Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Ryobi RA-RS6300-B

- Page 1 RA-RS6300-B AIR RECIPROCATING SAW OPERATOR'S MANUAL ORIGINAL INSTRUCTIONS...

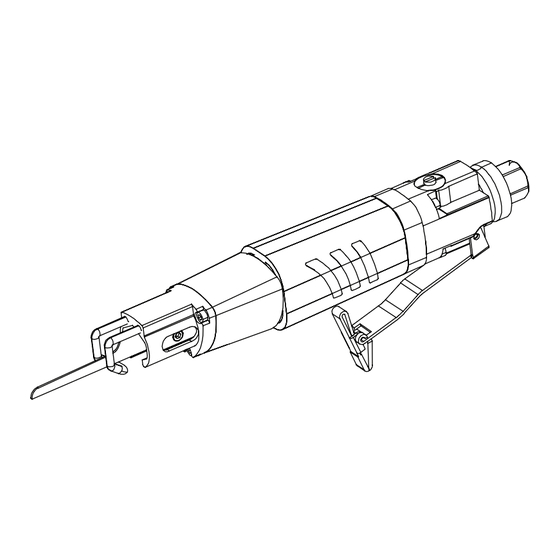

- Page 2 DESCRIPTION 1. Housing and grip 4. Blade 7. Trigger lock pin 10. Hex key 2. Regulator adj. knob 5. No mar tip and guard 8. Trigger 11. Workpiece 3. Air inlet 6. Blade holder 9. Air quick connector Fig.1 Fig.2 Fig.3 Fig.4 Fig.5...

- Page 3 Important! It is essential that you read the instructions in this manual before operating this machine. Subject to technical modifications.

-

Page 4: General Safety Rules

GENERAL SAfETy RULES hazards including cuts and abrasion and heat. Wear suitable gloves to protect hands. ■ For multiple hazards, read and understand the safety ■ Operators and maintenance personnel shall be instructions before installing, operating, repairing, physically able to handle the bulk, weight and power maintaining, changing accessories on, or working near of the tool. -

Page 5: Workplace Hazards

■ Inspect the saw blade before use. Do not use saw in the ears). Therefore, a risk assessment and blades which may have been dropped or which are implementation of appropriate controls for these chipped, cracked or otherwise defective. hazards are essential. ■... -

Page 6: Specifications

ADDITIONAL SAfETy INSTRUCTIONS fOR PNEU- Avg. air consumption 105 L/min (3.7 cfm) MATIC POWER TOOLS Operating pressure 90 psi (6.3 bar) ■ Air under pressure can cause severe injury. ■ Always shut off air supply, drain hose of air pressure Weight 0.72 kg and disconnect tool from air supply when not in use,... -

Page 7: Loading And Operation

■ Disconnect the product from the air supply before O-rings and other rubber parts. changing accessories or making adjustments. IMPORTANT! ■ Required air pressure of 6.3 bar (90 psi), and an air flow according to specifications. See Figure 7. ■ The air regulator controls the amount of air flow If a filter/regulator/lubricator is not installed on the air entering the rotor. -

Page 8: Troubleshooting

lubrication is essential to avoid internal corrosion and clutch parts, i.e. a typical oiled/lubricated tool requires possible failure. 14.20 ml (1/2 ounce) of oil. Grease lubrication ■ Lubricate the tool daily with a few drops of air tool oil dripped into the air inlet. NOTE: Heat usually indicates insufficient grease in chamber. -

Page 9: Parts List

PARTS LIST Description Description Description Description Blade 18 Safety nozzle Spring O-ring 5.6*1.8 Bearing housing Bolt M3*12 Trigger O-ring 11.2*1.6 Bolt M6*8 Safety set Bolt 3*22 Screw cap Blade chuck Bolt M3*3 Bolt M3*18 Washer Spring Gun body Valve Stem seat Air inlet plug Cylinder Cap Rubber grip... - Page 12 Techtronic Industries (Australia) Pty. Ltd. Level 1, 660 Doncaster Road Doncaster, VIC 3108, Australia Techtronic Industries New Zealand Ltd. 18-26 Amelia Earhart Avenue Mangere, Auckland 2022, New Zealand...

Need help?

Do you have a question about the RA-RS6300-B and is the answer not in the manual?

Questions and answers