Protec Algo-Tec 6500 Commissioning Manual

Interactive digital addressable fire control system (1-4 loops)

Hide thumbs

Also See for Algo-Tec 6500:

- Commissioning manual (40 pages) ,

- User manual (70 pages) ,

- Installation manual (28 pages)

Table of Contents

Summary of Contents for Protec Algo-Tec 6500

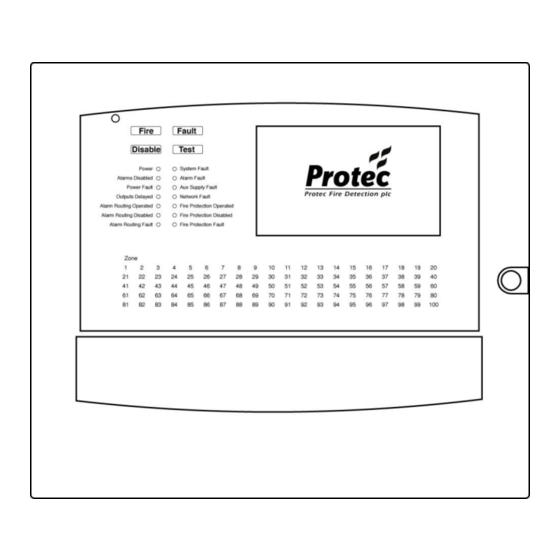

- Page 1 Algo-Tec™ 6500/6600 INTERACTIVE DIGITAL ADDRESSABLE FIRE CONTROL SYSTEM (1-4 LOOPS) COMMISSIONING MANUAL Protec Fire Detection plc, Protec House, Churchill Way, Nelson, Lancashire, BB9 6RT, ENGLAND +44 (0) 1282 717171 www.protec.co.uk sales@protec.co.uk...

-

Page 2: Document Revision Details

19/07/2019 Notice This manual may be revised as a result of enhancements to the system software or hardware. Check for revisions to this manual, and download them, from the website www.protec.co.uk RDM0002/3 Page 2 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 3: Table Of Contents

System Controller Card ........................48 Network Card ............................. 49 I/O Card ............................... 50 Loop Card ............................51 Display Card ............................52 TOUCH SCREEN CALIBRATION ..................... 53 6500 TECHNICAL SPECIFICATION ....................54 RDM0002/3 Page 3 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 4 6600 TECHNICAL SPECIFICATION ....................55 STANDARDS, DIRECTIVES AND REGULATIONS INFORMATION ..........56 RDM0002/3 Page 4 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 5: Introduction

Introduction This manual applies to the Protec 6500 and 6600 fire alarm control panels however for convenience; reference will be made only to the ‘6500’. Everything in this manual applies to the 6500 and 6600 unless stated otherwise. The Protec 6500 Fire Alarm Control Panel has been designed and manufactured in the United Kingdom and complies fully with current standards dictating fire alarm system design practice ( EN54 parts 2 and 4 ). -

Page 6: Commissioning Menus

Enter the engineer code by touching the relevant number buttons then touch Enter. If the code is correct then the display will show the main menu screen For information on the Service Info screen and the Upgrade screen refer to the relevant sections. RDM0002/3 Page 6 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 7: Entering The Menu System

- refer to the user manual Disable / Enable - refer to the user manual History - refer to the user manual Settings - refer to the user manual RDM0002/3 Page 7 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 8: Tools Menu

Touching Tools Menu displays options to show the commissioning tools The printer menu is displayed if the configuration file downloaded to the panel included the printer fitted option. RDM0002/3 Page 8 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 9: Loop Tools

Loop Tools Touching Loop tools displays the different loop options. RDM0002/3 Page 9 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 10: Loop Logging

Loop logging can take several minutes; its progress is indicated on the display. Touch Allocate to move direct to the allocation menu (see next section) else touch OK to exit the logging screen. RDM0002/3 Page 10 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 11: Allocate Addresses

A loop must be logged before it can be allocated Each Protec ‘6000’ loop device has a unique serial number. This serial number has to be linked to a unique address. The process of linking the serial number to an address is known as address allocation. - Page 12 Touch Exit to leave the allocation menu without saving any changes. Touch Continue to return to the allocation screen. Touch Save to store the newly allocated data. A progress bar is displayed as shown below. RDM0002/3 Page 12 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 13: Printer Menu

Prints Loop Device serial numbers and analogue values after selecting the panel, the loop card then the loop. Powers up the printer for a period of time to allow feeding of a new roll of paper. RDM0002/3 Page 13 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 14: Print Current Events

Print current events Touching Print Current Events displays the printer options. Prints the current faults. Prints the current disablements. Prints the current tests. Prints the current alarms. RDM0002/3 Page 14 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 15: Print Historic Events

Prints the last 100 Fire events from the historic log. Prints the last 100 Non- Fire events from the historic log. Prints the last 100 Alarm events from the historic log. RDM0002/3 Page 15 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 16: Diagnostic Tools

1.10 Diagnostic Tools Touching Diagnostic tools displays options to show the available tools. The Networking button is not available on a single panel system. RDM0002/3 Page 16 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 17: Networking

1.11 Networking Touching Networking displays options to show the network diagnostic tools. RDM0002/3 Page 17 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 18: Mapping Info

Yellow indicates that the panel has a fault. A red border to the yellow circle indicates that the panel is one side of a network break. Blue indicates a slave panel that is acting as the master. RDM0002/3 Page 18 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 19 When the system was programmed, two panels have been set up as the master panel. Download the corrected configuration to both panels. Fault too many nodes The master panel discovered too many nodes when it initialised the network. RDM0002/3 Page 19 of 57 © 2015 - 2019 Protec Fire Detection plc...

- Page 20 Duplicate, two panels have the same panel number Unknown, an unknown panel is on the network Reverse, a panel has its channel 1 & 2 wiring reversed RDM0002/3 Page 20 of 57 © 2015 - 2019 Protec Fire Detection plc...

- Page 21 More info displays the panel sequence downloaded to the panel. The panel sequence downloaded to the panel can be compared with the sequence found to assist fault finding. RDM0002/3 Page 21 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 22: Quality

Note: - This data can be used to check for network problems. Leaving the panel for one hour then rechecking should show no additional CH1 or CH2 UART errors. RDM0002/3 Page 22 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 23: Loop Info

The shield resistance is not measured on a 6500 panel so ignore this value Scan Time Denotes the time taken to communicate with every loop device. This time period varies between 2.5 and 8 seconds RDM0002/3 Page 23 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 24 This figure should always be zero. Touch Reset Counts to clear the Total Device Missed Replies and the Total Exchange Errors to zero RDM0002/3 Page 24 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 25: Clear All Disablements

Unlike the previous Protec 6400 panel, during a rebuild each panel does not regenerate its own faults. Each panel simply retransmits its own events that already exist in its database. -

Page 26: Test Menu

- refer to the user manual Zone Test - refer to the user manual Complete System Test - refer to the user manual Panel Test - refer to the user manual RDM0002/3 Page 26 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 27: Test Options

If the user wishes to use the selective display then the selective display option must be set before any test events are created. RDM0002/3 Page 27 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 28: Service Info

A five digit number indicates the contractor code of the servicing company It is possible to upgrade a panel to support more loops or to connect to more network panels. Contact Protec for further details. It is recommended that a picture of the Service Info screen is emailed to Protec. -

Page 29: Upgrade

1.20 Upgrade Touch Upgrade to enter the upgrade code supplied by Protec Once the upgrade code has been entered, return to the Service Info screen and confirm that the Panel Type is correct The upgrade code is valid for a specific date; ensure that you use it on the correct date and that the panel date and time is correct before you enter the code. -

Page 30: Fault Events

2. The alarm outputs are disabled There is a conflict between the disablement information held by Loop Disablement CRC Fault the controller card and that held by the loop card RDM0002/3 Page 30 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 31 (Wefa 562) that is connected to the display card via the Printer WODU Interface Board Missing Data port is not communicating. Check that the green led on the interface board is flashing. RDM0002/3 Page 31 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 32: Panel Faults (Latching)

Press Reset to clear this fault. If the problem persists then the fault will be regenerated however the time taken to regenerate this fault depends upon the number of panels on the network. RDM0002/3 Page 32 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 33 The fault can only be cleared by taking the panel offline Internal Error – DLP Queue and back online If the fault persists, contact Technical @ Protec RDM0002/3 Page 33 of 57 © 2015 - 2019 Protec Fire Detection plc...

- Page 34 Contact the panel supplier for details of how to upgrade a panel. Only one licence fault can be generated by a panel at a time. Other licence faults may be present. RDM0002/3 Page 34 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 35: Network Faults

64 panels The network has initialised with a panel that is not in the master Network - Unknown Panel(s) panel’s network configuration data RDM0002/3 Page 35 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 36 Network - Short A Leg To Screen the screen There is a short circuit fault in the network between CH1- and Network - Short B Leg To Screen the screen RDM0002/3 Page 36 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 37: Loop Faults

1. The panel reporting the fault must be taken offline then Loop Drive Processor Fault back online to clear this fault 2. Report this fault to Technical @ Protec RDM0002/3 Page 37 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 38 Loop Card Processor Fault – back online to clear this fault 0xabcd 2. Report this fault to Technical @ Protec along with the number ‘abcd’ This fault normally occurs during commissioning and indicates that a device that hasn’t been allocated onto the loop has an active input.

-

Page 39: Loop Device Faults

1. Press Reset or Output Group Fault 2. Remove the device, wait till the panel reports it missing then replace it. If the problem persists, replace the device RDM0002/3 Page 39 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 40 DCM Supply Fault An open circuit at the Fault Input terminals This is not a DCM fault and the cause of the missing power supply should be investigated. RDM0002/3 Page 40 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 41: 6000 Digital Device Fault Information

Zone open circuit and alarm fault Loss of zone comms eg aux 24V Normal Fire and alarm fault – Device LED switched ON Fire – Device LED switched ON RDM0002/3 Page 41 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 42 Normal (PSU+5 = 0V, Evac Groups 17 – 32) Normal (PSU+4 = 0V, Evac Groups 33 – 48) Reply byte 2 Use ‘Device Data’ in Engineer menu to obtain the analogue value Normal RDM0002/3 Page 42 of 57 © 2015 - 2019 Protec Fire Detection plc...

- Page 43 None of the faults below are present Water fill fault or no water Expansion board fault LED fault PSU or battery fault Vacuum, sample, purge or chamber seal fault RDM0002/3 Page 43 of 57 © 2015 - 2019 Protec Fire Detection plc...

- Page 44 Input 1 shorted – Reset No change Input 2 shorted – Lamp Test Propoint Air flow fault device 1 WEFA 414 Air flow fault device 2 Normal RDM0002/3 Page 44 of 57 © 2015 - 2019 Protec Fire Detection plc...

- Page 45 Use ‘Device Data’ in Engineer menu to view the analogue value (decimal) 8 Way DIL Switch Value – ‘H’ is the msb, ‘A’ is the lsb Refer to PID 243 for the 24V dampers RDM0002/3 Page 45 of 57 © 2015 - 2019 Protec Fire Detection plc...

-

Page 46: Io Faults

IO Card Short Circuit Fault – There is a short circuit fault in one of the sounder outputs on the Sounder Output n terminal board. ‘n’ indicates the output number RDM0002/3 Page 46 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 47: Alarm Events

Loop card 1&2 Loop card 3&4 Local Network card Display card 16 - 20 Mimic LED Controller 1 - 5 21 - 28 Zone Expansion 1 - 8 RDM0002/3 Page 47 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 48: Card Hardware Indications

Item Function Description Normal Operation Power LED Indication to show the card is powered Solid Red Run LED Indication to show the card is communicating Flashing Green RDM0002/3 Page 48 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 49: Network Card

Indication to show the card is powered Solid Red Network Isolate Switch Isolates panel from the network Unused Unused Don’t Care Processor B functionality is not currently implemented. RDM0002/3 Page 49 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 50: I/O Card

Item Function Description Normal Operation Run LED Indication to show the card is communicating Flashing Green Power LED Indication to show the card is powered Solid Red RDM0002/3 Page 50 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 51: Loop Card

Indication to show the card is powered Solid Red The LEDs are partially obscured by the daughter board. The operation of the LEDs can be checked by viewing the card from the top-edge. RDM0002/3 Page 51 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 52: Display Card

Normal Operation See Section 4.0 Status Status Solid Red Traffic Indication to show the card is communicating Flashing Red Mute Buzzer Slide left to mute buzzer As shown RDM0002/3 Page 52 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 53: Touch Screen Calibration

20 seconds so that the calibration can be tested. Touch the screen and check that a marker appears where you have touched. RDM0002/3 Page 53 of 57 © 2015 - 2019 Protec Fire Detection plc... -

Page 54: 6500 Technical Specification

Mounting method 3 points surface mount or flush ( bezel required when flush mounting ) Weight (excluding batteries & packaging) Weight (including 2 x 12V,12Ah 16kg batteries) RDM0002/3 Page 54 of 57 © 2015 - 2019 Protec Fire Detection plc... - Page 55 3 points surface mount or flush ( bezel required when flush mounting ) Weight (excluding batteries 10.5kg (internal charger) & packaging) Weight (including 2 x 21kg (internal charger) 12V,18Ah batteries) RDM0002/3 Page 55 of 57 © 2015 - 2019 Protec Fire Detection plc...

- Page 56 Standards, directives and regulations information 0086-CPR-575026 KM 575025 Protec Fire Detection plc, Nelson, Lancashire, England BB9 6RT PFD-CPR-0138 This equipment has been manufactured in conformance with the requirements of all applicable EU council directives and regulations. BS EN 54-2:1997 + A1:2006...

- Page 57 The policy of Protec Fire Detection plc is one of continuous improvement. As such we reserve the right to make changes to product specifications at any time and without prior notice. Errors and omissions excepted. Electrical or electronic devices that are no longer serviceable must be collected separately and sent for environmentally compatible recycling (in accordance with the European Waste Electrical and Electronic Equipment Directive).

Need help?

Do you have a question about the Algo-Tec 6500 and is the answer not in the manual?

Questions and answers