustments are saved. With an SD card, the following functions can be carried out: For further information about the commissioning menu see page 14. -

Page 9: Operation And Function

Operation and function Selecting menu points and adjusting values During normal operation of the controller, the display is in the main menu. If no Buttons button is pressed for 1 min, the display illumination goes out. After 3 more minutes, The controller is operated via the 7 buttons next to the display: the controller switches to the Status menu. - Page 10 adjusted value (not yet confi rmed) Adjustment channel If only one item of several can be selected, they will be indicated with "radio but- tons". When one item has been selected, the radio button in front of it is fi lled. minimum value current value saved maximum value...

- Page 11 Adjusting the timer Adding a time frame: The time frames can be adjusted in steps of When the Timer option is activated, a timer is indicated in which time frames for 15 min. the function can be adjusted. In order to add a time frame, proceed as fol- First of all, an overview of the current adjustments is displayed.

- Page 12 Removing a time frame: In order to delete a time frame, proceed as follows: Î Determine the point from which on the time frame is to be removed by pressing button ❸. Î Move the cursor to the desired ending point of the time frame by pressing but- tons ❷...

-

Page 13: Menu Structure

Menu structure The menu items and adjustment values selecta- Main menu ble are variable depending on adjustments al- Status ready made. The figure only shows an exempla- ry excerpt of the complete menu in order to Solar Solar visualise the menu structure. Basic setting Arrangement Basic setting... -

Page 14: Commissioning

Commissioning 1. Language: Î Adjust the desired menu language. When the hydraulic system is fi lled and ready for operation, connect the controller to the mains. The controller runs an initialisation phase in which the directional pad fl ashes red. When the controller is commissioned or when it is reset, it will run a commis- sioning menu after the initialisation phase. - Page 15 Î Adjust the desired energy unit. 4. Daylight savings time adjustment: Î Activate or deactivate the automatic 8. Completing the commissioning menu: daylight savings time adjustment. After the system has been selected, a security enquiry appears. If the safety enquiry is confi rmed, the adjustments are saved.

-

Page 16: Basic Systems And Hydraulic Variants

Basic systems and hydraulic variants The selection of the basic solar system is one of the most important adjustments System and is thus requested already in the commissioning menu. First, the basic system is adjusted by means of the number of stores and collectors fields, then the hydraulic variant. -

Page 17: Overview Of Relay And Sensor Allocation

Overview of relay and sensor allocation System 1 Relay / sensor allocation Optional Optional Optional Optional Relay Solar pump function function function function Sensor Collector 1 Store base Free Free Free Free Free Free Free System 2 variant 1 S1 S6 Relay / sensor allocation Optional Optional... - Page 18 System 2 variant 2 Relay / sensor allocation Optional Optional Relay 2PV coll. 1 2PV coll. 2 Solar pump function function Sensor Collector 1 Store base Free Free Free Collector 2 Free Free Free System 3 variant 1 Relay / sensor allocation Optional Optional Optional...

- Page 19 System 3 variant 2 Relay / sensor allocation Solar pump Solar pump Optional Optional Optional Relay Store 1 Store 2 function function function Sensor Collector Store 1 base Free Store 2 base Free Free Free Free Free System 3 variant 3 Relay / sensor allocation Optional Optional...

- Page 20 System 4 variant 1 S1 S6 Relay / sensor allocation Optional Optional Pump coll. 1 Pump coll. 2 Relay Store 2 function function Collector 1 Store 1 base Free Store 2 base Free Collector 2 Free Free Free Sensor System 4 variant 2 S1 S6 Relay / sensor allocation Optional...

- Page 21 System 4 variant 3 S1 S6 Relay / sensor allocation Solar pump Solar pump Optional 2PV coll. 1 2PV coll. 2 Relay store 1 store 2 function Collector 1 Store 1 base Free Store 2 base Free Collector 2 Free Free Free Sensor...

- Page 22 System 5 variant 1 Relay / sensor allocation Optional Solar pump Relay Store 1 Store 2 Store 3 function Collector 1 Store 1 base Free Store 2 base Store 3 base Free Free Free Free Sensor System 5 variant 2 Relay / sensor allocation Solar pump Solar pump...

- Page 23 System 5 variant 3 Relay / sensor allocation Optional Optional Solar pump Relay Store 1 Store 2 function function Collector 1 Store 1 base Free Store 2 base Store 3 base Free Free Free Free Sensor System 6 variant 1 Relay / sensor allocation Pump coll.

- Page 24 System 6 variant 2 Relay / sensor allocation Solar pump Solar pump Solar pump 2PV coll. 1 2PV coll. 2 Relay store 1 store 2 store 3 Collector 1 Store 1 base Free Store 2 base Store 3 base Collector 2 Free Free Free...

- Page 25 System 6 variant 4 S1 S6 Relay / sensor allocation Optional Pump coll. 1 Pump coll. 2 Relay store 1 store 2 function Collector 1 Store 1 base Free Store 2 base Store 3 base Collector 2 Free Free Free Sensor System 7 variant 1 Relay / sensor allocation...

- Page 26 System 7 variant 2 Relay / sensor allocation Optional Solar pump Relay Store 1 Store 2 Store 3 function Collector 1 Store 1 base Free Store 2 base Store 3 base Store 4 base Free Free Free Sensor System 7 variant 3 Relay / sensor allocation Solar pump Solar pump...

-

Page 27: Main Menu

Main menu Solar In this menu, the different menu areas can be selected. In the Status / Solar menu, the status of the solar system, the solar loading and the The following menus are available: selected optional functions are indicated. •... -

Page 28: Messages

Messages Messages Error code Display Monitoring function Cause 0001 !Sensor fault! Sensor line break Sensor line broken 0002 !Sensor fault! Sensor short circuit Sensor line short-circuited 0011 !∆T too high! DT too high Collector 50 K > than store to be loaded 0021 !Night circulation! Night circulation... -

Page 29: Meas. / Balance Values

Meas. / Balance values In the Status / Meas. / Balance values menu, all current measurement values as The progression chart shows the development of the temperature at the corre- well as a range of balance values are displayed. Some of the menu items can be sponding sensor over the last 24 hours. -

Page 30: Basic Solar Settings

Basic solar settings In this menu, all basic settings for the solar part of the arrangement can be adjusted. In this menu, the hydraulic system, which is the basis for the arrangement, can be adjusted. The setting is divided into systems and variants. Both system and variant have usually been adjusted during commissioning. - Page 31 Store (1 / 2 / 3 / 4) Solar / Basic settings / Store (1 / 2 / 3 / 4) Adjustment Adjustment range / Description Factory setting channel selection ∆Ton Switch-on temperature difference 1.0 … 20.0 K 6.0 K ∆Toff Switch-off temperature difference 0.5 …...

-

Page 32: Solar Optional Functions

Loading logic Solar optional functions In this menu, optional functions can be selected and adjusted for the solar part of Solar / Basic settings / Loading logic the arrangement. Adjustment Adjustment range / Description Factory setting By selecting Add new function, different pre-programmed functions can be se- channel selection lected. - Page 33 The menu item Relay selec. is available in all optional functions. Therefore, it will With the menu item Function, an optional function already selected can be tem- not be explained in the individual function descriptions. porarily deactivated or re-activated respectively. In this case, all adjustments remain stored, the allocated relays remain occupied and cannot be allocated to another With this menu item, a relay can be allocated to the function.

- Page 34 Bypass Depending on whether the bypass is energised by a valve or by a second pump, a The Bypass function can be used for avoiding an energy loss from the store di- corresponding adjustment can be made in the menu item Variant. Depending on rectly after loading has started.

- Page 35 CS bypass External heat exchanger Solar / Opt. functions / Add new function / CS bypass Solar / Opt. functions / Add new function / Ext. HX Adjustment Adjustment range / Adjustment Adjustment range / Description Factory setting Description Factory setting channel selection channel...

- Page 36 The heat exchanger is protected by a non-adjustable antifreeze function. If the runtime is set to more than 10 s, the pump will be run at 100 % for the fi rst 10 s of the runtime. For the remaining runtime, the pump will be run at the When the temperature at the Reference sensor ext.

- Page 37 Antifreeze Afterheating suppression Solar / Opt. functions / Add new function / Antifreeze Solar / Opt. functions / Add new function / AH suppression Adjustment Adjustment range / Adjustment Adjustment range / Description Factory setting Description Factory setting channel selection channel selection Frost on...

- Page 38 Parallel relay Cooling mode In the Cooling mode menu, different cooling functions are available. They can be used for keeping the solar system operational for a longer time during strong solar irradiation. For this purpose, the adjusted maximum store temperatures can be exceeded. The store order for this overloading can be adjusted.

- Page 39 Store cooling option: Solar / Opt. functions / Add new function / Cooling mode When the store cooling function is activated, the controller aims to cool down the Adjustment Adjustment range / Description Factory setting store during the night in order to prepare it for solar loading on the following day. channel selection When the store cooling function is activated, the solar pump is switched on if...

- Page 40 Drainback option In a drainback system, the heat transfer fl uid will fl ow into a holding tank if solar loading does not take place. The drainback option initiates the fi lling process if solar loading is about to start. If the drainback option is activated, the following adjustment can be made: Note: A drainback system requires additional components such as a holding...

- Page 41 Twin pump The Twin pump function controls the equal distribution of pump runtime in sys- tems with 2 equally usable pumps. If the allocated relay has exceeded its adjusted Runtime and the next switch-on process is imminent, the Reference relay is switched on instead. All characteris- tics are adopted.

- Page 42 Heat dump The Heat dump function can be used to direct excess heat generated by strong solar irradiation to an external heat exchanger (e. g. fan coil) in order to keep the collector temperature within the operating range. Whether the heat dump is activated via an additional pump or a valve can be ad- justed in the menu item Variant.

- Page 43 Flow rate monitoring Pressure monitoring Solar / Opt. functions / Add new function / Flow rate mon. Solar / Opt. functions / Add new function / Pressure monitoring Adjustment Adjustment range / Adjustment Adjustment range / Description Factory setting Description Factory setting channel selection...

-

Page 44: Function Control

Overpressure Solar / Function control If the system pressure exceeds the adjustable switch-on value On, an error mes- Adjustment Adjustment range / Description Factory setting sage will appear. channel selection ∆T too high ∆T monitoring option Yes, No If the Shutdown option has been activated for the overpressure monitoring func- tion, the solar system will be shut down as well in the case of a fault condition. -

Page 45: Solar Expert Menu

Solar expert menu The delay time of 1 min ensures that the message is not triggered by short-term fault conditions. Possible causes are: • defective non-return valves • defective valve • wrongly adjusted time Flow and return interchanged Solar / Expert This function is used for detecting an interchange of the fl ow and return pipe or a Adjustment Adjustment range /... -

Page 46: Arrangement

Arrangement The menu item Relay selec. is available in all optional functions. Therefore, it will not be explained in the individual function descriptions. In this menu, all adjustments for the non-solar part of the arrangement can be With this menu item, a relay can be allocated to the function. All free relays are made. - Page 47 Parallel relay With the menu item Function, an optional function already selected can be tem- Arrangement / Opt. functions / Add new function / Parallel relay porarily deactivated or re-activated respectively. In this case, all adjustments remain Adjustment Adjustment range / stored, the allocated relays remain occupied and cannot be allocated to another Description Factory setting...

- Page 48 Mixer Boiler loading Arrangement / Opt. functions / Add new function / Mixer Arrangement / Opt. functions / Add new function / Boiler loading Adjustment Adjustment range / Adjustment Adjustment range / Description Factory setting Description Factory setting channel selection channel selection Relay closed...

- Page 49 Error relay Heat exchange Arrangement / Opt. functions / Add new function / Error relay Arrangement / Opt. functions / Add new function / Heat exchange Adjustment Adjustment range / Adjustment Adjustment range / Description Factory setting Description Factory setting channel selection channel...

- Page 50 When the Set temperature difference is exceeded, pump speed control starts. Arrangement / Opt. functions / Add new function / Solid fuel boiler For every deviation of 2 K, the pump speed will be adjusted by 10 %. Adjustment Adjustment range / Description Factory setting When the Timer option is activated, a timer is indicated in which time frames for...

- Page 51 Circulation The Circulation function can be used for controlling a circulation pump. For the control logic, 5 different variants are available: • Thermal • Timer • Thermal + Timer • Demand • Demand + Timer If one of the variants is selected, the corresponding adjustment channels will appear. Arrangement / Opt.

- Page 52 Demand Return preheating The allocated FS08 fl ow switch is monitored for circuit continuity. If circuit conti- nuity is detected at the fl ow switch, the relay switches on for the adjusted runtime. After the runtime has ended, the relay is switched off. During the adjusted break time, the relay remains switched off even if continuity is detected at the fl ow switch.

- Page 53 ∆T function The switch-on condition for the DT function is considered fulfi lled when the ad- justed switch-on temperature (DT(x) on) is reached. It is considered unfulfi lled when the adjusted switch-off temperature (DT(x)off) is reached. Sen. HSource Relay The DT function is equipped with a speed control function. A set temperature dif- ference and a minimum speed can be adjusted.

- Page 54 ∆ Tha-S3 * Thb-S4 * T-S3>S4 * Timer Reference relay R3 * Function Relay Thermostat a Thermostat b ∆ T - Function Timer Reference relay * exemplary selection, sensors and relays can be allocated freely Reference relay Ref. relay 1 Ref.

- Page 55 Arrangement / Opt. functions / Add new function / Function block Adjustment Description Adjustment range / selection Factory setting channel Relay Relay selection system dependent system dependent Thermostat a Thermostat a Yes, No Th-a on Switch-on temperature Thermostat a -40 … +250 °C +40 °C Th-a off Switch-off temperature Thermostat a...

-

Page 56: Heating

Irradiation switch Heating In this menu, all adjustments for the heating part of the arrangement or for the Arrangement / Opt. functions / Add new function / Irrad. switch heating circuits respectively can be made. Adjustment Description Adjustment range / selection Factory setting Demands can be activated, heating circuits can be parameterised and optional func- channel tions can be selected and adjusted. -

Page 57: Heating Circuits (With Em Extension Modules Only)

10.2 Heating circuits (with EM Extension Modules only) Summer mode The Mode channel adjustment determines how the heating circuit is set to sum- mer mode: The controller is able to control 2 external, weather-compensated heating circuits by means of extension modules. If one or more extension modules are connected, they have to be registered with the controller. - Page 58 Heating curves If the Timer RTH option is activated, time frames can be set for the room ther- mostats. During these time frames, the adjusted room temperature is decreased by the Correction value. To each room thermostat, an additional relay can be allocated. That relay will op- erate when the temperature at the allocated sensor falls below the adjusted room temperature.

- Page 59 Heating / Heating circuits / new HC… Adjustment channel Description Adjustment range / selection Factory setting HC pump Heating circuit pump system dependent system dependent Mixer open Relay selection mixer open system dependent system dependent Mixer closed Relay selection mixer closed system dependent system dependent Flow sensor...

- Page 60 Chimney sweeper function Adjustment channel Description Adjustment range / selection Factory setting The chimney sweeper function can be used for ena- Days of the week Day selection All days, Monday … Sunday, Continue bling a quick access to measurement conditions with- Timer Time frame adjustment 00:00 …...

-

Page 61: Optional Functions

10.3 Optional functions ternal modules are connected and registered, their relays will be displayed in cor- responding sub-menus. In this menu, optional functions can be selected and adjusted for the heating part of the arrangement. When a function has been selected and adjusted, it will appear in the Opt. func- By selecting Add new function, different pre-programmed functions can be se- tions menu above the menu item Add new function. - Page 62 If the menu item Delete function is confi rmed by pressing button ➄, a safety enquiry appears. The setting can be changed between Yes and No by pressing Heating / Opt. functions / Add new function / Th. disinfection buttons ❷ and ❹. If Yes has been selected and confi rmed by pressing button ➄, the function will be deleted and become available under Add new function again.

- Page 63 DHW heating Note: For information on timer adjustment see page 11. Heating / Opt. functions / Add new function / DHW heating Adjustment Adjustment range / Description Factory setting channel selection Demand Demand relay selection system dependent system dependent The DHW heating is used for demanding an afterheating for heating the DHW Loading pump Loading pump option Yes, No store.

-

Page 64: Hqm

When the Alternative unit is activated, the controller will convert the heat quantity into the quantity of fossil fuels (coal, oil or gas) saved, or the CO emission saved respectively. The alternative Unit can be selected. A Conversion factor must be adjusted for the calculation. The conversion factor depends on the ar- rangement in use and has to be determined individually. -

Page 65: Basic Settings

HQM / new HQM… Basic settings Adjustment Adjustment range / Description Factory setting channel selection Flow sen. Flow sensor selection system dependent system dependent Return sen. Return sensor selection system dependent system dependent Flow rate sen. Flow rate sensor option Yes, No Flow rate sen. -

Page 66: Sd Card

The controller will only recognise a fi rmware update fi le if it is stored in a folder named RESOL on the fi rst level of the SD card. Î Create a folder named RESOL on the SD card and extract the downloaded ZIP fi le into this folder. -

Page 67: Manual Mode

Loading controller adjustments All relays are displayed in numerical order, fi rst those of the controller, then those of the individual modules connected. Modules are listed in numerical order. Î To load controller adjustments from an SD card, select the menu item Load adjustments. -

Page 68: User Code

User code 16.1 Modules The access to some adjustment values can be restricted via a user code (customer). In this menu, up to 2 external modules can be registered. 1. Installer 0262 (Factory setting) All modules connected and acknowledged by the controller are available. All menus and adjustment values are shown and all values can be altered. -

Page 69: Inputs

16.2 Inputs In- / Outputs / Inputs Adjustment Description Adjustment range / selection Factory setting channel S1 … S9 Sensor input selection Switch, KTY, Pt500, RTA11M, Type Selecting the sensor type Pt1000 Pt1000, None Switch inversion (only when Type Inverted Yes, No = Switch) In this sub-menu, the type of the sensor connected can be adjusted for each indi-... -

Page 70: Outputs

16.3 Outputs In- / Outputs / Outputs Adjustment Description Adjustment range / selection Factory setting channel R1 … R5 Relay output selection Signal Signal type Adapter, 0-10 V, PWM, Standard Standard Output PWM output selection A, B Profi le PWM characteristic curve Solar, Heating Solar Min. -

Page 71: Vbus

PWM/0-10V IP20 Temp. Sensor Allocate the sensors and relays to the SDFK or SD6 respectively in the corre- sponding sub-menus. The following selections are available: S1 … S9: Sensor inputs S1 … S9 CS10: CS10 irradiation sensor (only if a corresponding sensor is connected) VFD: VFD temperature value (only if a corresponding sensor is connected and registered) -

Page 72: Troubleshooting

Troubleshooting If a malfunction occurs, a message will appear on the display of the controller. WARNING! Electric shock! Upon opening the housing, live parts are exposed! Î Always disconnect the controller from power supply before opening the housing! The controller is protected by a fuse. The fuse holder (which also holds the spare fuse) becomes accessible when the cover is removed. - Page 73 Pump is overheated, but no heat transfer from the collector to the store, flow Pump starts up very late. and return have the same temperature; perhaps also bubbling in the lines. Switch-on temperature difference Air or gas bubbles in the system? Vent the system;...

- Page 74 The solar circuit pump does not work, although the collector is considerably Stores cool down at night. warmer than the store. Collector circuit pump runs during the night? Display illuminated? If not, press button ➄. Display illuminated again? Check controller There is no current;...

- Page 75 Does the DHW circulation run for a very long time? Use the circulation pump with timer and switch-off thermostat Circulation pump and blocking (energy-efficient circulation). valve should be switched off for 1 night; less store losses? Check whether the pumps of the after-heating circuit run at night;...

-

Page 76: Accessories

Accessories Sensors SD3 Smart Display / GA3 Large Display CS10 Solar cell AM1 Alarm module Overvoltage protection KM1 Communication module device VFD and RPD Grundfos Direct Sensors™ DL2 Datalogger VBus / USB & VBus / LAN ® ® interface adapters V40 fl owmeter DL3 Datalogger... -

Page 77: Sensors And Measuring Instruments

18.1 Sensors and measuring instruments The GA3 is a completely mounted large display module for visualisation of collec- Sensors tor- and store temperatures as well as the heat quantity yield of the solar system The product range includes high-precision platinum temperature sensors, flatscrew via one 6-digit and two 4-digit 7-segment displays. -

Page 78: Interface Adapters

18.3 Interface adapters VBus / USB & VBus / LAN interface adapters ® ® The VBus ® / USB interface adapter is the interface between the controller and a personal computer. With its standard mini-USB port it enables a fast transmission of system data for processing, visualising and archiving data via the VBus . -

Page 79: Index

Index Flow rate monitoring ........... 43 Parallel relay, optional arrangement function ..47 Afterheating suppression ..........37 Formatting the SD card ..........67 Parallel relay, solar optional function ......38 Antifreeze, solar optional function ......37 Function block ............... 53 Pressure monitoring ............. - Page 80 This mounting- and operation manual including all parts is copyrighted. Another some examples. They can only be used at your own risk. No liability is assumed for use outside the copyright requires the approval of RESOL – Elektronische Re- incorrect, incomplete or false information and / or the resulting damages.

Need help?

Do you have a question about the DeltaSol BX Plus and is the answer not in the manual?

Questions and answers