Table of Contents

Advertisement

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — This Document is customer property and is to remain with this unit.

*UH1

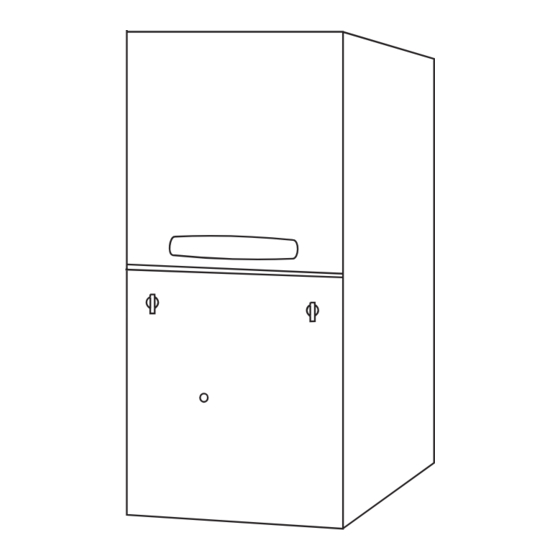

UPFLOW/HORIZONTAL

Installer's Guide

Upflow/ Horizontal, Downflow/ Horizontal,

Gas-Fired, Direct Vent Condensing

Furnaces

*UH1B040A9241A

*UH1B060A9361A

*UH1B080A9421B

*UH1C080A9601A

*__First letter may be "A" or "T"

Please return to service information pack upon completion of work.

UPFLOW

*UH1

*UH1C100A9481A

*UH1D100A9601A

*UH1D120A9601A

*DH1

*DH1

DOWNFLOW/HORIZONTAL

18-CD29D1-11

*DH1B040A9241A

*DH1B065A9421A

*DH1C085A9481A

*DH1D110A9601A

DOWNFLOW

A341624P13

Advertisement

Table of Contents

Summary of Contents for Trane AUH1B040A9241A

- Page 1 18-CD29D1-11 Installer’s Guide Upflow/ Horizontal, Downflow/ Horizontal, Gas-Fired, Direct Vent Condensing Furnaces *UH1B040A9241A *UH1C100A9481A *DH1B040A9241A *UH1B060A9361A *UH1D100A9601A *DH1B065A9421A *UH1D120A9601A *UH1B080A9421B *DH1C085A9481A *UH1C080A9601A *DH1D110A9601A *__First letter may be “A” or “T” ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES IMPORTANT —...

-

Page 2: Safety Section

8. After it has been determined that each appliance connected to the venting system properly vents where tested as outlined above, return doors, win- dows, exhaust fans, fireplace dampers and any other gas-fired burning appliance to their previous conditions of use. 18-CD29D1-11 © 2014 Trane All Rights Reserved... - Page 3 Installer’s Guide Contents The furnace return air temperature range is between 55 and 80 degrees Fahrenheit. g. Clean the furnace, duct work, and components INSTALLATION INSTRUCTIONS upon substantial completion of the construc- tion process, and verify furnace operating con- General Installation Instructions Location and Clearances ditions including ignition, input rate, tempera- Outline Drawings...

- Page 4 Installer’s Guide UPFLOW INSTALLATION WARNING Standoffs and screws (See Figure 1) are included with EXPLOSION HAZARD! the cased coils for attachment to the furnace. There PROPANE GAS IS HEAVIER THAN AIR AND MAY are clearance alignment holes near the bottom of the COLLECT IN ANY LOW AREAS OR CONFINED SPAC- coil wrapper.

- Page 5 Installer’s Guide 18-CD29D1-11...

- Page 6 Installer’s Guide 18-CD29D1-11...

- Page 7 Installer’s Guide A (width) B (depth) FURNACE FRONT HORIZONTAL INSTALLATION UPFLOW/ The coil and furnace must be fully supported when used in HORIZONTAL the horizontal position. It is always recommended that an SHOWN auxiliary drain pan be installed under a horizontally in- stalled evaporator coil or 95% gas furnace.

- Page 8 Installer’s Guide OUTSIDE AIR IS RECOMMENDED 1. All air from inside the building as in Figure 8: The con- The use of indoor air for most applications is acceptable, fined space shall be provided with two permanent open- unless there is the presence of corrosive chemicals or ings communicating directly with an additional room(s) contamination.

- Page 9 Installer’s Guide On any job, flexible connections of nonflammable materi- al may be used for return air and discharge connections to pre vent transmission of vibration. Though these units have been specifically designed for quiet, vibration free operation, air ducts can act as sounding boards and could, if poorly in- stalled, amplify the slightest vibration to the annoyance lev- When the furnace is located in a utility room adjacent to the living area, the system should be carefully designed...

- Page 10 Installer’s Guide When the upflow furnace is installed in the horizontal 7. Connect the duct work to the furnace. See Outline application and a close coupled (less than 36") return Drawing (pages 5-6) for supply and return duct size duct is attached to the bottom side of the furnace as and location.

- Page 11 Installer’s Guide TABLE 5 NOTE: The narrow 14.5" width furnace cabinet prevents use of the filter rack for right side return. Pre-drill clear- UPFLOW FURNACE RETURN AIR FILTERS ance holes and then attach filter clips with the screws CABINET CABINET CABINET provided.

- Page 12 Installer’s Guide TABLE 6 SIDE Cabinet Width Left Side Bottom Right Side CUTOUT 14.5 Use Alternate Filter Clips Only 17.5 RETAINING 24.5 (Both Sides) 1. UC1B060C has 10x7 blower which requires use of alternate filter clips for left side filter. "K1" and later use the filter rack. 2.

- Page 13 Installer’s Guide RETURN AIR FILTERS FOR UPFLOW FURNACE TYPICAL DOWNFLOW FURNACE IN HORIZONTAL CONFIGURATION RETURN AIR FILTER INSTALLATIONS When the Upflow Furnace is installed in a horizontal Two high velocity type air filters are required for each down- configuration, the filter must never be installed inside or flow furnace.

-

Page 14: General Venting

Installer’s Guide GENERAL VENTING WARNING WARNING CARBON MONOXIDE POISONING HAZARD CARBON MONOXIDE POISONING HAZARD Failure to follow the steps outlined below for each FURNACE MUST BE VENTED PROPERLY. FAILURE TO appliance connected to the venting system being FOLLOW THE INSTALLATION INSTRUCTIONS FOR THE placed into operation could result in carbon monoxide VENTING SYSTEM COULD RESULT IN CARBON MONOXIDE poisoning or death. - Page 15 Installer’s Guide For DIRECT VENT APPLICATION: The Furnaces must The following are EXAMPLES ONLY: be vented to the exterior of the house and combustion air EX. 1 — MUST come through the inlet air pipe FROM OUTSIDE Example 1 shows the vent pipe exhausting through the roof AIR.

- Page 16 Installer’s Guide WARNING PVC VENT FITTING MATERIAL These fittings available from your Furnace Distributors. CARBON MONOXIDE POISONING HAZARD Straight Pipe Sections, Couplings, 45° Elbows, 60° Elbows, Do not use cement on polypropelene venting systems. 90° Elbows, Vent or Sanitary Tee, or other necessary fittings Follow the manufacturer's installation instructions when may be 2", 2½", 3", or 4"...

- Page 17 Installer’s Guide 15 minutes before handling. Cure time varies according WARNING to fit, temperature and humidity. CARBON MONOXIDE POISONING HAZARD NOTE: FAILURE TO FOLLOW THE DURAVENT INSTALLATION Follow venting instructions carefully when using PVC cement. INSTRUCTIONS IF THE POLYPROPELENE VENTING SYSTEM IS BEING PLACED INTO OPERATION COULD IMPORTANT: RESULT IN CARBON MONOXIDE POISONING OR DEATH.

-

Page 18: Vent Clearances

Installer’s Guide DOWNFLOW/ HORIZONTAL VENTING TABLE TABLE 12 MAXIMUM VENT LENGTH: DIRECT VENT (2 PIPE SYSTEM) - MAXIMUM TOTAL EQUIV- NONDIRECT VENT (1 PIPE SYSTEM) - MAXIMUM TOTAL ALENT FEET FOR VENT AND INLET AIR PIPES (S EQUIVALENT FEET FOR VENT PIPE ONLY (S OTES OTES 2"... - Page 19 Installer’s Guide Table 13 - See Figure 22 Direct Vent Terminal Clearances Canadian Installations US Installations Clearance above grade, veranda, porch, deck, 12 inches (30 cm) 12 inches (30 cm) or balcony Clearance to window or door that may be 6 inches (15 cm) for appliances =/<...

- Page 20 Installer’s Guide 12” Min. 15” Max 12” Min. 12” Min. 15” Max 15” Max 6” Min. 6” Min. 6” Min. 24” Max. 24” Max. 24” Max 9” Minimum 9” Minimum 9” Minimum minimum from end minimum from end minimum from end of exhaust pipe to of exhaust pipe to of exhaust pipe to...

- Page 21 Installer’s Guide Avoid areas where staining or condensate drippage may be a problem. COUPLING PVC WALL Location of the vent/ wind terminal should be chosen to (PLASTIC MOUNT FLANGE STUD VENTING) meet the requirements of Figure 26 for either direct or non- (OPTIONAL) direct vent applications.

- Page 22 Installer’s Guide NOTE: VENT AND INLET MUST BE SUPPORT- ED AT A MAXIMUM OF 3' INTERVALS SEE VENTING TABLE STRAPS OR OTHER SUITABLE SUPPORTS USE ONLY AT MAXIMUM OF 3'-0" INTERVALS APPROVED TERMINATION COMBUSTION AIR INLET UPWARD PITCH -- 1/4" PER FOOT FIRST SUPPORT SHOULD BE AS CLOSE TO FURNACE CONNECTION OUTSIDE...

- Page 23 Installer’s Guide All pipe joints must be fastened and sealed to prevent es- DOWNWARD VENTING cape of combustion products into the building. Furnace may be in vertical or horizontal configuration. NOTE: Both venting methods shown in Figure 39 & 41 must also DOWNWARD VENT have the combustion air inlet installed - meeting dimen- LENGTH IS LIMITED...

- Page 24 Installer’s Guide SEAL BETWEEN FLANGE, PIPE, COUPLING AND METAL PANEL WITH HI TEMP RTV SILICONE SEALANT FLUE PIPE COUPLING SUPPORT FLANGE CEILING GALVANIZED FIRESTOP SHOULD BE FABRICATED WITH 3-7/8" DIA. HOLE FOR SUPPORT FLANGE (12" x 12" PANEL OR 12" DIA MIN.) CLEARANCE ( 0"...

- Page 25 Trane INSTALLATION OF CARBON MONOXIDE 6200 Troup Highway DETECTORS. At the time of installation of the side wall...

- Page 26 Installer’s Guide HORIZONTAL INSTALLATION CONDENSATE DRAIN INSTRUCTIONS VERTICAL APPLICATIONS Upflow/ Horizontal NOTE: CAUTION In horizontal venting when the factory supplied “off- It is recommended that a drain pan be installed under the set” (2X3 reducing coupling) is used for 3” vent pipe furnace to prevent property damage or personal injury installation, make sure the marking “Top”...

- Page 27 Installer’s Guide HORIZONTAL APPLICATIONS Upflow and Downflow furnaces - All horizontal appli- cations are left side only. It is always recommended that the auxiliary drain pan be installed under a horizontally installed evaporator and/or 95% gas furnace. Connect the auxiliary drain pan to a separate drain line (no trap is needed in this line).

- Page 28 Installer’s Guide NOTE: to prevent water from damaging furnace controls if the pri- Use 1/2" or larger PVC or CPVC pipe and fittings as re- mary drain outlet plugs up. Where the furnace is installed quired for drain connections (fittings, pipe and solvent ce- above a finished ceiling, the primary drain vent stack must ment not provided).

- Page 29 Installer’s Guide FIELD WIRING DIAGRAM FOR 1 STAGE FURNACE 1 STAGE HEATING, 1 STAGE COOLING USING A 1 STAGE HEATING, 1 STAGE COOLING THERMOSTAT (OUTDOOR SECTION WITHOUT TRANSFORMER) FURNACE OUTDOOR UNIT (NO TRANSFORMER) NOTE 6 NOTE 8 TO 115 V 1 PH., 60 HZ., POWER SUPPLY PER LOCAL CODES...

- Page 30 Installer’s Guide TWINNING CONNECTION DIAGRAM FOR TWINNING 1 STAGE FURNACES WITH SINGLE WIRE TWINNING FEATURE 1 STAGE HEAT 1 STAGE HEATING ONLY THERMOSTAT ONLY THERMOSTAT (WITH FAN SWITCH) FURNACE NO. 1 FURNACE NO. 2 BLOWER OPERATION OF UNIT NO. 2 IS SYNCRONIZED WITH UNIT NO.

- Page 31 Installer’s Guide GAS PIPING NOTE: The upflow/ horizontal furnace is shipped standard for left Maximum pressure to the gas valve for natural gas is side installation of gas piping. A knock-out is provided on 13.8" W.C. Minimum pressure is 5.0" W.C. Maximum the right side for an alternate gas piping arrangement.

- Page 32 Installer’s Guide MAIN MANUAL AUTOMATIC GAS VALVE WITH GROUND UNION JOINT SHUTOFF VALVE MANUAL SHUTOFF DRIP MAIN MANUAL SHUTOFF VALVE DRIP GROUND UNION JOINT AUTOMATIC GAS VALVE WITH MANUAL SHUTOFF HORIZONTAL FURNACE GAS PIPING MAY BE FROM EITHER SIDE (UPFLOW SHOWN) TABLE 15 4.

- Page 33 Installer’s Guide 5. Adjust gas heat by removing the adjustment regulator NOTE: cover screw. The manifold pressure must be referenced to the burner a. To increase outlet pressure, turn the regulator ad- box. The burner box pressure tap equalizes the gas valve just screw clockwise.

- Page 34 Installer’s Guide HIGH ALTITUDE DERATE ROTATE THE FRONT Input ratings (BTUH) of these furnaces are based on sea COVER AS SHOWN level operation and should not be changed at elevations up to 2,000 ft. If the installation is 2,000 ft. or above, the furnace input INSERT THE TOP rate (BTUH) shall be reduced 4% for each 1,000 ft.

- Page 35 Installer’s Guide See Table 19 & 20 for help in selecting orifices if orifice Check all gas connections for leaks with a soapy solution change is required. Furnace input rate and temperature — DO NOT CHECK WITH AN OPEN FLAME. Allow 5 rise should be checked again after changing orifices to con- minutes for any gas that might have escaped to dissipate.

- Page 36 Installer’s Guide To shut off. AIRFLOW ADJUSTMENT For complete shut-down: Flip the switch on the main gas Check inlet and outlet air temperatures to make sure they valve to the “OFF” position, (See Figure 57 & 58). Discon- are within the ranges specified on the furnace rating name- nect the electrical supply to the unit.

- Page 37 Installer’s Guide ABNORMAL CONDITIONS Carbon monoxide, fire or smoke can cause serious bodily in- 1. EXCESSIVE COMBUSTION PRESSURE (WIND IN jury, death, and/or property damage. EXCESS OF 40 M.P.H.) VENT OR FLUE BLOCKAGE A variety of potential sources of carbon monoxide can be If pressure against induced draft blower outlet becomes found in a building or dwelling such as gas-fired clothes excessive, the pressure switch will open and shut off...

- Page 38 Installer’s Guide 18-CD29D1-11...

- Page 39 Installer’s Guide TABLE 21 INTEGRATED FURNACE CONTROL ERROR FLASH CODES Flashing Slow --- Normal - No call for Heat Flashing Fast --- Normal - Call for Heat Continuous ON --- Replace IFC Continuous OFF --- Check Power 2 Flashes --- System Lockout (Retries or Recycles exceeded) Draft Pressure Error - Possible problems a) Venting problem...

- Page 40 Literature Order Number 18-CD29D1-11 File Number 18-CD29D1-11 Trane Supersedes 18-CD29D1-10 6200 Troup Highway Tyler, TX 75707 Date 03/14 The manufacturer has a policy of continuous product and product data improvement and reserves the right to For more information contact change design and specifications without notice.

Need help?

Do you have a question about the AUH1B040A9241A and is the answer not in the manual?

Questions and answers