Table of Contents

Advertisement

Instruction and parts manual

RG2, RGN2

TFG2

RG4, RG8

RGE2, RGEN2

RGE4

TRG2

Manual Nº:

MA210314-12ENG

Publishing date:

11-12-2017

Table of contents

Definitions ............................................................................... 2

Note .......................................................................................... 2

Quality Standards/Norms and Directives .......................... 2

Safety ....................................................................................... 3

Identification ........................................................................... 4

Assembly ................................................................................. 5

Working with KOOI-REACHFORKS® .................................. 6

Maintenance Schedule......................................................... 6

Wear ......................................................................................... 7

Instructions for Replacement of Sleeve ............................ 8

Replacement of Hydraulic Parts ......................................... 10

Troubleshooting ...................................................................... 12

Replacement parts list RG2, RGN2 ...................................... 14

Replacement parts list TFG2 ................................................ 15

Replacement parts list RG4 .................................................. 16

Replacement parts list RG4 .................................................. 18

Replacement parts list RG8 .................................................. 20

Replacement parts list RG8 (cont'd) ................................... 21

Replacement parts list RGE2, RGEN2 ................................. 22

Replacement parts list RGE4 ................................................ 23

Replacement parts list TRG2 ................................................ 25

Language: ENG

Revision: 12

Advertisement

Table of Contents

Summary of Contents for Meijer KOOI-REACHFORK Series

-

Page 1: Table Of Contents

Instruction and parts manual RG2, RGN2 TFG2 RG4, RG8 RGE2, RGEN2 RGE4 TRG2 Manual Nº: MA210314-12ENG Language: ENG Publishing date: 11-12-2017 Revision: 12 Table of contents Replacement parts list RG8 (cont’d) ........21 Replacement parts list RGE2, RGEN2 ......... 22 Definitions ................ -

Page 2: Definitions

Please note that information in this manual may be changed at any time without prior notice and that it may contain tech- nical inaccuracies and typing errors. Meijer Handling Solutions B.V. makes every effort to avoid errors in this manual, but cannot guarantee this. -

Page 3: Safety

Safety Warning: Caution: Do not ride on the KOOI-REACHFORKS® or on Bear in mind the space above and beneath the the load. KOOI-REACHFORKS®. Warning: Caution: Do no walk or stand under the KOOI-REACH- The load must be distributed as evenly as pos- FORKS®. -

Page 4: Identification

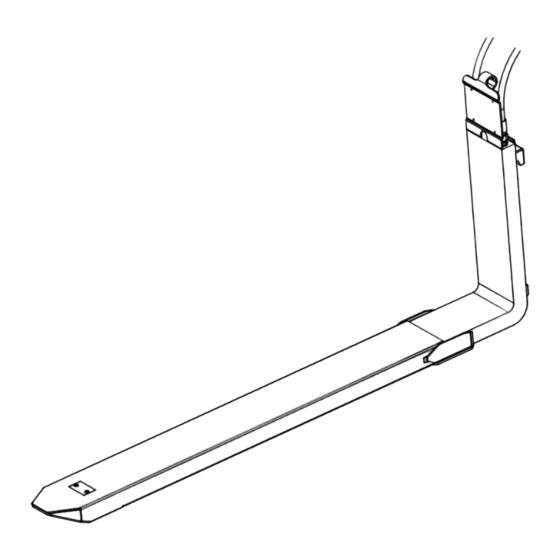

Identification Type plate legend: Mounting type description of KOOI-REACHFORKS®:... -

Page 5: Assembly

Assembly The KOOI-REACHFORKS® type plates are stamped with an ‘L’ and an ‘R’. Mount the KOOI- REACHFORKS® on the left (L) and right (R) as viewed from the forklift operator’s seat. Connect the KOOI-REACHFORKS® to the hydraulic sys- tem. Slide the KOOI-REACHFORKS® onto the carriage plate. RG2 / 7,5-12,5 (L/ RGE2 /... -

Page 6: Working With Kooi-Reachforks

Working with KOOI-REACHFORKS® The KOOI-REACHFORKS®, type RG, feature an integrated synchronising system that enables both forks to extend and retract simultaneously. However, should the KOOI-REACHFORKS® fail to operate simultaneously, slide the KOOI-REACH- FORKS® fully in and, whilst the sleeves are in the retracted position, operate the valve for another ±10 seconds. This gives the hydraulic system a chance to reset both sleeves in their rearmost position. -

Page 7: Wear

Wear The thickness of Wear Strips (1) may not be less than The inner fork must be replaced when S1 is 5% thinner 1.5 mm (1/16”). When Wear Strips (1) have worn to this than S2. See point 7 of the Maintenance Schedule. thickness, replace them or fill with spacers (2) (Art. -

Page 8: Instructions For Replacement Of Sleeve

Instructions for Replacement of Sleeve Position the KOOI-REACHFORKS® at hip height, tilt the mast of the forklift slightly forward and remover the key from the ignition switch of the forklift. Warning: Do not carry out maintenance work on the KOOI-REACHFORKS® whilst there is pressure in the hydraulic system (remove key from forklift ignition switch). - Page 9 Applies only to: KOOI-REACHFORKS® type TRG2; Tap the spring pin(s) (2) into the (new) sleeve (1). Slide the (new) inner sleeve (8) onto the fork. Tighten the screws (6) (on both sides in the stops (7). Lock the screws Caution: (6) with Loctite 270 Ensure that the holes in the sleeve (1) are aligned Tools required: Allen key 4, Loctite 270...

-

Page 10: Replacement Of Hydraulic Parts

Tools required: Cylinder head spanner, 1/2’’ ratchet. a burner. Tools required: Open-ended spanner 24, clamp. *Cylinder head spanners are only available from Meijer Handling Solutions B.V. (Art. Nº RE0058034). Note: When heating the piston with a burner, it must be re- placed due to the damage to the seals caused by heating. - Page 11 Slide the (new) cylinder head (5) onto the piston rod (10). When piston (9) is removed, the cylinder head (5) can be removed, should it need to be replaced. Caution: Do not damage the cylinder head seals (5) during assembly as this can result in leakage. Pay par- ticular attention when the sliding cylinder head (5) over the thread (10) of the piston rod.

-

Page 12: Troubleshooting

Replacement of Sleeve’. Cylinder diameter (mm) Torque (Nm) Finally, follow step 5 of the chapter on ‘Assem- bly’. *Cylinder head spanners are only available from Meijer Handling Solutions B.V. (Art. Nº RE0058034). See www.loctite.com See www.kroon-oil.com Caution: Do not damage the piston or cylinder head seals during assembly as this can result in leakage. - Page 13 The left sleeve reaches its Connect the KOOI-REACH- end position first. When the KOOI-REACHFORKS® have FORKS® as indicated in the left sleeve is at its end posi- been connected the wrong instructions in the chapter tion, the right one reaches way round on ‘Assembly’...

-

Page 14: Replacement Parts List Rg2, Rgn2

Replacement parts list RG2, RGN2 Pos. Nº Description Article Nº Number of parts per set and type of forks RG2-20 RG2-30 RGN2-30 RGN2-35 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008009 Piston30 (for piston rod18) Piston35 (for piston rod18) RE2008011 Inner fork Wear strip PA6... -

Page 15: Replacement Parts List Tfg2

Replacement parts list TFG2 Pos. Nº Description Article Nº Number of parts per set and type of forks TFG2-20 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008011 Piston35 (for piston rod20) Piston40 (for piston rod20) RE2008014 Inner fork Wear strip PA6 RE0020000 Piston rod 20... -

Page 16: Replacement Parts List Rg4

Replacement parts list RG4 Pos. Nº Description Article Nº Number of parts per set and type of forks RG4-25 RG4-35 RG4-45 RG4-58 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008009 Piston30 (for piston rod18) Piston30 (for piston rod18) RE2008010 RE2008011 Piston35 (for piston rod18) - Page 17 Parts from left fork Parts from right fork. Article Nº depending on specific model. Please provide serial number when ordering.

-

Page 18: Replacement Parts List Rg4

Replacement parts list RG4 Pos. Nº Description Article Nº Number of parts per set and type of forks RG4-77 RG4-105 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008011 Piston35 (for piston rod20) Piston35 (for piston rod20) RE2008012 RE2008014 Piston40 (for piston rod20) RE2008015 Piston40 (for piston rod20) - Page 19 Parts from right fork. Article Nº depending on specific model. Please provide serial number when ordering.

-

Page 20: Replacement Parts List Rg8

Replacement parts list RG8 Pos. Nº Description Article Nº Number of parts per set and type of forks RG8-90 RG8-116 RG8-154 RG8-210 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008009 Piston30 (for piston rod18) Piston30 (for piston rod18) RE2008010 RE2008011 Piston35 (for piston rod18) -

Page 21: Replacement Parts List Rg8 (Cont'd)

Replacement parts list RG8 (cont’d) Spring pin 55 mm RE0033015 Spring pin 65 mm RE0033014 Spring pin 75 mm RE0033023 Type plate Engraved type information and serial number Available separately from KOOI-REACHFORKS® supplier, is not supplied a standard with KOOI-REACHFORKS®. Parts from left fork Parts from right fork. -

Page 22: Replacement Parts List Rge2, Rgen2

Replacement parts list RGE2, RGEN2 Pos. Nº Description Article Nº Number of parts per set and type of forks RGE2-20 RGE2-30 RGEN2-30 RGEN2-35 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008009 Piston30 (for piston rod18) Piston35 (for piston rod18) RE2008011 Inner fork Wear strip PA6... -

Page 23: Replacement Parts List Rge4

Replacement parts list RGE4 Pos. Nº Description Article Nº Number of parts per set and type of forks RGE4-25 RGE4-35 RGE4-45 RGE4-58 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008009 Piston30 (for piston rod18) Piston30 (for piston rod18) RE2008010 RE2008011 Piston35 (for piston rod18) - Page 24 Parts from left fork Parts from right fork. Article Nº depending on specific model. Please provide serial number when ordering.

-

Page 25: Replacement Parts List Trg2

Replacement parts list TRG2 Pos. Nº Description Article Nº Number of parts per set and type of forks TRG2-30 Cylinder head spanner RE0058034 Straight male coupling 12L RE2017001 RE2008042 Piston30 (for piston rod18) Piston35 (for piston rod18) RE2008043 Inner fork Inner sleeve Piston rod 18 Cylinder Head30 (for piston rod18) - Page 26 Production and safety standards Meijer Handling Solutions B.V. requires its products to be of the highest quality and we can only guarantee this by complying with all applicable international standards and regulations such as: ISO 9001 Quality management systems - Requirements.

Need help?

Do you have a question about the KOOI-REACHFORK Series and is the answer not in the manual?

Questions and answers