Ryobi RTS30 Operator's Manual

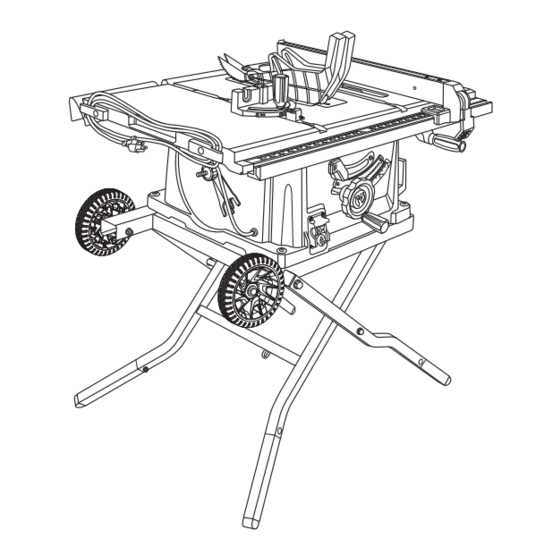

10 in. table saw

Hide thumbs

Also See for RTS30:

- Manual del operador (44 pages) ,

- Operator's manual (42 pages) ,

- Manuel d'utilisation (42 pages)

Table of Contents

Advertisement

Your table saw

has been engineered and manufactured to our high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING:

To reduce the risk of injury, the user must read and understand the operator's manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

OPERATOR'S MANUAL

10 in. TABLE SAW

RTS30

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Ryobi RTS30

- Page 1 OPERATOR’S MANUAL 10 in. TABLE SAW RTS30 Your table saw has been engineered and manufactured to our high standard for dependability, ease of operation, and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

-

Page 2: Table Of Contents

The replacement power tool will be covered by the limited warranty for the balance of the two year period from the date of the original purchase. WHAT THIS WARRANTY COVERS: This warranty covers all defects in workmanship or materials in your RYOBI power ®... -

Page 3: General Safety Rules

GENERAL SAFETY RULES SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer than using your hand and frees both WARNING: hands to operate tool. Read and understand all instructions. Failure to follow DON’T OVERREACH. Keep proper footing and balance all instructions listed below, may result in electric shock, at all times. -

Page 4: Specific Safety Rules

GENERAL SAFETY RULES BLADE COASTS AFTER BEING TURNED OFF. STAY ALERT AND EXERCISE CONTROL. Watch what you are doing and use common sense. Do not operate NEVER USE IN AN EXPLOSIVE ATMOSPHERE. tool when you are tired. Do not rush. Normal sparking of the motor could ignite fumes. -

Page 5: Specific Safety Rules

SPECIFIC SAFETY RULES NEVER perform any operation “freehand” which means USE ONLY RECOMMENDED ACCESSORIES listed in this manual or addendums. Use of accessories that using only your hands to support or guide the workpiece. are not listed may cause the risk of personal injury. Always use either the rip fence or miter gauge to position Instructions for safe use of accessories are included with and guide the work. -

Page 6: Symbols

SYMBOLS Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper inter- pretation of these symbols will allow you to operate the tool better and safer. Indicates a potential personal injury hazard. Safety Alert To reduce the risk of injury, user must read and understand Read Operator’s Manual... -

Page 7: Symbols

If you do not understand ing, use only identical replacement parts. the warnings and instructions in the operator’s manual, do not use this product. Call Ryobi customer service for assistance. WARNING: The operation of any power tool can result in foreign objects being thrown into your eyes, which can result in severe eye damage. -

Page 8: Electrical

ELECTRICAL EXTENSION CORDS SPEED AND WIRING Use only 3-wire extension cords that have 3-prong ground- The no-load speed of this tool is approximately 5,000 rpm. This speed is not constant and decreases under a load or ing plugs and 3-pole receptacles that accept the tool's plug. with lower voltage. -

Page 9: Glossary Of Terms

GLOSSARY OF TERMS Push Blocks (for jointer planers) Anti-Kickback Pawls (radial arm and table saws) Device used to feed the workpiece over the jointer planer A device which, when properly installed and maintained, cutterhead during any operation. This aid helps keep the is designed to stop the workpiece from being kicked back operator’s hands well away from the cutterhead. -

Page 10: Features

FEATURES PRODUCT SPECIFICATIONS Input ..............15 Amps Blade Arbor .............. 5/8 in. No Load Speed ........5,000 r/min. (RPM) Blade Diameter ............10 in. Cutting Depth at 0˚ ..........3-1/2 in. Blade Tilt ..............0˚ - 45˚ Cutting Depth at 45˚ ..........2-1/2 in. Rating ..........120 V, AC only, 60 Hz BLADE GUARD... - Page 11 FEATURES KNOW YOUR TABLE SAW HEIGHT/BEVEL ADJUSTING HANDWHEEL - Located on the front of the cabinet, use this handwheel to lower and raise See Figure 2. the blade for height adjustments or blade replacement. This The safe use of this product requires an understanding of handwheel also makes the adjustment for bevel angles easy.

-

Page 12: Operating Components

FEATURES OPERATING COMPONENTS WARNING: The upper portion of the blade projects up through the table and is surrounded by an insert called the throat plate. The ALWAYS remove the switch key when the tool is not in height of the blade is set with a handwheel on the front of the use and keep it in a safe place. -

Page 13: Tools Needed

FEATURES BLADES WARNING: For maximum performance, it is recommended that you use the 36-tooth, 10 in. carbide-tipped combination blade pro- Do not use blades rated less than the speed of this tool. vided with your saw. Additional blade styles of the same high Failure to heed this warning could result in personal injury. -

Page 14: Loose Parts

LOOSE PARTS The following items are included with your table saw: Fig. 5 A. Anti-Kickback Pawls ..............................1 B. Handle Assembly ................................ 1 C. Dust Bag..................................1 D. Screw ..................................4 E. Leg Stand Tube ................................4 F. Nut ....................................4 G. -

Page 15: Assembly

ASSEMBLY UNPACKING WARNING: This product requires assembly. Carefully lift saw from the carton and place it on a level Do not connect to power supply until assembly is work surface. complete. Failure to comply could result in accidental starting and possible serious personal injury. NOTE: This tool is heavy. - Page 16 ASSEMBLY TO ATTACH THE WHEEL ASSEMBLY See Figure 6. BOLT SLEEVE Locate the wheels, bolts, flat washers, sleeves, and nuts. FLAT Slide a flat washer on a bolt then slide the bolt / washer FLAT WASHER into the wheel hole of a wheel. WASHER ...

- Page 17 ASSEMBLY TO OPEN/CLOSE (SET-UP/TEAR DOWN) THE SET-UP TEAR DOWN LEG STAND See Figure 9. To open (set-up) the leg stand: Step 1: With the saw table on end and standing to the side, use your left hand to pull the leg stand latch towards you.

-

Page 18: Riving Knife

ASSEMBLY TO REMOVE/REPLACE THE THROAT PLATE THROAT See Figure 10. PLATE Lower the blade by turning the height/bevel adjusting handwheel counterclockwise. SPREADER/ To remove the throat plate, place your index finger in RIVING KNIFE the hole and lift the front end pulling the throat plate out toward the front of the saw. -

Page 19: Blade Guard

ASSEMBLY TO CHECK SAW BLADE INSTALLATION BLADE See Figure 12. WRENCH BLADE WRENCH CAUTION: To work properly, the saw blade teeth must point down toward the front of the saw. Failure to do so could cause damage to the saw blade, the saw, or the workpiece. ... - Page 20 ASSEMBLY To install blade guard: Lift the guard lever up to unlock. With the front of the blade guard raised, lower the back of the guard into the middle hole of the spreader/riving knife. Push the front of the guard down until it is paral- lel to the table (see figure 15).

- Page 21 ASSEMBLY TO MOVE THE LEG STAND DUST See Figure 17. CHUTE Holding the leg stand firmly, pull the leg stand toward you until the leg stand and saw are balanced on the wheels. Push the saw to the desired location then either open the leg stand for immediate saw operation or store the saw ELBOW in a dry environment.

-

Page 22: Operation

OPERATION Kickback can be caused by any action that pinches the WARNING: blade in the wood such as: Making a cut with incorrect blade depth Do not allow familiarity with tools to make you careless. Remember that a careless fraction of a second is suf- ... -

Page 23: Cutting Aids

OPERATION CUTTING AIDS See Figure 21. Push sticks are devices that may be used for pushing a workpiece through the blade in any rip cut. When making PUSH STICKS non-through cuts or ripping narrow stock, always use a push stick, push block, and/or featherboard so your hands do not come within 3 inches of the saw blade. -

Page 24: How To Mount A Featherboard

OPERATION FEATHERBOARD WARNING: A featherboard is a device used to help control the Mount the featherboard in front of the saw blade. If workpiece by guiding it securely against the table or fence. Featherboards are especially useful when ripping small positioned improperly, kickback can result from the workpieces and for completing non-through cuts. -

Page 25: Cutting Tips

OPERATION TYPES OF CUTS See Figure 26. There are six basic cuts: 1) the cross cut, 2) the rip cut, 3) the miter cut, 4) the bevel cross cut, 5) the bevel rip cut, and 6) the compound (bevel) miter cut. All other cuts are combina- tions of these basic six. - Page 26 OPERATION TO CHANGE BLADE DEPTH GULLET See Figure 27. The blade depth should be set so that the outer points of the blade are higher than the workpiece by approximately 1/8 in. to 1/4 in. but the lowest points (gullets) are below the top surface.

- Page 27 OPERATION WARNING: To reduce the risk of injury, always make sure the rip fence CLAMP is parallel to the blade before beginning any operation. SCREW TO USE THE RIP FENCE FENCE See Figure 29. Place the rip fence flat on the saw table, push the fence towards the front rail to align the fence to the saw table.

- Page 28 OPERATION TO USE THE MITER GAUGE MITER See Figure 31. GAUGE BODY LOCK The miter gauge provides greater accuracy in angled cuts. KNOB For very close tolerances, test cuts are recommended. MITER GAUGE There are two miter gauge grooves, one on either side of the blade.

- Page 29 OPERATION HEELING (PARALLELING) THE BLADE TO THE RIGHT MITER COMBINATION MITER GAUGE GROOVE GAUGE GROOVE SQUARE See Figures 35 - 37. WARNING: The blade must be parallel to the miter gauge groove so the wood does not bind resulting in kickback. Failure to do so could result in serious personal injury.

-

Page 30: Making Cuts

OPERATION MAKING CUTS CROSS CUT This table saw can perform a variety of cuts that are not all PLACE RIGHT HAND mentioned in this manual. DO NOT attempt to make any cuts ON MITER GAUGE not covered here unless you are thoroughly familiar with the HERE proper procedures and necessary accessories. - Page 31 OPERATION MAKING A RIP CUT RIP CUT See Figure 40. FENCE BLADE WARNING: Make sure the blade guard assembly is installed and working properly to avoid serious possible injury. Set the blade to the correct depth for the workpiece. ...

- Page 32 OPERATION MAKING A BEVEL CROSS CUT VIEWED FROM THE FRONT, BELOW THE TABLE SAW See Figures 42 - 43. WARNING: Make sure the blade guard assembly is installed and TIGHTEN working properly to avoid possible serious injury. Remove the rip fence. HEIGHT/BEVEL ADJUSTING ...

- Page 33 OPERATION Position the workpiece flat on the table with the edge BEVEL RIP CUT flush against the rip fence. Let the blade build up to full speed before feeding the workpiece into the blade. BLADE FENCE ANGLED Once the blade has made contact with the workpiece, use the hand closest to the rip fence to guide it.

- Page 34 OPERATION MAKING A LARGE PANEL CUT LARGE PANEL CUT See Figure 46. Make sure the saw is properly secured to a work surface to RIP FENCE avoid tipping from the weight of a large panel. WARNING: Make sure the blade guard assembly is installed and working properly to avoid possible serious injury.

-

Page 35: Operation

OPERATION MAKING A DADO CUT Once all dado cuts are completed: Unplug your saw. See Figure 48. Reinstall the spreader/riving knife in the “up” position An optional dado throat plate is required for this procedure then install the blade guard and anti-kickback pawls. (see the Accessories section of this manual and check with the retailer where the table saw was purchased). -

Page 36: Adjustments

ADJUSTMENTS BLADE WARNING: WRENCH BLADE WRENCH Before performing any adjustment, make sure the tool is unplugged from the power supply and the switch is in the OFF position. Failure to heed this warning could result in serious personal injury. The table saw has been adjusted at the factory for making very accurate cuts. - Page 37 ADJUSTMENTS TO ADJUST THE MITER GAUGE MITER See Figure 52. KNOB GAUGE BASE You can set the miter gauge at 0° and plus or minus 45° with the miter gauge stop pin and adjustable stop screws. NOTE: The miter gauge provides close accuracy in angled cuts.

- Page 38 ADJUSTMENTS TO SET THE BLADE AT 0° AND 45° BLADE COMBINATION BEVEL See Figures 54 - 55. SQUARE LOCKING The angle settings of the saw have been set at the factory LEVER and, unless damaged in shipping, should not require set- ting during assembly.

-

Page 39: Maintenance

MAINTENANCE WARNING: WARNING: When servicing, use only identical replacement parts. Do not at any time let brake fluids, gasoline, petroleum- Use of any other parts may create a hazard or cause based products, penetrating oils, etc., come in contact product damage. with plastic parts. -

Page 40: Troubleshooting

TROUBLESHOOTING PROBLEM CAUSE SOLUTION Excess vibration. Blade is out of balance. Replace blade. Blade is damaged. Replace blade. Saw is not mounted securely. Tighten all hardware. Work surface is uneven. Reposition on flat surface. Adjust legs of leg stand. Blade is warped. Check saw blade installation. -

Page 41: Troubleshooting

TROUBLESHOOTING PROBLEM CAUSE SOLUTION Saw does not make accurate Positive stops inside cabinet need Adjust positive stops. 90º or 45º cuts. adjusting (Bevel Cuts). Adjust the miter gauge. Miter gauge is misaligned (Miter Cuts). Height/bevel adjusting hand- Clean the gears or screw post. Gears or screw post inside wheel is hard to turn. -

Page 42: Parts And Service

HOW TO OBTAIN CUSTOMER OR TECHNICAL SUPPORT: To obtain Customer or Technical Support please contact us at 1-800-525-2579. RYOBI is a registered trademark of Ryobi Limited used under license. ® ONE WORLD TECHNOLOGIES, INC. 1428 Pearman Dairy Road, Anderson, SC 29625 Phone 1-800-525-2579 www.ryobitools.com...

Need help?

Do you have a question about the RTS30 and is the answer not in the manual?

Questions and answers