Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

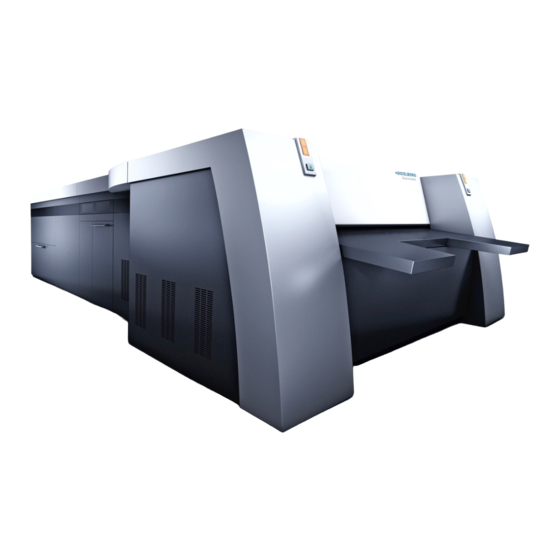

Summary of Contents for HEIDELBERG Suprasetter 145

- Page 1 Suprasetter 145/162/190 User’s Guide 02/2019 Order No. PG.999.0005...

- Page 2 ............. . . Heidelberg and the Heidelberg logo...

-

Page 3: Table Of Contents

Standards/Sources ....... . . 18 Disposal of the Suprasetter 145/162/190 ....18 Converting the Suprasetter 145/162/190 . - Page 4 Heidelberg online ........21...

- Page 5 Semi-automatic Device ....... . 61 Suprasetter 145/162/190 – User’s Guide...

- Page 6 CE-Declaration of Conformity ......82 Labels on the Suprasetter 145/162/190 ....83 Disposal Disposal .

- Page 7 Dismantling ........135 Suprasetter 145/162/190 – User’s Guide...

-

Page 9: Safety Notes

All other use that does not comply with the correct use is prohibited. Avoid Misuse Do not place any objects or liquids on the Suprasetter. Ventilation outlets must be kept clear at all times. Do not use the Suprasetter as a seat. Suprasetter 145/162/190 – User’s Guide... -

Page 10: Qualification Of The Users

Qualification of the Users After installation, users will be instructed in the operation and service and maintenance of the Suprasetter by Heidelberg service personnel. Further instruction, for example, for new staff employed subsequently, must be ensured by the operator of the Suprasetter. -

Page 11: Power Switch With Emergency Cutoff Function

Power Switch with Emergency Cutoff Function The Suprasetter is fully cut off from the power supply by the power switch (red rotary switch). Suprasetter 145/162/190 – User’s Guide... -

Page 12: Emergency Stop Switch

Before you start ... The power switch (red rotary switch) separates the Suprasetter's four poles from the power supply. In an emergency, this power switch is used as an emer- gency stop switch for the Suprasetter. Emergency Stop Switch All mechanical motions in the device are stopped and the invisible laser beam is switched off when the emergency stop switches (fully automated device: 8 units, semi-automated device: 4 units) are used. -

Page 13: Service And Maintenance

Servicing may only be carried out by Heidelberg personnel who have been trained by appropriate laser protection officers for this purpose. Service and Maintenance Servicing may be done solely by persons who are authorized by Heidelberg to do so. The relevant accident prevention regulations must be observed at all times. -

Page 14: Safety Loop

Before you start ... Safety Loop For your safety, the Suprasetter is equipped with a safety loop. If the safety loop is interrupted, e.g. by removing the insertion table, all mechanical motions are stopped and the invisible laser beam is switched off in the expo- sure head. -

Page 15: Manual Check Of The Safety Loop

Caution: During the test no imaging jobs may be processed! In other words, no plates must be in the device and no jobs are waiting for pro- cessing. You must stop processing beforehand. Suprasetter 145/162/190 – User’s Guide... -

Page 16: Esd Protective Measures For Prepress Systems And Operators

Before you start ... Timeframe This displays the interval until the next regular safety loop test. ESD Protective Measures for Prepress Systems and Operators Basics Devices from Heidelberger Druckmaschinen AG are resistant to electrostatic discharges (within the limits of EN 55024:2001). In order to protect devices and users from being unnecessarily exposed to such discharges, we have listed a few tips below that will help reduce the frequency and intensity of the discharges. -

Page 17: Practical Tips

For example, a relative humidity of 10 - 20% will produce 35,000 V when crossing a carpet. This value drops to 1,500 V with a relative air humidity of 65 - 90%. Suprasetter 145/162/190 – User’s Guide... -

Page 18: Standards/Sources

• Electrostatic Society of America http//www.electrostatics.org Disposal of the Suprasetter 145/162/190 The disposal of the Suprasetter 145/162/190 is described in chapter Disposal. Converting the Suprasetter 145/162/190 Any conversion work on the Suprasetter 145/162/190 may be performed only by Heidelberg service personnel. -

Page 19: About This Documentation

The user, having attended a training course, should be familiar with the Supra- setter. Further Documentation You can find more information in the following documentation: • Prinect MetaDimension - User's Guide/Workflow • Prinect Integration Manager - User's Guide/Workflow Suprasetter 145/162/190 – User’s Guide... -

Page 20: Symbols And Styles

Symbols and Styles The following typographical conventions are used in this manual: • References to other chapters and sections are blue (on the screen) and underlined. Example: See section "Symbols and Styles", page • Quotes are used to indicate menus, folders, functions, hardware condi- tions, switch settings, system messages, etc. -

Page 21: Important Information

Prerequisite: Lists requirements which must be fulfilled before the steps which follow can be performed. Heidelberg online Do you have questions concerning our products? Do you want to improve your workflows? Then visit us on the Internet. You can find us at: http://www.heidelberg.com/ Suprasetter 145/162/190 – User’s Guide... -

Page 23: Introduction

• As a fully automated device, with the plates ejected at the front of the device to an ejection table that conveys them straight ahead, to the right or to the left. Suprasetter 145/162/190 – User’s Guide... -

Page 24: Status Leds

Introduction Status LEDs Load buttons On/Off button Power switch Insertion table Operating elements on the manual device and on the semi-automatic device Recorder Separator Waste box Drawer for plate trays Cassette magazine Additional functional groups and operating units on the fully automated device Status LEDs The following actions of the Suprasetter are indicated by the status LEDs: Version 2019... - Page 25 The LEDs on each level flash, alternating between left and right. A beep also indicates the error status. The user must go to the GUI of the Supraset- ter to learn more details about the error. Suprasetter 145/162/190 – User’s Guide...

-

Page 26: Power Switch

Introduction Waiting: The Suprasetter is waiting for something within it (e.g. until the operating temperature is reached) or is waiting for a connected device (online processor or the cassette loader). The top LEDs flash alternately. A brief beep is also heard if an operator intervention is required. -

Page 27: On/Off Button

Note: Local regulations on keeping access routes clear must also be complied with. Suprasetter 145/162/190 – User’s Guide... -

Page 28: Notes On The Use Of Plates

Notes on the Use of Plates Note: Only printing plates and slip sheets approved by Heidelberg may be used in the Suprasetter as only these produce the specified results. The use of unapproved plates and slip sheets can result in malfunc- tions. -

Page 29: Notes On Installation

Notes on Installation Transport of the Suprasetter 145/162/190 The Suprasetter 145/162/190 is to be transported solely by companies that are authorized by Heidelberg to do so. Transport may be done only by qualified persons. The appropriate transport regulations must be observed during trans- port.. -

Page 30: Software Installation (Container Version)

Notes on Installation Software Installation (Container Version) Prerequisite: · The Suprasetter is switched off. · The workstation is switched on and ready for operation. · All Windows applications were run down. · A backup of the recorder configuration is saved, see the section "Saving a Backup of the Recorder Configuration"... -

Page 31: Saving A Backup Of The Recorder Configuration

Click the "Change to Device" button. Select "Options" in the vertical menu bar. 3. Select the "Miscellaneous" tab. 4. Select the language you want in "Language". Click "Apply". The user interface switches over to the selected language. Suprasetter 145/162/190 – User’s Guide... -

Page 33: Operation

Note: If you need the workstation (PC) without the recorder (e.g. for a job transfer), it is advisable to restart the PC before starting the recorder. The recorder must be in an off-state when you restart the workstation (PC). Suprasetter 145/162/190 – User’s Guide... -

Page 34: Switching On The Device

Operation Note: The workstation (PC) must remain powered on in the time switch mode of the recorder. It is advisable to restart the PC before the time switch mode. The recorder must be in an off-state when you restart the workstation (PC). -

Page 35: Automatic Startup

The startup time is set at the work- station. Prerequisite: · The power switch of the Suprasetter is set to 'I'. · The Suprasetter GUI is running. Suprasetter 145/162/190 – User’s Guide... -

Page 36: Switching Off The Device

Operation Operation: Click the "Device" button in the Suprasetter GUI. Click "Configuration" in the vertical menu bar. 3. Select the "Timer" tab. 4. Select "Switch on Timer". Set the startup cycle you want in "Schedule" in the "Settings" box. 6. Set the switch-on time you want in "Start Time" in the "Settings" box. Note: If you selected "Once"... -

Page 37: Shutdown Using The User Interface On The Workstation

Note: You must repeat the shutdown procedure from the start if the beep sounds for a second time before you have done step 3. 4. Set the power switch to '0' on the Suprasetter for cleaning and servicing. Switch off the workstation (PC). Suprasetter 145/162/190 – User’s Guide... -

Page 38: Quick Shutdown With The On/Off Button On The Suprasetter

Operation On/Off button Power switch Fig. 2 Switch off power switch Note: The workstation (PC) must remain powered on in the time switch mode of the Suprasetter. The power switch must be at 'I' if the Suprasetter is to be started auto- matically, e.g. - Page 39 6. Press the On/Off button a second time. The Suprasetter interrupts error correction and shuts down. Note: In this case as well, you must repeat shutdown if the beep sounds for a second time before you have done step 3 or 6. Suprasetter 145/162/190 – User’s Guide...

-

Page 40: Material Handling

Operation Material Handling Observe the following when handling printing plates: • Plate edges can be sharp. Put on protective gloves. This will protect you from injury. • Never touch the emulsion side of the printing plate with your bare hands. Finger prints will appear on the printing plate which can adversely affect the print quality. - Page 41 Operation Lower part is flashing Load buttons are lit Fig. 3 Load buttons are lit and lower part of the status LEDs is flashing Suprasetter 145/162/190 – User’s Guide...

-

Page 42: Operation

Operation Operation Warning: Sharp plate edges. Plate edges can be sharp. You can injure your hands if you do not wear protective gloves. Caution: Never handle printing plates on your own. Two persons are always required to transport printing plates so that they do not buckle or bend during loading and unloading. - Page 43 Press one of the two load buttons. The plate is loaded to the device. This is accompanied by a brief beep. Note: If you do not press the load button, the plate is drawn into the device automatically after the period that is set in parameter 40115. Suprasetter 145/162/190 – User’s Guide...

- Page 44 Operation Load buttons Fig. 5 Press load buttons Note: The device checks the length of the plate after it is inserted. The plate is immediately transported back to the insertion table if the wrong length was detected. Three beeps are heard and the load buttons flash. You must remove the plate from the device and repeat loading using a plate with the correct length.

-

Page 45: Unloading The Plates On A Manual Device

Caution: Never handle printing plates on your own. Two persons are always required to transport printing plates so that they do not buckle or bend during loading and unloading. Put on protective gloves. Remove the printing plate from the device for further processing. Suprasetter 145/162/190 – User’s Guide... -

Page 46: Loading Plates On A Fully Automated Device

Operation Fig. 6 Removing a Printing Plate Loading Plates on a Fully Automated Device You can load a maximum of six different plate sizes on the fully automated device. To do this, remove the plates from the packaging and place them with the slip sheets into the trays of the fully automated device. - Page 47 You will find the tray into which you have to load the plates in the drawer. Fig. 7 Drawer pulled out 3. Set the four magnets down away from the tray. 4. Put on protective gloves. Suprasetter 145/162/190 – User’s Guide...

- Page 48 Operation Remove the plates from the packaging and place them into the tray. Make sure that there is always a slip sheet between two plates. A tray can hold a maximum of 100 plates. 6. Position the plates along the stop edge and center them lengthwise. The markings on the tray surface will help you find the center position.

-

Page 49: Empty Waste Box

Make sure that there are no objects in the area that is marked off by black-and-yellow tape on the floor, see Fig. 10: Open cover. Then pull out the waste box until it is fully out of the device. Suprasetter 145/162/190 – User’s Guide... - Page 50 Operation Fig. 9 Pull out waste box 3. Open the cover of the waste box. Version 2019...

- Page 51 Operation Fig. 10: Open cover 4. Remove the slip sheets from the waste box and dispose of them. Suprasetter 145/162/190 – User’s Guide...

- Page 52 Operation Fig. 11 Remove slip sheets Close the cover of the waste box. 6. Push the waste box back into the device until you can hear it lock in place. Version 2019...

-

Page 53: Troubleshooting

Caution: Do not run an error correction during imaging. The Autoloader turns red in the 3D display if an error occurs in the Autoloader. If imag- ing is also running parallel to that, you can run an error correction only Suprasetter 145/162/190 – User’s Guide... -

Page 54: Fixing Jamming

Operation after imaging is finished and the recorder has switched to an error state. If you run the error correction without waiting, imaging will be aborted, and you may have to restart the system because of the undefined states that result from such an action. Fixing Jamming Material can jam when a slip sheet is being transported from the cassette to the waste box. - Page 55 Close the service covers on both sides of the device. 6. Click the "Correct error" button. This action returns the Suprasetter to its initial status and the function which was interrupted by the error can be repeated. Suprasetter 145/162/190 – User’s Guide...

-

Page 56: Switching On An Automatic Cutout

Operation Switching on an Automatic Cutout You must switch on an automatic cutout again after you eliminated the mal- function that triggered this cutout. Proceed as follows: Remove the right-hand side panel. Side panel Fig. 13 Remove side panel Switch on the automatic cutout that was triggered. Version 2019... - Page 57 Automatic Cutouts Fig. 14 Automatic Cutouts 3. Please inform your maintenance service if you cannot switch on an auto- matic cutout again so that this malfunction can be remedied. 4. Put the side panel back on. Suprasetter 145/162/190 – User’s Guide...

- Page 58 Operation Side panel Fig. 15 Insert side panel Version 2019...

-

Page 59: Service And Maintenance

This maintenance work is not part of war- ranty. Messages in the Suprasetter user interface will draw your attention to such servicing. Please contact your local service technicians. Suprasetter 145/162/190 – User’s Guide... -

Page 60: Qualification Of The Users

Qualification of the Users After installation, users will be instructed in the operation and service and maintenance of the Suprasetter by Heidelberg service personnel. Further instruction, for example, for new staff employed subsequently, must be ensured by the operator of the Suprasetter. -

Page 61: Cleaning The Cleaning Roller On A Manual Device And On A Semi-Automatic Device

Note: The "Cleaning Roller" button is enabled only if no imaging is run- ning, i.e. the imaging drum must not be moving. The recorder is set to an error state after you click the "Cleaning Roller" button. Open the cover on the front of the device. Suprasetter 145/162/190 – User’s Guide... - Page 62 Service and Maintenance Fig. 1: Open cover 3. Clean the cleaning roller using a sponge or sponge cloth moistened with water. Turn the cleaning roller while cleaning in order to clean the whole surface. Caution: Scratches. Do not use any abrasive or scratching cleaning agents or equipment.

-

Page 63: Cleaning The Cleaning Roller On A Fully Automated Device With A Cross Conveyor Or Olp Table

Note: The "Cleaning Roller" button is enabled only if no imaging is run- ning, i.e. the imaging drum must not be moving. The recorder is set to an error state after you click the "Cleaning Roller" button. Unlock the wheels of the cross conveyor. Suprasetter 145/162/190 – User’s Guide... - Page 64 Service and Maintenance 3. Push the cross conveyor approx. 70 cm away from the recorder to be able to reach the cleaning roller. Note: If you use an OLP table instead of a cross conveyor, you must first manually swing up the protective cover on the insertion/ejection table in order to swing up the OLP table.

-

Page 65: Removing Punch Waste On A Manual Device And On A Semi-Automatic Device

Semi-automatic Device If your Suprasetter has an optional punch, a message will request you at cer- tain intervals to remove the punch waste. In such a case, proceed as follows: Maintenance interval: 2000 punches Suprasetter 145/162/190 – User’s Guide... - Page 66 Service and Maintenance In the Suprasetter user interface, click the "Punch Waste" button in "Administration > Maintenance > Maintenance Work". The cover on the front of the device is unlocked. Note: The "Punch Waste" button is enabled only if no imaging is run- ning, i.e.

- Page 67 Click "Apply" and confirm the query with "Yes". The maintenance interval for removing the punch waste starts from the beginning. 8. Run a troubleshooting routine to eliminate the error state of the recorder, see the section "Troubleshooting", page Suprasetter 145/162/190 – User’s Guide...

-

Page 68: Removing Punch Waste On A Fully Automated Device With A Cross Conveyor Or Olp Table

Service and Maintenance Removing Punch Waste on a Fully Automated Device with a Cross Conveyor or OLP Table If your Suprasetter has an optional punch, a message will request you at cer- tain intervals to remove the punch waste. In such a case, proceed as follows: Maintenance interval: 2000 punches In the Suprasetter user interface, click the "Punch Waste"... - Page 69 Service and Maintenance Fig. 6: Open cover Remove the punch waste containers from the device and empty them. Fig. 7: Punch waste containers Suprasetter 145/162/190 – User’s Guide...

- Page 70 Service and Maintenance Caution: Disposal of punch waste. Punch waste may not be disposed of as household waste. Dispose of the punch waste together with any printing plates you no longer need at your local waste disposal com- pany. 6. Place the punch waste containers back on the guides. Push them to the back as far as they can go so that the punch waste is sure to fall into the container.

-

Page 71: Changing The Filter Kit In The Suction Device

We strongly recommend that you also proceed as described above if you use plates that are not recommended by Heidelberg. It is essential to take note of the information supplied by the plate manufacturers. You are advised to request this information if you do not have it. - Page 72 Service and Maintenance Inform the Heidelberg Service if during filter changing you notice that one of the filter kits is heavily soiled or both filter kits are still clean. The maintenance interval can then be changed accordingly. Remove the right-hand side panel.

- Page 73 Loosen the six rocker arm locks and move the casing cover to the side. Rocker arm locks Fig. 9: Loosen rocker arm locks 3. Remove the high-efficiency submicron particulate air filter from the filter casing and place it in a plastic bag. Suprasetter 145/162/190 – User’s Guide...

- Page 74 Service and Maintenance Wing nuts Preliminary filter High efficiency submicron particulate air filter Fig. 10: Exhaust Filter 4. Unscrew the four wing nuts from the cover and remove the washers as well. Remove the cover above the preliminary filter. 6. Place the preliminary filter in the plastic bag as well. Clean the filter casing with a vacuum cleaner.

- Page 75 18. Click "Apply" and confirm the query with "Yes". The maintenance interval for replacing the air filter starts from the beginning. 19. Run a troubleshooting routine to eliminate the error state of the recorder, see the section "Troubleshooting", page Suprasetter 145/162/190 – User’s Guide...

-

Page 77: Technical Data

Heat Radiation 36000 KJ/h, ≤34000 BTU/h Compressed air connection max. 8 bar / 120 PSI Ambient conditions (operation) Temperature +20°C to +27°C Air pressure 700 mbar to 1060 mbar Rel. humidity 40% to 70% non-con- densing Suprasetter 145/162/190 – User’s Guide... -

Page 78: Protection And Safety Requirements

Temperature -10°C to +50°C Air pressure 250 mbar to 1060 mbar Noise emission < 70 dB (A), workplace-related value Plate sizes Suprasetter 145 Min. 500 mm x 650 mm Max. 1425 mm x 1460 mm Suprasetter 162 Min. 500 mm x 650 mm Max. -

Page 79: General

Please refer to the label overview at the end of this chapter for laser labels and their positions. DGUV regulation 11 Germany EN 60825-1 Europe IEC 60825-1 Europe 21 CFR 1040 Mechanical Safety EN ISO 12100 Europe EN 1010-1/2 Europe IEC 68-2-6 International IEC 68-2-7 International Suprasetter 145/162/190 – User’s Guide... -

Page 80: Electrical Safety

Technical Data Electrical safety EN ISO 13849-1 (International) EN 60204-1 Europe IEC 60204-1 International EN 60950-1 Europe IEC 60950-1 International UL 60950-1 CSA C22.2 No. 60950-1 Canada Electromagnetic compatibility (EMC) Law regarding electromagnetic compatibility of Germany technical equipment (EMVG) Interference Emission (Stray Radiation and Interfer- ence Voltage) EN 61000-6-4: 2007 + A1:2011 Europe... -

Page 81: Interference Immunity

European Union mark of conformity (CE) and the instructions for installation, operation and service are followed. Approvals and Conformity Germany CE: Declaration of Conformity Europe CDRH: Accession-No. (submitted) cETLus USA / Canada GOST-R Russia Suprasetter 145/162/190 – User’s Guide... -

Page 82: Ce-Declaration Of Conformity

Technical Data ACN 004 395 779 Australia CE-Declaration of Conformity The circumstances listed below are valid solely within the member states of the European Union (EU): • You received a copy of the CE Declaration of Conformity together with your accounting documents. •... -

Page 83: Labels On The Suprasetter 145/162/190

Technical Data Labels on the Suprasetter 145/162/190 Type label, recorder Type label, separator Suprasetter 145/162/190 – User’s Guide... - Page 84 Technical Data Type label, cassette lift Type label, cassette magazine Version 2019...

- Page 85 Technical Data I/O table type label CE conformity label Suprasetter 145/162/190 – User’s Guide...

- Page 86 Technical Data LASER PRODUCT CLASS 1 IEC 60825-1:2007 Laser Product Class 1 Caution! Class 4 laser radiation Version 2019...

- Page 87 Technical Data Installation instructions Note on conformance Beware of moving parts Suprasetter 145/162/190 – User’s Guide...

- Page 88 Technical Data Flash, electrical hazard warning Data cable connection warning Version 2019...

- Page 89 Technical Data High leakage current Air Inlet Air Outlet Suprasetter 145/162/190 – User’s Guide...

- Page 90 Technical Data AC outlet Warning/information labels on suction unit Version 2019...

- Page 91 Technical Data Recorder with plate loader Type label, recorder Laser Product Class 1 Note on conformance Type label, recorder CE conformity label Suprasetter 145/162/190 – User’s Guide...

- Page 92 Technical Data Recorder power connection and fuses Flash, electrical hazard warning Version 2019...

- Page 93 Technical Data Recorder power supply box, outside Air Inlet High leakage current Installation instructions Flash, electrical hazard warning Suprasetter 145/162/190 – User’s Guide...

- Page 94 Technical Data Recorder, compressed air outlet, connector socket for cross table Outlet, compressed air connector for separator Version 2019...

- Page 95 Technical Data Recorder, right side Beware of moving parts Caution! Class 4 laser radiation Warning/information labels on suction unit Suprasetter 145/162/190 – User’s Guide...

- Page 96 Technical Data Recorder, left side Beware of moving parts Caution! Class 4 laser radiation Flash, electrical hazard warning Version 2019...

- Page 97 Technical Data Recorder, cross beam in front of exposure drum Beware of moving parts Caution! Class 4 laser radiation Suprasetter 145/162/190 – User’s Guide...

- Page 98 Technical Data Recorder, lifting table of plate loader Beware of moving parts (on both sides of the upper side rail) Version 2019...

- Page 99 Technical Data Recorder, electronics unit Data cable connection warning Flash, electrical hazard warning Suprasetter 145/162/190 – User’s Guide...

- Page 100 Technical Data Separator electronics unit 1:Type label, separator Flash, electrical hazard warning Data cable connection warning Version 2019...

- Page 101 Technical Data Separator Beware of moving parts Suprasetter 145/162/190 – User’s Guide...

- Page 102 Technical Data Tray loader Flash, electrical hazard warning Beware of moving parts Type label, cassette lift Data cable connection warning Version 2019...

- Page 103 Technical Data Magazine Type label, cassette magazine Suprasetter 145/162/190 – User’s Guide...

-

Page 105: Disposal

The details of this disposal description are made to the best of our knowledge. They do not release persons disposing of the unit from their obligation to observe the regulations and legal provisions applicable at the time of disposal. Suprasetter 145/162/190 – User’s Guide... -

Page 106: Disposal Of The Recorder

Disposal Disposal of the Recorder Recorder disposal Size of the device (width, depth, height): 3400 mm x 1836 mm x 1560 mm Weight of the device: 1600 kg Harmful Substances The table below lists the parts that contain harmful substances and, therefore, must be disposed of or recycled separately. - Page 107 Disposal of Glysantin BASF's safety data sheet "Glysantin G48-00" that is valid at the time you dis- pose of the product must always be followed. BASF Aktiengesellschaft, 67056 Ludwigshafen, Germany, ph. +49-621-60-43333 E-mail: Productinformation.Performance-Chemicals@basf-ag.de Suprasetter 145/162/190 – User’s Guide...

-

Page 108: Recyclable Materials

Disposal Recyclable Materials The following table lists the main parts that do not contain harmful substances and that can undergo environmentally safe recycling. The positions of such parts in the device can be found in the graphics below. Pos. Description Material Weight Image No. -

Page 109: Dismantling

Image 8 Dismantle the sheet-metal cover- Hinged or screwed ings Image 9 Remove table or conveyor Screwed from below (1.2) (option) Remove cables and hoses Remove electronic components Dispose of professionally as elec- tronic waste Suprasetter 145/162/190 – User’s Guide... -

Page 110: Version

Disposal Pos. Description Material Image 6 Remove filters Remove the filter mats (option) only when wearing gloves and dust mask and dispose of them as commercial waste. Dismantle sheet-metal compo- Screwed nents Image 8 Dismantle base plates Screwed Image 8 Dismantle the frame Screwed Drain remaining coolant at lowest... - Page 111 Disposal Fig. 2: Recorder disposal 1, 3: Various PCBs and power supply modules 2: Distributor PCB Suprasetter 145/162/190 – User’s Guide...

- Page 112 Disposal Fig. 3: Recorder disposal 1: PCBs in punches 2: Distributor PCB Version 2019...

- Page 113 Disposal Fig. 4: Recorder disposal 1, 3, 4: Interface PCBs 2: Laser module Suprasetter 145/162/190 – User’s Guide...

- Page 114 Disposal Fig. 5: Recorder disposal 1: Light barrier pcb Version 2019...

- Page 115 Disposal Fig. 6: Recorder disposal 1: Filters in suction device Suprasetter 145/162/190 – User’s Guide...

- Page 116 Disposal Fig. 7: Disposal of the recorder 6 1: Pilot lamps Version 2019...

- Page 117 Disposal Fig. 8: Recorder disposal 1: Cover plates 2:Base frame 3:Base plates Suprasetter 145/162/190 – User’s Guide...

- Page 118 Disposal Fig. 9: Recorder disposal 1, 2: Table top Version 2019...

- Page 119 Disposal Fig. 10: Recorder disposal 1: Punch bar 2: VCT bar 3: Side panels (2 off) 4: Imaging drum 5: Machine base 6: Imaging rails Suprasetter 145/162/190 – User’s Guide...

-

Page 120: Disposal Of The Loader/Unloader

Disposal Disposal of the Loader/Unloader Fig. 11: Disposal of loader/unloader Disposal of loader/unloader Size of the device (width, depth, height): 3400 mm x 1255 mm x 1560 mm Weight of the device: 800 kg Harmful Substances The table below lists the parts that contain harmful substances and, therefore, must be disposed of or recycled separately. -

Page 121: Recyclable Materials

The following table lists the main parts that do not contain harmful substances and that can undergo environmentally safe recycling. The positions of such parts in the device can be found in the graphic below. Suprasetter 145/162/190 – User’s Guide... - Page 122 Disposal Pos. Description Material Weight Image No. approx. (Pos.) (kg) Cover plates Aluminum plate, 12 (4) EN AW AlMg3, pow- der-coated Base plates Sheet steel, galva- 12 (6) nized Base frame Aluminum, AlMg- 12 (7) SiO, 5F25 Tables Aluminum plate, 12 (5) EN AW-AlMg3, pro- file, AlMgSiO, 5F25...

-

Page 123: Dismantling

Dismantle the chiller and dispose Screwed of it professionally (see disposal instructions below for the Termo- tek chiller) Dismantle sheet-metal compo- Screwed nents Dismantle tables Screwed Dismantle base plates Screwed Dismantle the frame Screwed Dismantling Suprasetter 145/162/190 – User’s Guide... - Page 124 Disposal Fig. 12: Disposal of loader/unloader 1, 2: Various PCBs 3: Electronic components and coolants in the chiller 4: Cover plates 5: Tables 6: Base plates 7: Base frame 8: Beams (aluminum) Disposal instructions for the Termotek chiller (printed with the permission of Termotek AG) The chiller comprises several components that must be disposed of separately.

- Page 125 • Dirty cooling water or cooling water with additives must not enter the sewerage system or waters. Cooling water is classified as hazardous waste and may only be disposed of at an authorized company or recy- cling center. Suprasetter 145/162/190 – User’s Guide...

-

Page 126: Disposal Of The Separator

Disposal Disposal of the Separator Image: Disposal of separator Size of the device (width, depth, height): 2870 mm x 1165 mm x 1560 mm Weight of the device: 520 kg Harmful Substances The table below lists the parts that contain harmful substances and, therefore, must be disposed of or recycled separately. -

Page 127: Recyclable Materials

Aluminum plate, 14 (1) EN AW AlMg3, pow- der-coated Base plates Sheet steel, galva- 14 (3) nized Base frame Aluminum, AlMg- 14 (2) SiO, 5F25 Drawer Aluminum plate, 14 (5) EN AW-AlMg3, pro- file, AlMgSiO, 5F25 Suprasetter 145/162/190 – User’s Guide... -

Page 128: Dismantling

Disposal Pos. Description Material Weight Image No. approx. (Pos.) (kg) Various parts: Steel, aluminum, mounting parts, plastic, cast alumi- motors, pumps, num, copper cables, rubberized rollers Recyclable Materials Dismantling Pos. Description Material Dismantle the sheet-metal cover- Hinged or screwed ings Remove electronic components, Dispose of professionally as elec- assemblies and motors... - Page 129 Disposal Fig. 14: Disposal of separator 1: Cover plates 2: Base frame 3: Base plates 4: Various PCBs 5: Drawer Suprasetter 145/162/190 – User’s Guide...

-

Page 130: Disposal Of The Tray Loader

Disposal Disposal of the Tray Loader Fig. 15: Disposal of tray loader Size of the device (width, depth, height): 2870 mm x 1220 mm x 1560 mm Weight of the device: 520 kg Harmful Substances The table below lists the parts that contain harmful substances and, therefore, must be disposed of or recycled separately. -

Page 131: Recyclable Materials

Sheet steel, galva- 16 (3) nized Base frame Aluminum, AlMg- 16 (2) SiO, 5F25 Lift Mainly aluminum 16 (5) Various parts: Steel, aluminum, mounting parts, plastic, cast alumi- motors, pumps, num, copper cables, rubberized rollers Suprasetter 145/162/190 – User’s Guide... -

Page 132: Dismantling

Disposal Dismantling Pos. Description Material Dismantle the sheet-metal cover- Hinged or screwed ings Remove cables and hoses Remove electronic components, Dispose of professionally as elec- assemblies and motors tronic waste Remove and dismantle the lift Screwed Dismantle sheet-metal compo- Screwed nents Dismantle base plates Screwed... - Page 133 Disposal Fig. 16: Disposal of tray loader 1: Cover plates 2: Base frame 3: Base plates 4: Various PCBs 5: Lift Suprasetter 145/162/190 – User’s Guide...

-

Page 134: Disposal Of The Magazine

Disposal Disposal of the Magazine Fig. 17: Disposal of magazine Size of the device (width, depth, height): 2870 mm x 1720 mm x 1560 mm Weight of the device: 1070 kg with trays, 650 kg without trays Recyclable Materials The following table lists the main parts that do not contain harmful substances and that can undergo environmentally safe recycling. -

Page 135: Dismantling

Recyclable Materials Dismantling Pos. Description Material Dismantle the sheet-metal cover- Hinged or screwed ings Remove and dismantle cassettes Screwed (if any) Dismantle built-in parts Screwed Dismantle the frame Screwed Dismantling Suprasetter 145/162/190 – User’s Guide... - Page 136 Fig. 18: Disposal of magazine 1: Cover plates 2: Base frame 3: Base plates 4: Cassette (0-6)

- Page 138 Heidelberger Druckmaschinen AG Kurfuersten-Anlage 52-60 69115 Heidelberg Germany Phone +49 (62 21) 92-00 Fax +49 (62 21) 92 69 99 www.heidelberg.com/ For further information please contact your local Heidelberg representative.

Need help?

Do you have a question about the Suprasetter 145 and is the answer not in the manual?

Questions and answers

What is the feeder timing degree of CD 102