Table of Contents

Advertisement

TABLE OF CONTENTS

A

Precautions...............................................................................................2

B

Check List.......................................................................................................3

C

Component Diagram................................................................................4

LCD Monitor Menu and Function.............................................................5

Technical Specifications ..............................................................................6

F

Hardware Installation On Printer..............................................................7

G

Software installation on PC.......................................................................10

SD Printing(recommended)......................................................................39

I

Troubleshooting...........................................................................................40

J

Maintenance...............................................................................................41

USER MANUAL

- 1 -

Advertisement

Table of Contents

Summary of Contents for Malyan M200

-

Page 1: Table Of Contents

USER MANUAL TABLE OF CONTENTS Precautions..………………………………………………....………………...2 Check List.…………........………....…......3 Component Diagram.……………..…………....….....………..4 LCD Monitor Menu and Function.............5 Technical Specifications ................6 Installation Hardware Installation On Printer..............7 Software installation on PC...............10 Printing SD Printing(recommended)..............39 Troubleshooting...................40 Maintenance....……………......………......41 - 1 -... -

Page 2: Precautions

PRECAUTIONS Do not strip the yellow paper on the glass sheet, it is for anti-slip printing. Do not strip the wrapper which wraps up the nozzles, it is for holding the nozzle temperature. Use this printer under the right power and follow all local laws. Be aware of hot heat blocks, nozzles, extruded filament and heating plate. -

Page 3: Check List

. check list 3D printer USB cable SD card Power adapter Filament rack Plastic scraper - 3 -... -

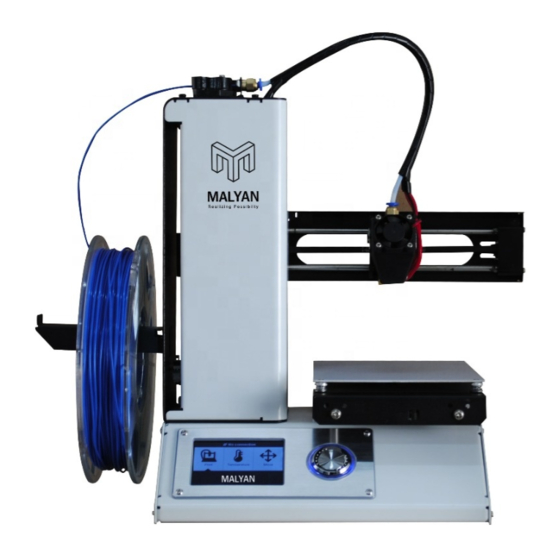

Page 4: Component Diagram

Component Diagram Feeding Machine Filament Rack Extruder Control Panel USB and SD card Power supply interface and Switch - 4 -... -

Page 5: Dlcd Monitor Menu And Function

LCD MONITOR MENU Print Off-line print Gcode files from SD card Monitor Extruder Preheat extruder Platform Preheat platform Start Preheat Preheat all the above Move X Axis Rotate knob to move extruder along X axis Y Axis Rotate knob to move extruder along Y axis Z Axis Rotate knob to move extruder along Z axis Extruder... -

Page 6: E Technical Specifications

TECHNICAL PARAMETERS Product FDM Desktop 3D Printer Rapid Prototyping, print 3D models, samples, Usage parts, toys... Construction ABS with power-coated steel reinforcement Extruder Single Nozzle diameter 0.4 mm (0.015 in) Positioning XY 11 microns (0.0004 in), Z 2.5 micron (0.0001 in) Precision Layer Resolution 100 micron (0.0039 in) -

Page 7: Installation

. INSTALLATION HARDWARE INSTALLATION ON PRINTER 1 Adjusting platform The heating platform has been adjusted and is level before leaving the factory. It may have moved a little during transport which will affect the printing quality. You will need to check and adjust the platform before you start using the printer. - Page 8 • If the heating plate is too close to the nozzle, it will directly affect the nozzle action and possible lead to damage of the plate. • Leveling the base plate before printing helps to ensure the print objects stay attached to the heating plate Nozzle and platform too far, will lead to material wrong...

- Page 9 3 Install the filament rack on the left side of the machine and hang the filament on the holder. 4 When the temperatures are ready, cut the top of filament to sharp point, and then press down the feed mechanism, thread and push the filament through to the mouth of the nozzle, stop pushing when the filament comes out of the nozzle.

-

Page 10: Software Installation On Pc

We recommend that new users start with Cura as it includes a slicing engine. Slicers These programs take the M200 model (typically STL/OBJ) and determine the 3D printer tool path based on the options selected. The slicing engine uses the nozzle diameter, printing and movement speeds, layer height and other variables to determine the coordinates where it needs to move and the rates at which it will do so. - Page 11 as shown below: After pressing next the next screen will ask you to choose the component and the formats you would like to open in Cura. Make the selection as bellow and press next. - 11 -...

- Page 12 Now press next to complete the installation Now press finish button to finish the process: - 12 -...

- Page 13 Now you will see the front screen of Cura with all the options as shown below: Now to print with our machine go to machine option in the header and select add new machine option. - 13 -...

- Page 14 Now select the radio button with the option as follows: Other(Ex: RepRap, MakerBot, Witbox) and press next button. Then choose Custom and click next. - 14 -...

- Page 15 Then modify the parameters. Now press Finish and you will be redirected to the below screen: Now load the object with the load file button as shown below and make the changes in the parameters as shown in the image. - 15 -...

-

Page 16: Quick Print Settings

1.3 Quick Print Settings After setting up Cura for the first time, you will be shown the main interface screen. Selecting a Quick Print Profile The print quality settings can be found in the top left-hand corner of the window. For most filaments, there will be High Quality, Normal Quality, or Fast Quality options. - Page 17 Most commonly used for quick iteration of designs found in rapid prototyping. Material Selection Choose your desired filament. The Malyan M200 ships with a 5 meter sample of PLA, that should be used in your first print. Printing Support Material...

- Page 18 Rotate The Rotate button will give you the ability to orientate your model along all three axis. Once you click the rotate button, three circles will surround your model. The red circle will allow you to rotate around the Z axis. The Yellow circle will rotate around the Y axis.

-

Page 19: View Options

Reset The Reset button will return your model to the original orientation as defined by the CAD program used to create the model. Scale The Scale button displays the model dimensions, along with the ability to scale along the X Y or Z axes. Anything below the number 1.0 will reduce the objects size, while anything above the number 1.0 will increase the objects size. - Page 20 Overhang Overhang mode shows where your model may need support material. In Fig. 1.6, page 16 the red highlighted areas show overhangs and more severe angles and areas where support material is recommended. Ghost Ghost view mode makes the model translucent to allow you to see what is behind it.

- Page 21 Xray Xray is very similar to Ghost mode. It will allow you to see into objects, ensuring that inner details are correct. Layers To view the tool path of your print head and to ensure no skipped layers or gaps then use this option. Use the slide bar on the righthand side of the window to move up and down through the tool path layers.

-

Page 22: Starting Your First Print

1.5 Starting Your First Print Once you have your model, profile, and filament loaded, it is time fo your first print! 1.6 Removing Your First Print After your first print has finished, you need to wait for the part to cool down. Your parts will be easier to remove if your allow your heated bed to cool down to optimal temperature. -

Page 23: Full Settings

1.7 Full Settings Full settings should not be used until enough experience with 3D printing has been gained to feel comfortable with all aspects of the printer and its operation. The simple settings will provide good results for most models. The first time Cura is launched it will default to the Quick Print interface. - Page 24 Shell Thickness This defines the number of vertical walls that comprise the outside of your model. We recommend keeping this set to multiples of your nozzle width. Your Mini 3D printer is equipped with 0.4mm nozzle. Enable Retraction Retraction tells your printer to pull filament out of the hot end upon travel moves.

- Page 25 Your overall printing speed can be adjusted here. If no other speeds are determined in the later sections your printer will automatically default to this speed. This speed will be different, depending on what type of filament your are using. Printing Temperature When using different filament materials you'll need to update the desired hot end and heated bed temperature.

-

Page 26: Filament Diameter

Platform Adhesion Type Some models have a small surface area contacting the plate. This can create adhesion issues causing your part to pop off at some point during the print. To fix this, use either Brim or Raft. Raft is better used when a model has small heated bed contact points and overhangs. -

Page 27: Advanced Tab Options

This will control how thick your first printed layer height is printed onto the heated bed. Having a larger initial layer height will help prevent your part from popping off the plate. Your MALYAN M200 auto leveling system could be affected if you change this from the standard profiles. Adjust at your own risk. - Page 28 Initial Layer Line Width This will control how wide your first extruded filament path is for the initial layer. A wider line width will help with bed adhesion. We have found 125% to be a good starting place. For models with moving printed in place parts. A smaller initial layer line width is recommended.

- Page 29 laying down each layer. If your layer print time falls below this your printer will automatically slow down to reach this time before moving onto the next layer. Tweaking this can help get cleaner, crisper prints. Enable Cooling Fan Enables operation of your extruder's active cooling fan. The fan settings can be adjusted in the Expert Settings options.

- Page 30 and print speeds. Fine turning these for specific STL files, can produce cleaner prints. Pause at Z height Pause your print at a specified height. You can also specify where to move the print head and how much filament to retract. This will prevent “lobs” from accumulating on your print while paused.

- Page 31 1.13 Retraction Retraction pulls filament out of your nozzle when it is not extruding to prevent your print head from dripping on your object. This section is where you will control how your extruder retracts its filament. Minimum Travel This sets the minimum travel distance of your print head in order to retract. If your print head is not moving this far during travel moves, it will not retract.

- Page 32 Start Distance This will define the distance away from your model that the skirt will be created. If using as a envelope to prevent drafts, it is recommended to be closer to your object. Minimal Length This will define the minimum extruded line length for the skirt. This will over ride your line count, producing as many lines as required to reach the minimal length.

- Page 33 1.16 Support You define how your support material is generated here. You must have some form of support turned on in the basic settings in order for these settings to have an effect. Structure Type You can choose between a Grid or a line pattern for your support material. The grid will be a checkerboard pattern in the X and Y direction.

-

Page 34: Black Magic

but makes it harder to remove. 1.17 Black Magic This section allows you to transform your model into a hollow shell, a single layer thick. Spiralize the outer contour this causes your Z axis to be constantly moving upward as printing your single outer wall shell. The results are no layer change lines, giving a much smoother surface. - Page 35 Brim Line Amount This will determine the distance the brim will cover around the outside of your object. The more brim used, the better your part will adhere to the plate. 1.19 Raft Raft is a platform built underneath your object, designed to help adhesion and prevent warping.It will lay down support material, and then a platform on top of the supports.

- Page 36 Base Thickness This defines how thick your raft will be. Base line Width This will define how wide your "support" material is for the raft. This setting will determine how well the surface layers of the raft print. Interface Thickness This will determine how thick the surface layers of the raft are.

-

Page 37: Fix Horrible

your raft. If you have a wide line spacing, you may want to increase this number to ensure a solid platform. 1.20 Fix Horrible These are some of the more advanced and experimental options. They are designed to help repair models with errors to make them suitable for 3D printing. - Page 38 Extensive Stiching This causes Cura to automatically add triangle meshes in an attempt to fix manifold errors. This algorithm will greatly increase GCode generation time and may end up adding in un-intended meshes. It is recommended that you repair your model through Meshlab or your CAD program before attempting this option.

-

Page 39: H Printing

H.PRINTING SD PRINTING (RECOMMENDED) We have uploaded sample x3g files onto our supplied SD card, you can insert it into the printer, click "Print from SD" on the LCD screen, choose the file and print. You can also download from (www.thingiverse.com etc) or create 3D STL files, enable our Cura, generate to G Code then G Code and save to SD card and print. -

Page 40: Troubleshooting

I. Troubleshooting 1. Nozzle seems blocked: Please clean the nozzle carefully with tools, check and make sure the extruder motor is rotating and pulling filament and that temperatures are right. 2. Software prompts timeout, no response while operating: Please close software, restart the printer, then reconnect to PC printing. -

Page 41: Maintenance

Maintenance Clean extruder and nozzle frequently Oil the X/Y/Z axis occasionally. Preheat extruder properly before loading filament. Calibrate extruder and platform every time before printing. Keep platform clean and empty when idle. Keep printer away from dust and grime. Keep printer clean and dry. Keep printer at a comfortable room temperature.

Need help?

Do you have a question about the M200 and is the answer not in the manual?

Questions and answers